-

Posts

1,600 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by vaddoc

-

-

So sorry for your loss Michael. When I was much younger our cat died after being part of our lives for 18 years. I still think of him and visiting familiar places miss his presence.

- michael mott, FriedClams, mtaylor and 3 others

-

5

5

-

1

1

-

Fantastic metal work Keith but the net indeed is a step further. The more I look at it the more difficult it looks...

- KeithAug, Keith Black, mtaylor and 1 other

-

4

4

-

Just finished going over the entire log JD. Very nice! I enjoyed the transom bit very much, properly complex to make!

Could I share couple of thoughts:

Re your issues with the height and position of frames, position of rabet and the shape/angle of transom: Rhino is really powerful, it can give you all these answers. One solution is to extend the frames, sternpost and stem beyond the sheer to the same horizontal plane. This way all frames and transom will sit at the proper height. You can also project the transom to an appropriately angled plane to get its shape. Also, perhaps consider before tackling the frame shape to first fully define sheer, rabet and edge of transom as a continuity.

I am very interested to see how you ll approach the planking, at this scale you ll probably be able to get away with a lot of edge setting.

Regards

Vaddoc

-

-3 Hakan but there is wind, real feel -8!

-

Very nice Hakan. Your frames came out great!

Epoxy thickened with gypsum could be a good alternative with gap filling properties, although epoxy has the potential to cause great mess.

-

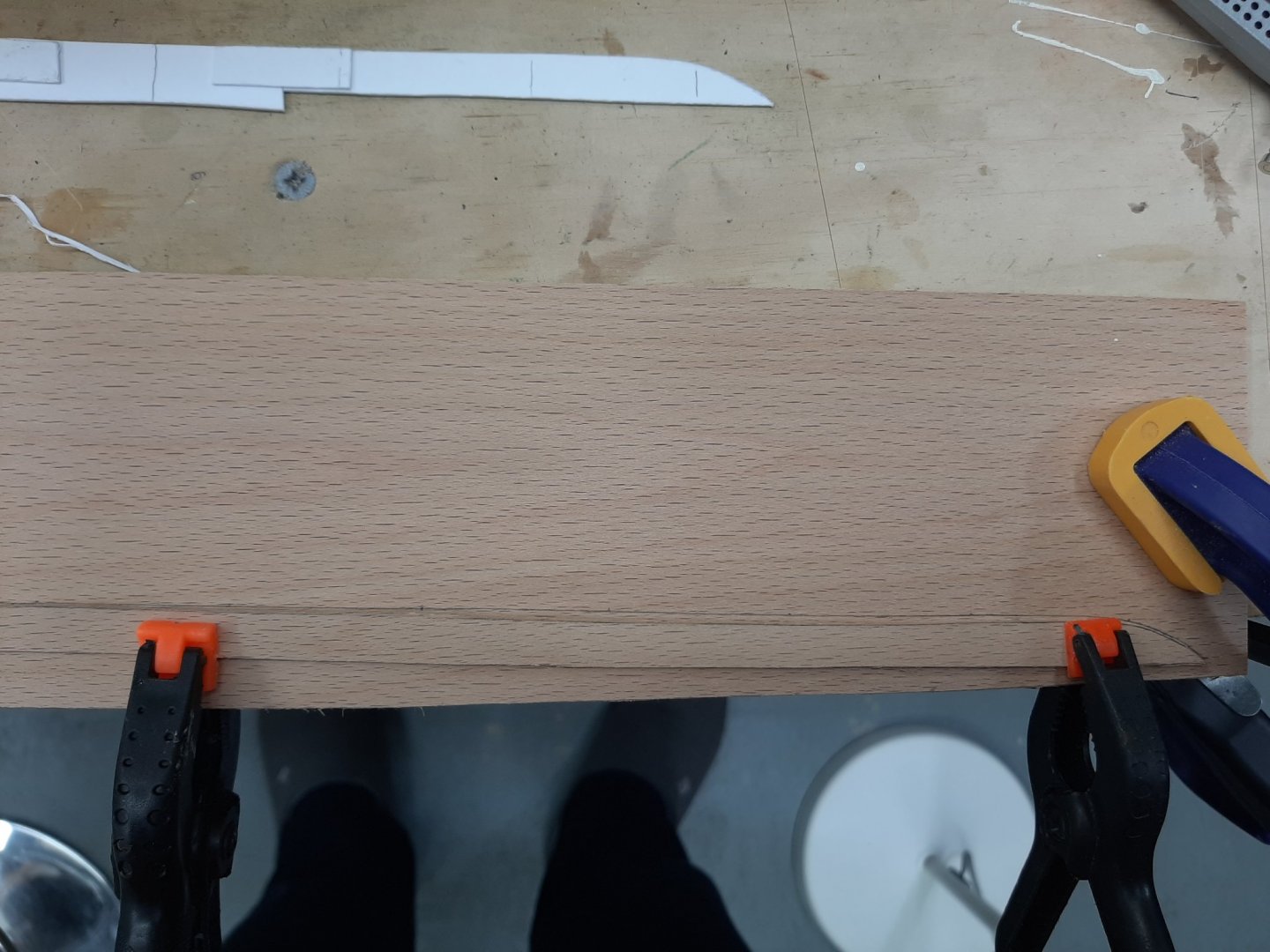

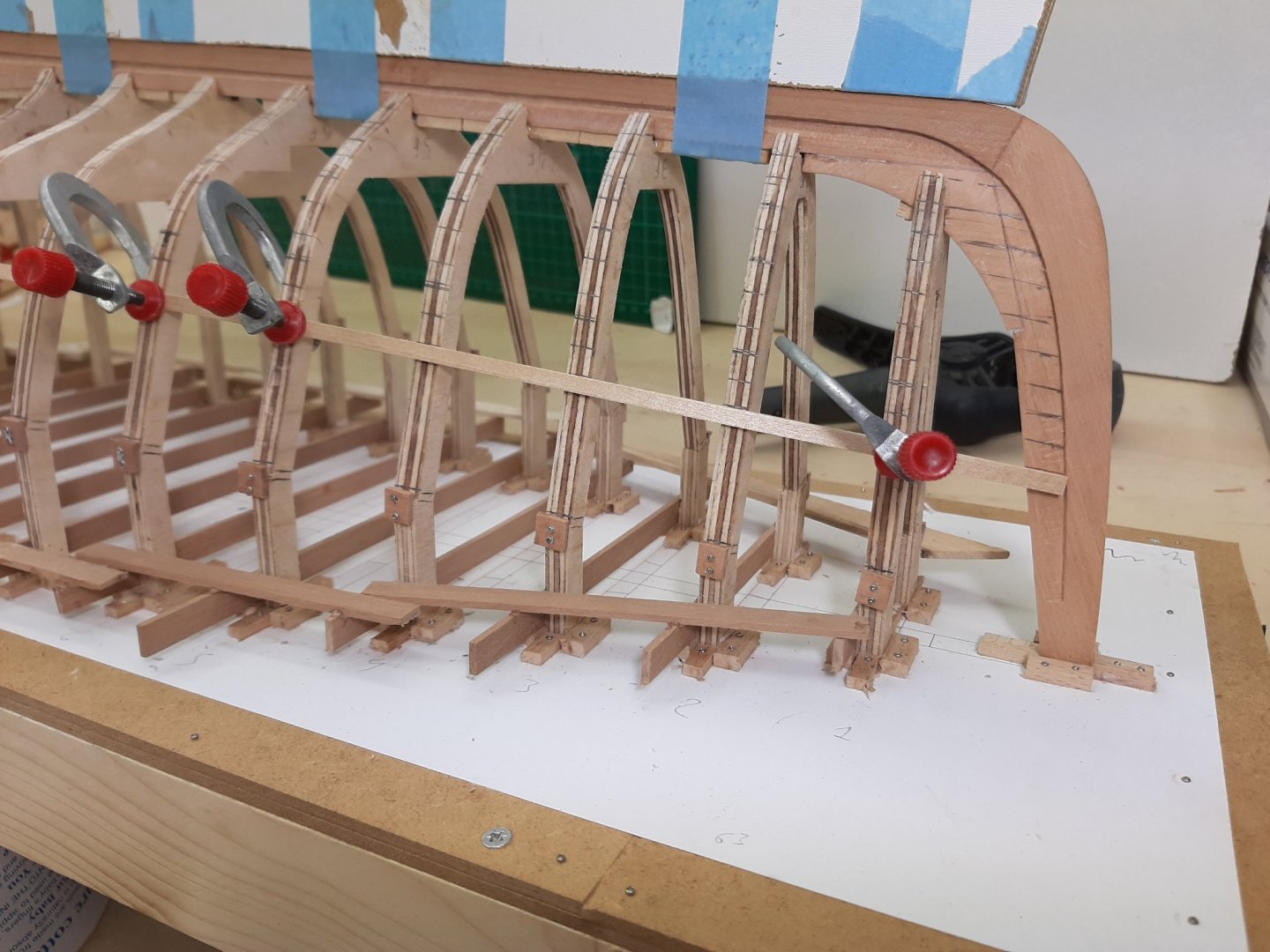

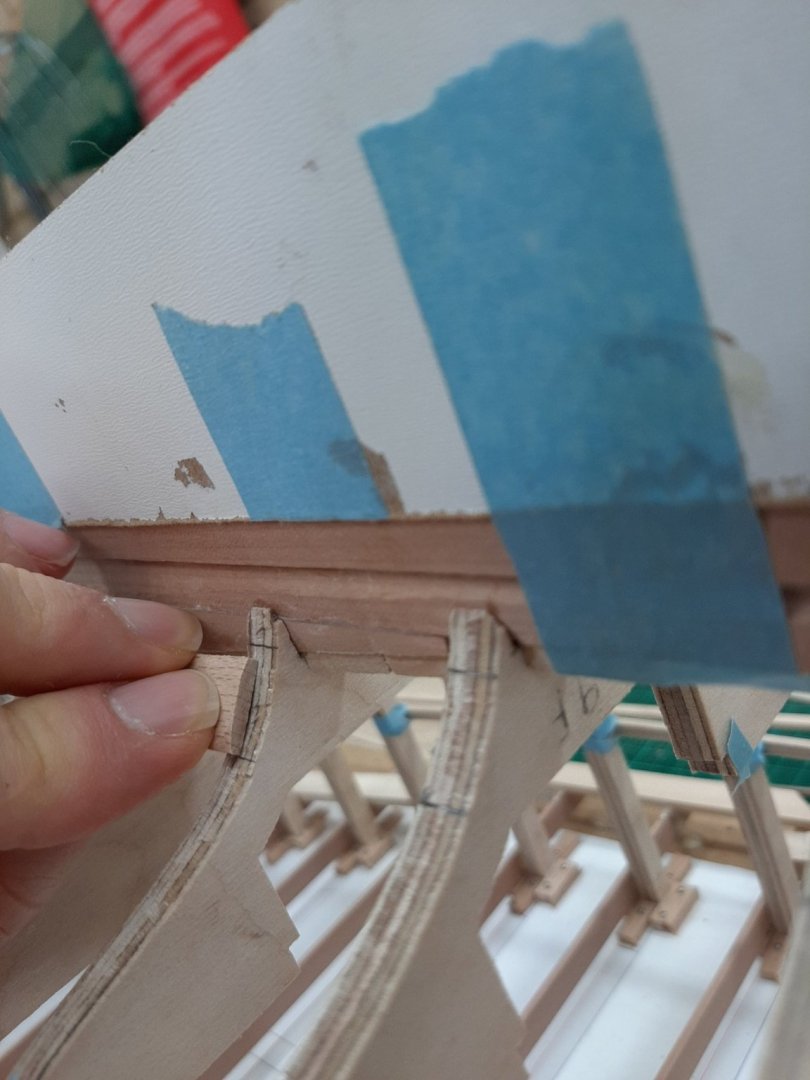

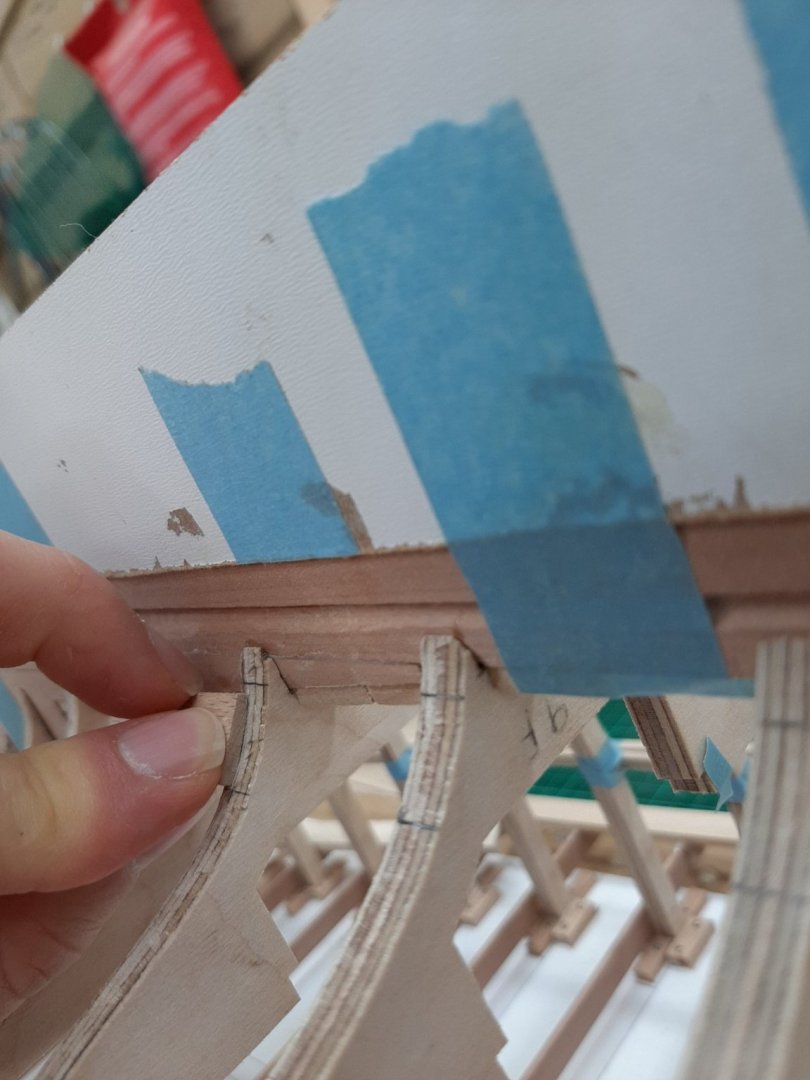

So I gave it another try and this time things worked better.

I actually remembered that planking the Deben, I had laminated the card to double its thickness. So I did the same and indeed the laminated card holds its shape much better. Also, I used spray glue instead of the water based glue sticks. This made a huge difference as the glue dries almost immediately and does not distort the paper.

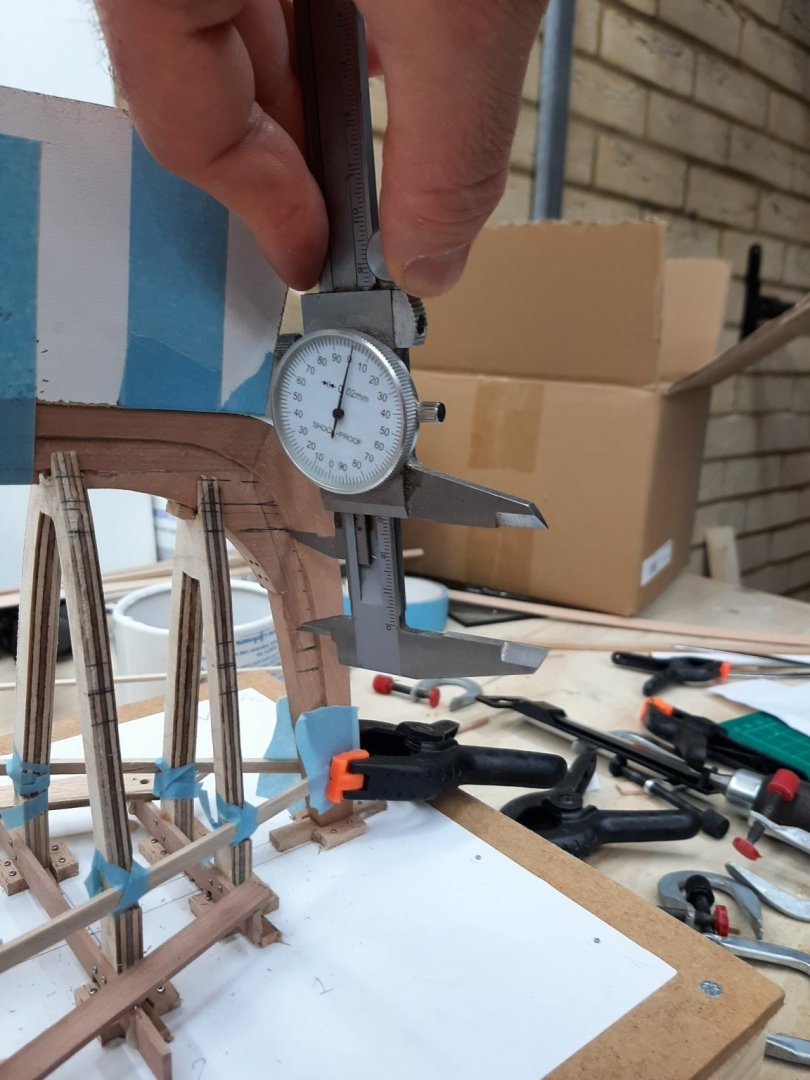

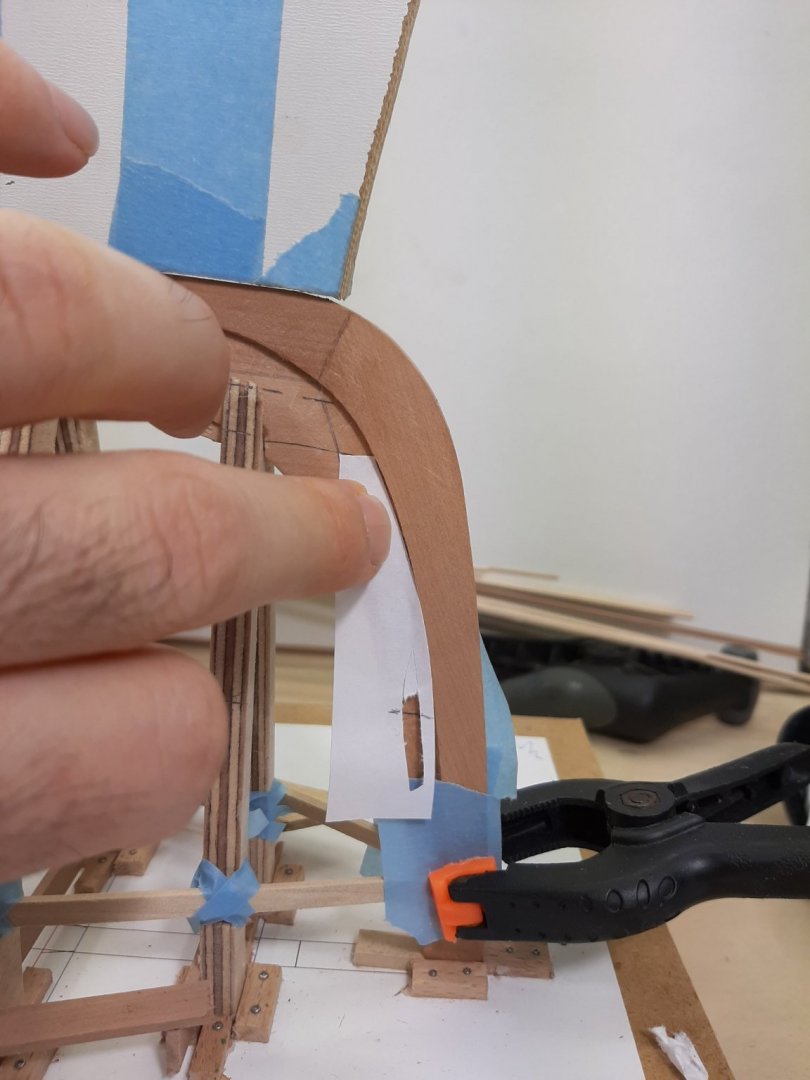

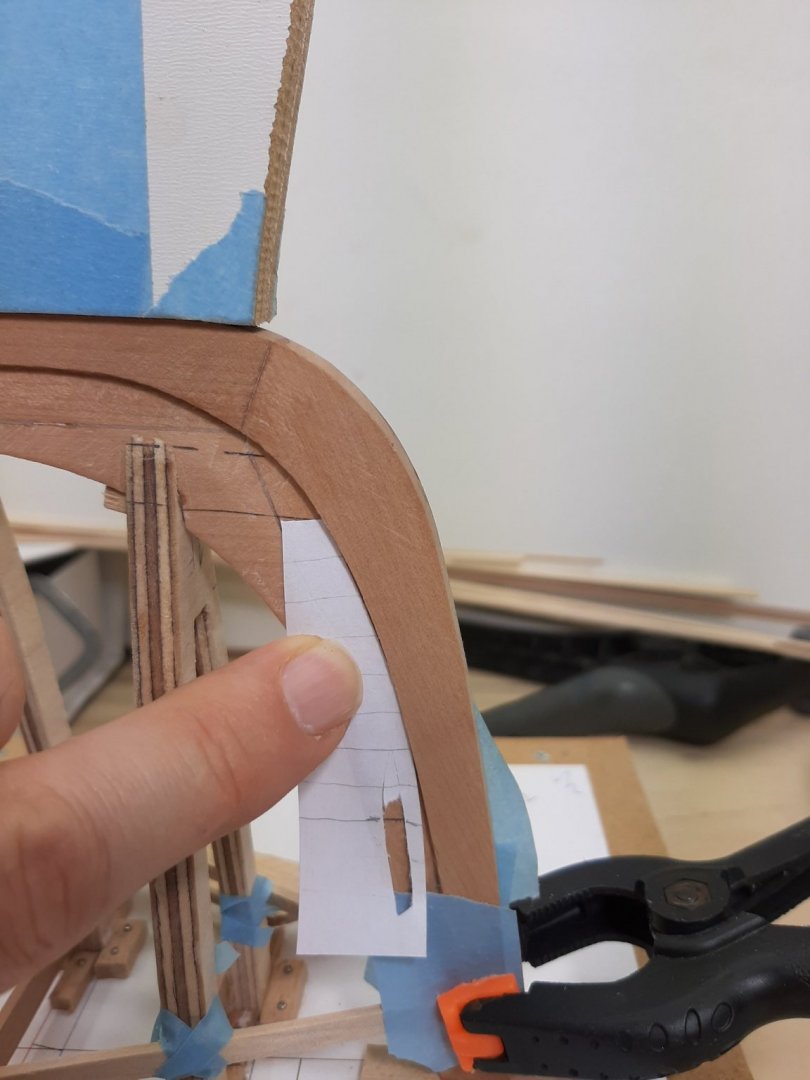

The new pattern was transferred to the wood but in a different way. I used paper template to define the rabet edge, the stern end and the turn of the plank at the stem. Then, with the compass I transferred the distances at all frame positions and used a baten to connect them with a fair line. This was the outcome, it worked just fine.

Compared to the first plank, it looks more correct as it probably will fill the previous gaps. But the first plank looks just wrong, it is clear the card had distorted at the fore end.

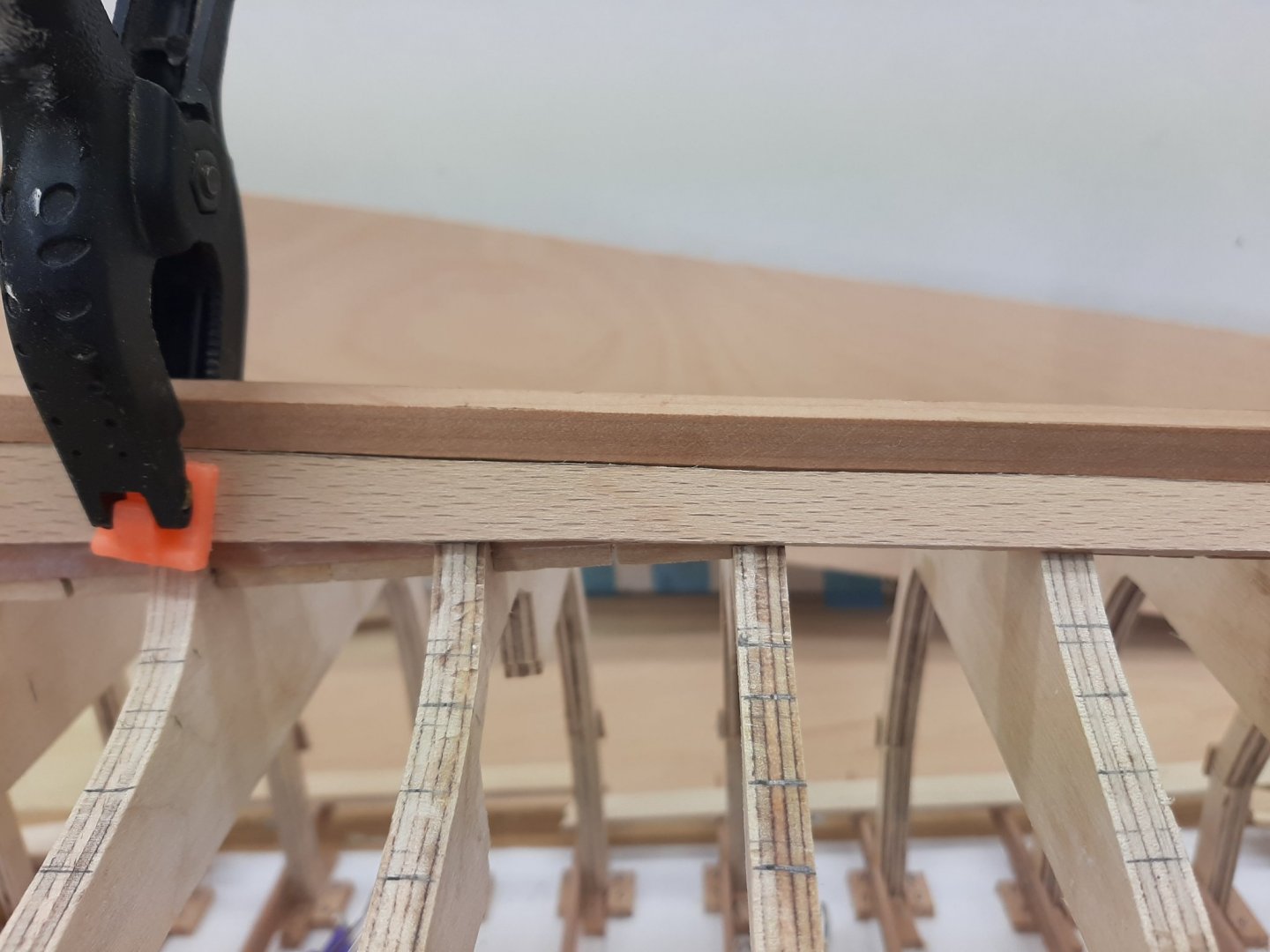

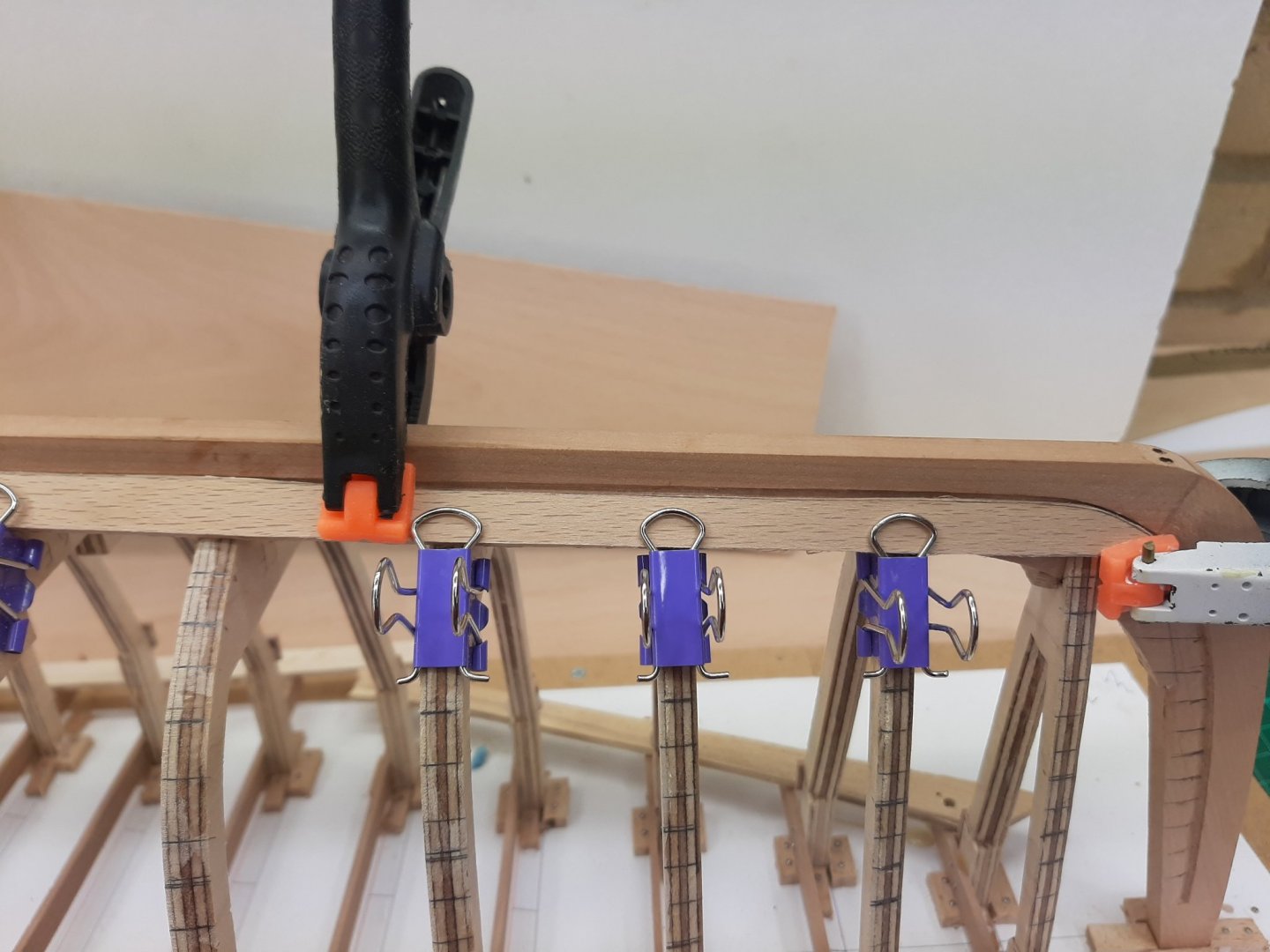

I then tried to install the plank. This was difficult, exactly as the ship builder mentions in the video a few posts earlier, the most difficult thing is to get the plank to twist and this garboard has a huge twist. I had to do a very minimal amount of scraping/sanding and with the help of many clamps, the plank seems to fit well with very little edge bending.

A little filler won't hurt I presume!

Now, all boat building activities are temporarily suspended, not only due to professional and family commitments but also because of the weather-it is freezing cold in Cambridgeshire.

Best wishes

Vaddoc

- ccoyle, FriedClams, BobG and 4 others

-

7

7

-

Indeed Hakan, this is why planks need spilling. I think the problem is that the card is not stiff enough. I actually have 2 mm thick card that I used to plank the Deben but it is too thick and difficult to cut. I ordered 1 mm thick cardboard, see how this will do

-

Well, so far planking was all talk and no action. So today I cut the first plank. Yep, it went pear shaped!

Lets go over this failed attempt.

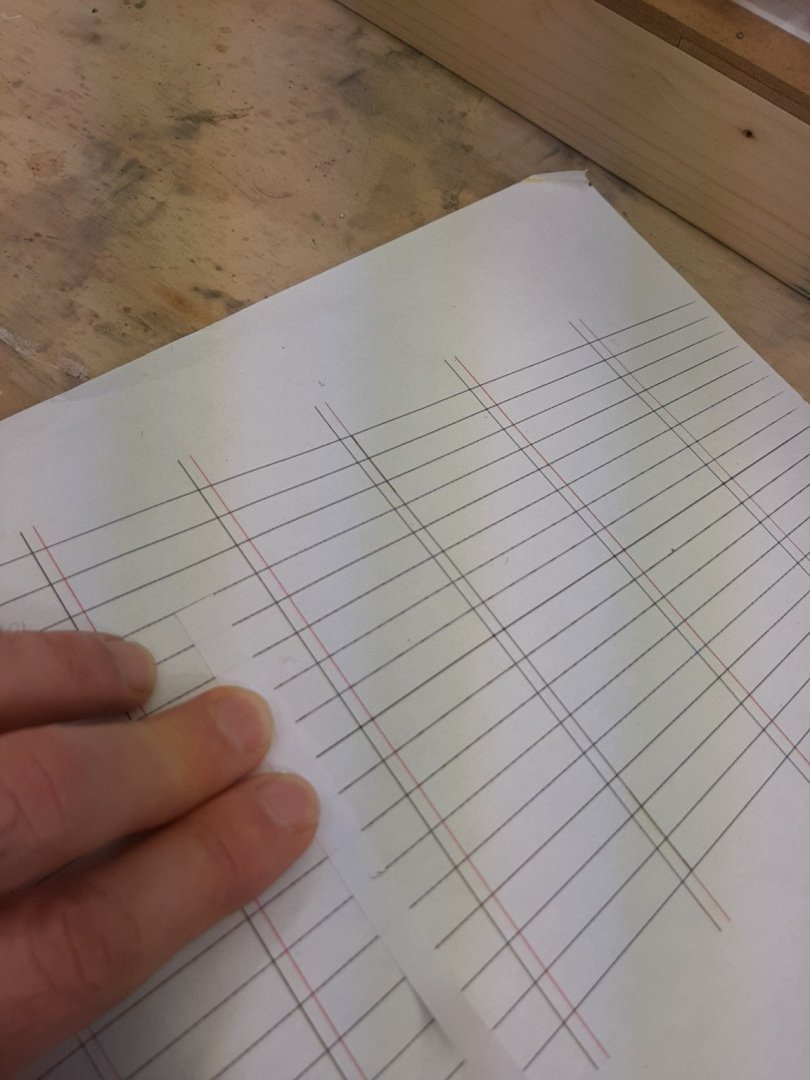

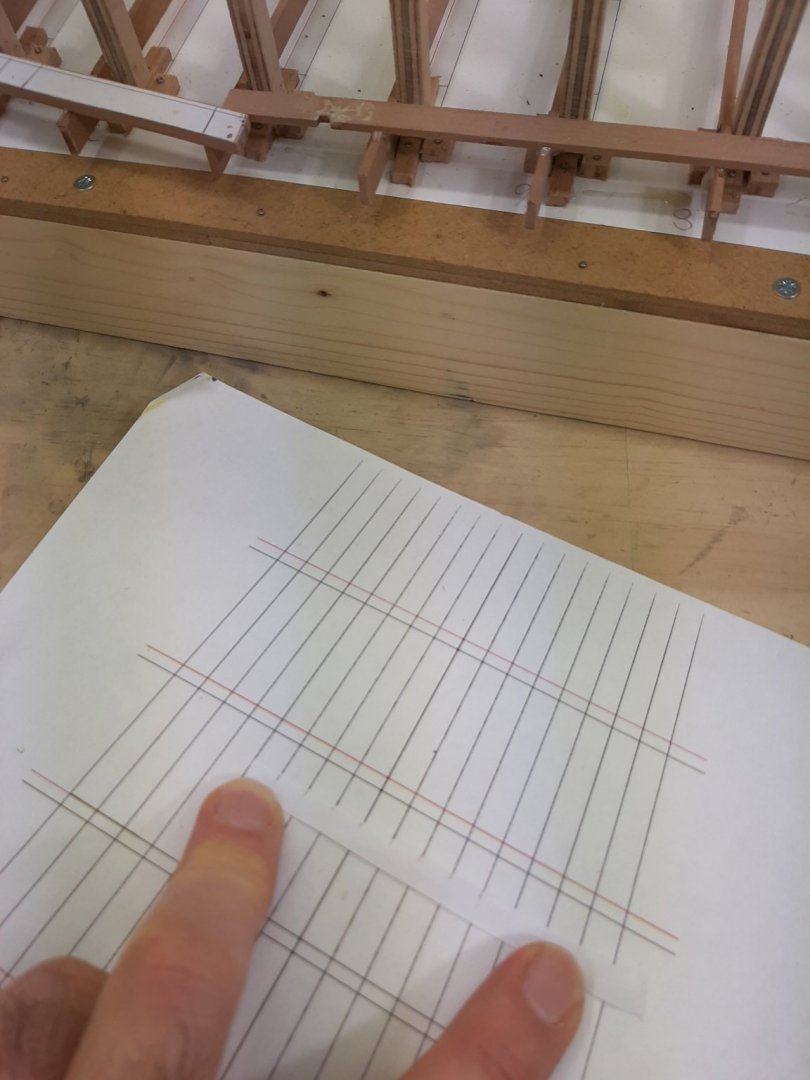

I finished the paper template and it looked ok. I intended the upper edge to be straight, it is not but it is not far off either.

Then I used a batten to connect the markings into a fair curve

The template was cut and seemed ok

Then transferred to the wood sheet. I used one of the warped ones as I suspected this first attempt would not go well.

I used a carpet knife to cut to the line. This went ok but the plank does not fit well.

What went wrong? Well, to start with the plank does not much the template

But also, now the template does not sit as well on the boat!

The card I am using is not stiff enough I think.

Now, this needs some further thought!

- BobG, GrandpaPhil, bruce d and 3 others

-

6

6

-

Regarding bending wood: In a recent thread on this subject, there was some good info.

- Soaking will make wood bend easier (up to a point) because increasing moisture content destroys some chemical bonds within the wood

- Heat will soften the wood lignin and allow the wood to bend. When cool, the wood will retain its new shape to a large degree

- Moisture will decrease the temperature needed to soften the lignin, depending on species sometimes very dramatically. Usually this temperature is well above 100 degrees C, moisture will bring it bellow 100.

Maybe best to leave the upper edge of the lower plank untouched and bevel the lower edge of the plank above it?

I am still trying to digest question No 3...😁

-

In this case I would think CA glue, which has actually been used previously in this model and can be removed with debonder. PVA glue might work as well. I wonder if varnish could be an option. Also, in the past I have used women's hair spray to preserve dried flowers, it works very well, it strengthen them and prevents the fragile leaves from falling apart-(is it a form of lacquer?). Maybe it would work.

-

Dan, I have absolutely no experience in such projects but those lines look too far gone. Even if they can be strengthened, they will probably fall apart soon. Is replacing all rigging an option?

- mtaylor, thibaultron, shipmodel and 1 other

-

4

4

-

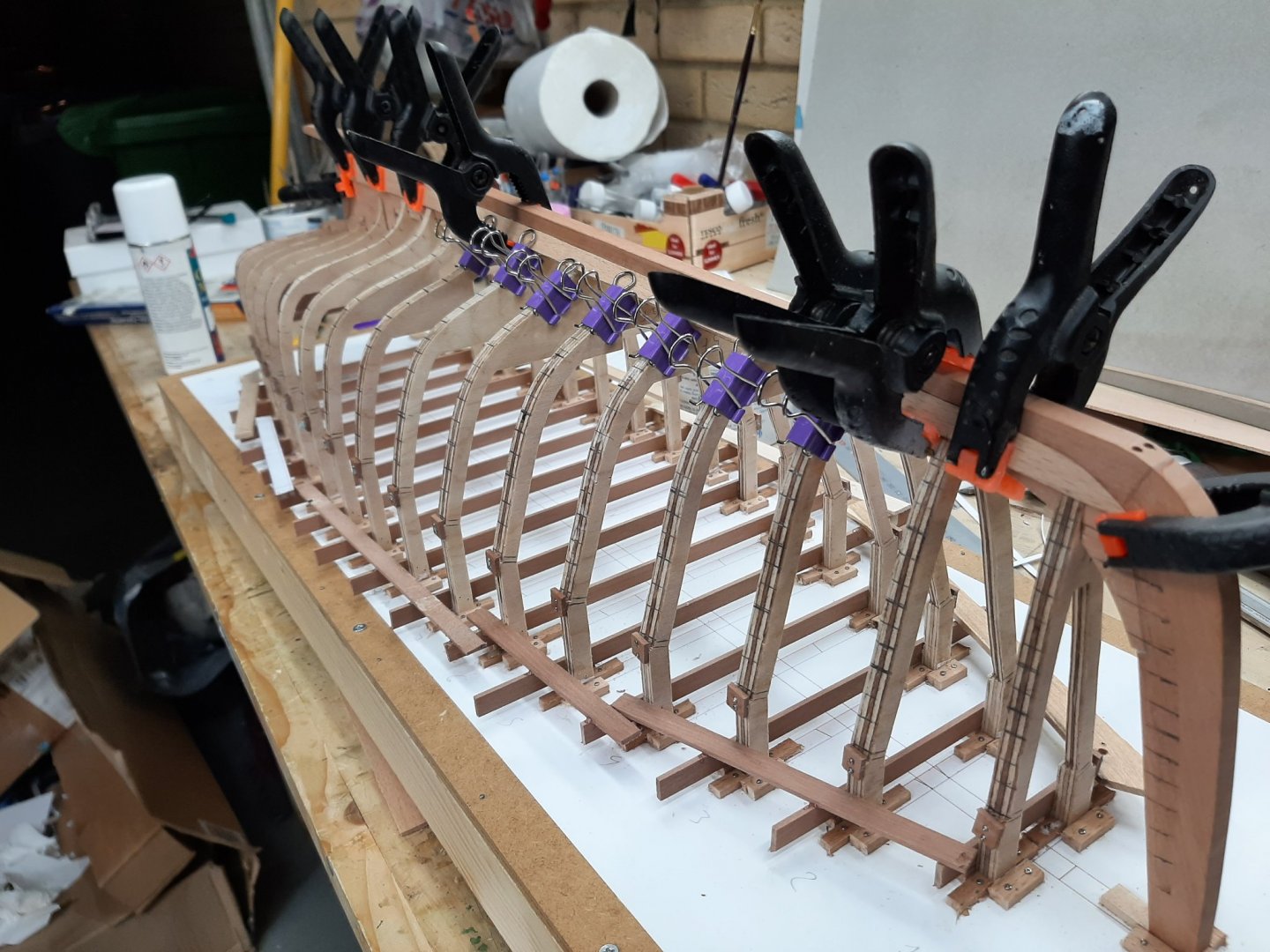

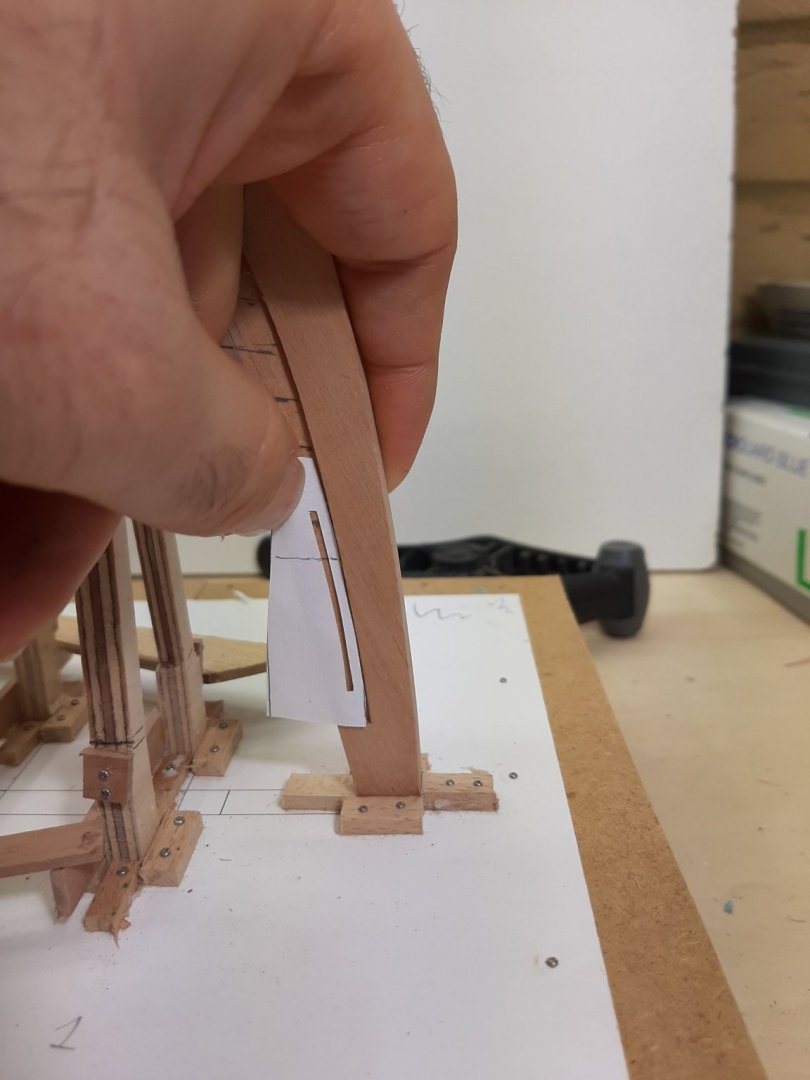

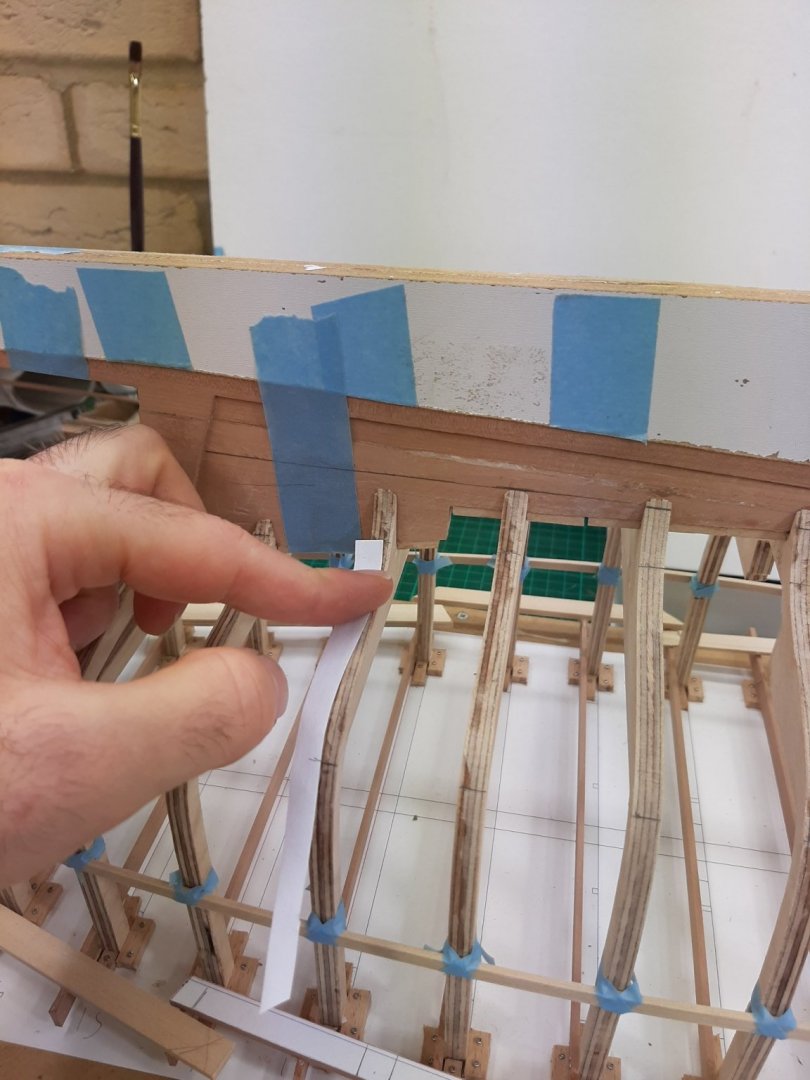

So now it is spilling time!

I tried just a bit of spilling, to see how this would go. I have a feeling it will not be as easy as the last boat due to the more narrow planks.

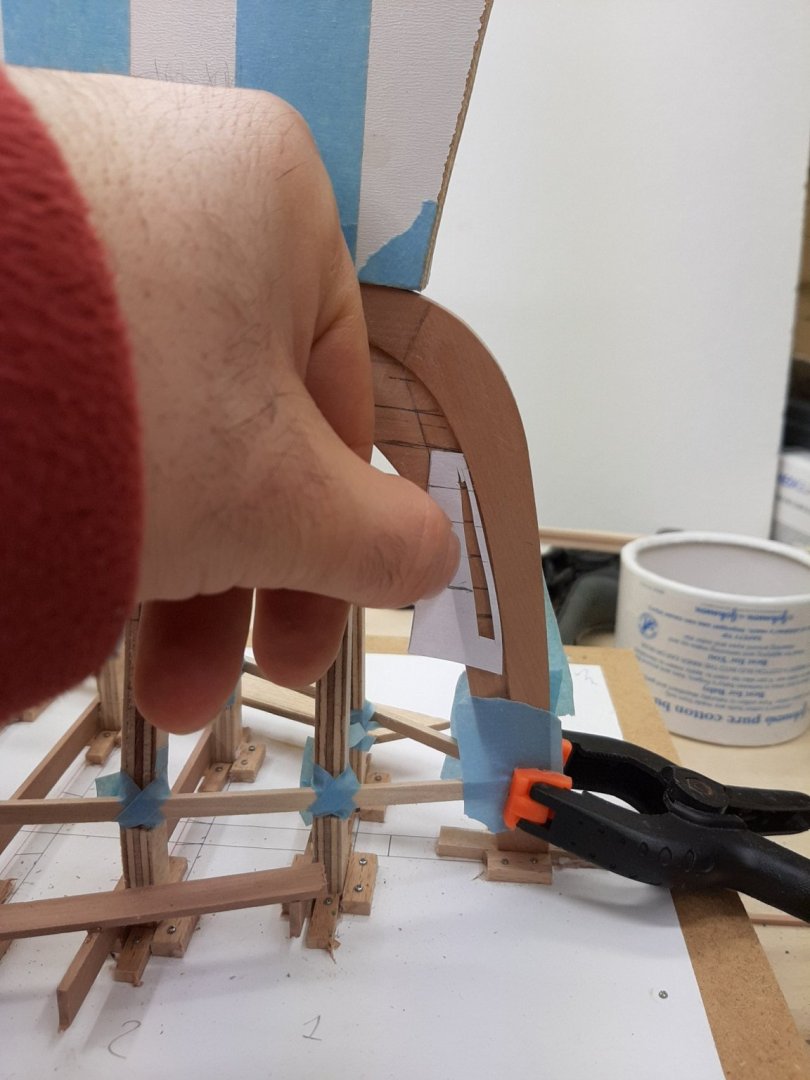

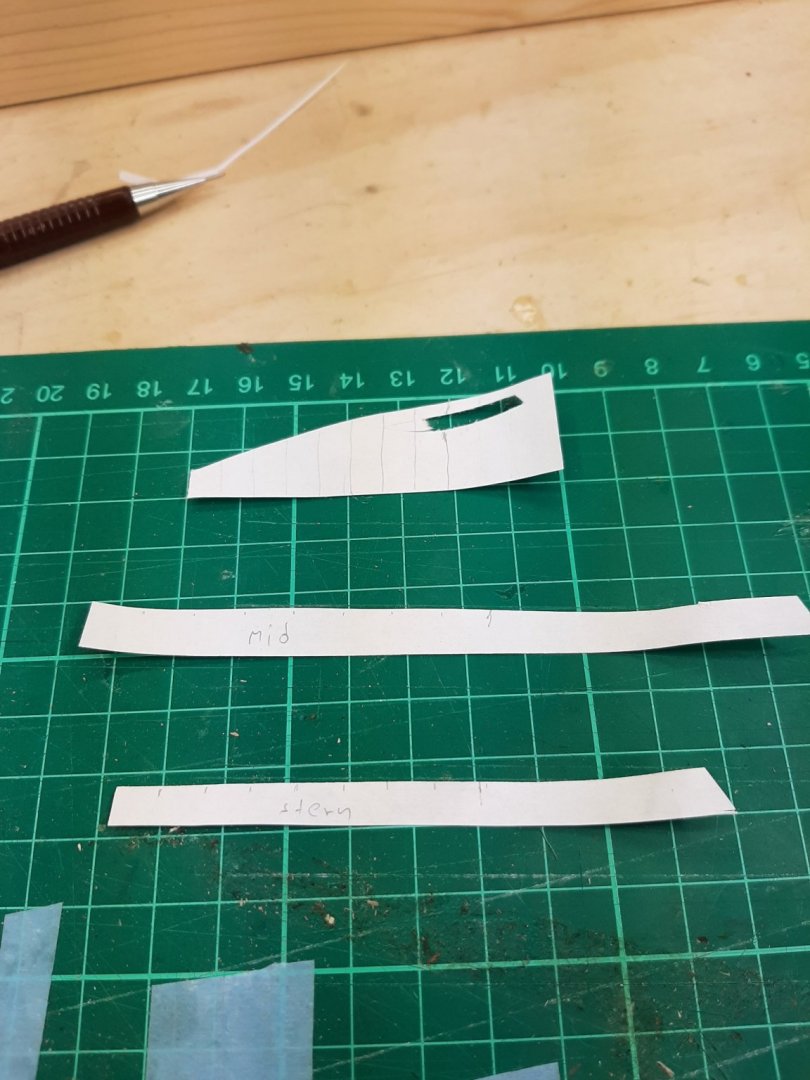

So we ll start with the garboard. Although the keel is dead straight, the corresponding edge of the garboard will not-there will be a curve to it. I used pieces of card paper to make patterns. The paper is attached to the frames, then a compass is drawn along the rabet at a constant angle, Then the positions of the middle of the frames are marked and the new edge cut.

it actually took two goes as the strip was too thick and was distorting things. After I had the edge, I marked the points where the other edge crosses the middle of the frames. I used the compass to mark this in relation to a random position on the frames.

This cross points will be connected later with a baten so the edge can be drawn.

I then moved a bit further and repeated the process.

Then I reached the stem with a third piece. All pieces are connected with pieces of card glued at the junctions, in the end we should end up with a solid piece that lies effortlessly on the frames. The rabet edge will be ready, the other will need to be drawn fair with a baten connecting all the cross points.

Then the plank will need to be cut, shaped appropriately and installed. Then do the same on the other side.

This will be a mountain of work, still the lapstrake on the yawl will be even more difficult.

Best wishes

Vaddoc

-

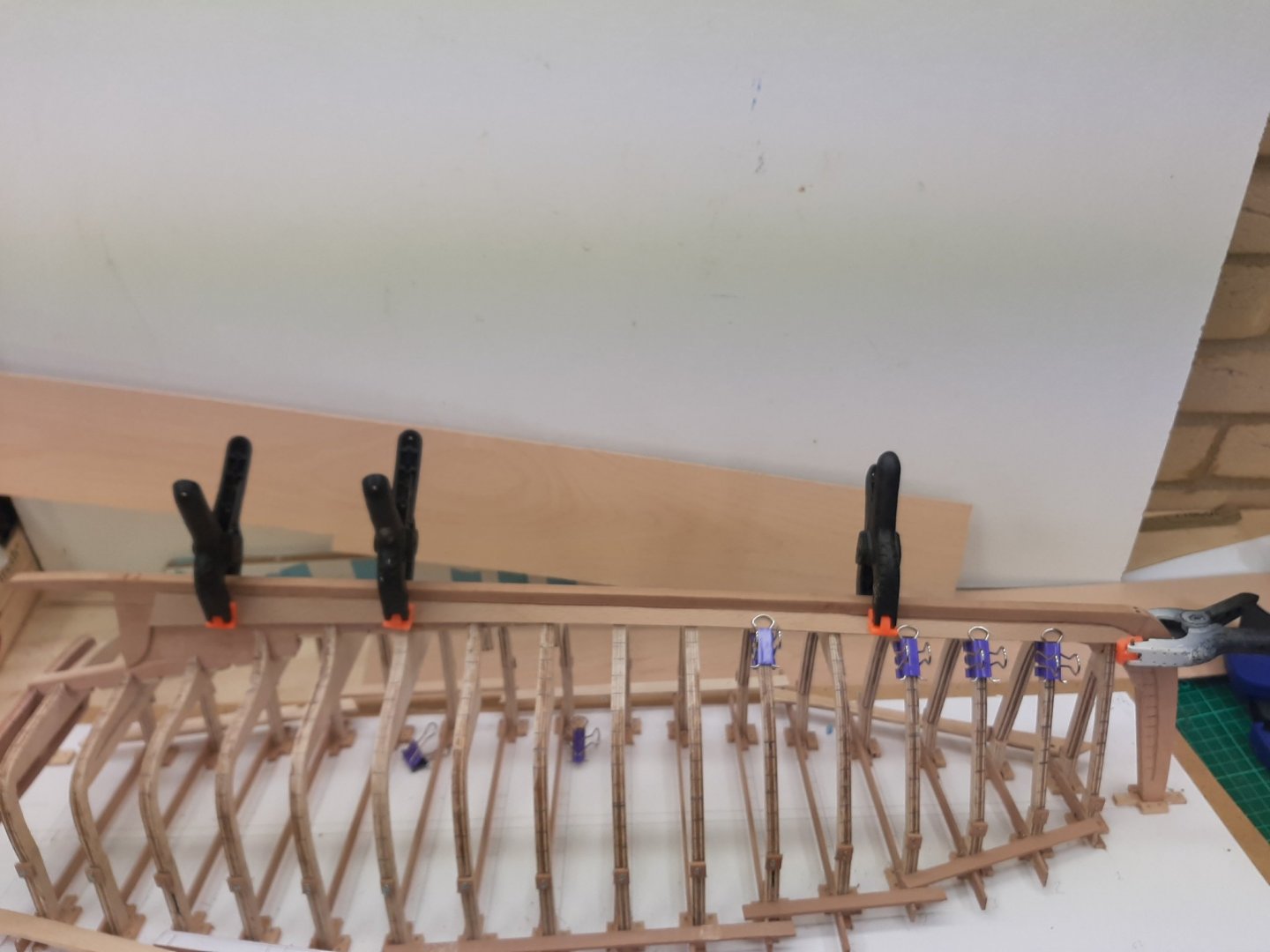

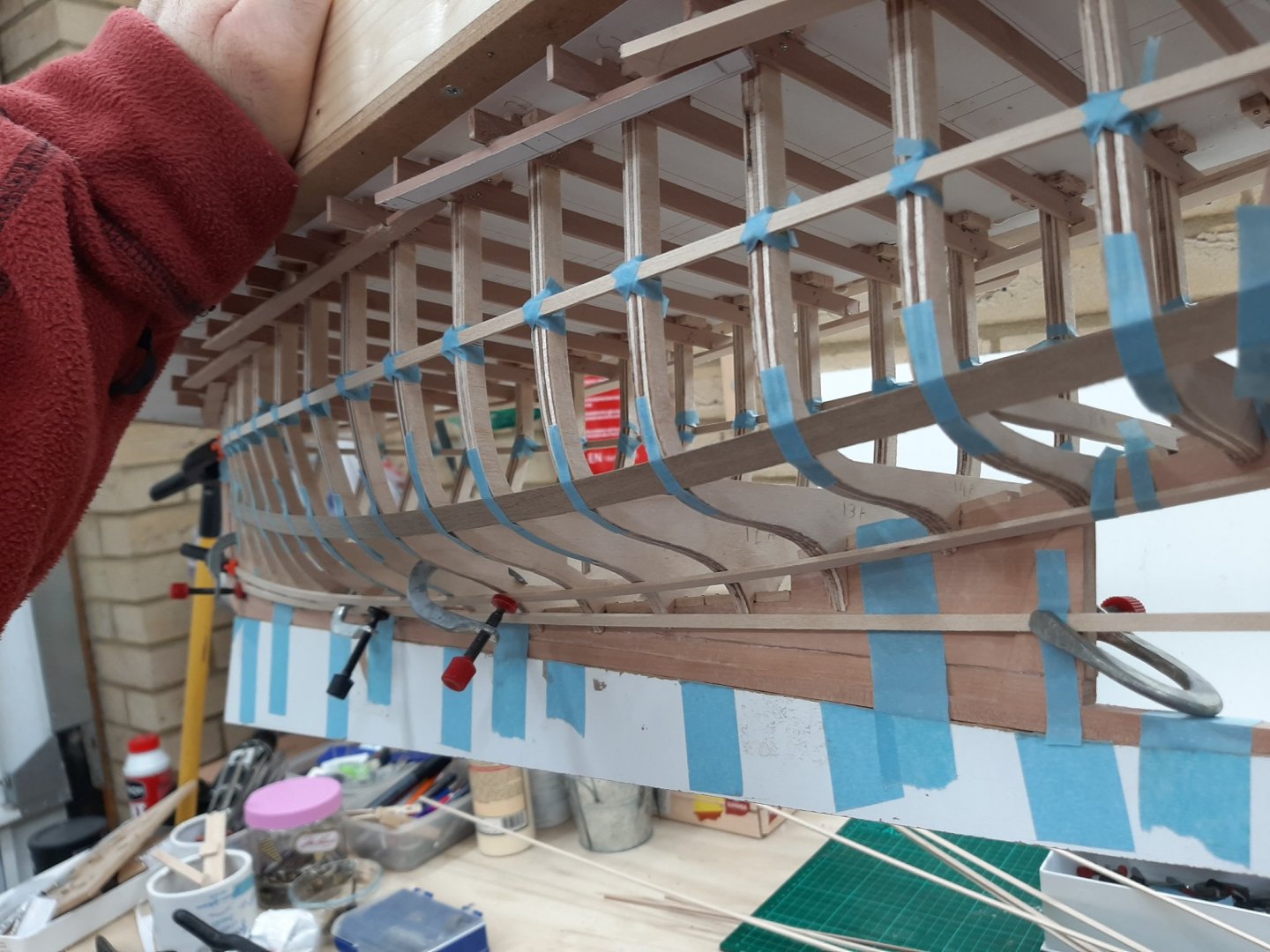

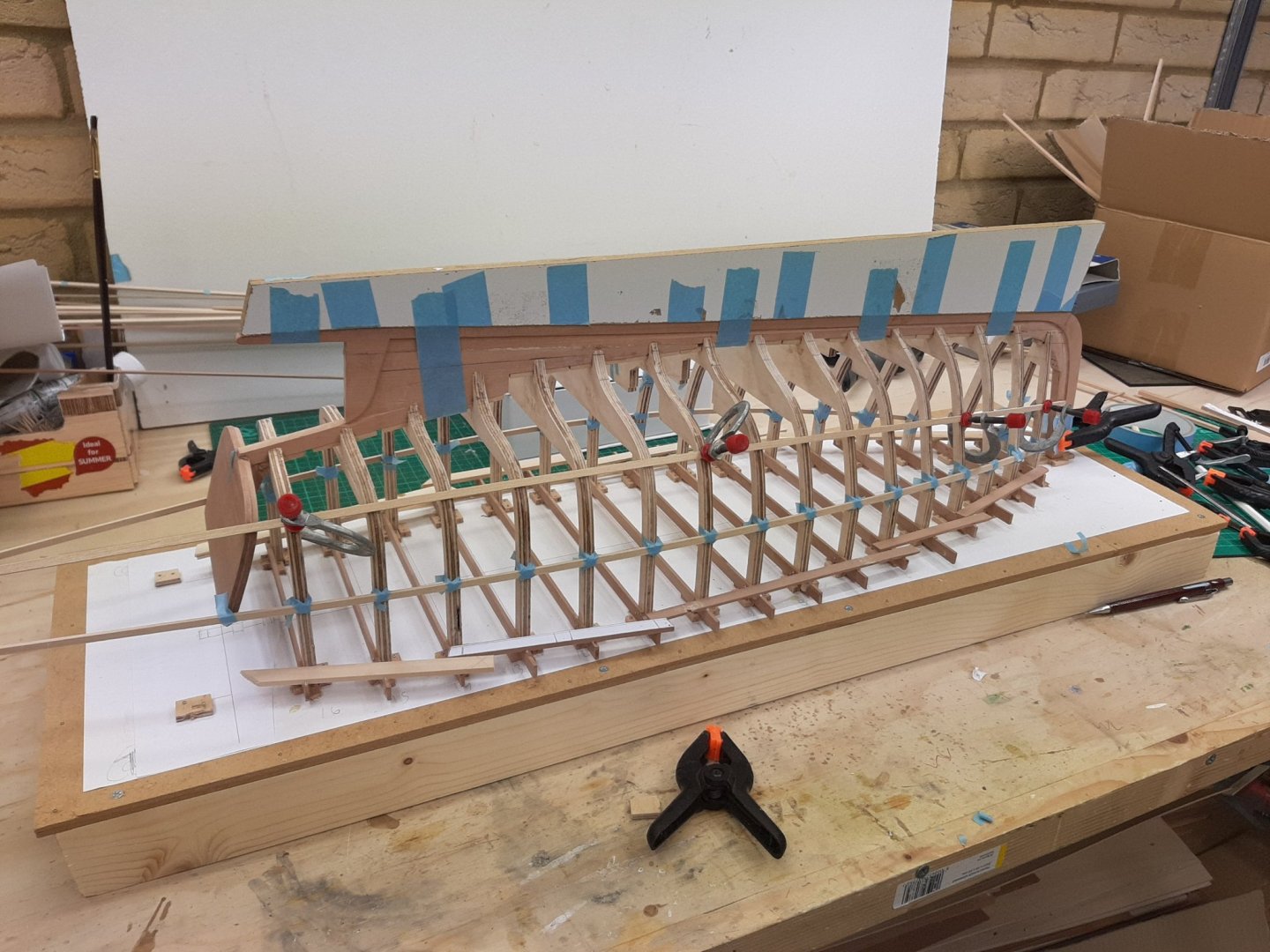

Many thanks to all for your likes and comments.

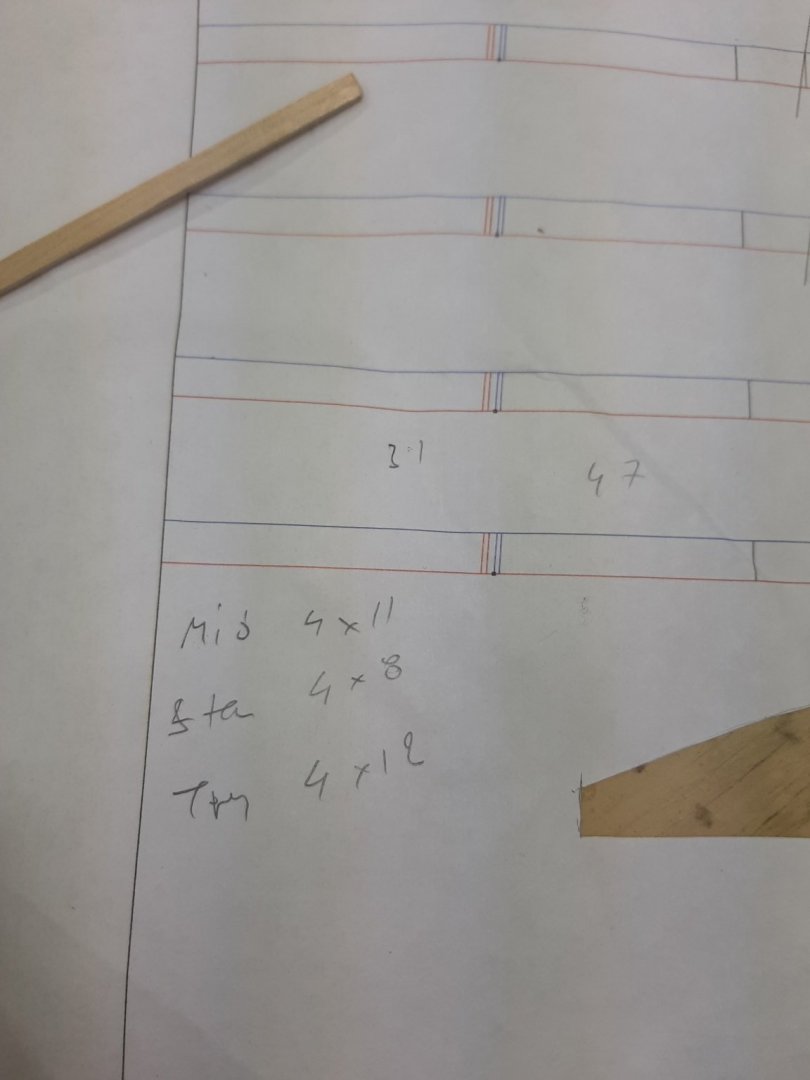

In the last post:

- The bottom and middle zones were marked

- The sheer has been defined

So we need to plank the upper zone. However this is not that straight forward.

We still have not cleared the curved parts of the transom and hull. The bottom plank of this upper zone cannot be very wide, I measured and the widest plank the transom can accept is 8 mm. So this plank will have its own width but the remaining planks will need to be as equal as possible.

So I deployed a batten and carved out a reasonable plank. Actually for some reason this took a bit of headscratching. Note that I removed the sheer batens but screwed pieces of wood to make sure I do not lose it.

With the boat right side up, it does not look too bad

For the rest of the zone, I measured the distances and I think the gap should be filled with 4 planks, so that there will be a symmetry with the rest of the planks. Everyone knows that the better a boat looks, the faster it goes!

So lets do it

Using the same method, the rest of the planks are marked.

So now all planks are marked and only the formality of actually planking the boat remains!

This is certainly a milestone!

I started spilling the planks but I ll make a new post for this

Regards

Vaddoc

- GrandpaPhil, G.L., wefalck and 4 others

-

7

7

-

-

Yes, all the above are very true!

The reason I am getting the proxon is that my dremel died just because the spindle lock pin wore out and it costs a third of the whole tool-it is also out of stock... The second reason is that I will need to drill a lot of 0.5 and 0.6 mm holes (a few thousands) and the dremel collets does not hold such thin drills well. The third is that I already have the power sourse so the proxon tool is less than £30.

-

-

Now this is a very interesting log! Great start George.

Visiting Averof next time I am in Athens is now on the priority list.

Actually, recently I read that they contemplated restoring the engines but it is completely out of the question. Apart from being prohibitively expensive, it seems that the whole ship would need to be cut to pieces or something similar.

- Old Collingwood, GeorgeKapas, lmagna and 1 other

-

4

4

-

Very nice Phil! The boat is starting to get busy.

- mtaylor, SIDEWAYS SAM, GrandpaPhil and 1 other

-

4

4

-

Brian, absolutely have your guns made, no reason not to. You are doing a fantastic job.

- J11, Keith Black, mbp521 and 2 others

-

5

5

-

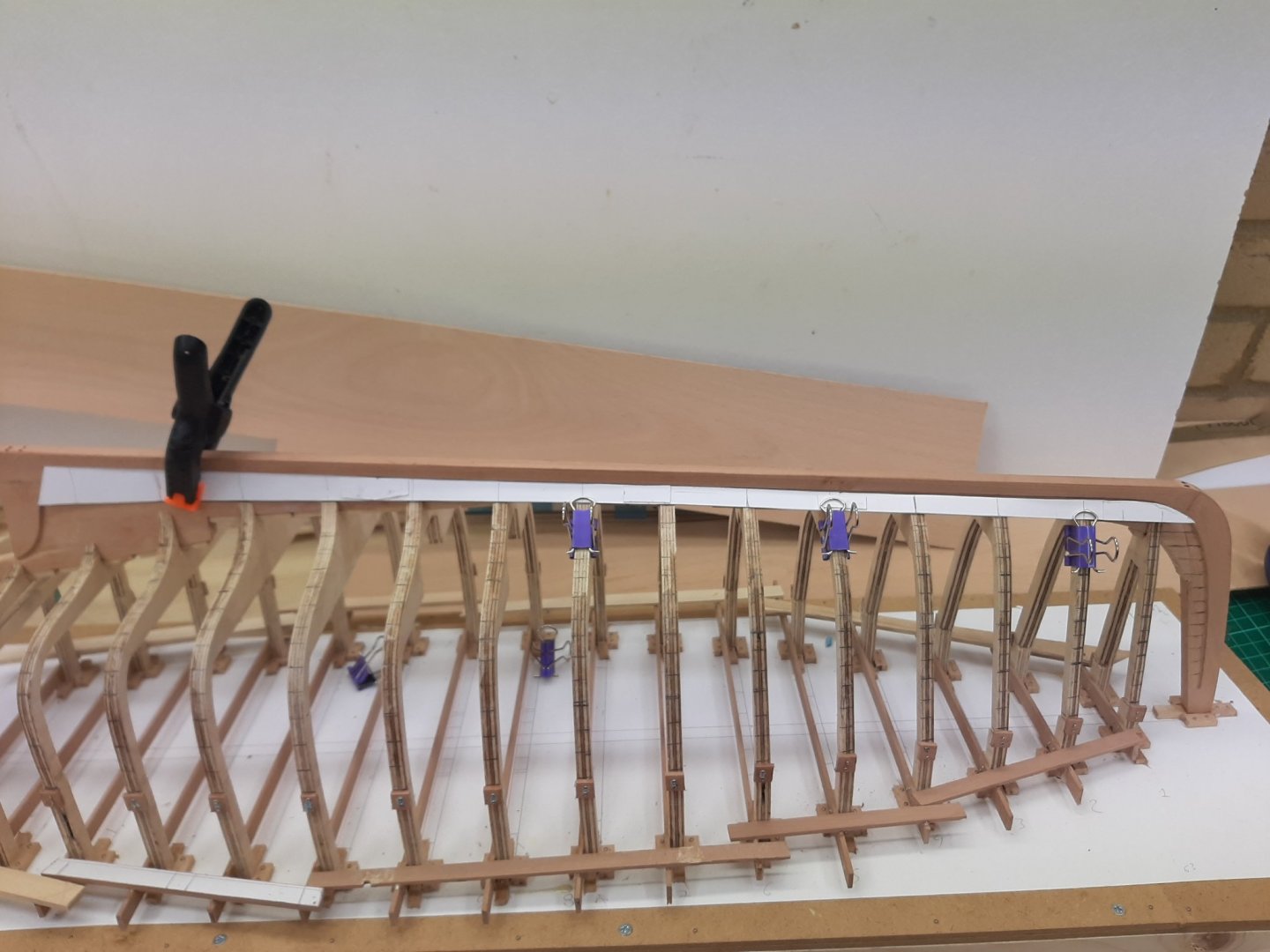

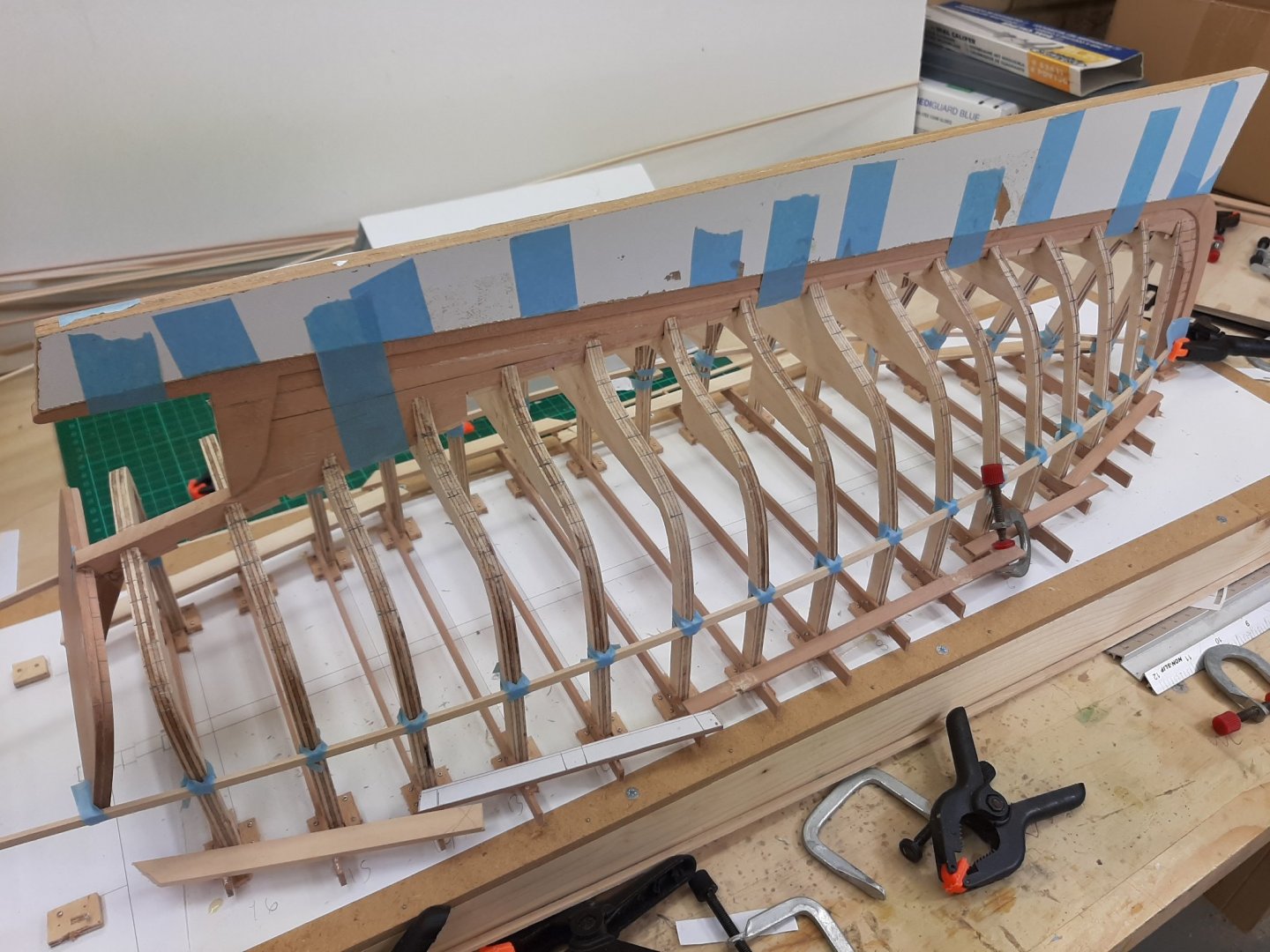

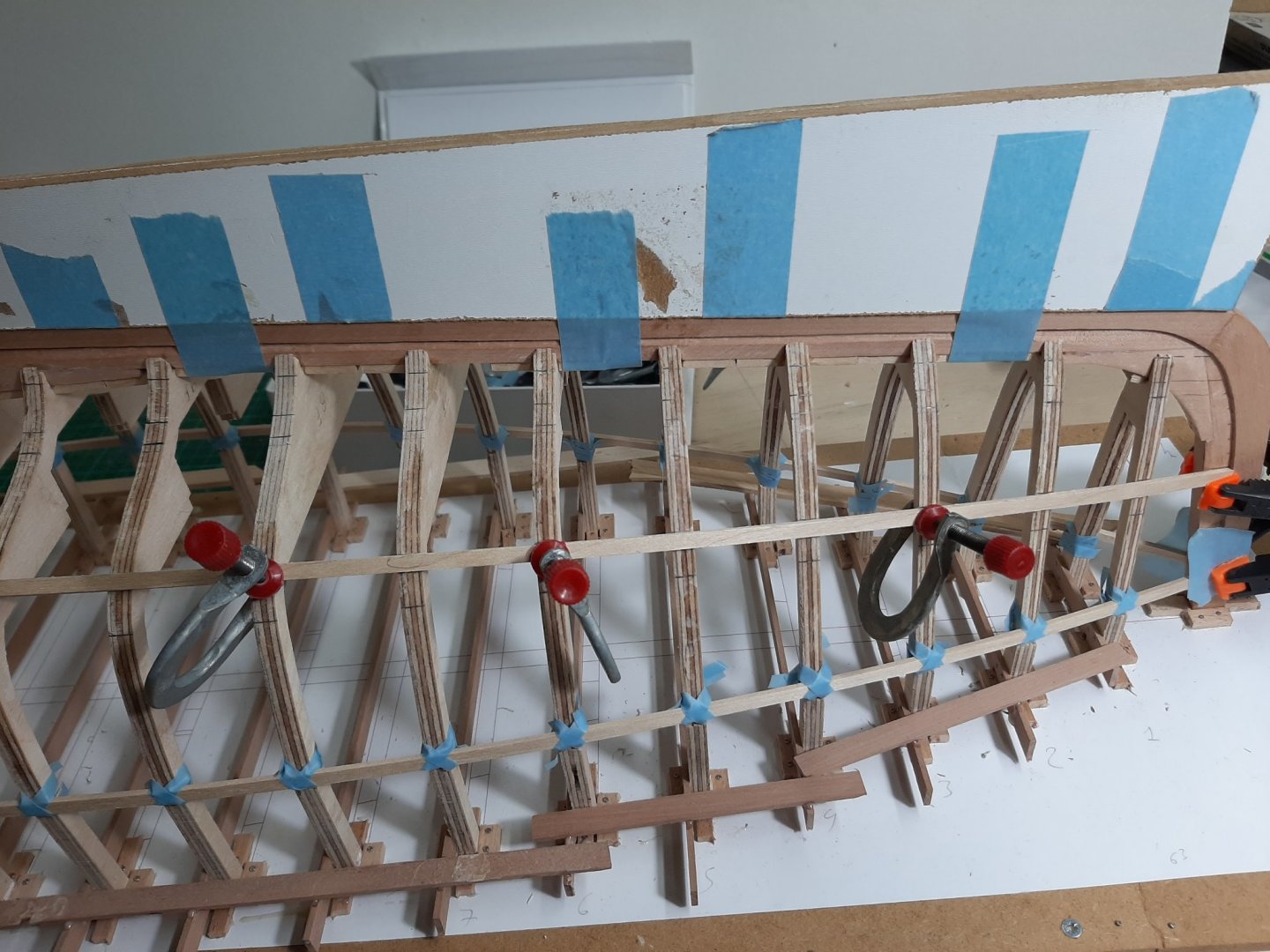

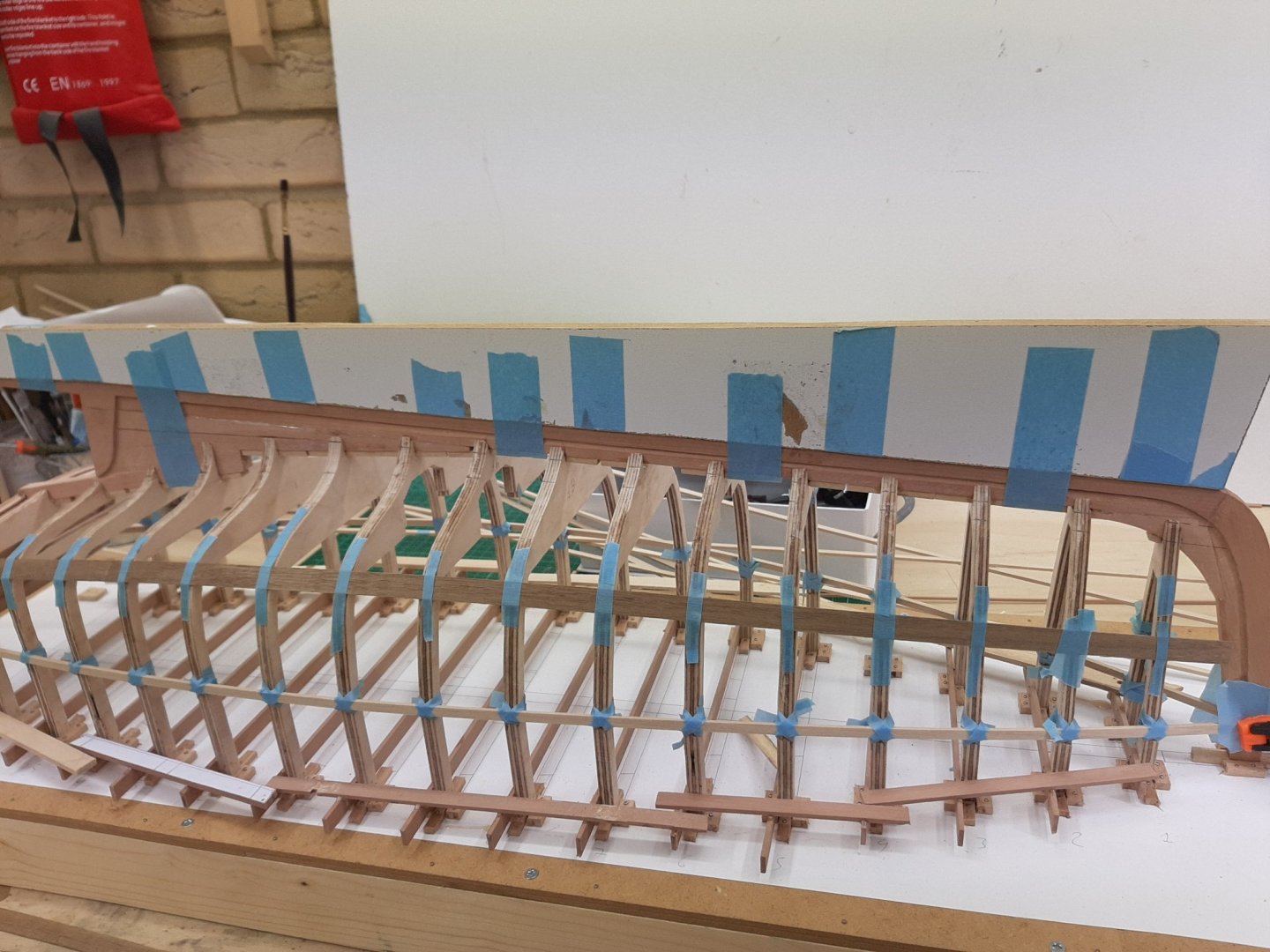

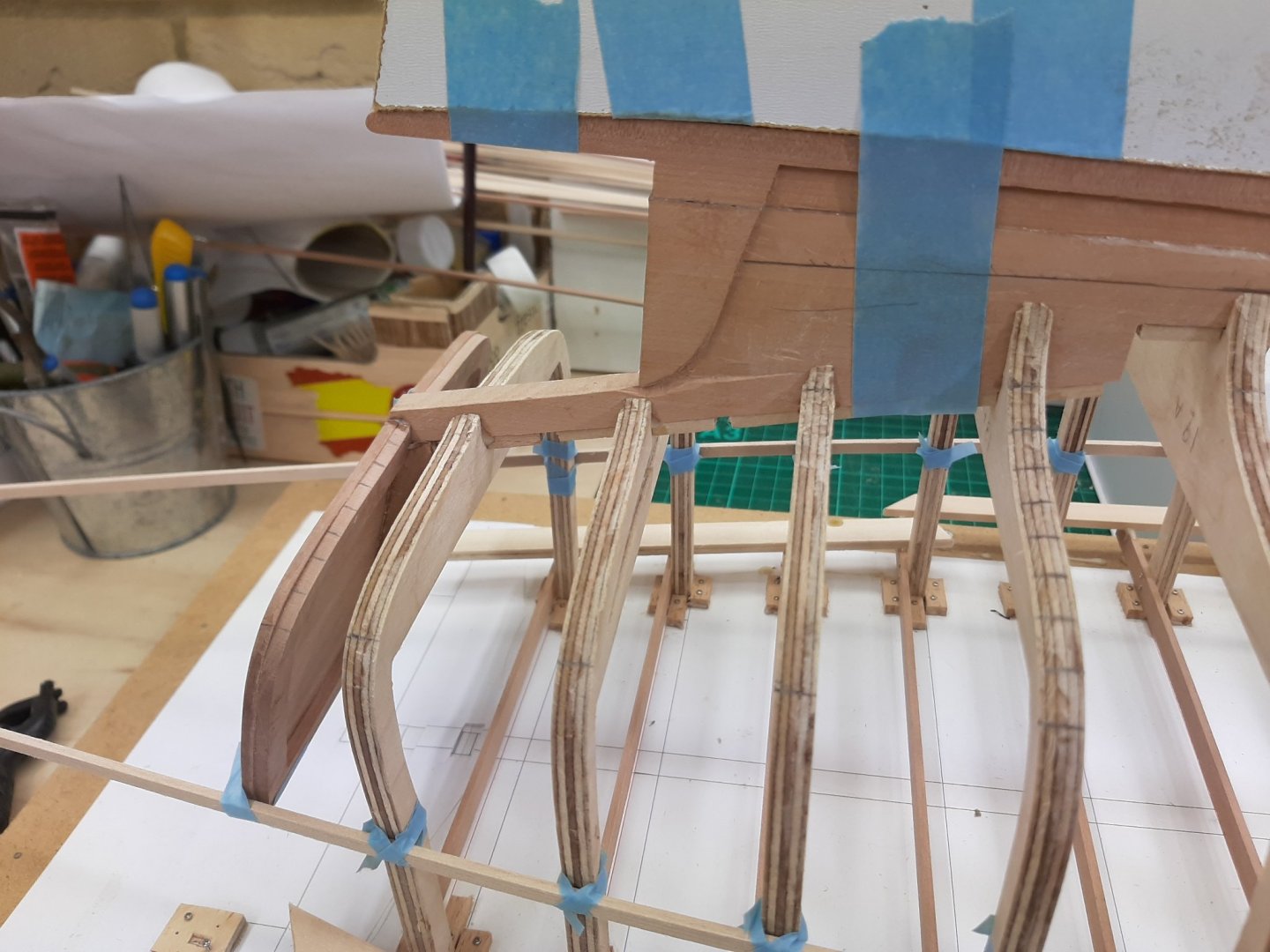

I did a bit more work so another update is in order.

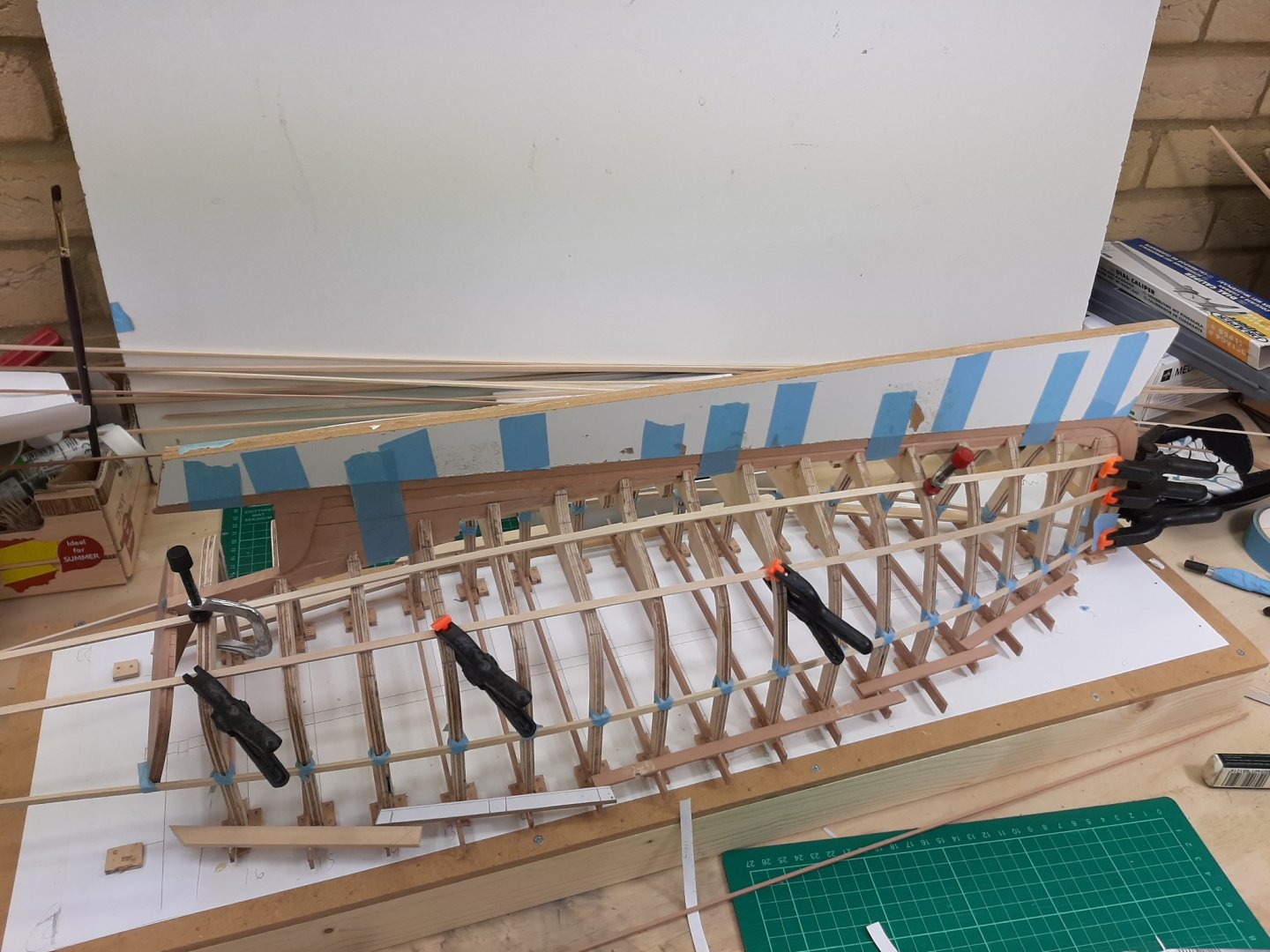

This is were we left things in the last post

- The sheer has been defined

- The hull has been divided in three zones

- The bottom zone has been covered with two planks, one being the garboard plank, and a stealer at the stern.

- In the middle zone, the first plank has been marked and the plank next to it (the first broad strake) was slightly adjusted to balance things out

- Two narrow planks will be at the upper edge of the middle zone due to the significant curvature of the hull at that point. The inner edge of these two planks has been defined.

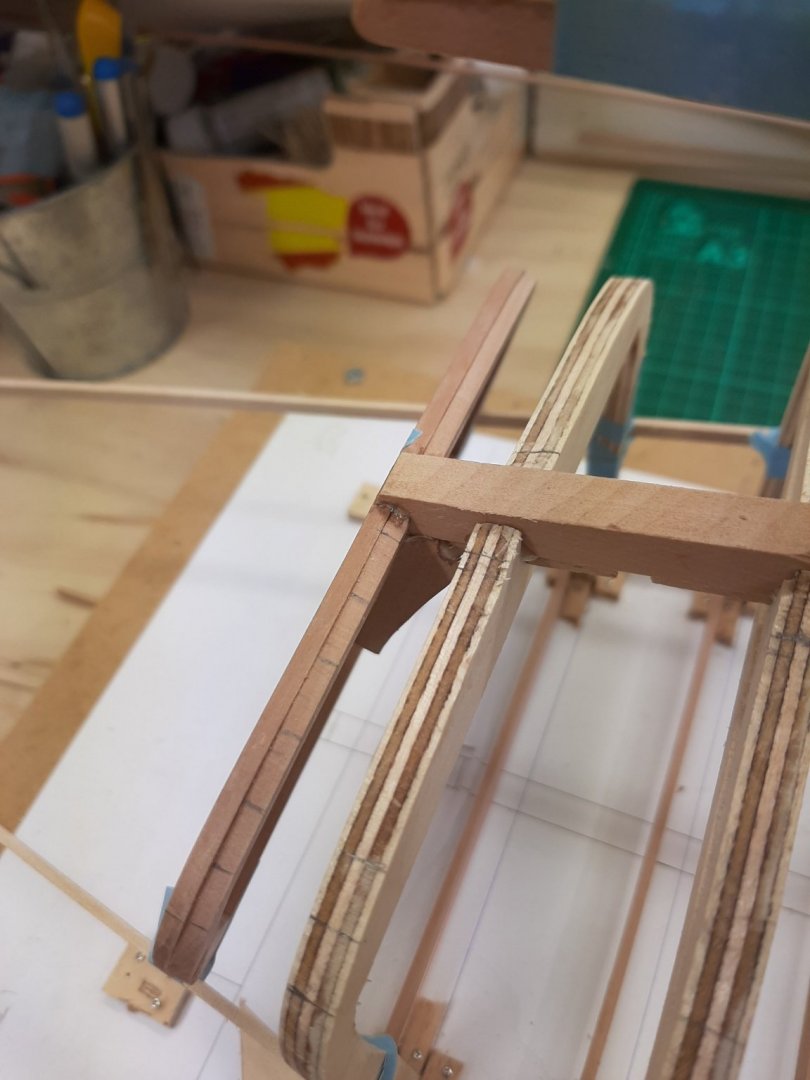

So I started by dividing the upper edge of the middle zone into two planks. Their width at the transom will be 8 mm (8 cm in the full size boat), i checked and with a bit of hollowing they can follow the shape of the transom. I also adjusted the first broad strake (the one next to the garboard) a bit better.

Next job is to divide the remaining mid zone into strakes. The gap is 30 mm at the stem, 40 mm at the transom and a bit more than that midships. This area is very flat so theoretically we can use very wide planks. However, I think that using for example only two planks, 22 mm each, will not look good. I decided to use 4 planks to cover the area, they should have a width of 7.5 mm at the stem, 10 mm at the transom and a bit more maybe midships.

So I measured the distances, divided by 4 and marked the frames.

Then I started laying batens to connect the dots and ensure a fair run of the planks, making sure the planks have more or less equal widths.

This is one of the batens, I think it looks ok and that the run of the planks is not unreasonable

The next photos show the 4 planks defined.

So the botom and middle zone are finished. The planks will of course need spilling, I think the planks at the middle of the mid zone will be the most curved but I hope the spilling needed will not be unrealistic.

So the next task will be to divide the upper zone into planks. This should be the easiest of the three, as it is very flat but also because the clamps are much easier to apply.

One thing to remember is that that the planks at the curved section of the hull will need to be slightly oversized and then beveled, so that they will fit snuggly. However, others may need to be cut exactly to size and then beveled.

Doing this bevels without destroying the planks will be a challenge.

On a different note, there is a new residential development near my house in St Neots and today we walked through. They ve built several ponds and one seems ideal to launch an RC sail boat! Def something to try one day.

Regards

Vaddoc

- G.L., FriedClams, bruce d and 6 others

-

9

9

-

Thanks Keith, this does not guarantee a good result but it is certainly fun!

Bob, I did a bit of testing and you are right, after contouring the plank it really dips bellow the level of the rest of the planks. Well, lets worry about this later.

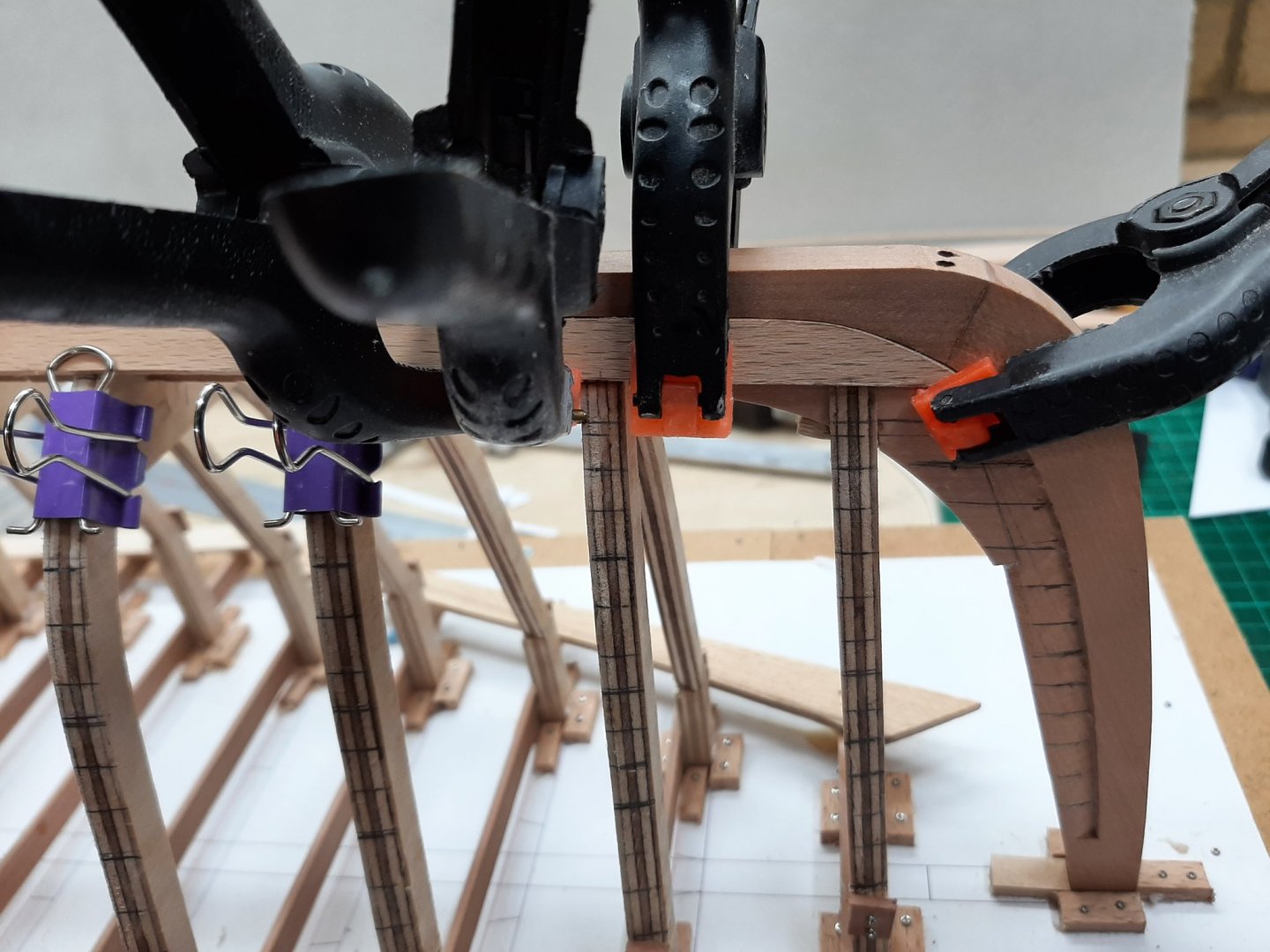

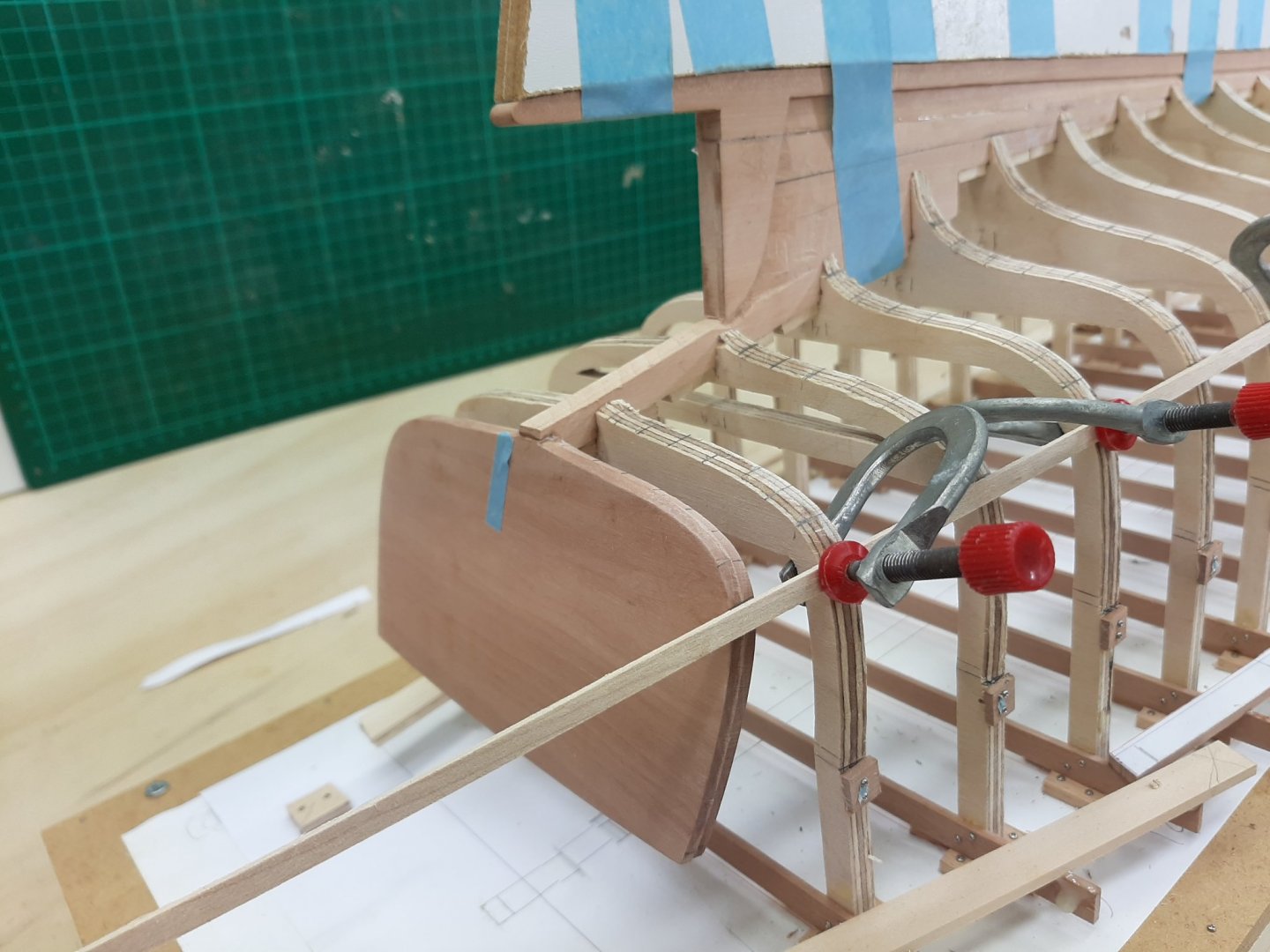

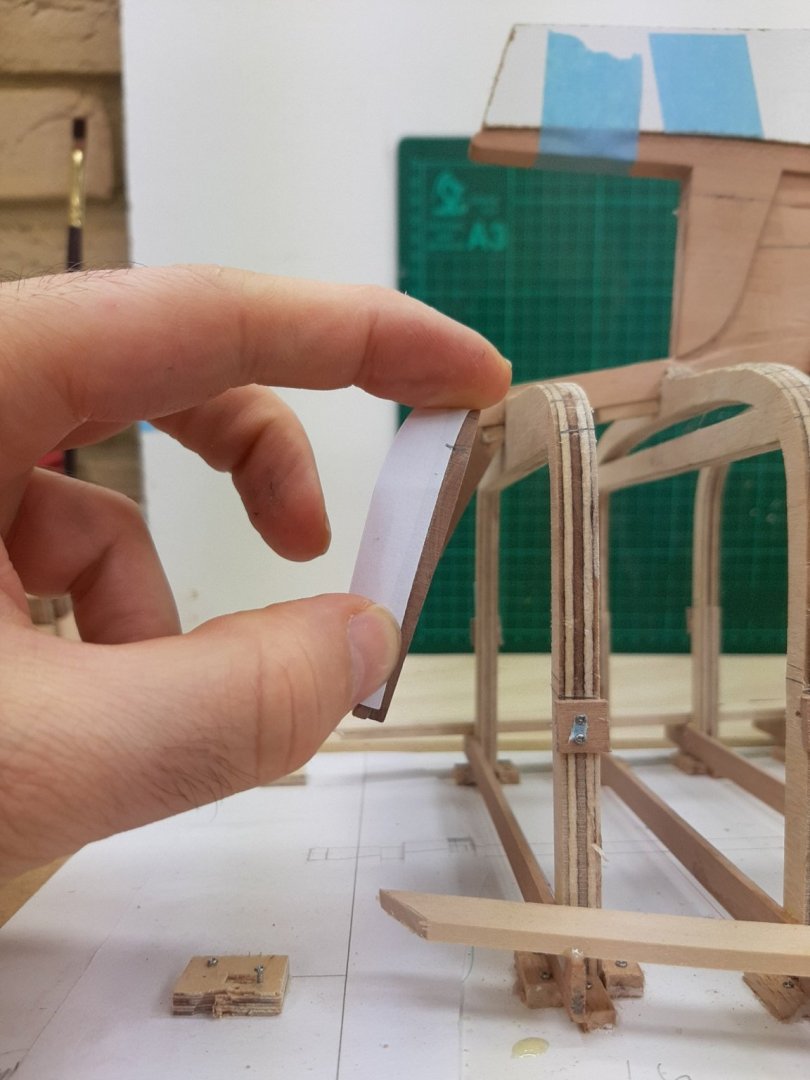

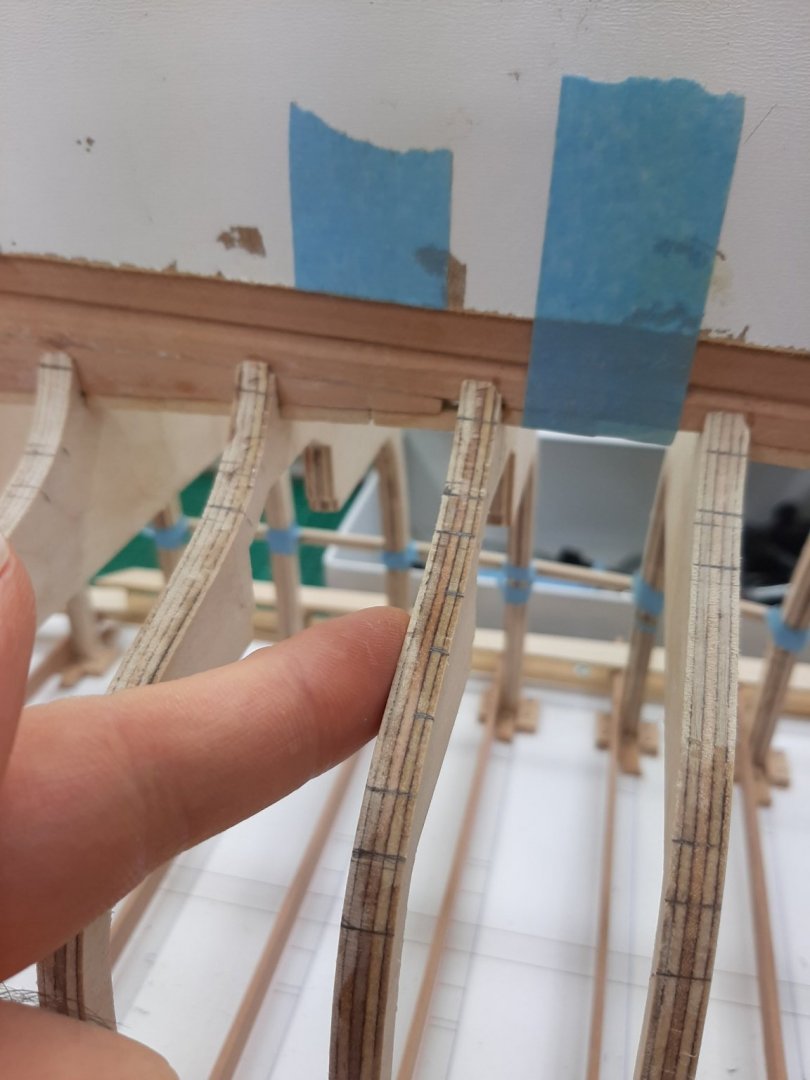

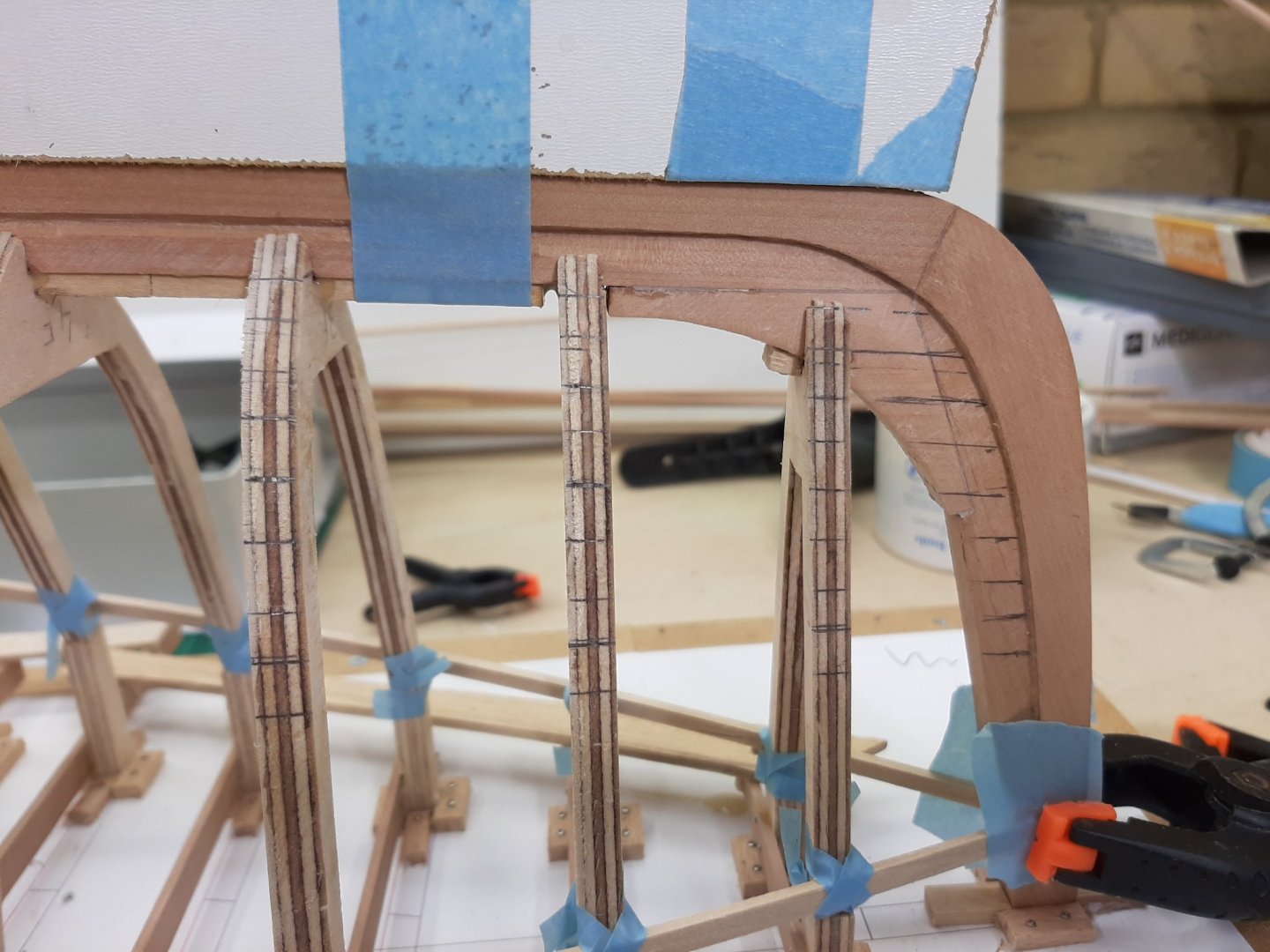

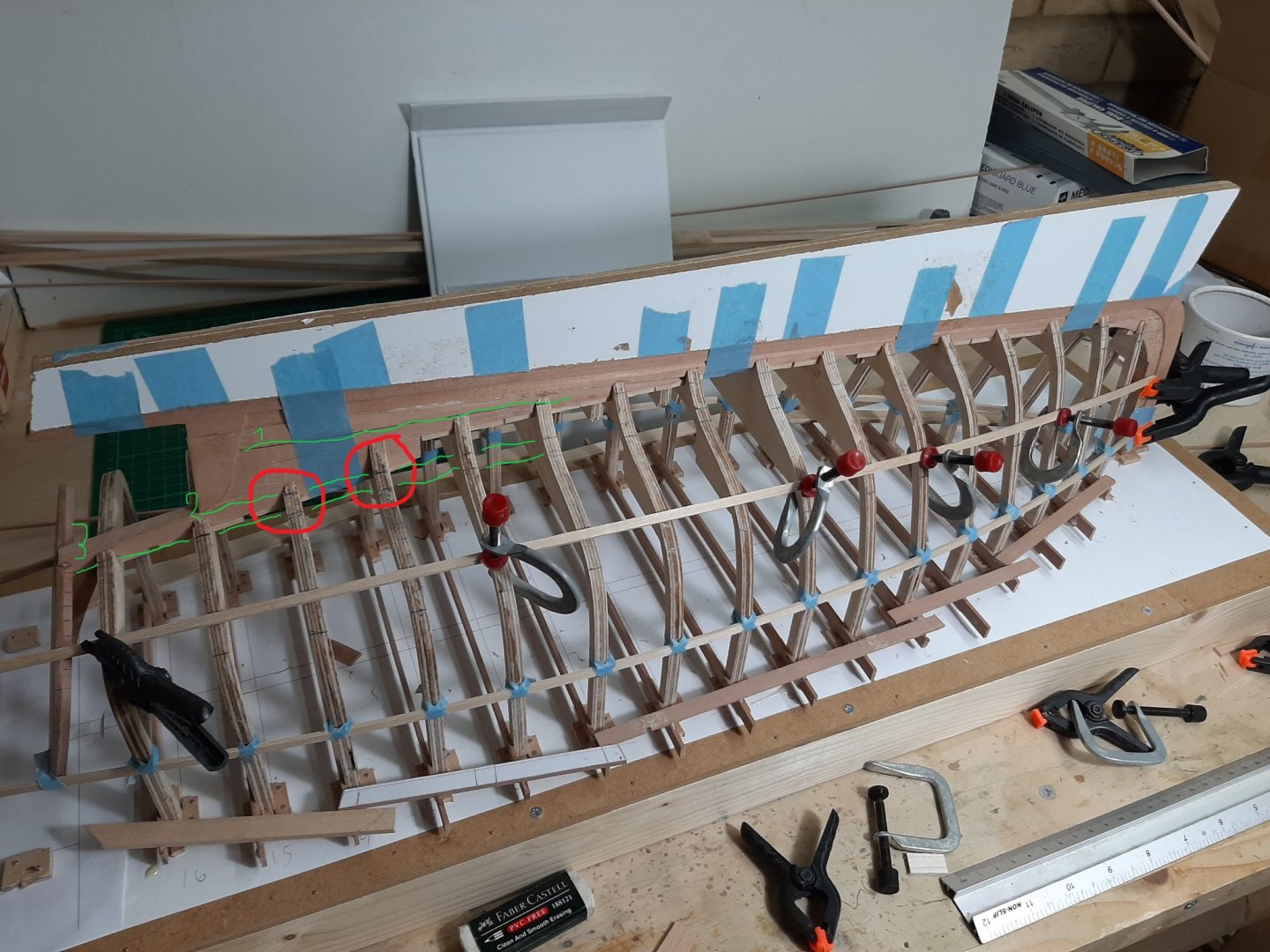

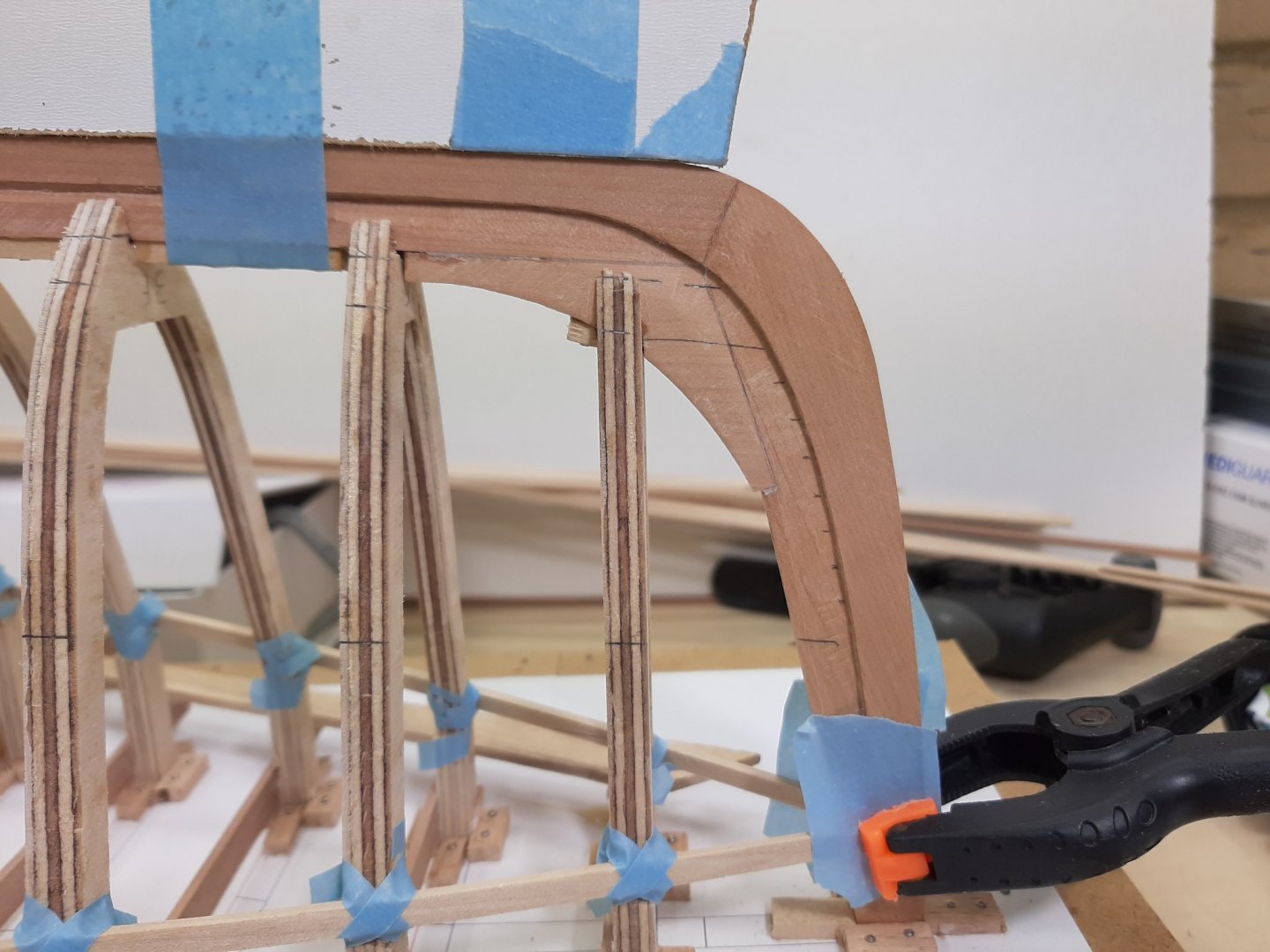

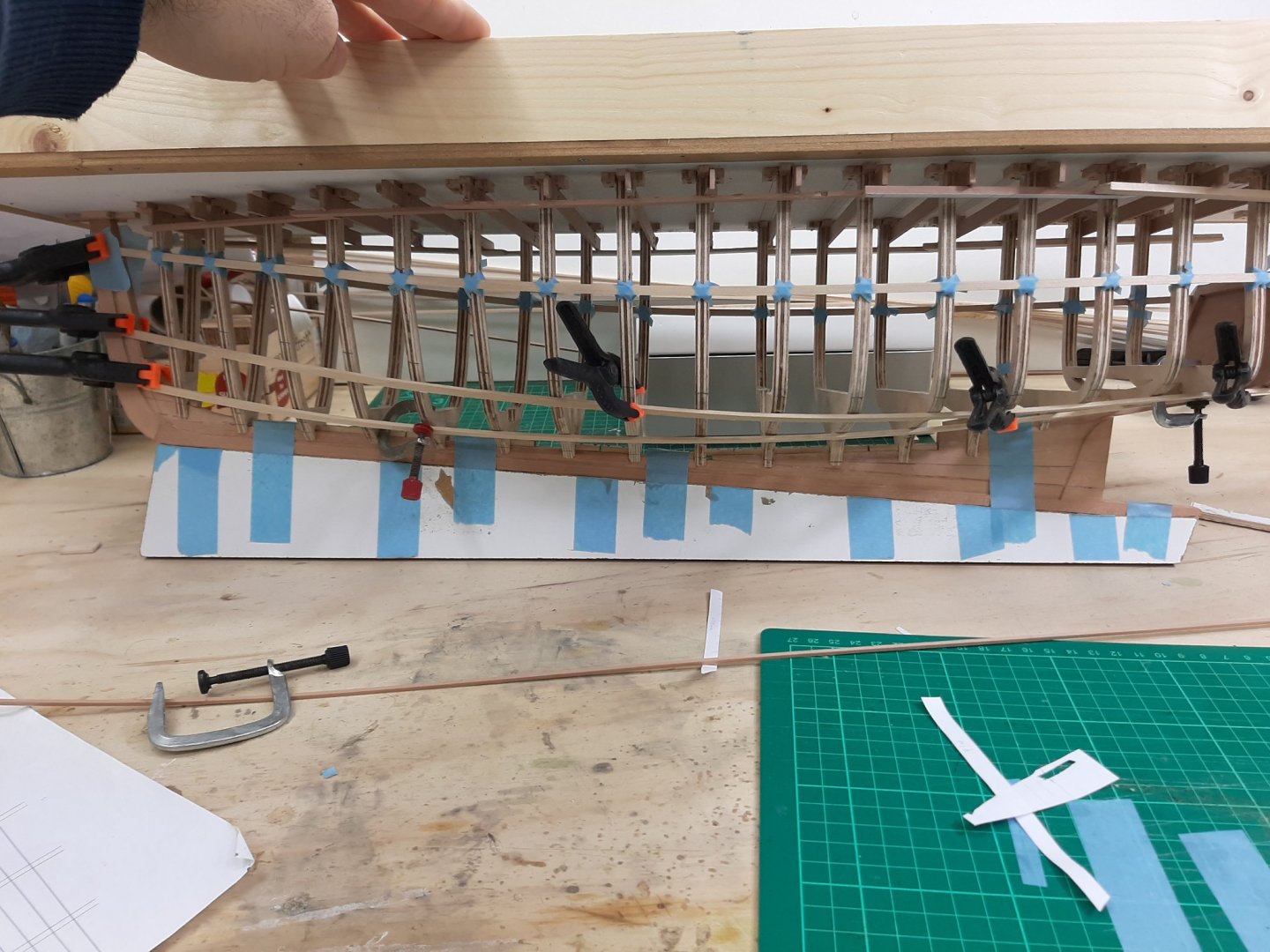

A problem suddenly appeared. This is the beauty of very large scale modelling, it is not at all forgiving and often recreates the true boat building experience.

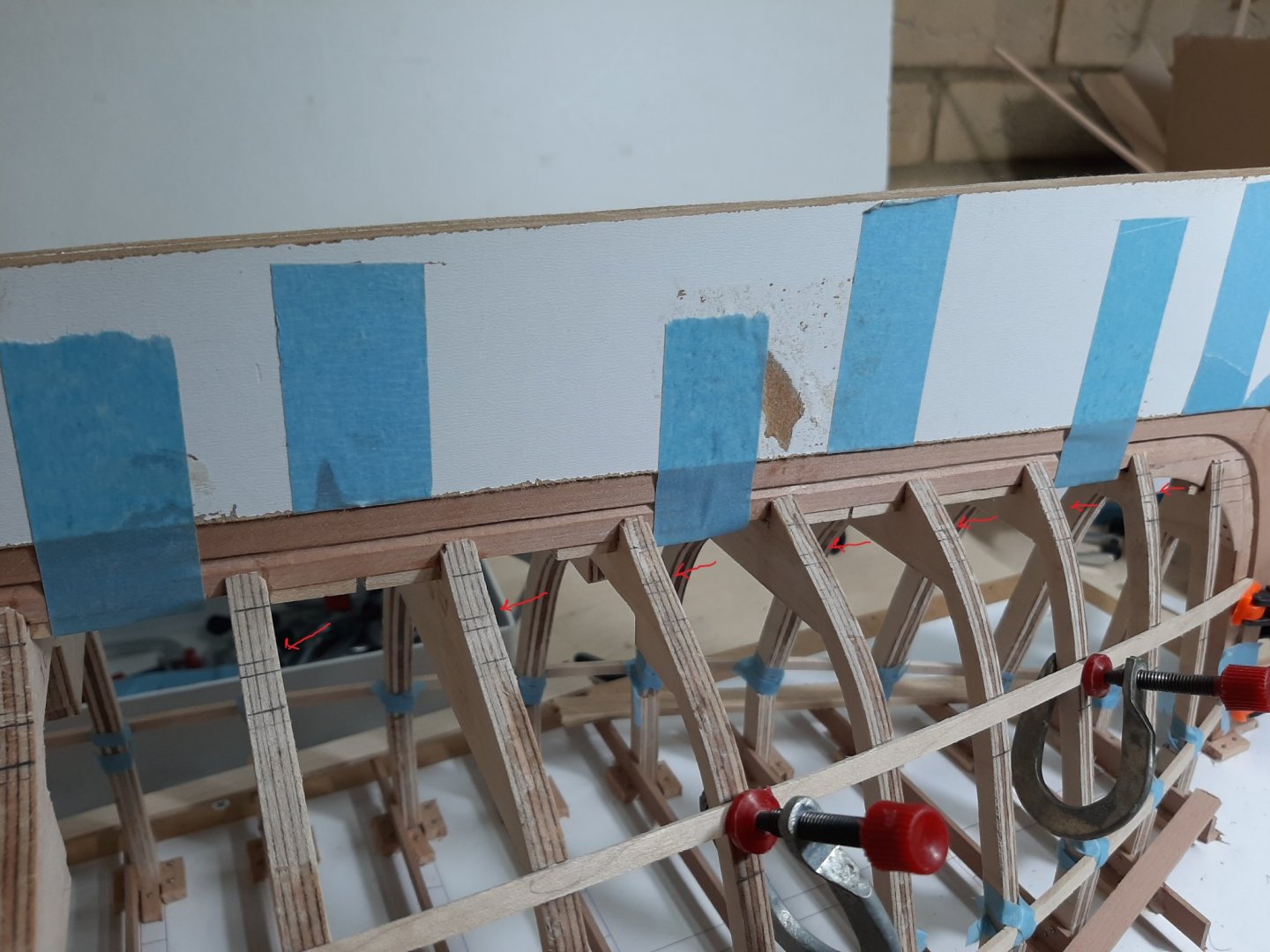

Last time, we defined the first plank of the middle zone. However, I realised it would not work: It is too wide to sit properly on the frames, at least the two really curved aft ones. I tested with pieces of wood and the initial 10 mm width is far too much.

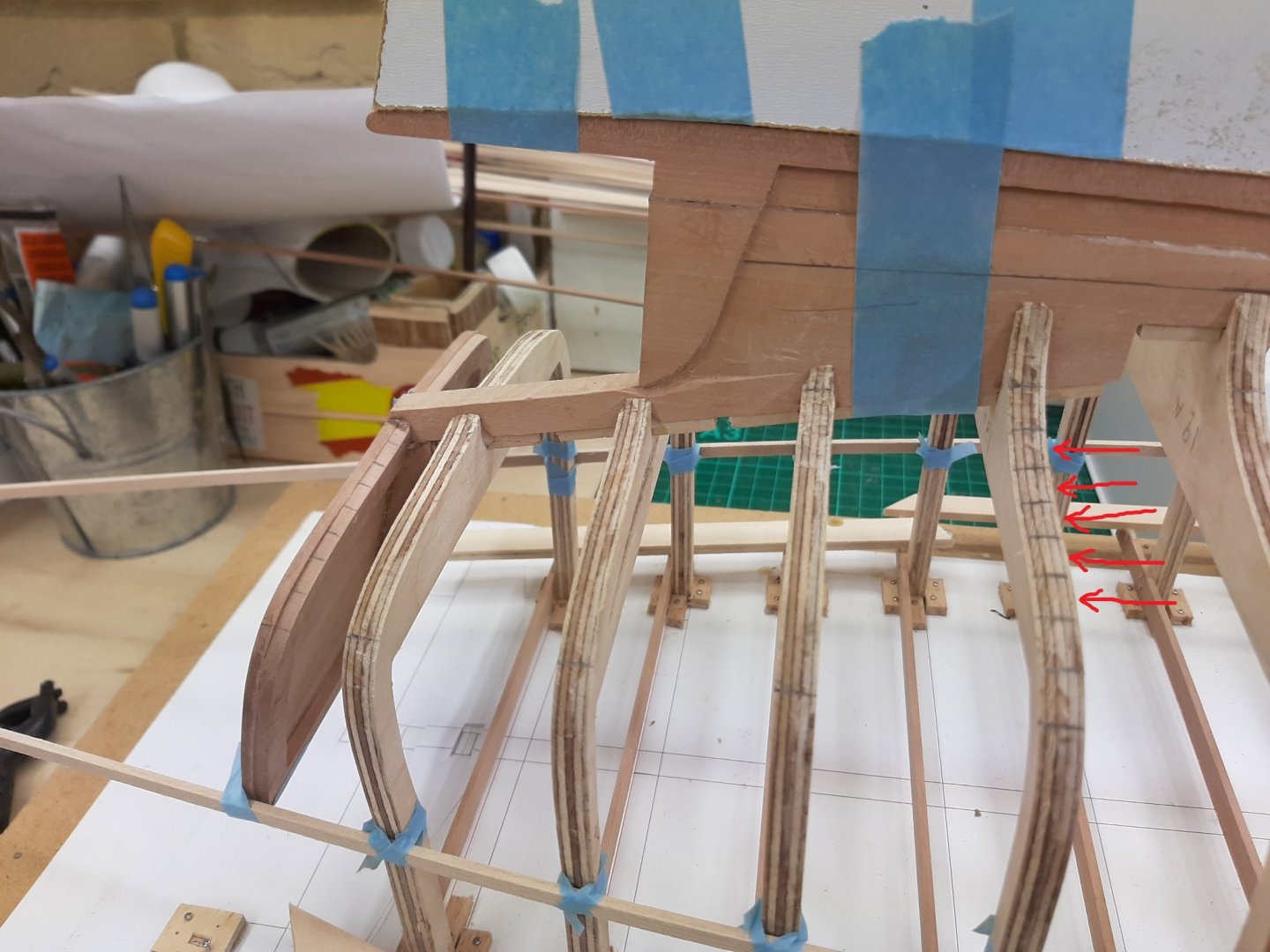

It took many tries and a lot of headscratching with the baten to find a fair run that reduces the width of the planks from 10 to 8 mm at those areas . In the next photos the problem areas are circled and the new markings on the frames can also be seen

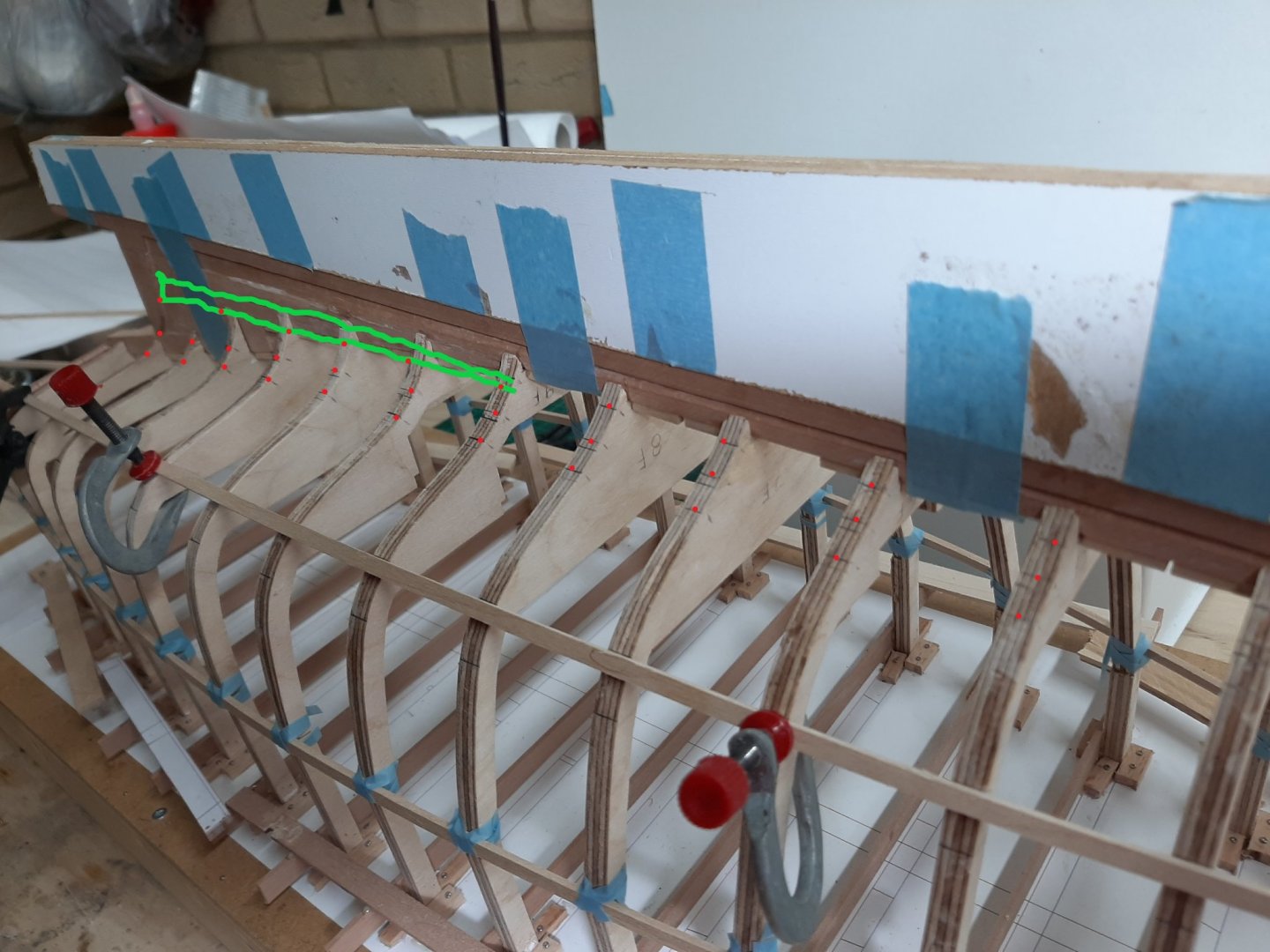

On the other side of this zone, things will get very tight as the transom and half the frames have a very acute angle. The planks there will need to be no more than 8 mm. The green line is the edge of the zone, I think the distance to the blue line can be covered with two planks.

However, now a new problem appeared. This third plank is far too narrow foreward and there is a visible mismatch with the second plank. It makes sense to reposition the second plank so it gives a couple of milimeters to the third plank.

This was not easy, however finally I got a fair curve that looks reasonable

The next photo shows the new position of the second plank, it now looks better. Maybe I need to split the difference at the stem and return 1 mm back to the second plank. The red arrows show the new position

Aft the changes are less dramatic but overall things seem to be more balanced. The green shows the position of the stealer plank

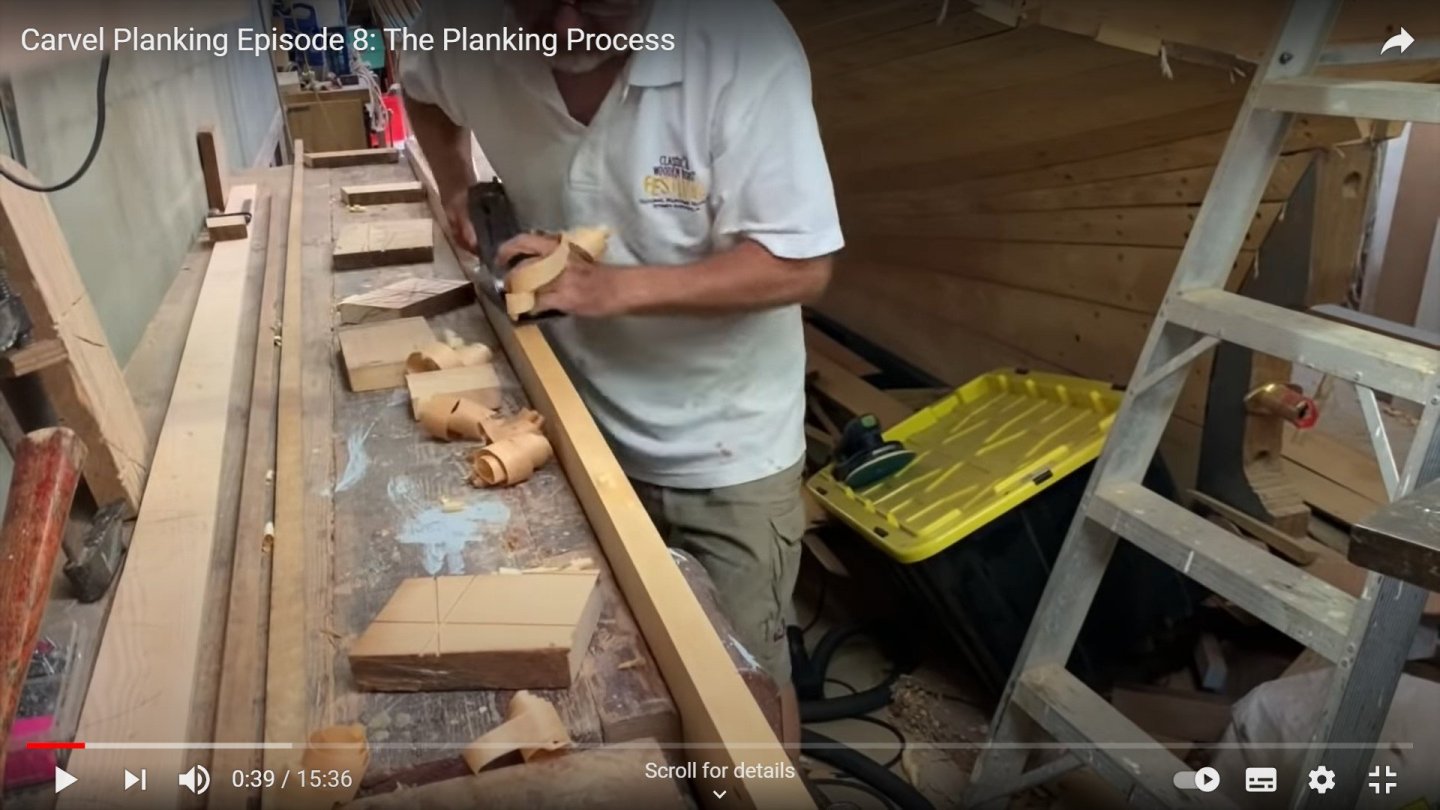

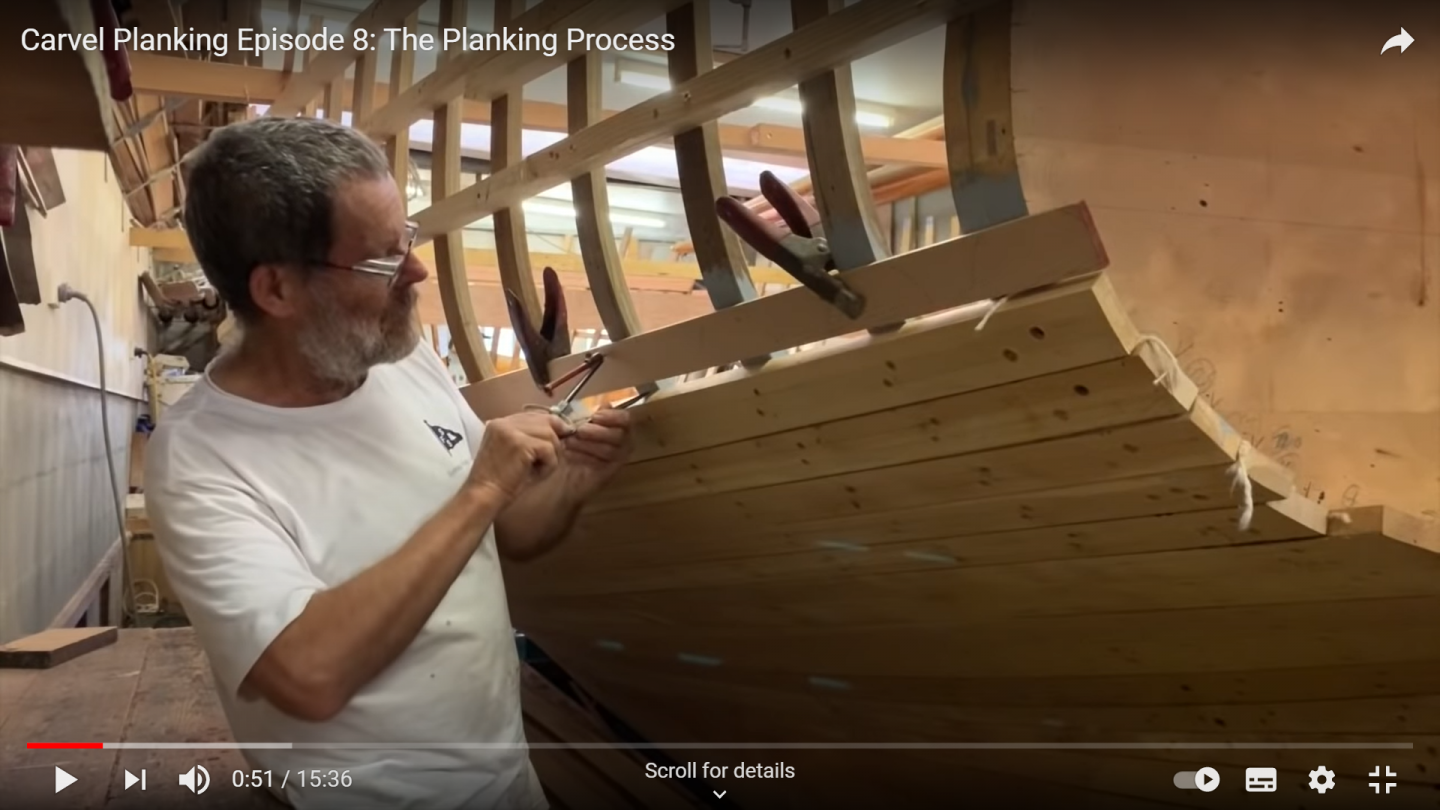

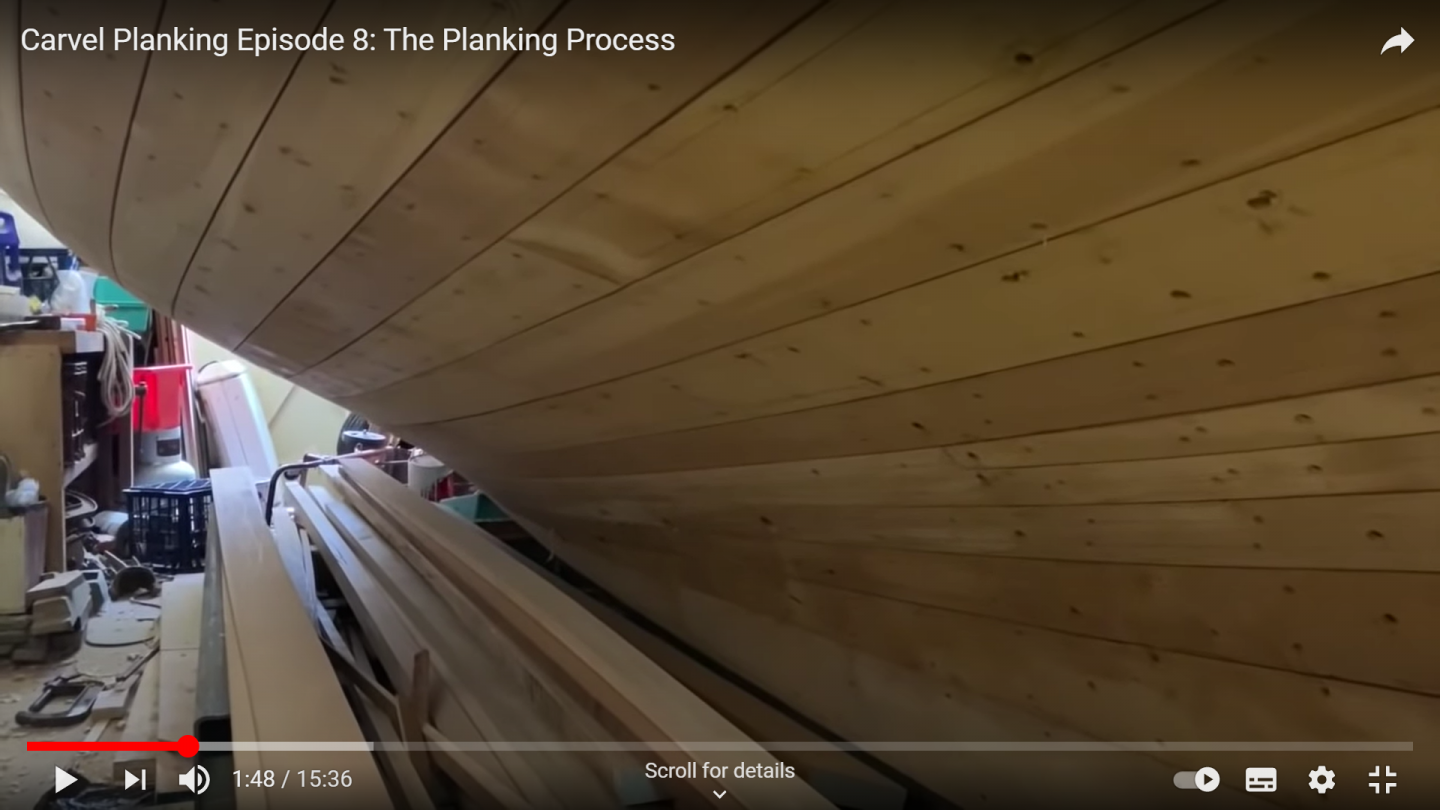

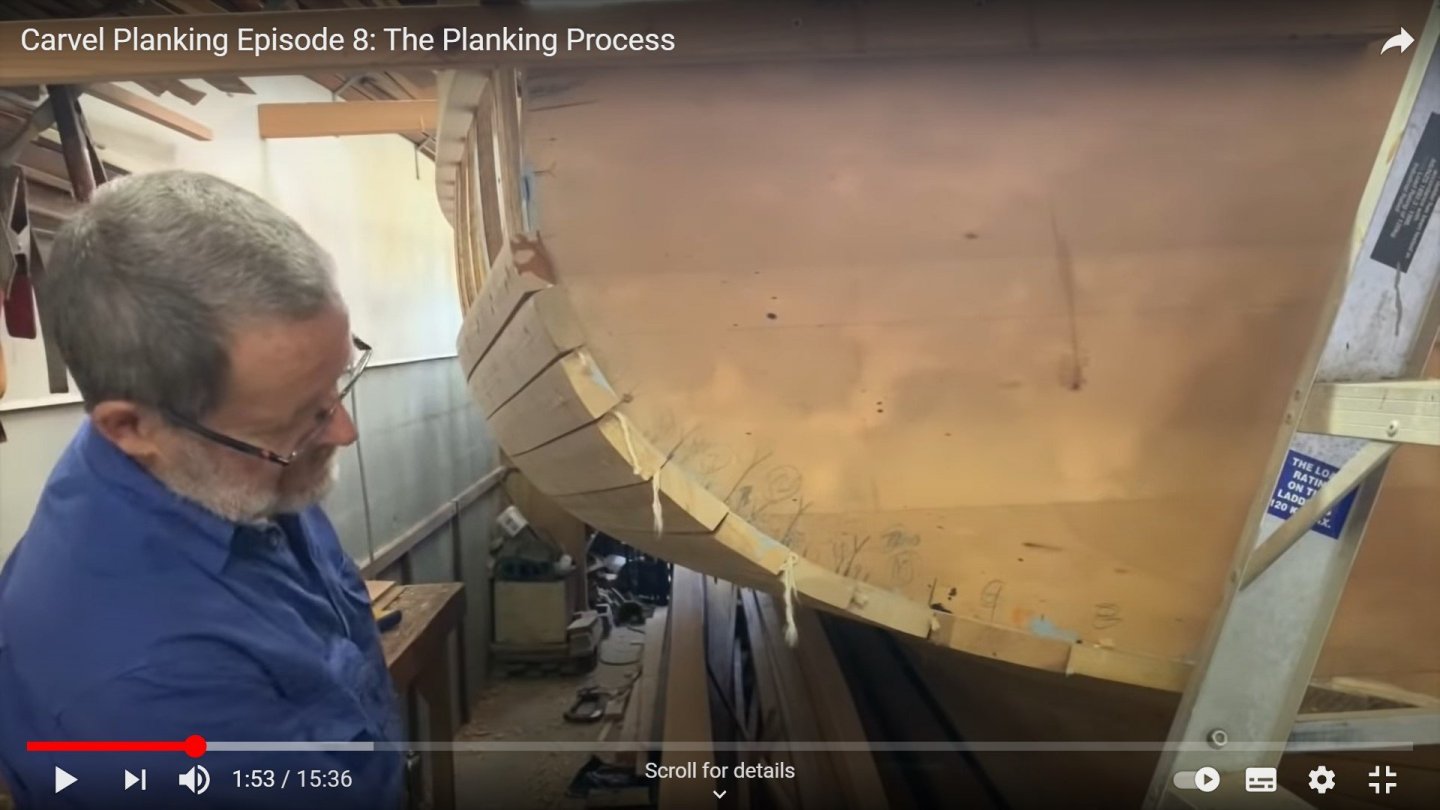

I hope that my planks are not too narrow but really this hull has so many twists and turns that wider planks simply cannot be used. The next photo show first the bow of the boat in the video-indeed some of the planks are very narrow. The other two photos show another boat being planked with relatively narrow planks, especially at the bow, but this one is a simpler shape.

I do hope this will work!

Best wishes

Vaddoc

-

58 minutes ago, Bob Cleek said:

or you'll have to take all the whole hull's planking down to that thickness to fair it

Now Bob, this is bit of worry! I have only 2 mm wood sheets and no thickness sander so I think the future holds a lot of sanding and scraping. Too bad that this particular beech wood I got seems really hard...

-

I did not do a huge amount of work but I did a bit of thinking and took some photos, so we can continue our reckoning. At this point I d like to say that I am not an experienced boat builder but just sharing my thought process as I go along. I would like to do the same with the yawl, which however will be much more difficult to plank (clinker in 1:10)

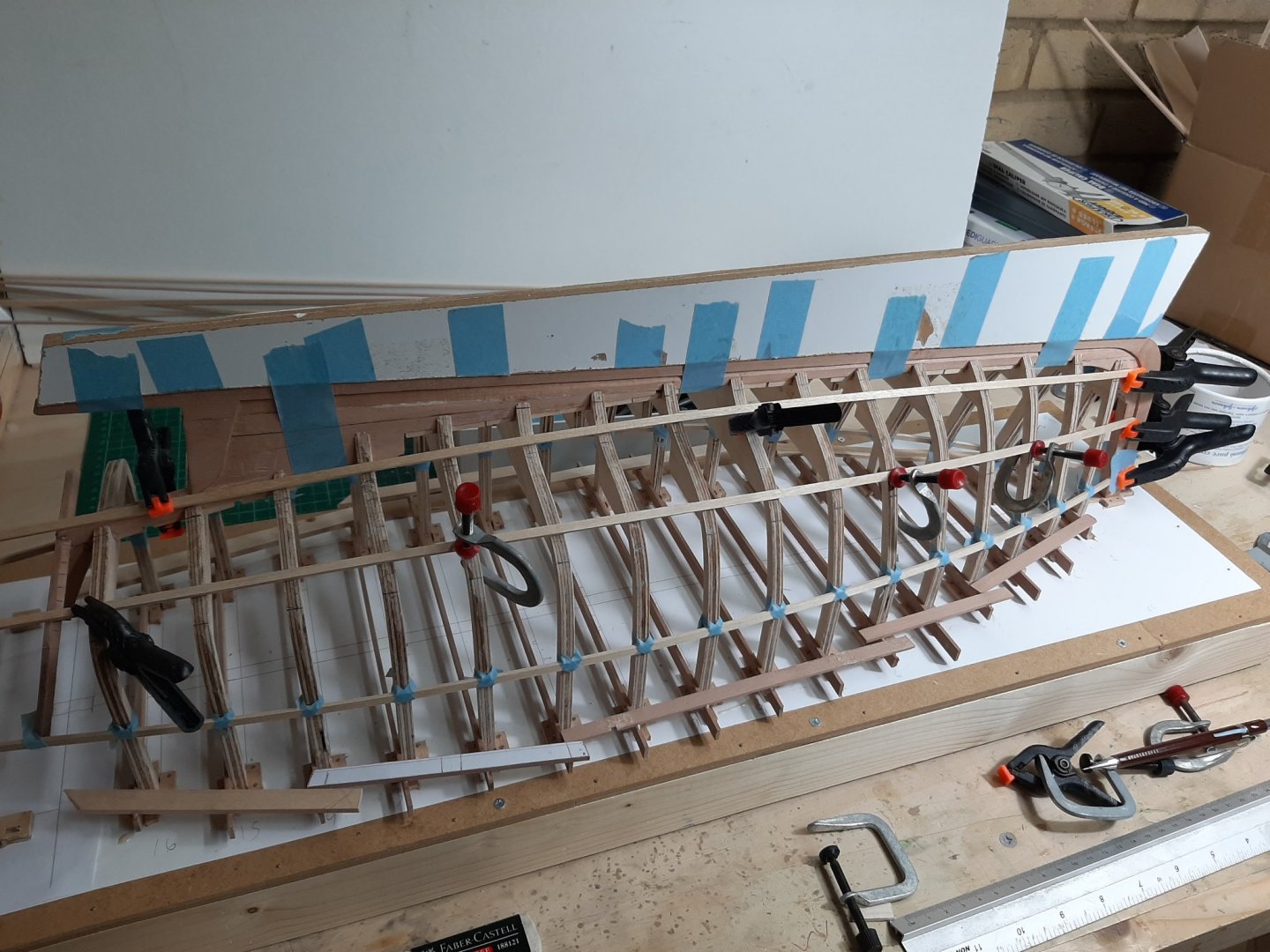

So in the last post, we managed to define the sheer and the three planking zones and we also defined the garboard and the first (not so) broad strake.

Now, we need to work out the rest of the planks. We have their general direction of the planks but we now need to define their width and decide how many planks we will aim for. The width of the planks will depend on how curved the hull is at a specific point but also on how much spilling the plank will need. I have 100 mm x 1000 mm sheets to cut my planks from but the actual boat builder would have much more narrow stock to work with.

The planks need to lie and be in complete contact with the frames. Even hollowing the plank, a certain plank width can only accommodate a certain hull curvature. After that, the width needs to be reduced.

Considering the above, my feeling is that the garboard and first broad strake cannot be any wider because a wider plank will not be in complete contact with the frames. The next photos show that even at the current width of the first strake, without contouring the surface, the plank will not lie in contact with the frame.

Wefalck suggested that planks should be 15 to 20 cm wide. Perhaps this is the case for large ships but for such small boats, I think the planks would be much more narrow but again it depends on the shape of the hull. I would think 13 cm would be a good number but actually, it can be much less. But lets continue and we ll pick this up later on.

So, now it is time to divide the middle zone into planks. The planks that are at the edges of the zone will need to accommodate quite tight curves so need to be pretty narrow. Based on that, I eyeballed that it makes sense to divide the zone into 8 planks-this was a completely random choice.

I first removed the wide walnut strip and replaced it with a baten.

Then I measured the widest frame, which on this boat is very near the stern, and divided the distance to 8 equal lengths.

Did the same with the transom

and also the same with the stem

This are the widths, pretty narrow

So I went ahead and marked these widths to the transom, frame and stem and then threw a couple of batens to see how the planks at the edges of the zone would run.

Now, we cannot use wide planks where the hull is very curved so these planks cannot be made any wider. However, the rest of the planks, in between these planks on the edges of the zone, run on a reasonably flat part of the keel so potentially they could be made wider.

Lets go back to the very nice you tube video. That boat builder, is actually doing the same. His planks are very narrow where the hull is curved and wide where it runs flat

Note the difference in plank width at the transom

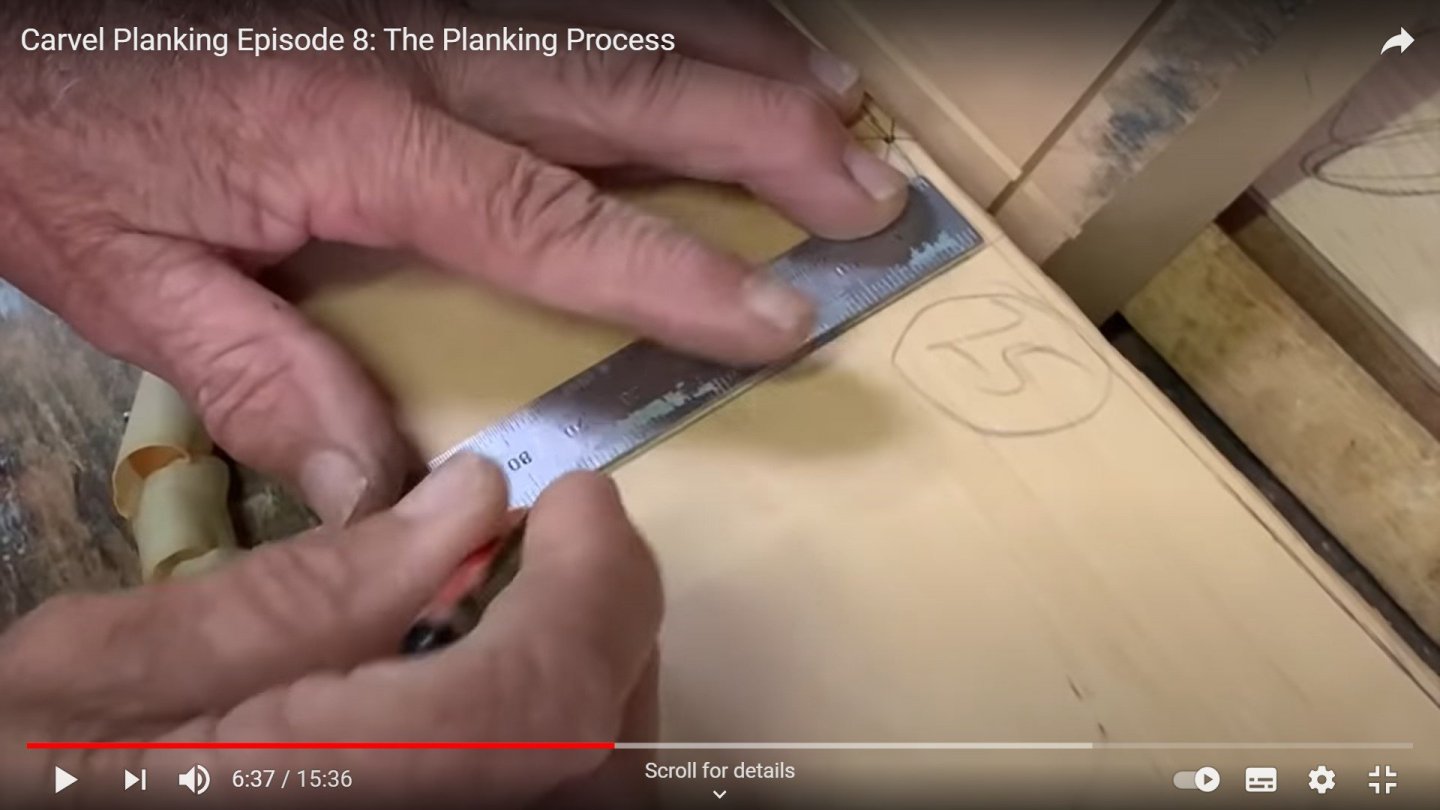

Somewhere on the video, he actually lays a ruler across the plank-it is 8 cm wide!

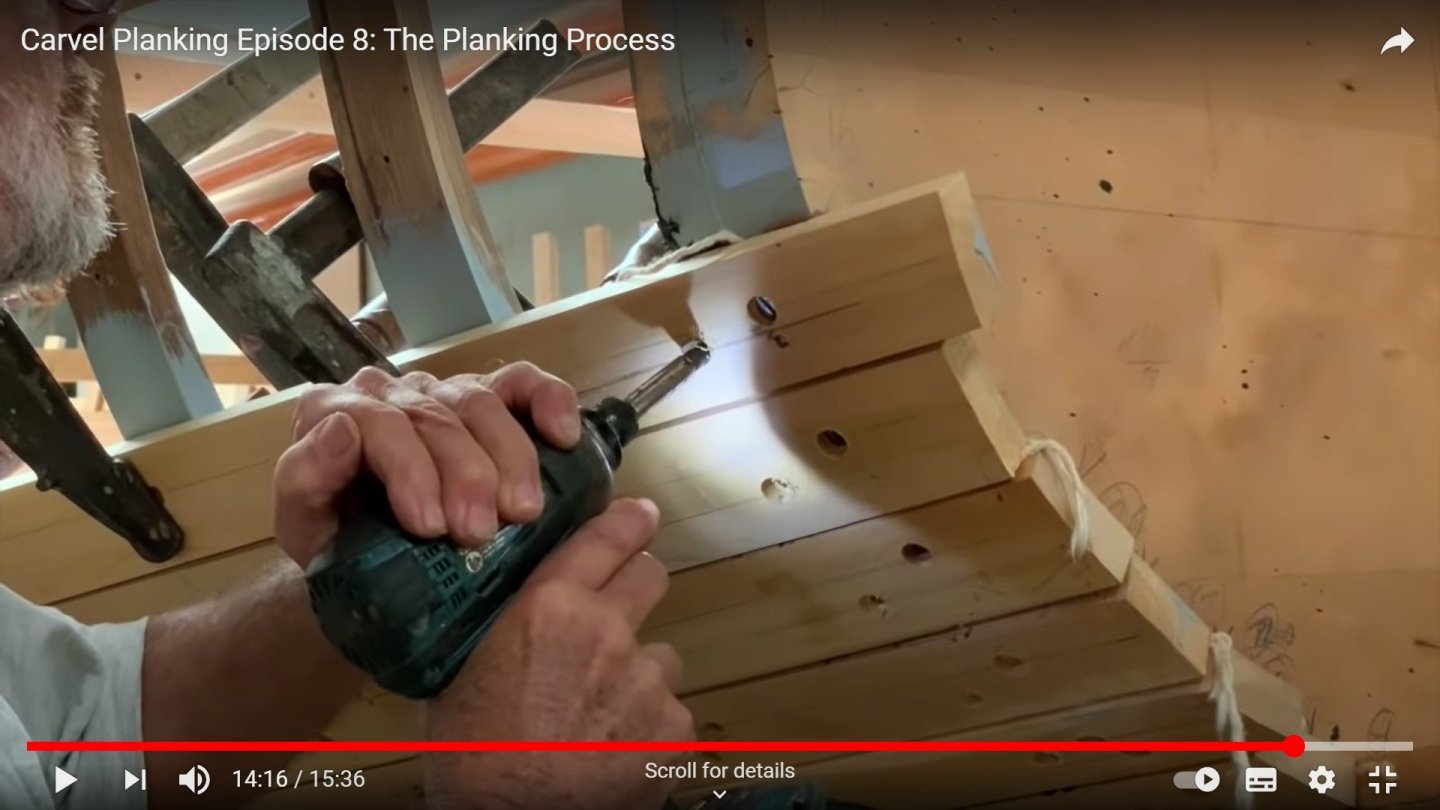

Even planks as narrow as this can be easily and safely screwed in place

Back to our model, I think that the 5 middle planks shown in the next photo could be replaced by 4 or even 3 wider planks

I feel a bit uneasy with the sheer, the batens are not secured well. I need to think a solution.

Regards

vaddoc

- wefalck, GrandpaPhil, FriedClams and 2 others

-

4

4

-

1

1

-

On 1/14/2021 at 3:32 AM, Bob Cleek said:

I lament the elevating of the technical above the artistic for therein lies the difference between an art and a craft.

46 minutes ago, michael mott said:True I echo these sentiments.

I think we should just make our models bigger, a few 1:10 cutty sharks and victories would certainly revive this craft/art😁

I once read that art has no purpose but itself so model boat building should be at the heart of this slowly forgotten art...

Vaddoc

- FriedClams, wefalck, Wintergreen and 1 other

-

4

4

.thumb.jpg.6fd4c1b78768bb3efd745ab810936005.jpg)

I have decided to build a steam box.

in Modeling tools and Workshop Equipment

Posted

Excellent Art, your steamer seems to be working well. Now, I need to make a similar one!

I have two boats to plank, about 50 planks altogether of 2 mm beech.

I am thinking to make a long box out of plywood, with one end closed, apart from an opening to accept the steam feed hose, the other with a loose fitting cap and a rag so steam can escape. I presume a drain hole will be needed, probably just drill a hole but attach a hose so that the condensation be directed to a bucket to avoid making a mess.

As you report things will get pretty hot in there so some caution will be needed.

I ll post my results