-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

MicroMark MicroMill - Review

mtaylor replied to mtaylor's topic in Modeling tools and Workshop Equipment

Wefalck, They're not rated for that speed, that's why I have monitor for heating. The tech I talked to, thought they would be ok if I had been using the mill and the bearings were run in. However, I'm only runing it at speeds above 3000 rpm in short bursts at this point. -

Rusty, The treenails and limber boards look great.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Hi Colin, Good to see that you and your build log are back.

- 80 replies

-

- deagostini

- victory

-

(and 1 more)

Tagged with:

-

Hi Kats, I'm happy to see your back and reposting. What the others say: This is a very special re-build.

- 237 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

Pop that question in the rigging section. It's possible someone has an answer. Or, PM Gill directly. Maybe he'll re-start his log.

- 188 replies

-

- surprise

- artesania latina

-

(and 1 more)

Tagged with:

-

Hi Denis, I'm happy to see you're putting the log back up. I was hoping to see it finished and now it looks like I will since your back and posting the progress. No rush.. no pressure.

- 555 replies

-

- sovereign of the seas

- mantua

-

(and 1 more)

Tagged with:

-

Mayohoo, good to see you found your way back and will carry on the build log. I'm looking forward to it.

- 188 replies

-

- surprise

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks for the nice comments everyone. Harvey, I almost tossed mine for the same reasons. But I remember walking her in around '74 in Baltimore. The kit looked like she did then. So it wasn't fiction. It was laziness. They never changed the kit after the truth was out. It was a few people pointing me in the right direction that spurred me into this bash. Funny thing.... I noticed that AL include the hull hog that was there in '74. BTW, the scale is pretty close to HO and not what they had on the box. A bunch of stuff was either fiction or the wrong scale. Thanks Frank. I've had few people say they like that stern shot. Maybe I should give up model making and go back to photography?

- 28 replies

-

- artesania latina

- constellation

-

(and 1 more)

Tagged with:

-

Ok... it's something else going on.. I'll get back to you when I find out.

- 208 replies

-

- meridea

- repair ship

-

(and 1 more)

Tagged with:

-

Hold that thought on the print and download buttions. They're not working right for me, but appears to be my settings. Might work for you.

- 208 replies

-

- meridea

- repair ship

-

(and 1 more)

Tagged with:

-

Better unshrink yourself Michael. At that size, jumping off the work table to get a piece of wood might...no... will be disasterous.

- 2,215 replies

-

ancre Le Fleuron by cabrapente - FINISHED

mtaylor replied to cabrapente's topic in - Build logs for subjects built 1501 - 1750

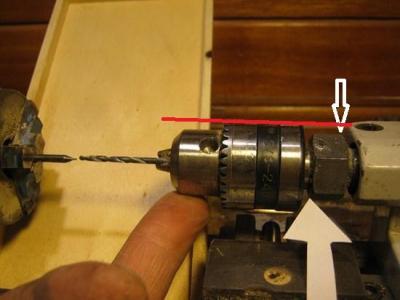

NIce work on the brass, Cabrapente. It looks like where the play is coming from on the right side of the nut (last photo of lathe). Is there a locking screw on the tailpiece that you can loosen and push it in further? The red line I drew shows that the whole assembly is loose. To the right of that line appears to be a set or lock screw. The white arrow is a mistake, I meant to point to the screw.- 332 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Walter, So far you only have one page. Down near the bottom on the left, is a printer icon and a download icon. That might be what you are looking for.

- 208 replies

-

- meridea

- repair ship

-

(and 1 more)

Tagged with:

-

Thanks for the nice comments, everyone. Sjors, it was on the old MSW.. probably buried somewhere. Patrick, when you're ready or before, ping me. The AL kit has a lot of pitfalls when built out of the box.

- 28 replies

-

- artesania latina

- constellation

-

(and 1 more)

Tagged with:

-

This tool is full of pluses and minuses. Relatively inexpensive (for a mill), lightweight, small, has reasonable power for its size. All controls are easily used and seem very precise. Two downsides.. the first is that accessories relatively hard to come by. Everyone sells accessories for the larger "mini" size, the R8 from MM or Sherline type. The other is the RPM is limited to 2800. I was able to rework the pulleys so it turns at about 12,000 rpm. But I have to monitor the bearing temperature and I killed the warranty with this mod. I've also had to adapt vises and hold pieces to fit as they are all for the larger mills. This also, not a production type tool. Not designed to run 8 hours a day even before the RPM boost. All in all, not a bad value for the money. However, given what I know now, I go for the mini type available from MicroMark, Harbor Freight and Sherline. Probably the Sherline with their RPM kit.

-

I've had mine for a few years. It does a good job as long as I'm not trying to take off too much wood, feed the wood through too fast (slowly feed, very slowly) and not trying to do too much at once. In other words, for a few pieces at a time, it works. There's no way of setting the thickness except by trial and error that I've found. This sander, is not a Byrnes Sander by any stretch. If I were buying one today, I'd hold off until I could afford a Byrnes.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.