-

Posts

948 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Moonbug

-

-

1 hour ago, glbarlow said:

However those friezes are done I know from my Pegasus they require meticulous work and steady hands - you've done a really nice job of it.

Thanks a lot Glenn. Definitely took some magnification, a very small brush, and lots of patience. Also - a fair amount of wiping off bits with a wet cue tip and "do overs". 😛

Btw - your Winny planking is looking fantastic.

-

So this is the time where I actually DID look far enough ahead - the frieze work. I knew along the way that I done a number of things that would directly affect how I applied the kit's photo etched decorations. I did debate heavily whether or not I should just paint them on. Fun fact - I actually dabble a bit with painting; here's a piece I did for my home office:

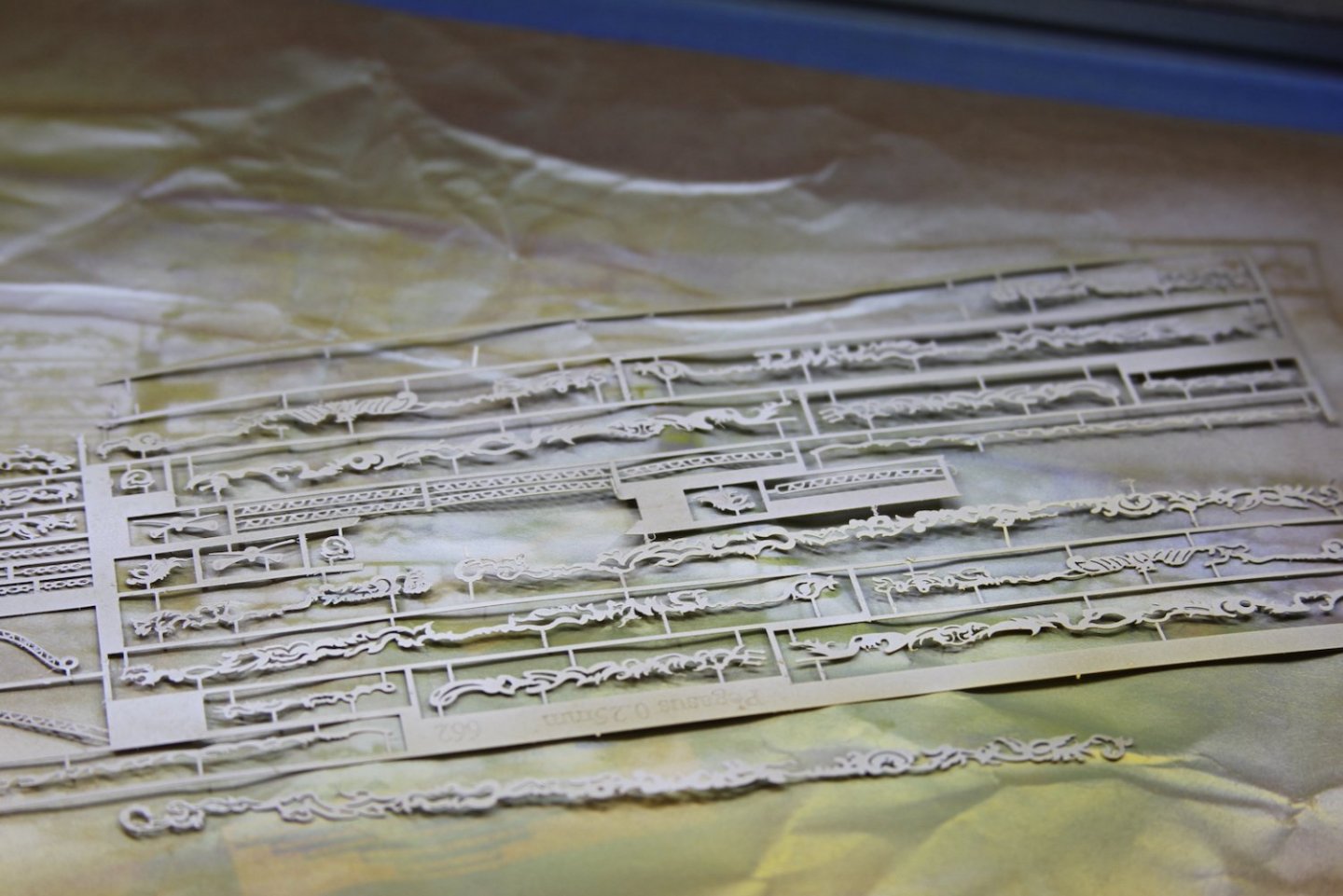

That said - I'm actually not that great at THIS kind of painting, so I decided to keep the PE stuff. Anyway - a bit of a tangent. Along with adding knees to the channels, I also used a wider sheer strake that blends into the hull at the fore of the ship. This in particular then changed the placement of the drift rails, etc. Finally my drift (and other) rails and decorations are a differing size than the kit.

To get the PE stuff to look moderately accurate, I painted a couple coats of air brushed white then yellow ochre to give it some depth. Then I followed the basic pattern of what decorations went where. There was NO space above the gun ports, so those bits were eliminated altogether and I filled in the rest leaving gaps for the fenders, steps, and chesstrees.

To finish off the frieze work, I went through (as advertised in some of the tips & tutorials here) and touched up the bottoms with this cool gold color from Army Painter, then the top highlights with a much lightened mixture of white and yellow ochre. Topped off with a coat of WOP that's brushed on then brushed off (which is why it looks a little glossy).

- flyer, Blue Ensign, gjdale and 4 others

-

7

7

-

-

-

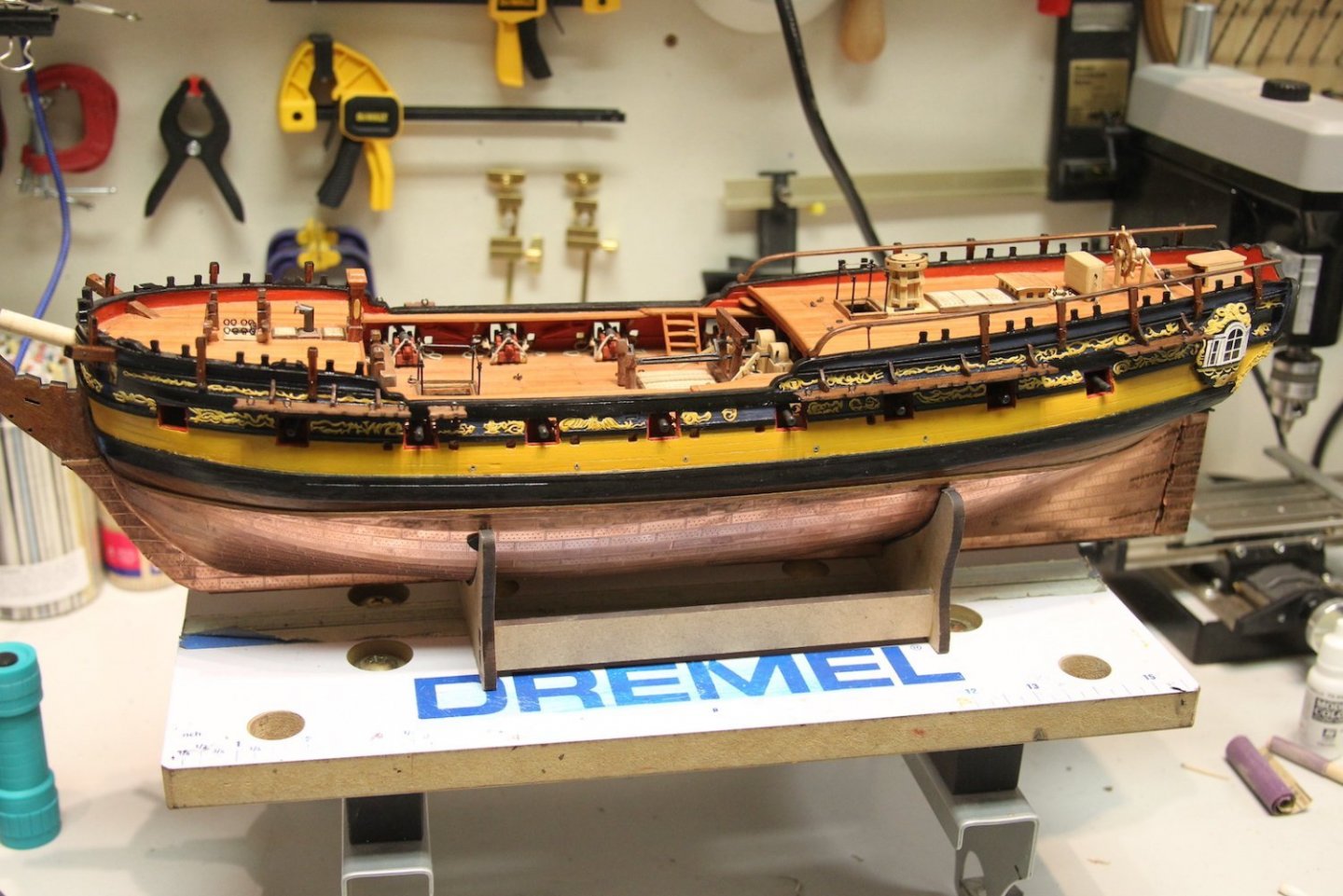

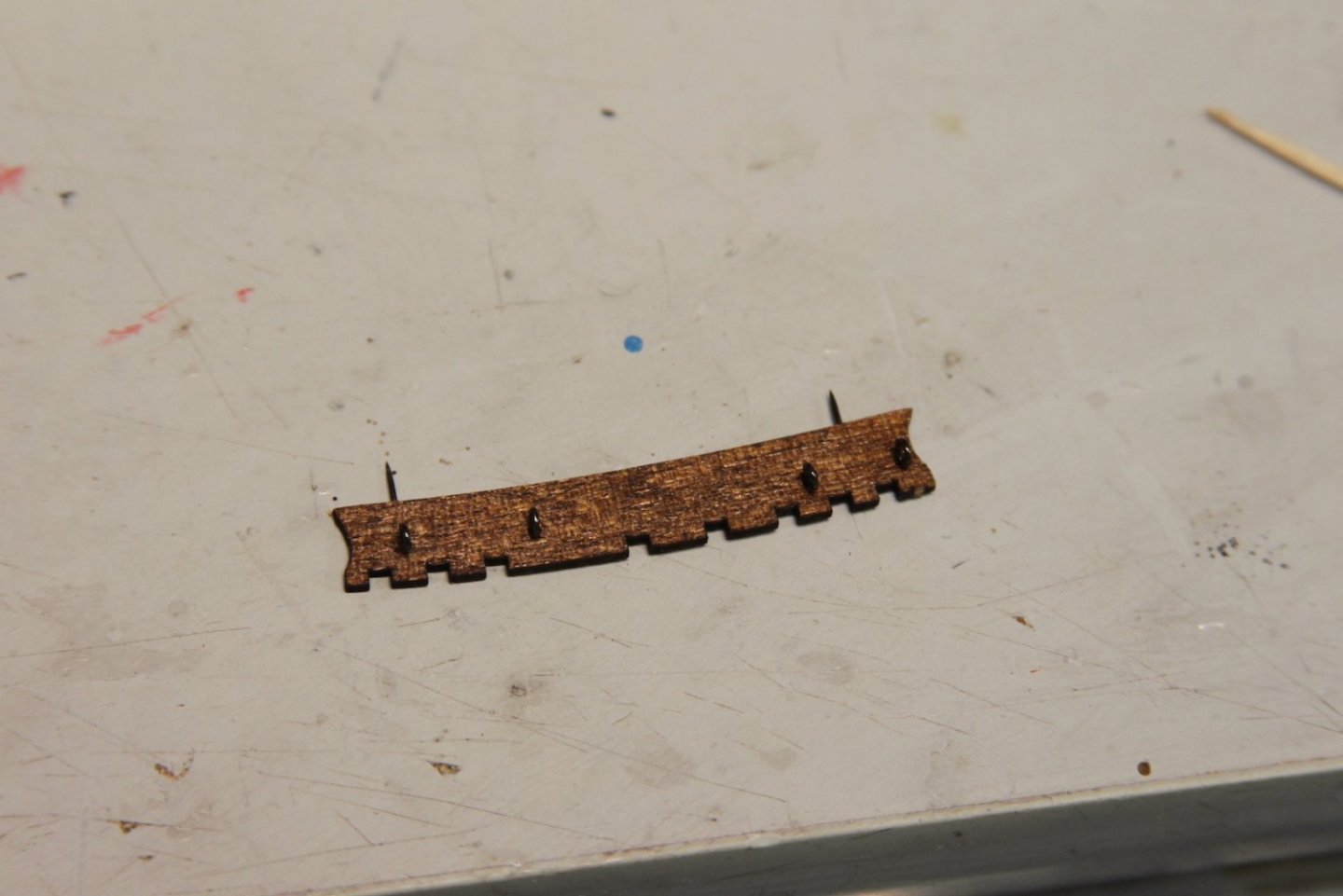

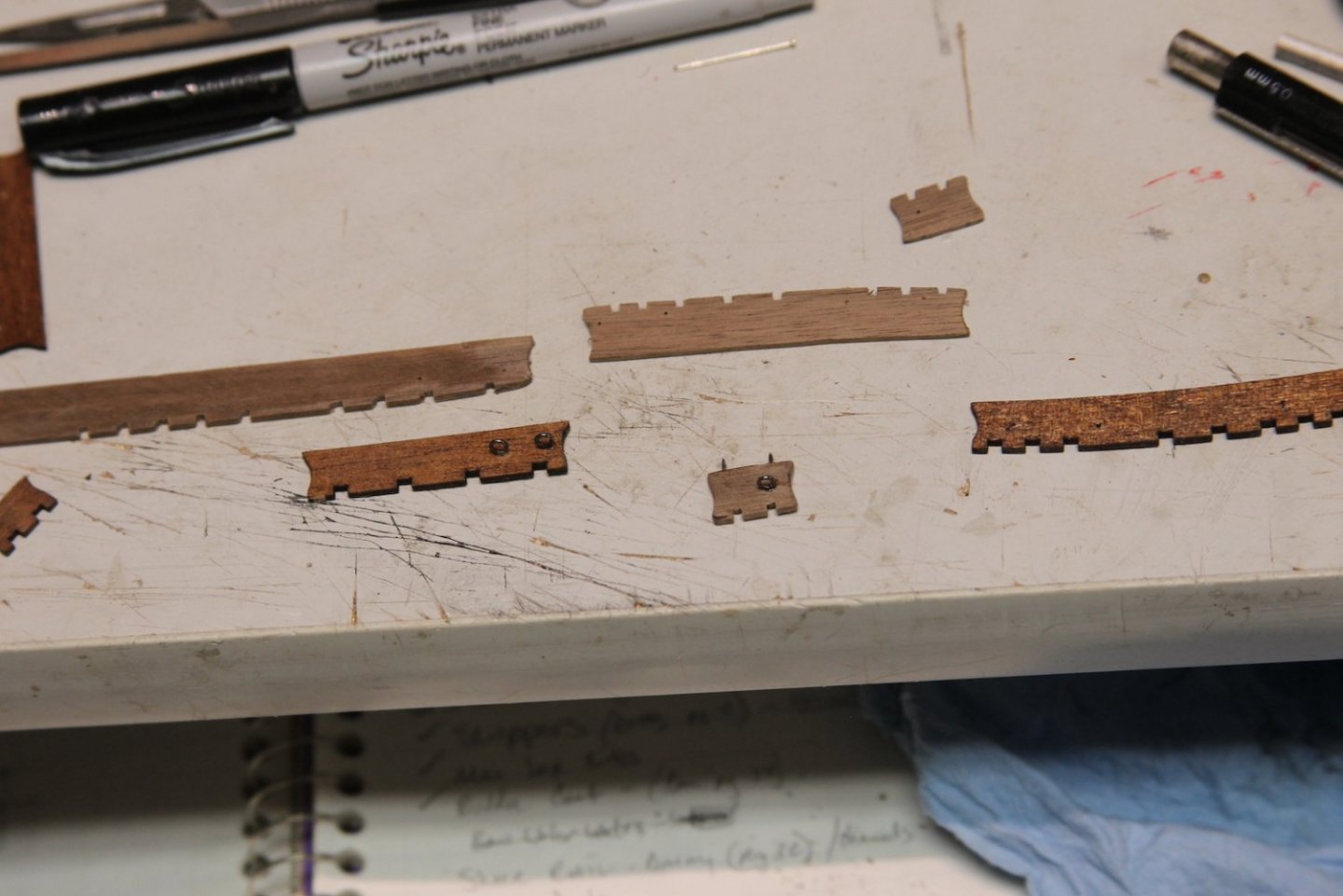

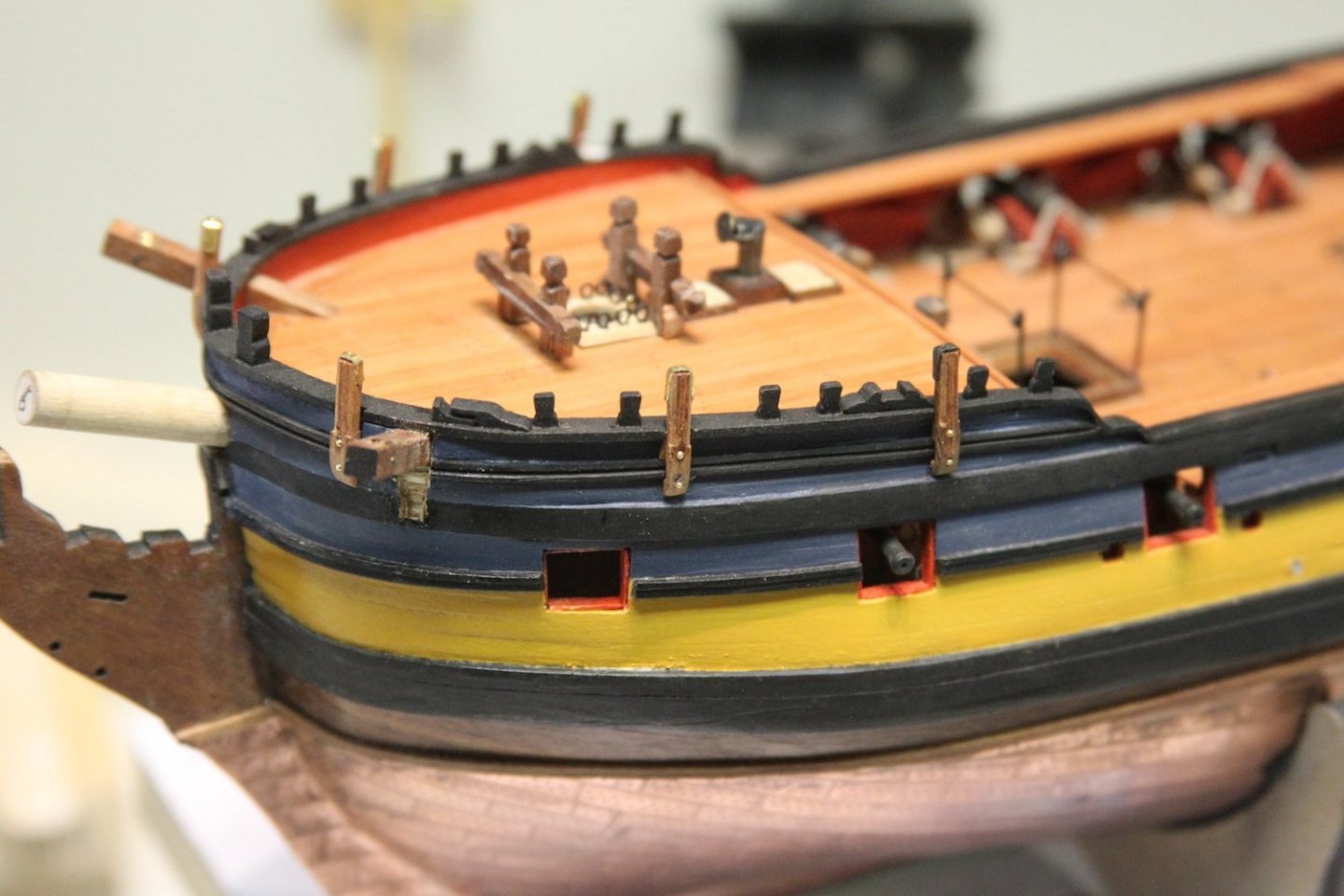

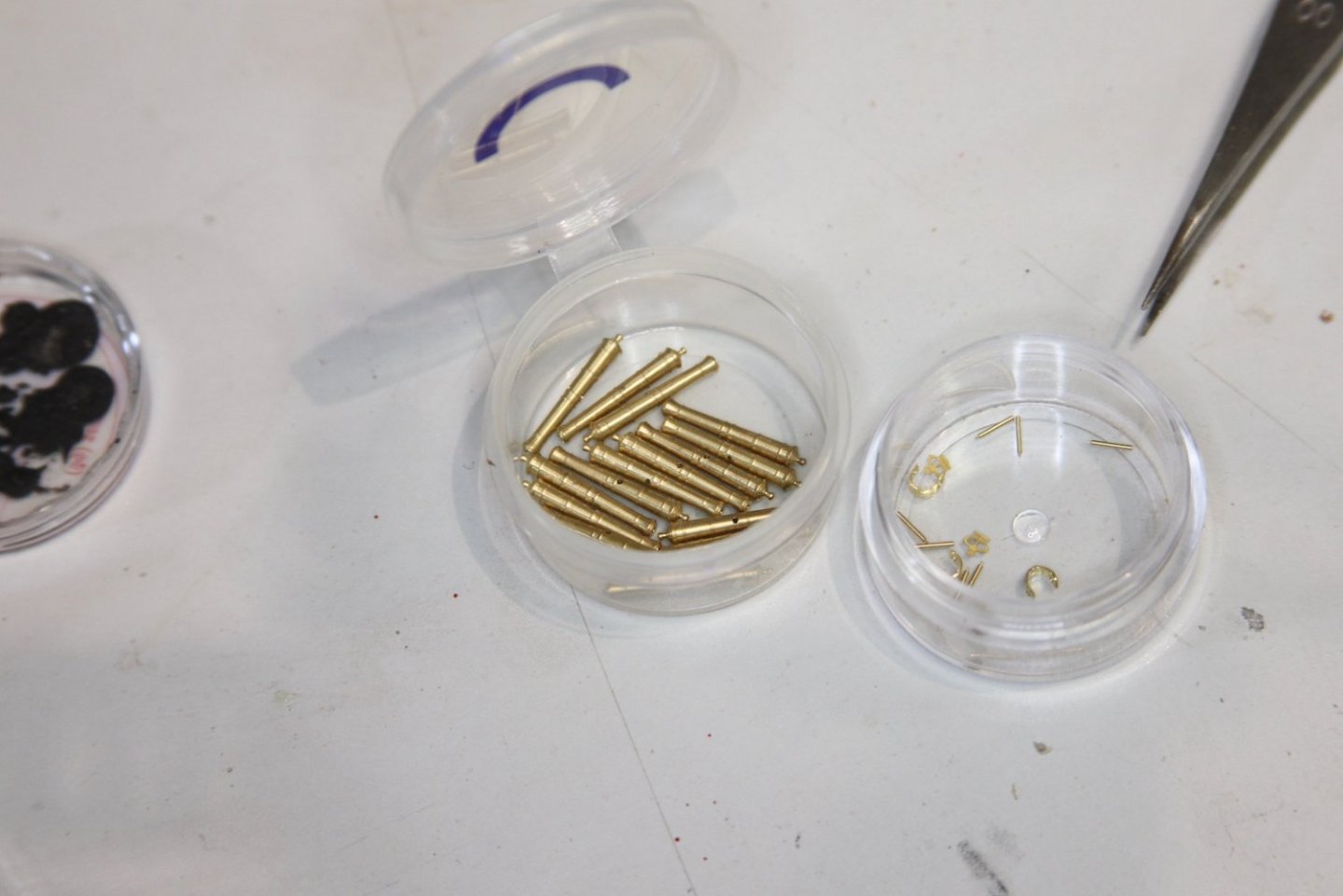

I fully intended to use Chris' precut channels from the kit - they look nice and obviously are shaped and sized properly. I even stained them so that would blend a little better without being painted and added the pins and rings.

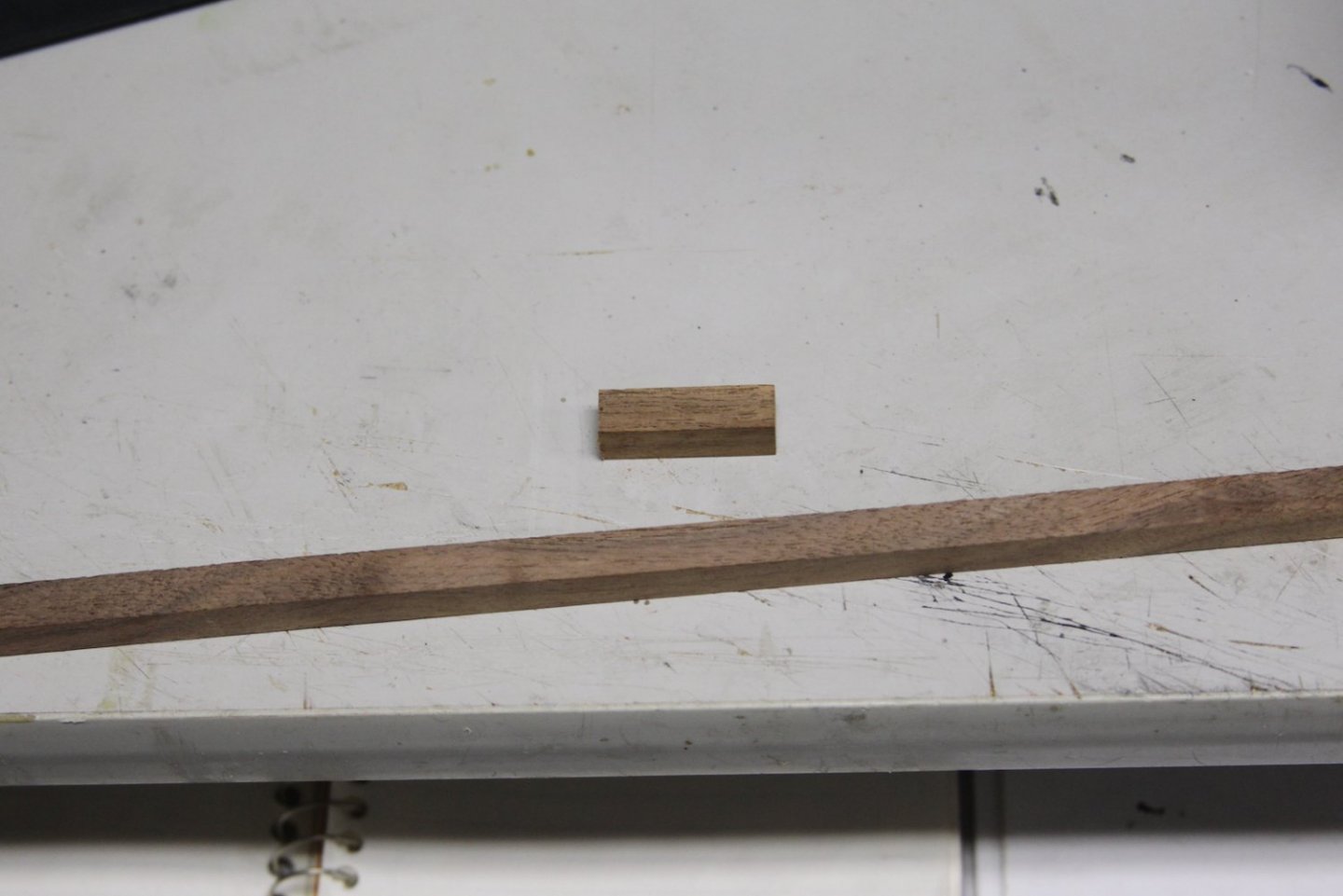

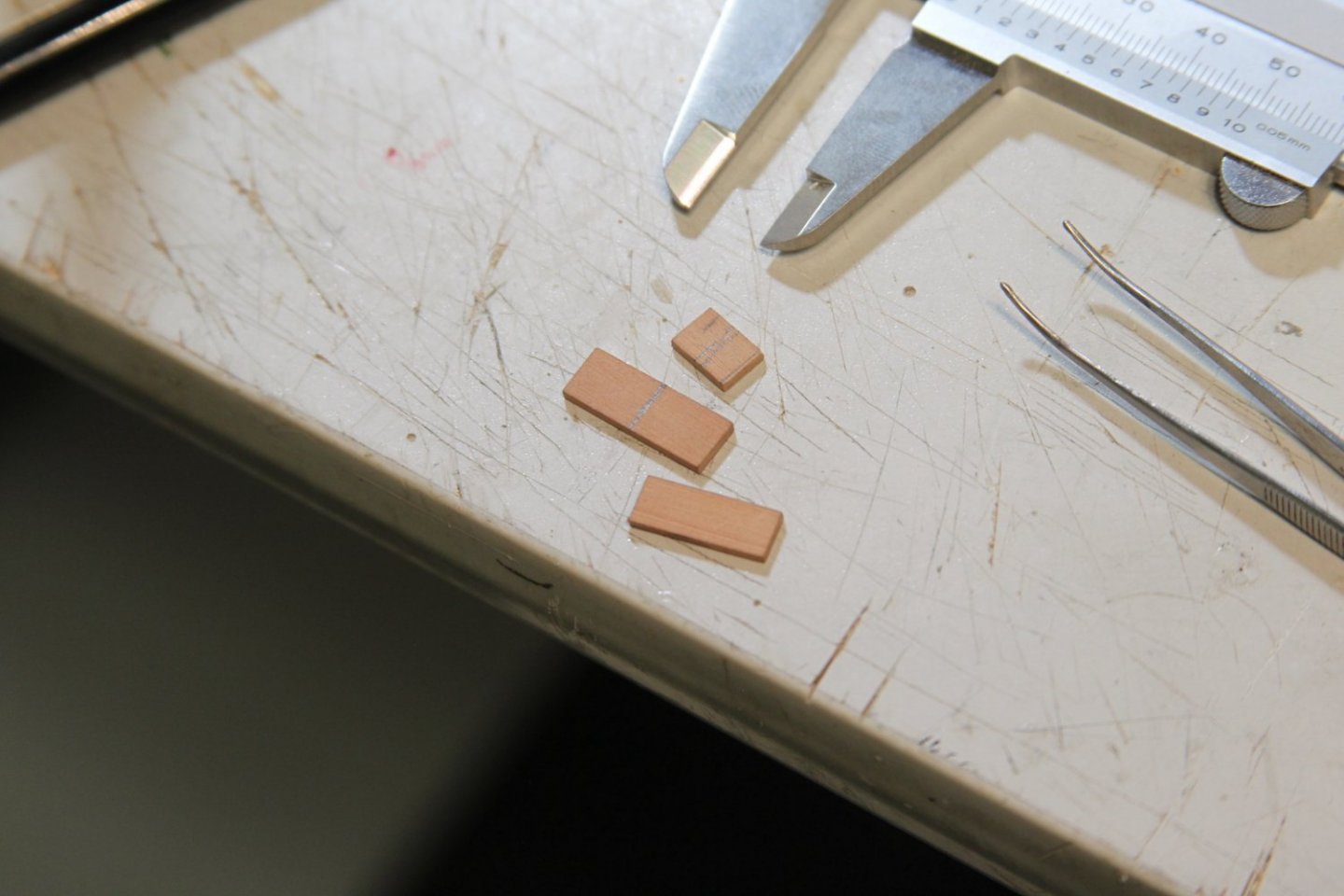

Then... I over sanded one trying to get it to fit snuggly against my larger-than-the-kit main wales. Totally screwed up the shape and made it too thin. So, I had to make all the channels from scratch so they'd match. Silver lining is that I got to make them out of walnut, which better matches my other pieces and overall scheme.

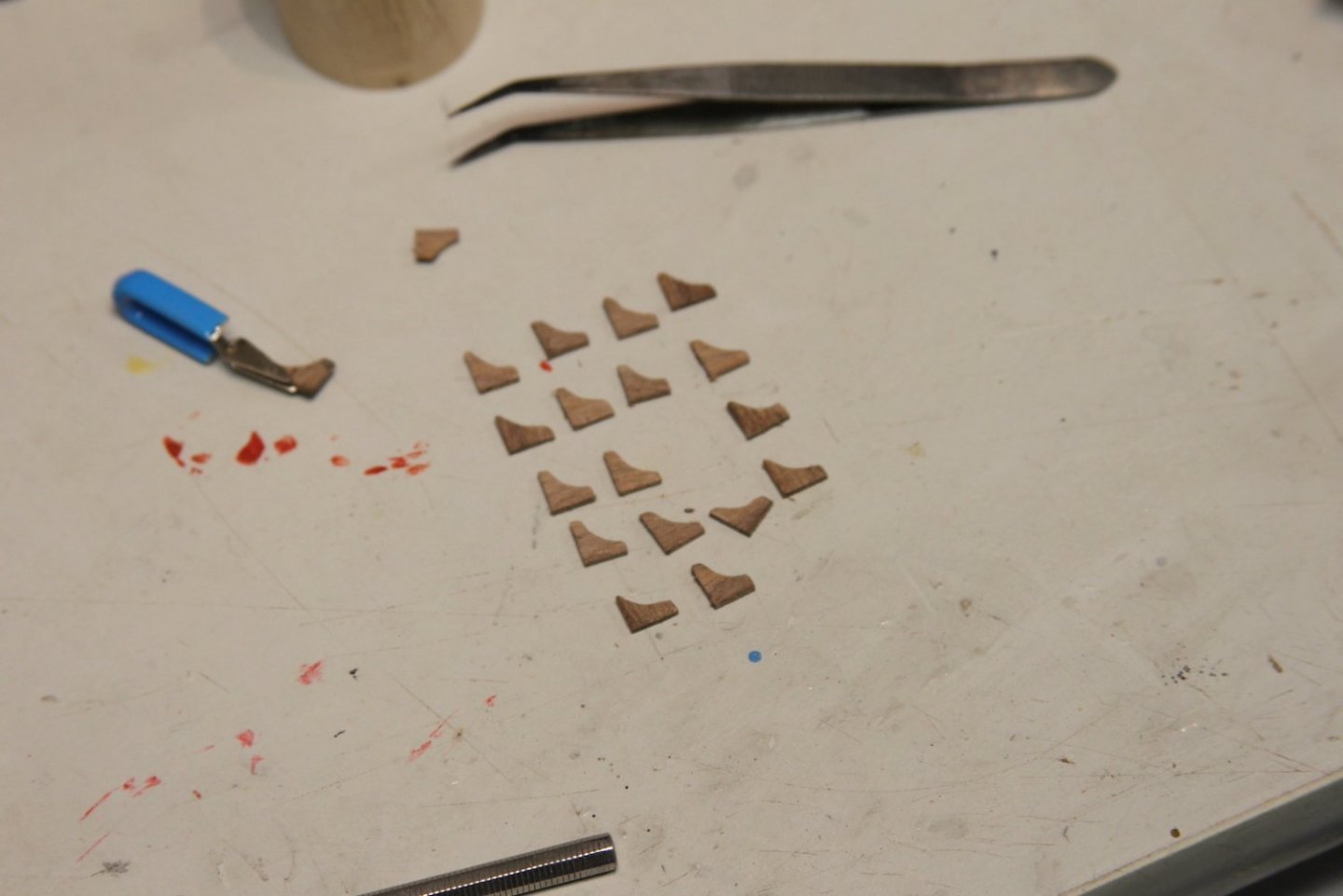

Another important addition are the knees to mount the channels - also out of walnut. Rather than mount the channels first and then the drift rails like a normal person - I did the drift rails first, so I went through and notched them all out to fit the knees.

I'll throw on a coat of tung oil to get the coloring to match the rails, and other fittings, then on to the decorations/frieze along the hull. I've had to wait on those because I've added a bunch of things that would be in the way of them. Also - my sheer strake is patterned after the FFM and quite a bit thicker than the kit version - which limits the area for the frieze. Much like the transom, I'll have to add the frieze in bits and pieces.

- Captain Poison, ccoyle, BobG and 6 others

-

9

9

-

-

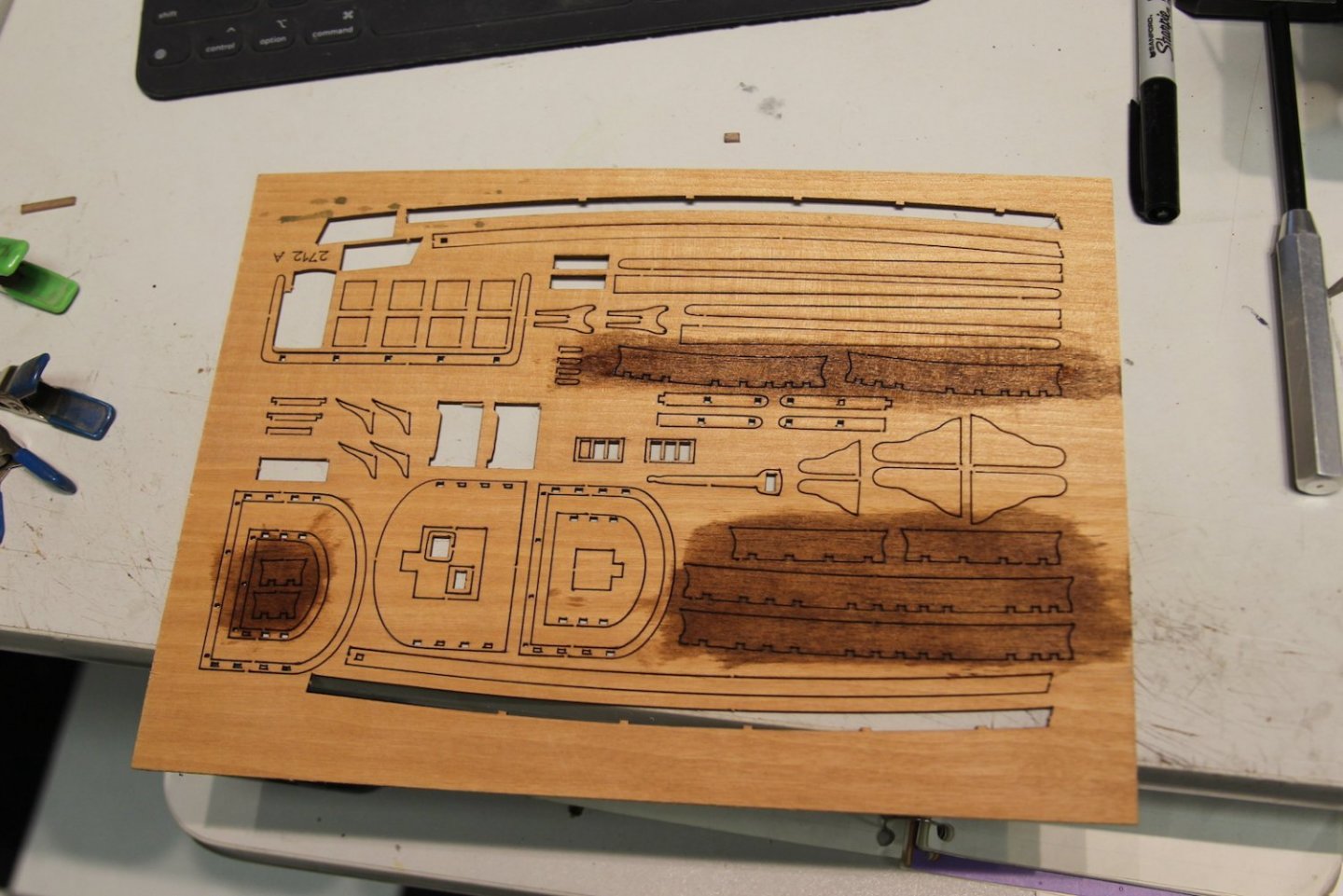

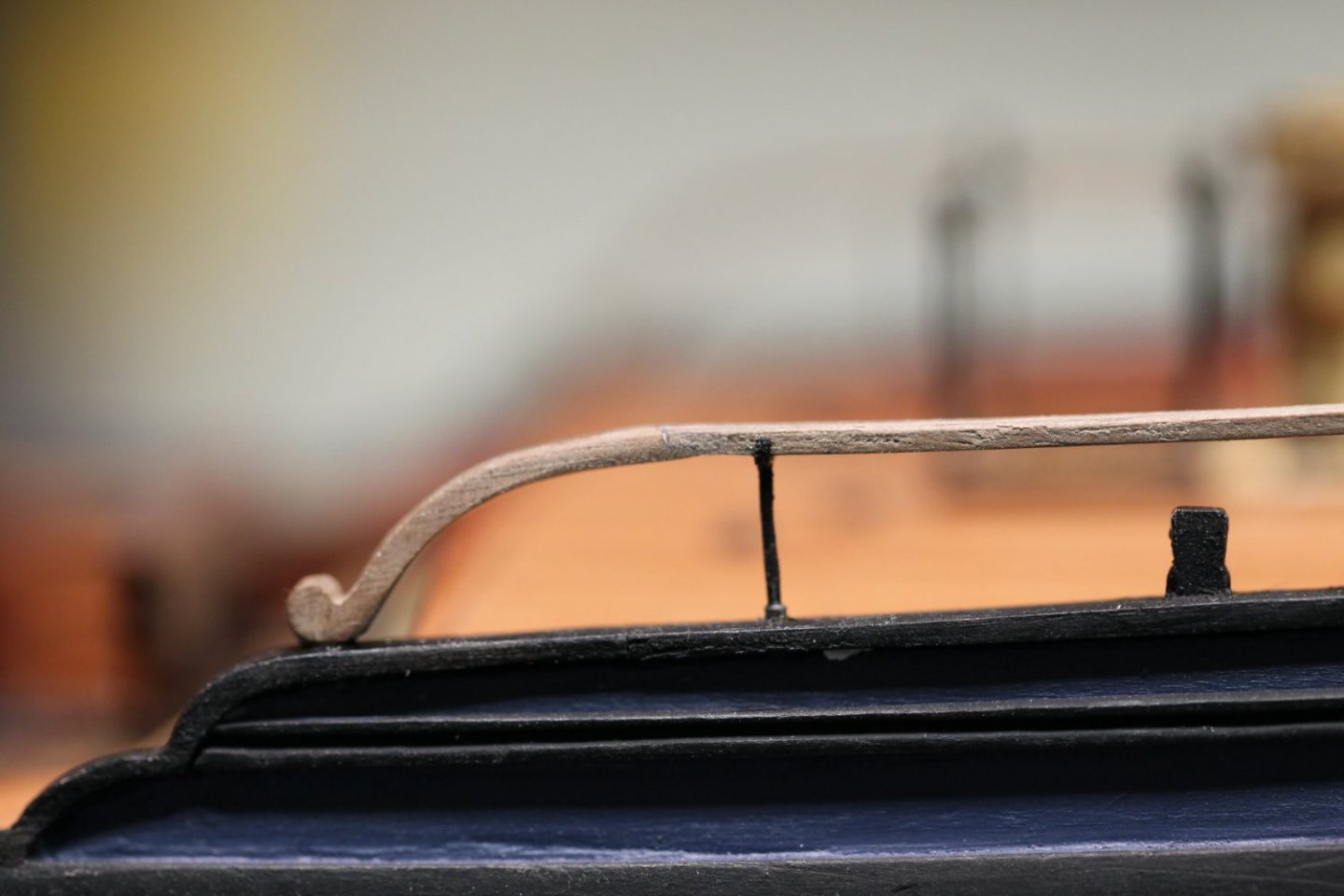

Like most of the other things I've put together, the quarter rail is patterned after Dan's version of the FFM. I used Walnut to match the darker shade of the crosstrees etc. I made a conscious early choice to only paint some of the fittings (rather than cover everything in red & black) so that the details of the furniture and other elements would come through. Black masks so much of that. I was hesitant about that choice early on, because of course very little painting means very little opportunity to cover flaws. But, it seems to be panning out pretty well thus far.

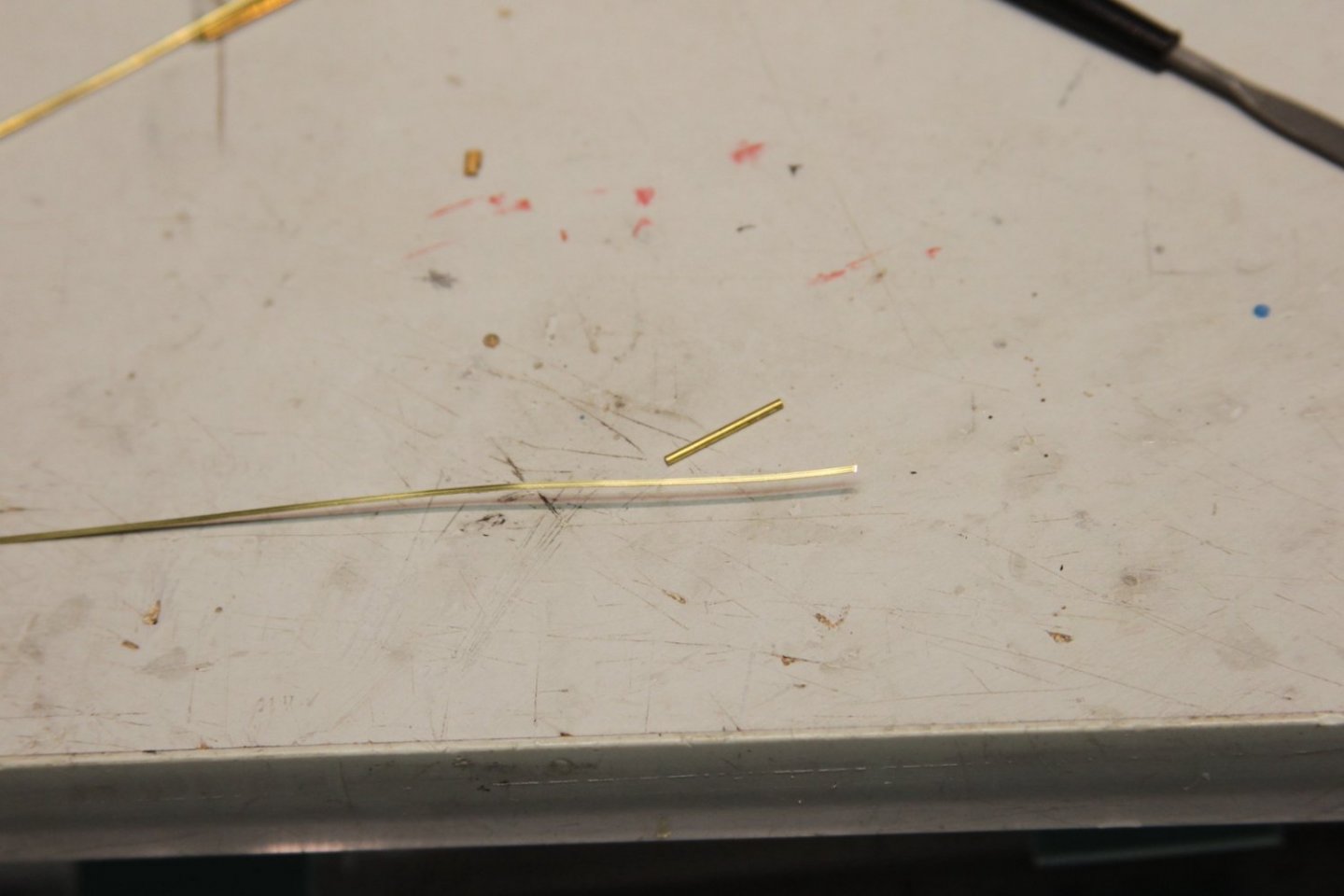

The stanchions for the quarter rail are made from a 1mm brass rod turned and shaved down to create a thin post with a thicker base. The cradle for the top is a 1mm brass strip cut & soldered on.

The 'curvy' end of the railing is drawn out and cut from a 10mm x 10mm walnut chunk on scroll saw. Lots of shaping and sanding to get the curvature first, then the chunk is cut down the middle with the table saw. I did it this way so I had a better chance of getting the two railing ends to look identical.

A little more shaping to do after it's lined up so that the railing and the end match up, then the whole thing is mounted and given a coat of tung oil.

-

1 hour ago, mtaylor said:

Wow.... that is a great looking stern.

Are we allowed to say that these days…? 😮 -

12 minutes ago, flyer said:

Gravity sucks.

Hehe, thanks Peter. I've definitely snapped a mast top or stanchion off on occasion by being a little abrupt and snagging something, but this is my first gravity-associated disaster. The wheel was definitely a chore. I'm glad Bellerophon's arm was successfully mended - a little physical therapy and I'm sure he was good as new.

-

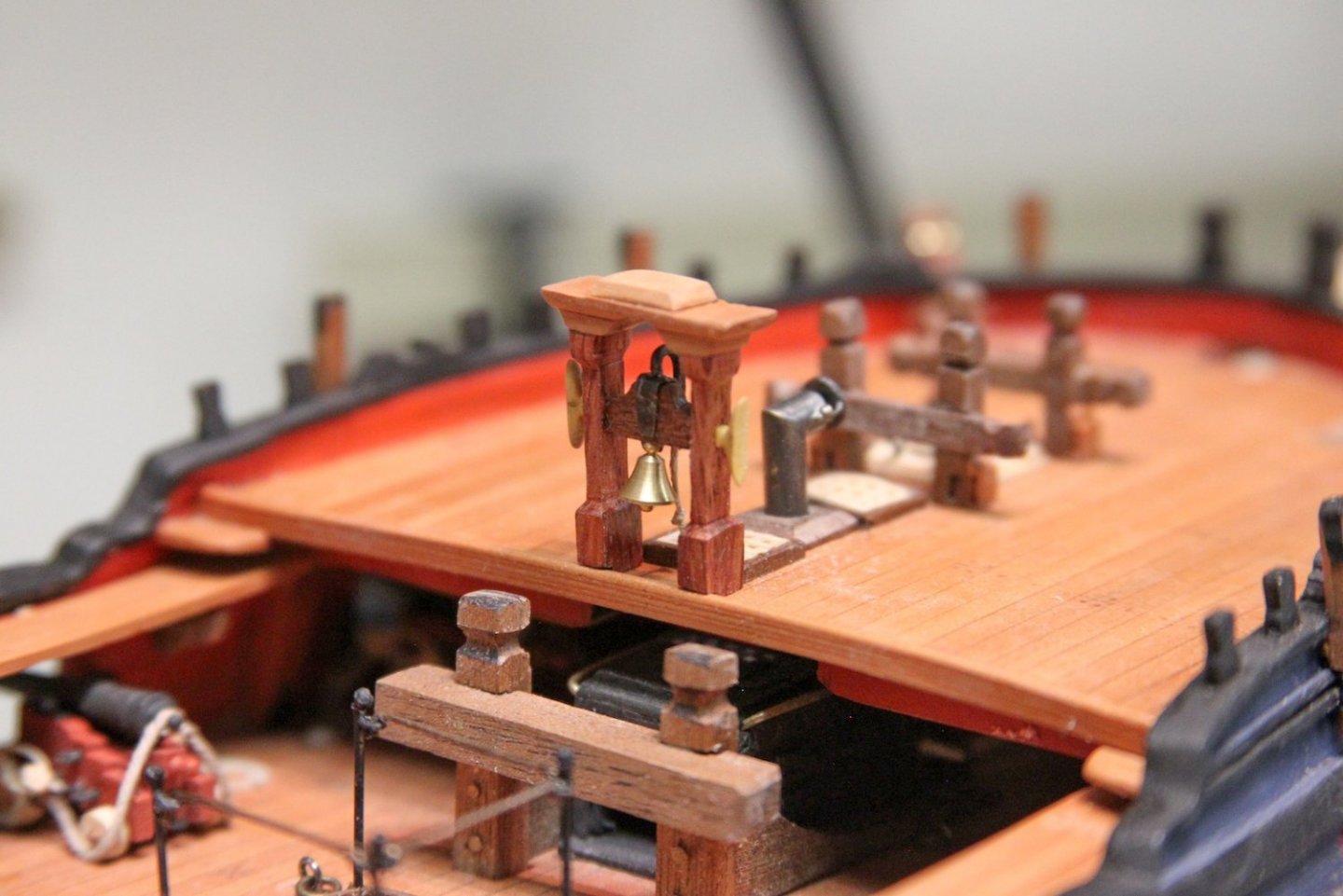

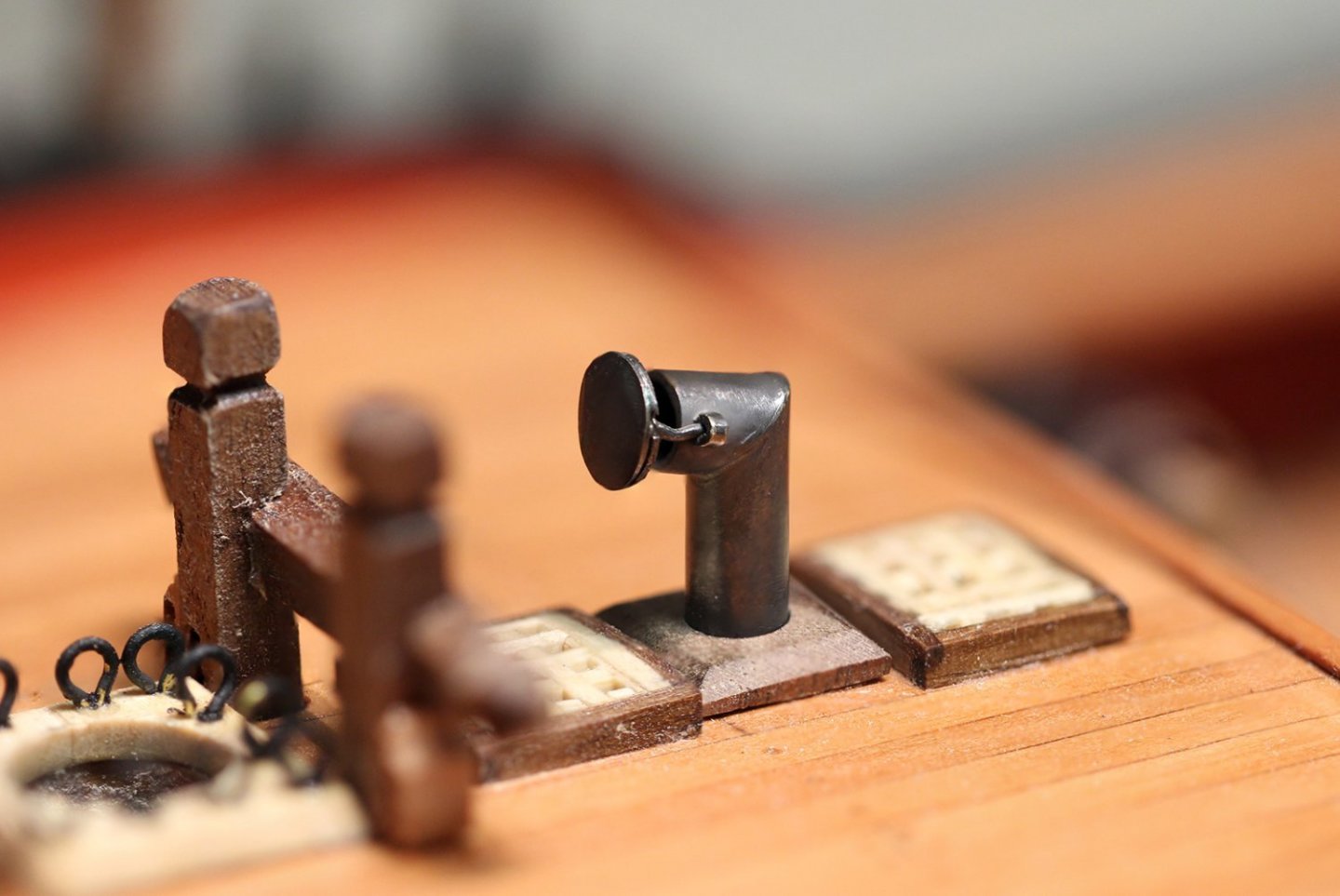

I've had something pretty specific in mind for the Belfry for quite a while, and of course I've been stalking Dan's Vulture (here's his belfry). A few years ago I purchased a couple of pens (I have a collection - don't ask. 😛 ) at a charity auction, and they came in this snazzy pen case. I've been looking for a reason to use the wood on these end pieces, but needed the Byrne saw to get a good cut on this really dense wood.

I cut two 5x5mm pieces to serve as the stanchions, and three pieces of Swiss Pear scrap for the roof and shaped/sanded it all. Really, one of the down sides to having the Byrnes saw is that I'm half tempted to go back and re-accomplish half the stuff I did by hand. heh

For the bell housing, I used walnut, and created a brass bracket to hold the handle. The handle is a shaved down piece of brass rod that fits into the bracket and bends over to hold the rope. Finally, I outfitted two boxwood cleats instead of metal - which I thought was an aesthetically pleasing and acceptable substitution.

The whole thing put together and mounted. To me, the Belfry was another opportunity to add a little bit of artistic flair.

-

Echoing everyone here - that's really good stuff BE. A real testament to your enviable patience.

For what it's worth - I completely agree regarding seeing the name. Accurate as it may be in some cases, it just feels as though something's missing when it's not there during this era.

- mtaylor, hollowneck and Blue Ensign

-

2

2

-

1

1

-

I've been rolling along with a few things - and had to make a couple of repairs. I didn't take any pictures in my frustration and eagerness to fix it - but I had something fall from a shelf onto the ship's wheel and it was destroyed. *Sigh* So I spent much of the weekend using Chuck's jig/templates to make a new one from scratch. What a chore.

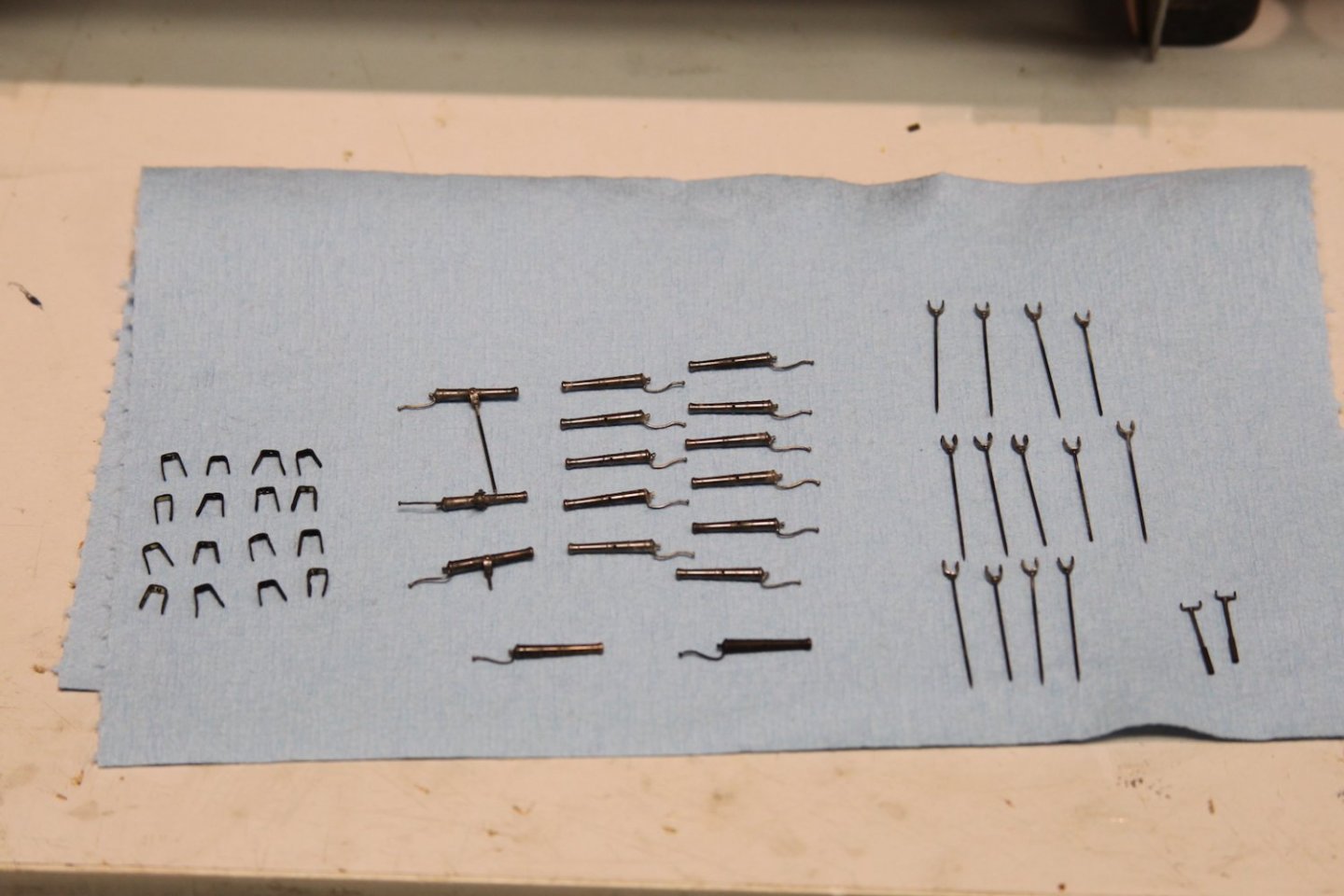

Along with that, I've finished up the swivel mounts and affixed them.

I've also been obsessing over the swivel guns themselves and I think I've landed where I've wanted. After blackening and polishing them, I fixed them all to their brackets.

So I hit them with a VERY light splash of this Vallejo "Nato Black" with an airbrush and low pressure, then polished them again. Here's a comparison of just the paint and then a really soft polishing with the dremel tool.

Finally, I added a smidge of my favorite Tamiya weathering rust and brushed off the excess with a soft toothbrush. Here's the end result. Overall, I'm pretty happy with them. Of course they'll be mounted on the swivels much later lest I snap a few off with a sleeve or other clumsiness.

- yvesvidal, Blue Ensign, gjdale and 10 others

-

13

13

-

Hey Chris - I spent 3 years in southern Italy and 3 years in Portugal, so I still keep my eye on football across the pond - mostly international, but I do check in on the Premier and Champions leagues, especially around tournament time so I'm loosely familiar with Everton.

-

A little bit of a chaotic weekend, but I did get some work done in between yelling at the television during the American Football playoffs. Full disclosure: I've been a MASSIVE 49ers fan my entire life. Here's me getting ready for the game in my bar:

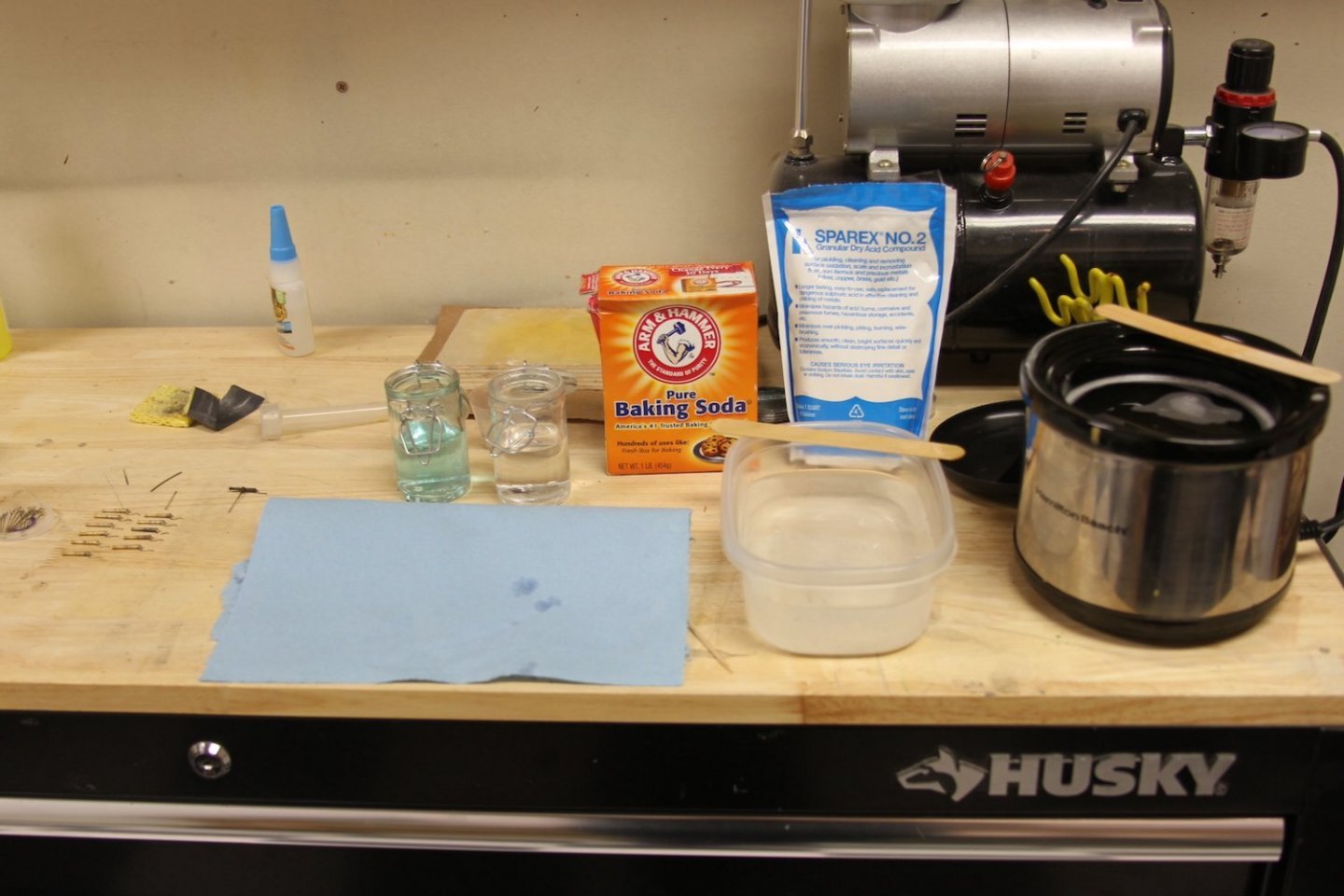

Anyway - on to the build. Like many folks, my success with blackening has been hit or miss, and I always ended up having to do touchups or over-weathering to make up for the inconsistencies. But with the success I had soldering the swivel guns, and how inevitably visible they are - I wanted to get the just right. So I went back to the basics on blackening by doing some MSW research and following Greg's (@dvm27) great tutorial post "Blackening Revisited" with all the steps. Ordered some Sparex, stole my wife's crockpot warmer, and set up my station.

Needless to say, my results were MUCH improved.

The improvement was so good in fact (and I've had a good learning curve with silver soldering) that I decided to complete Re-do my Stove vent. Here's a comparison with the old vs new:

-

17 hours ago, hollowneck said:

my new, screaming orange Aventador

Ron - That's amazing!

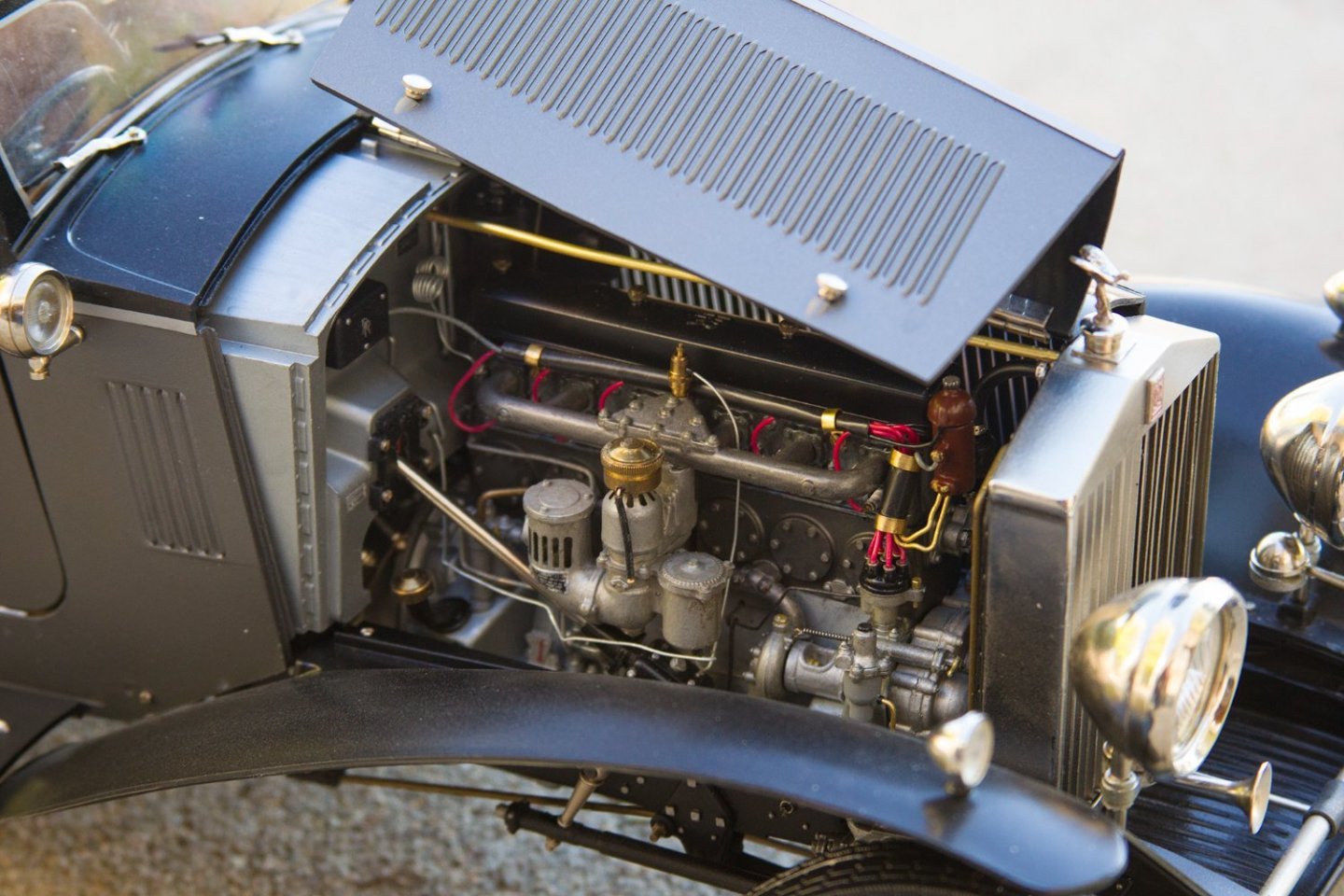

Where did you find it?? I'd been looking for one since they were released and have had NO luck what-so-ever.I do have this snazzy Rolls that I picked up at an Estate Sale a few years ago. It's the top one in Grant's post.

-

Nicely done BE - but more importantly, you just sent me down the rabbit-hole of VMS products - hadn't heard of them before being on this side of the pond.

Curses... I foresee some expenses coming my way soon.

- BobG, Blue Ensign, hollowneck and 1 other

-

4

4

-

Those straps are snazzy!

- Blue Ensign and mtaylor

-

2

2

-

I promise you you’re not alone in the “just don’t see some stuff” area. Honestly, at this point I’m kinda nervous about taking photos because so often I feel really good about something, then I see the photo and go “What the heck?”

Except I don’t say “Heck”Anyway, my point is - I think you’re doing a solid job: don’t lose confidence.

-

-

-

I have a Proxxon - it’s very user friendly and works like a champ.

- mtaylor, BikerMart, Keith Black and 3 others

-

6

6

-

Thanks for the comment and encouragement Dave!

4 hours ago, gjdale said:One idea you might try for the “knob” is a drop/blob of PVA

Thanks Grant, BE, & Andrew. I tried the drop of PVA initially and had a hard time getting it just the way I wanted. I have gotten it to work pretty well in the past - but this was just a bugger!

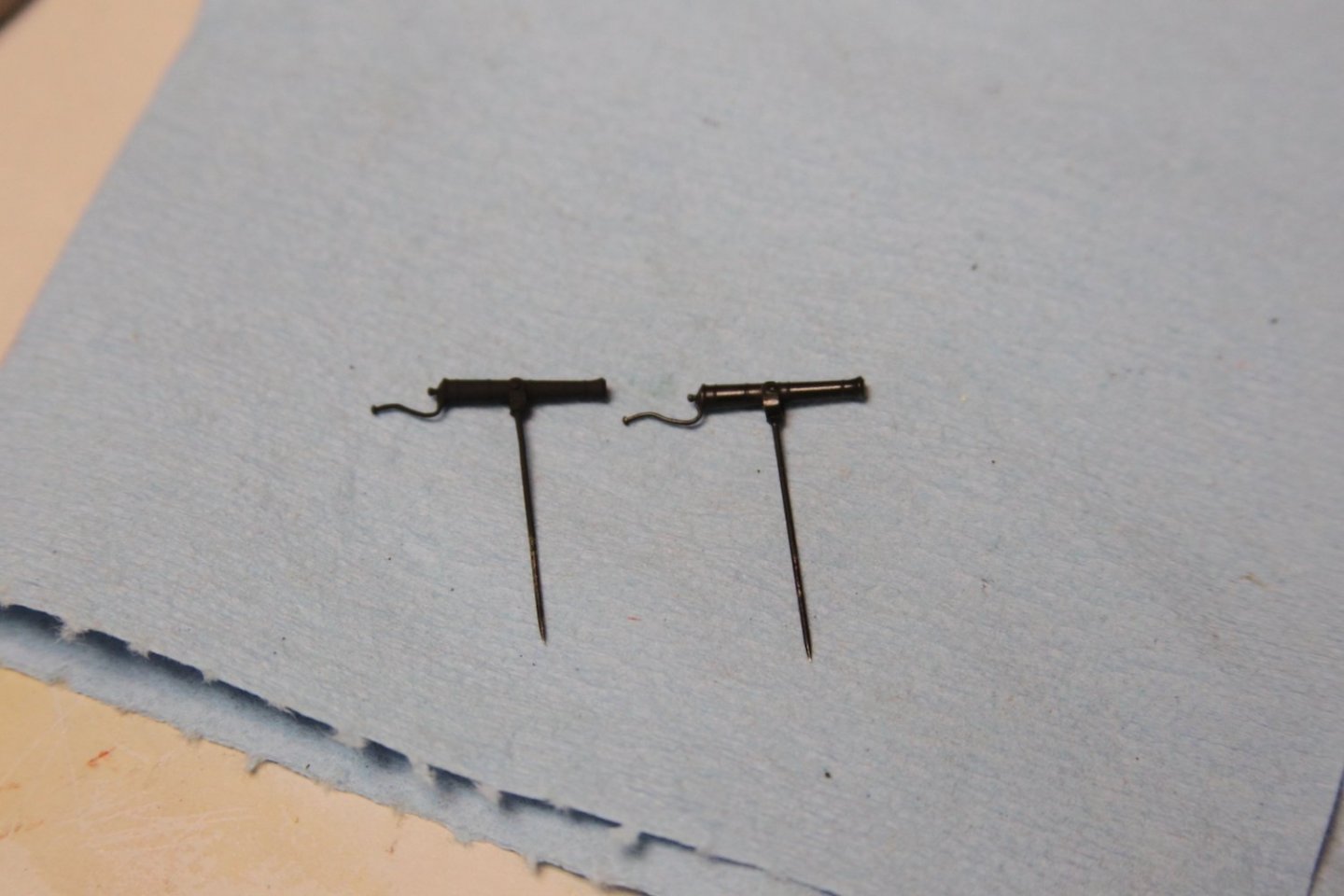

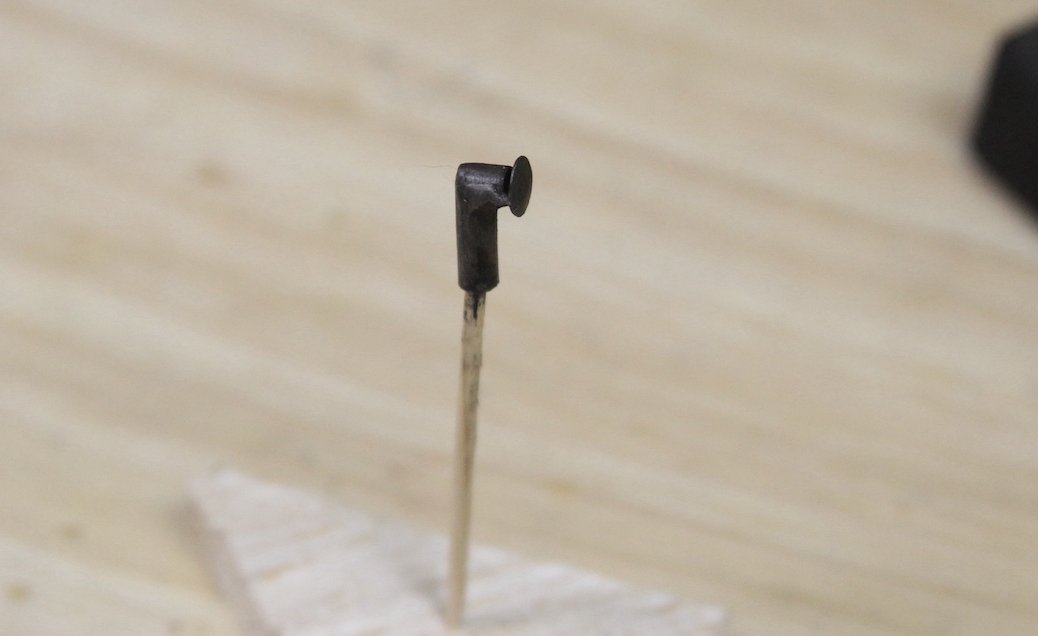

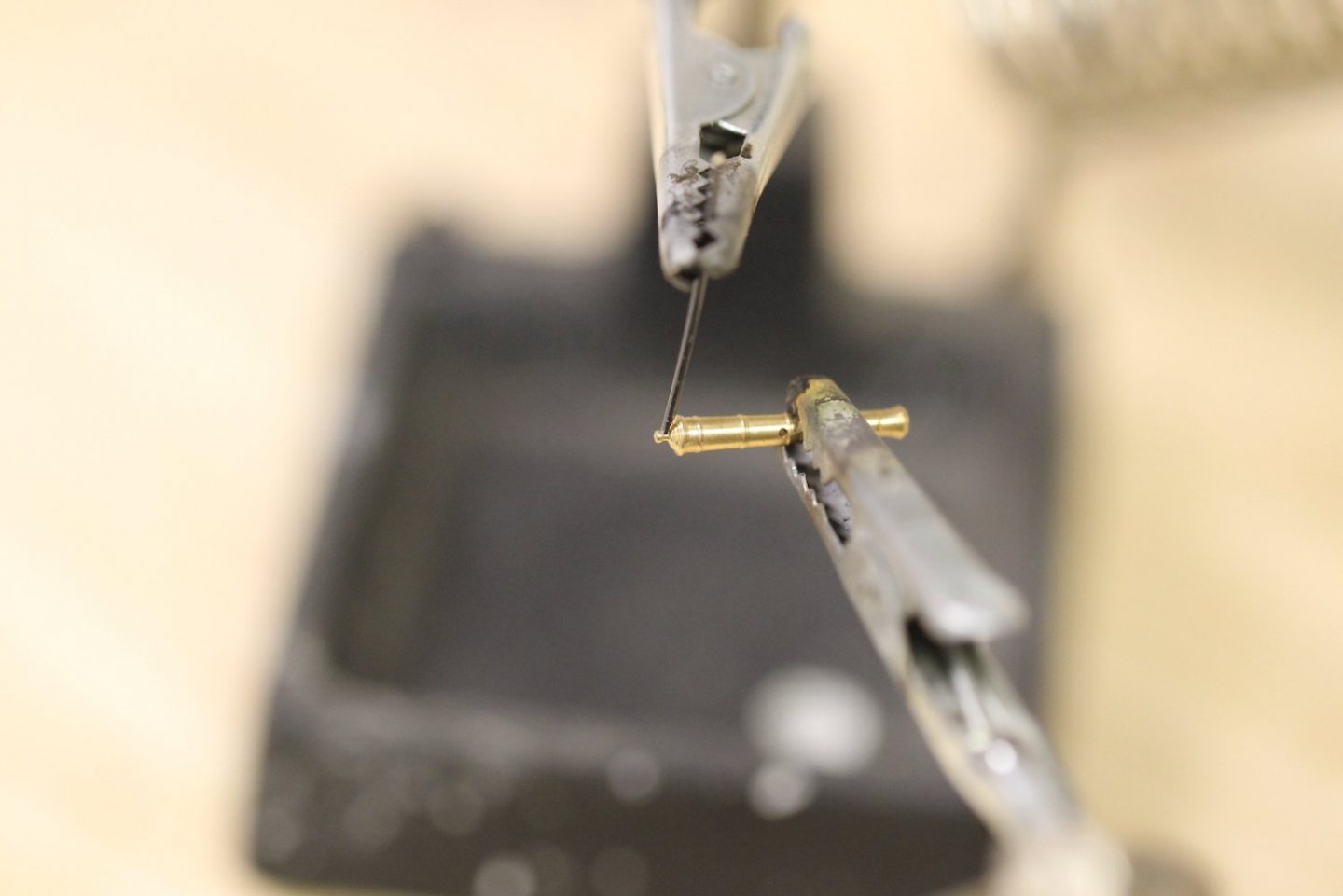

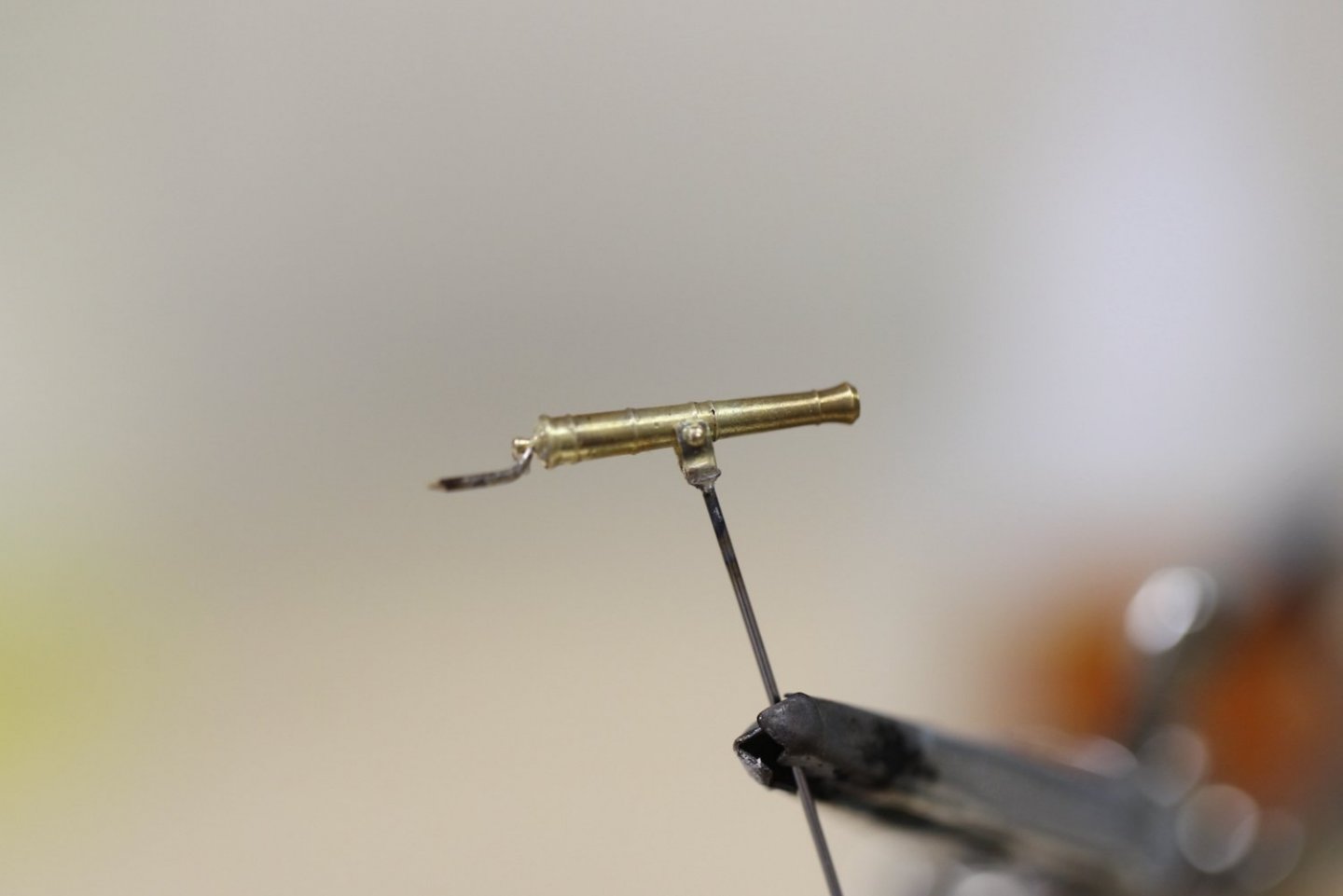

But then @Blue Ensign gave me a pretty great idea by mentioning the rudders - for my rudder brace bolts I used the ever handy .020" mico-mark tiny nails. So why not take another run at the guns using the longer version of those? Here is the result - I think I finally got close to what I wanted - as the handles themselves are more to scale with the guns.

It was a real trick soldering them however - as the melting point of the little brass nails was almost exactly that of my softest silver solder. So often the nail would melt a little along with the solder and had to be fiddled with. Then I shaped the handle after it was cooled. About 1/3 of the time, shaping the handle also meant snapping it off and starting over.

- mtaylor, Ryland Craze, ccoyle and 6 others

-

9

9

-

I started cutting and shaping the swivel gun mounts out of 3mm x 3mm mahogany that I have lying around. I don't really want to paint them, and I want them to stand out a little bit but compliment the rest of the subdued color scheme I have going. I shaped them based on FFM with the octagonal top and sized to fit my 'scale guy' once mounted. More on that later.

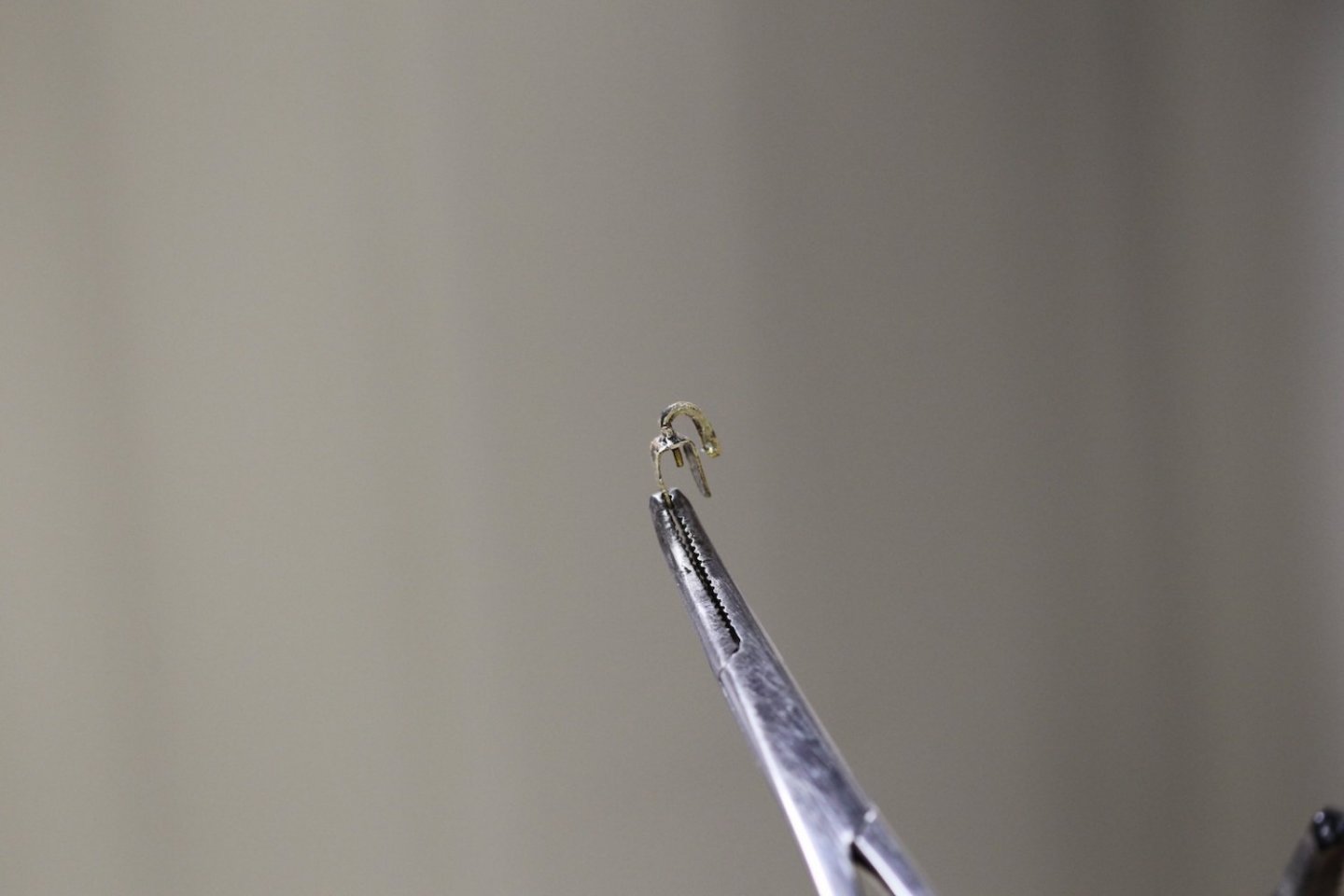

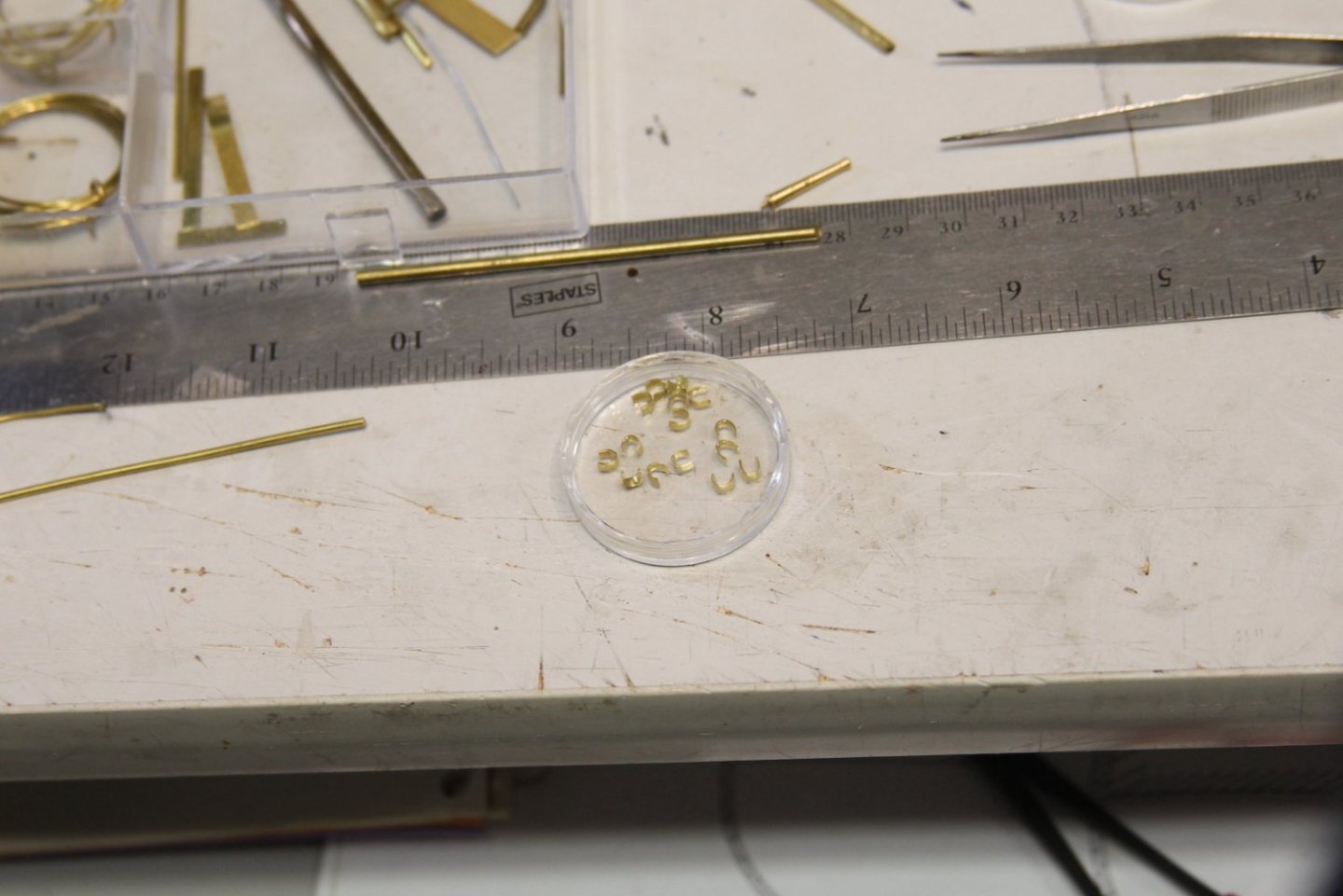

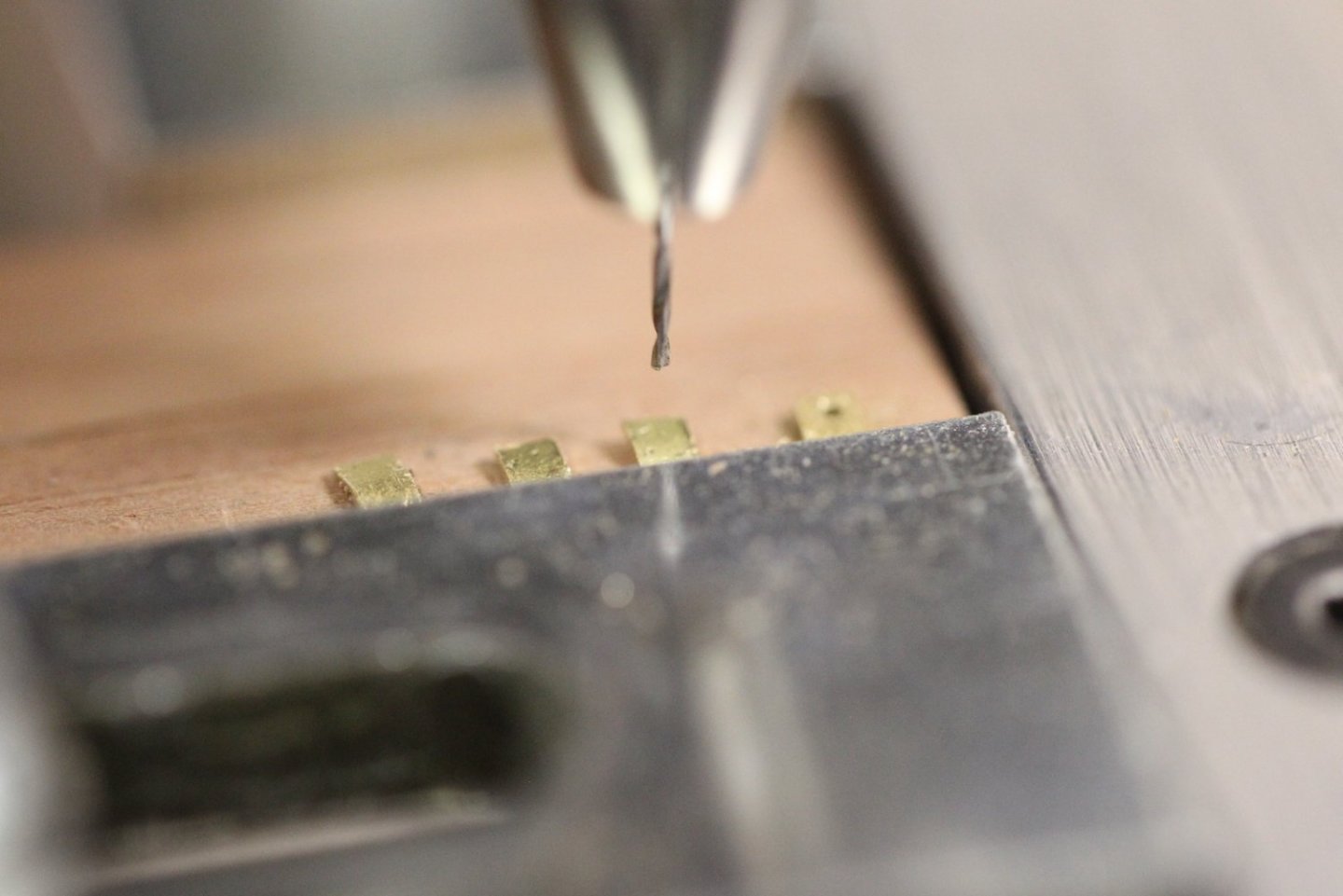

But of course this got me thinking about how to handle the swivel guns themselves. First, I cut some brass brackets, shaped them and drilled out bolt holes. They're then mounted to pinheads that have been sanded down flat to form a solder-able surface.

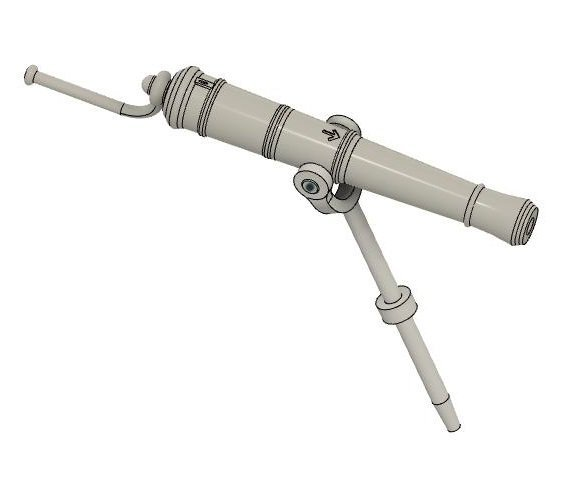

For the actual guns, I have these really sweet looking turned brass guns from Syren that I'm going to use instead of the molded die cast kit guns.

However - one of things that is accurate about the kit guns is the way in which the rear handle extends back. I briefly considered hacking off the breach button from the brass one and trying to extend a handle back - but quickly realized this was beyond my capabilities without the entire thing looking like crap. So I opted for the secondary style that you sometimes see in which the handle extends from the rear of the gun. I know it's not ideal - but it's what I think I can achieve. Here's a good representation from @AON's Bellerophon build:

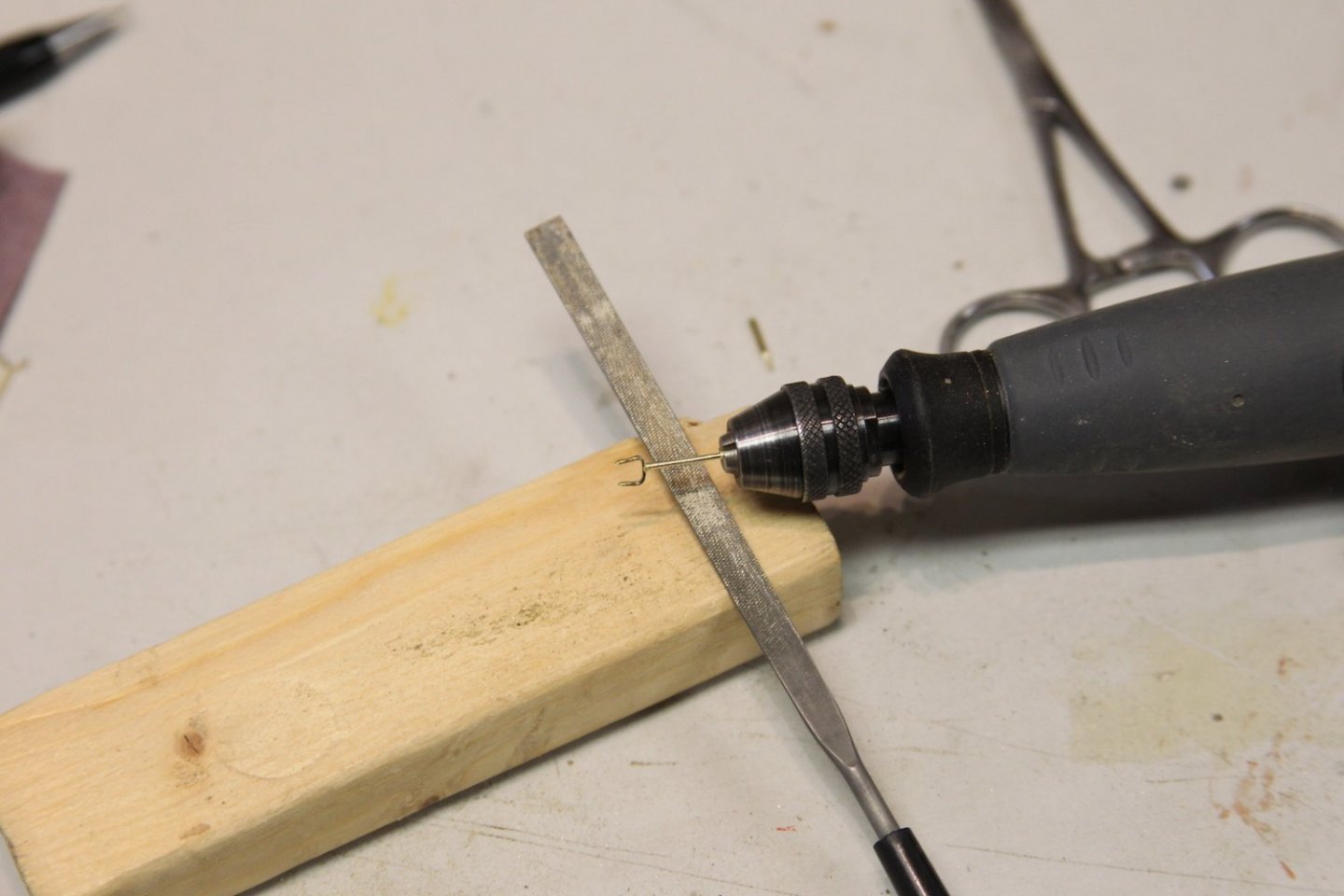

After a lot of attempts at trying to get the handle to "loop" around the button, it was just too small of a scale and everything I did once again looked like crap. My first working attempt was to try and mount/solder it to the bottom of the gun instead:

At first, I felt like this was acceptable. Mostly since at the end of the day, the combination of the very small scale and the bottom of the gun not being visible made this passable. Then, of course the more I looked at it the more annoyed with it I got. So I tried again - this time, taking the wire handle, flattening the end, and cutting a small groove in the end with the smallest cut pin file I could find. That groove allowed me to solder it to the rear of the gun and kind of "simulate" the loop over the button.

Here's a comparison of the two tries:

Following the idea of my hatch railing stanchion tops, I created the "knob" at the end of the handle by taking a small amount of this ebony wood filler and rolling it into a ball. Still have to work on getting the size acceptable, so I'm not sold on this technique.

I still need to do some work on the blackening and finishing touches, as this doesn't look great for a final product (and the knob is way too big) but here's basically what the guns will look like.

- Blue Ensign, Ryland Craze, VTHokiEE and 11 others

-

11

11

-

3

3

-

I love Vallejo paints - very easy to work with, especially when mixing is involved.

And you're right of course about paints represented in photos - with most of today's automatic cameras (and phones) the color temperature is automatically and independently adjusted with every shot - so even photos taken of the same subject in the same light can have slightly different color temperatures - which changes the look of the paint in the image. I'd say unless you're using a top-end SLR camera with manual ISO settings and looking at it on a VERY good (and calibrated) monitor - the eye is always the best judge.

USF Confederacy by Brucealanevans - FINISHED - Model Shipways - 1:64

in - Kit build logs for subjects built from 1751 - 1800

Posted

Nice work Bruce - looks great! Worthy of pride, to be sure.