-

Posts

962 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Moonbug

-

-

Thanks so much Pete - appreciate the encouragement.

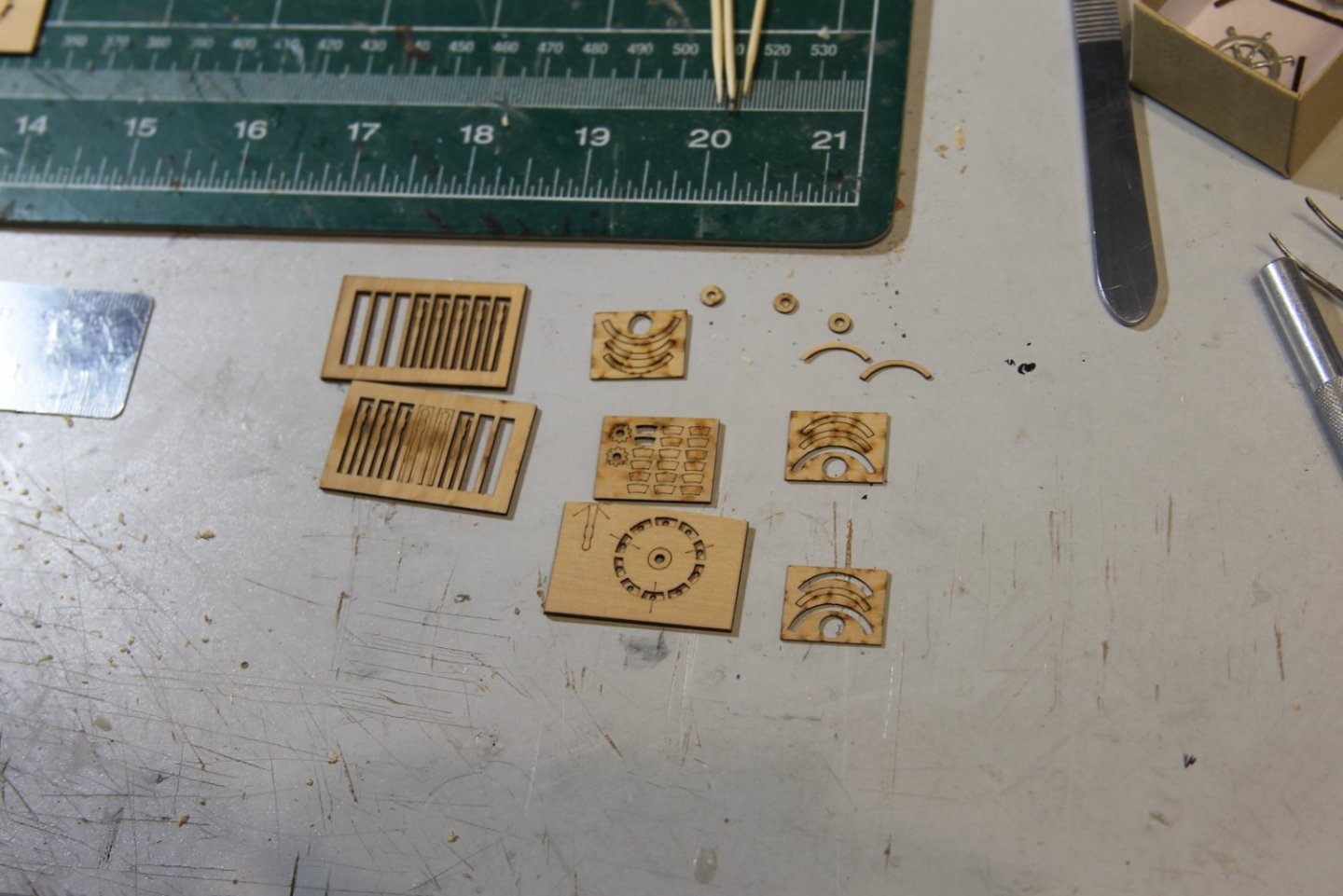

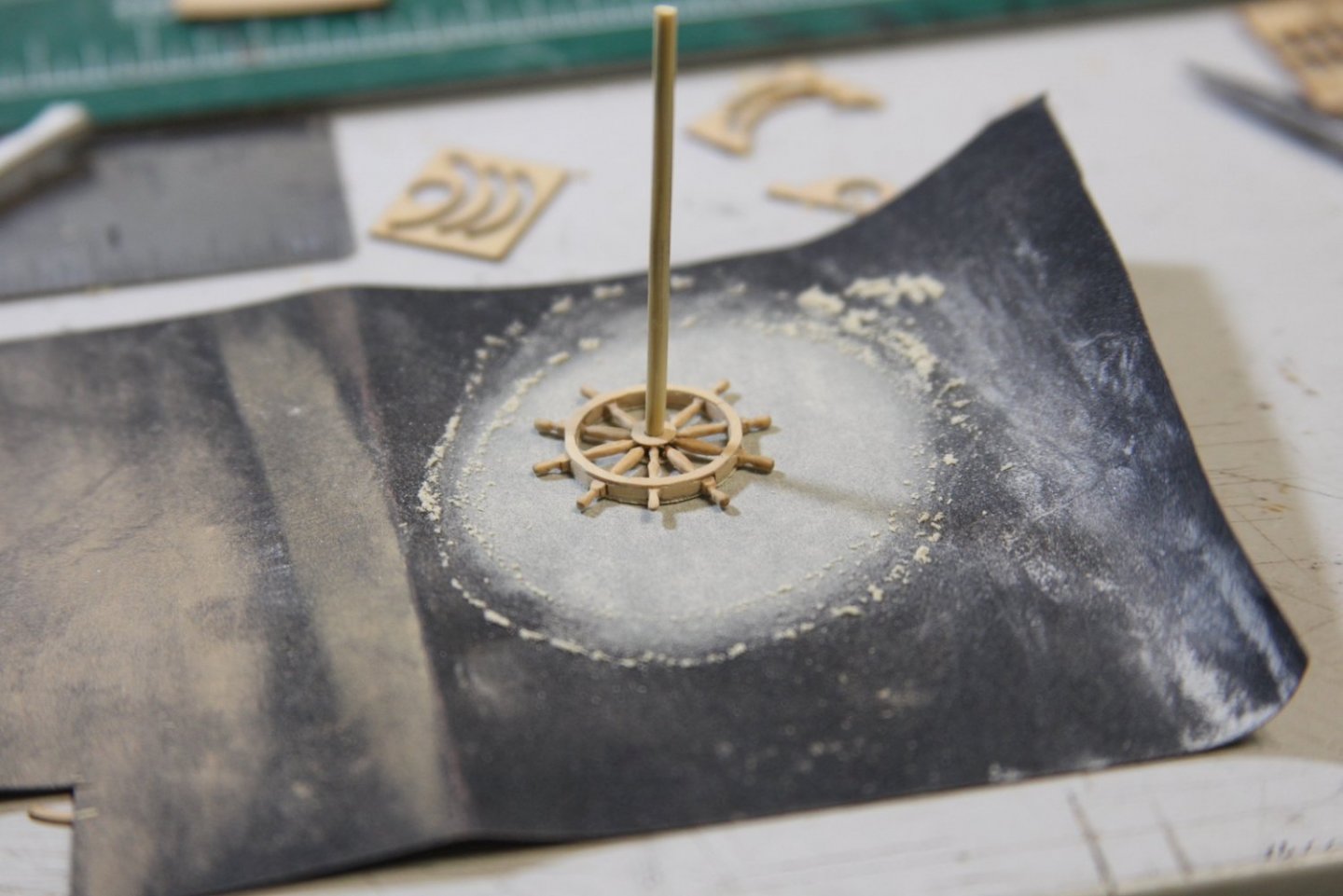

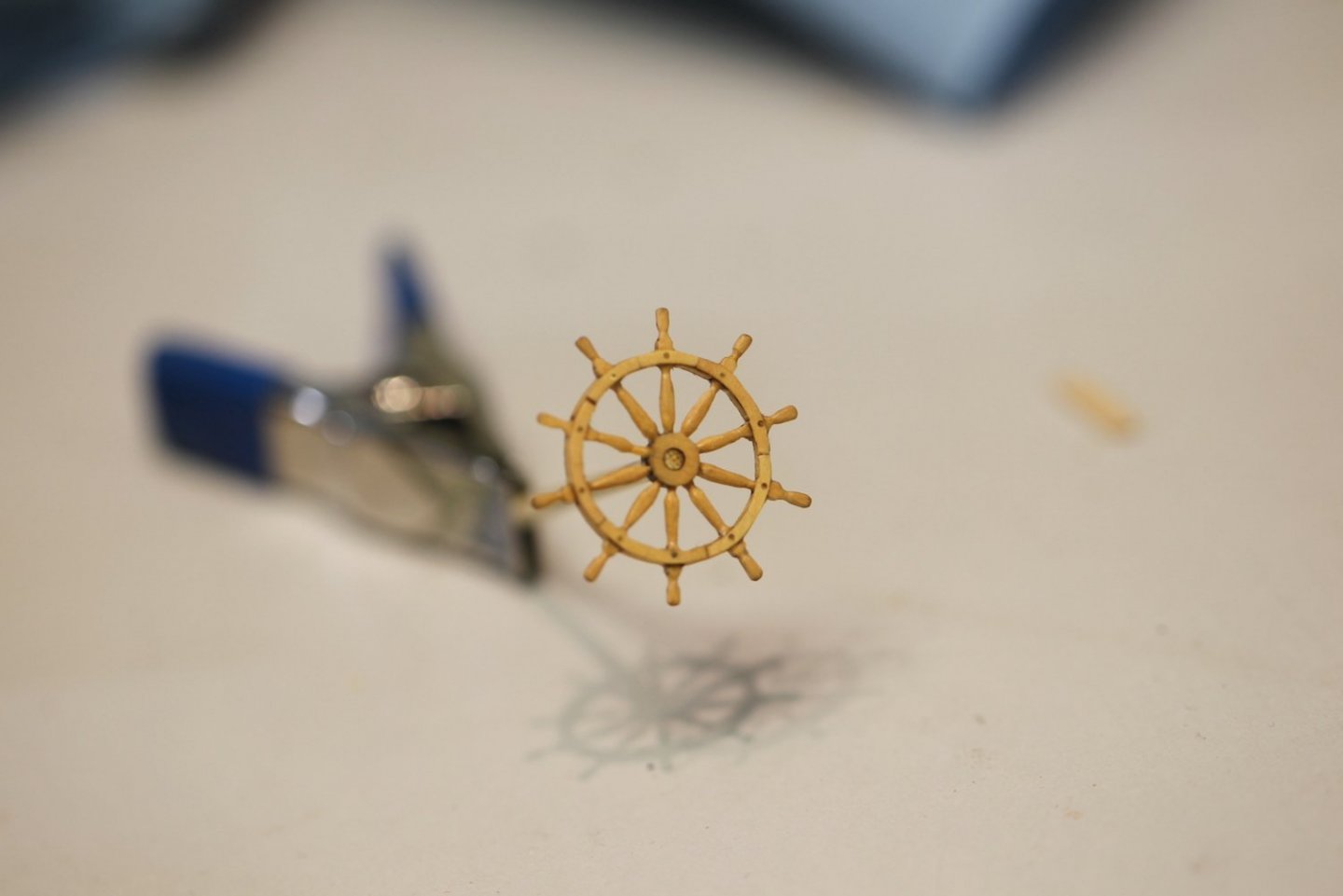

The ship's wheel is @Chuck's kit from Syren which I've worked with before on the Confederacy and is a real joy to put together.

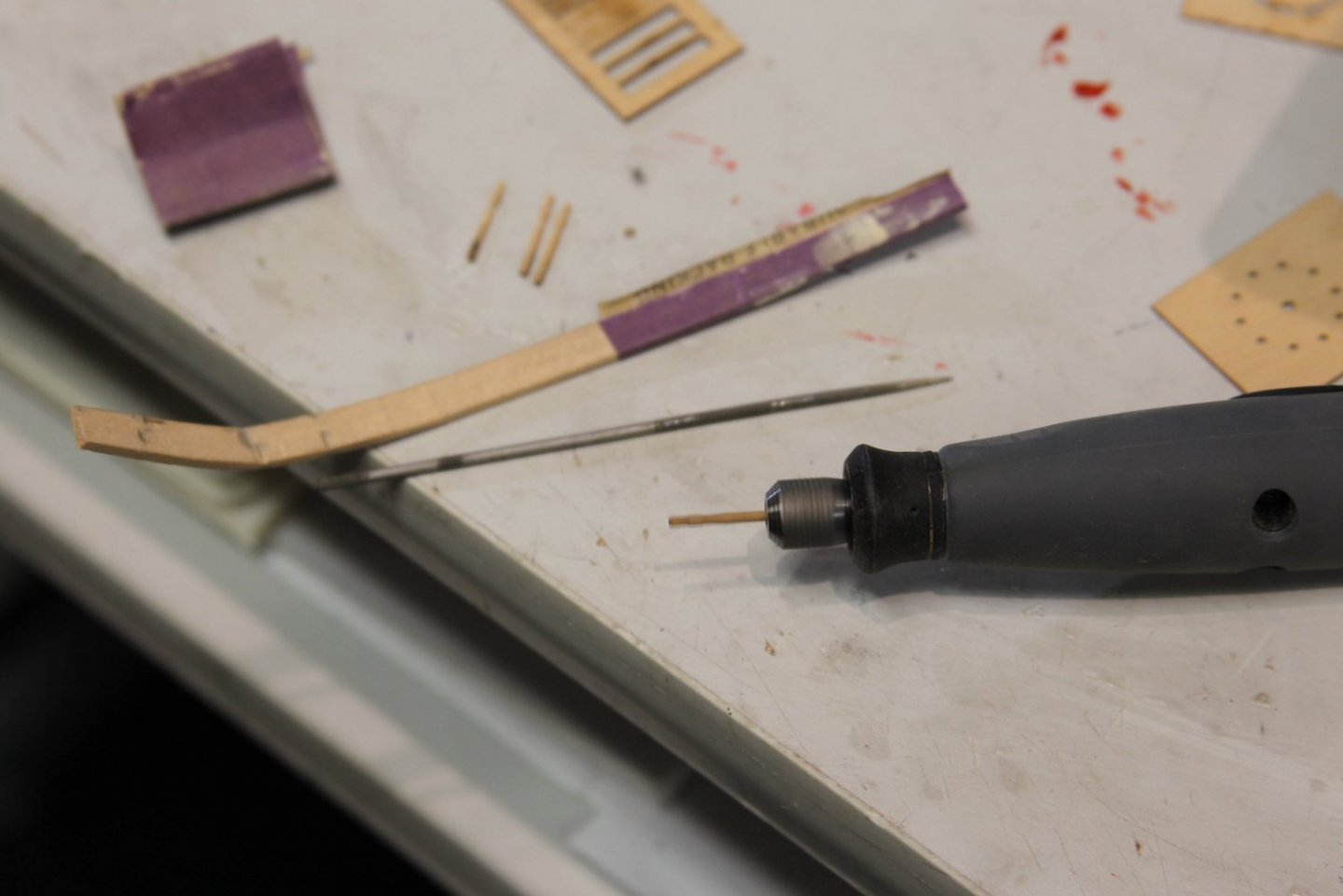

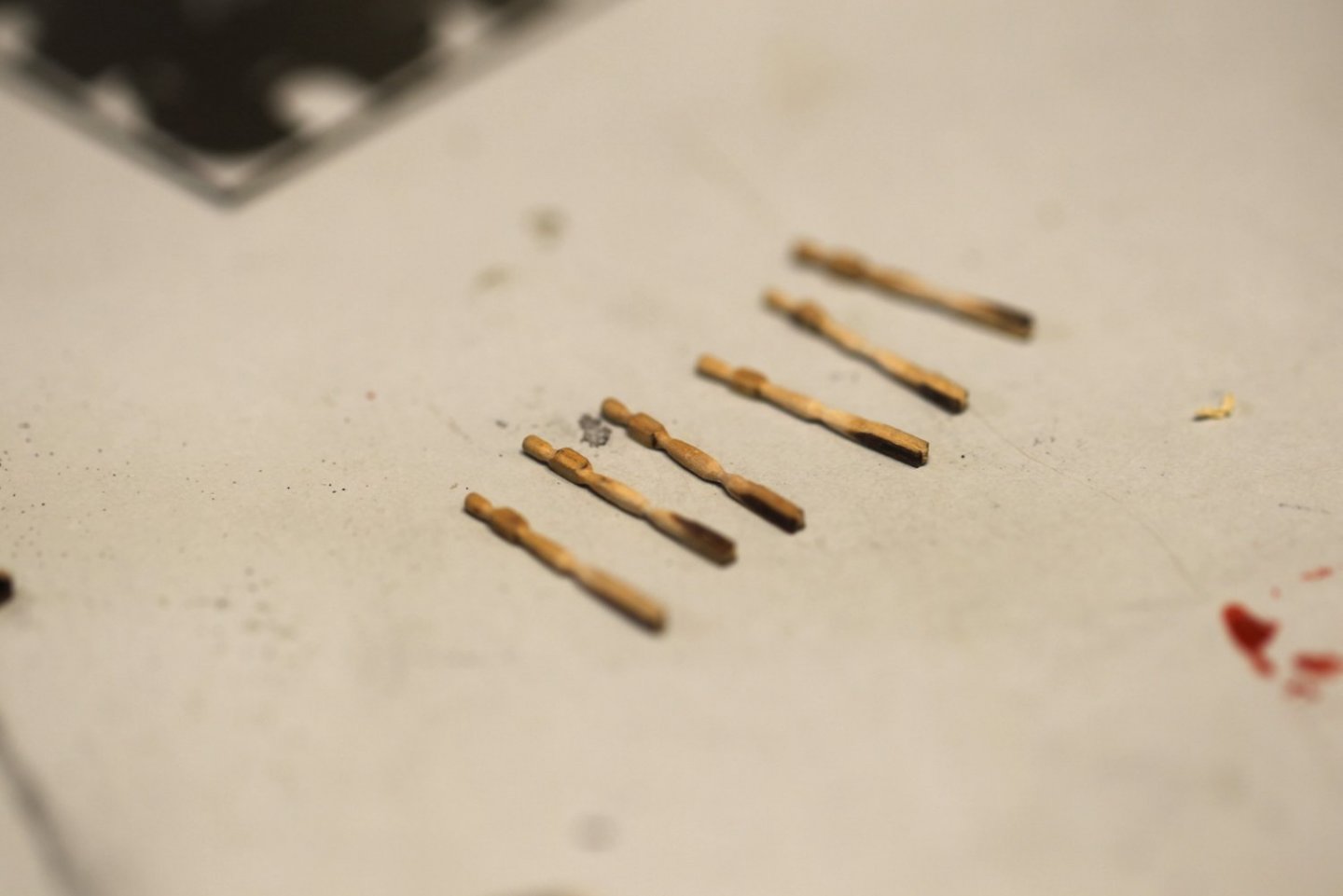

I tapered both ends of the spokes using a variety of needle files and sanding sticks and I cut off a toothpick to run through the center of the jig which held the hub and helped hold everything steady when I put it all together. The toothpick also helped quite a bit when sanding down the sides as thin as possible. I cut the outer circle pieces into several pieces to more mirror the look of the wheel from the FFM. Finally, I added some simulated treenails (as Chuck suggests in the directions) for an additional detailed look by using the drill/fill method with pva and sawdust.

-

Nicely done Mark - I'm with you on the macro photography. At this point I'm considering putting a little Vaseline on the lens like they did with the old 50's Lauren Bacall movies... 😆

- Keith Black, BobG, Edwardkenway and 4 others

-

2

2

-

5

5

-

-

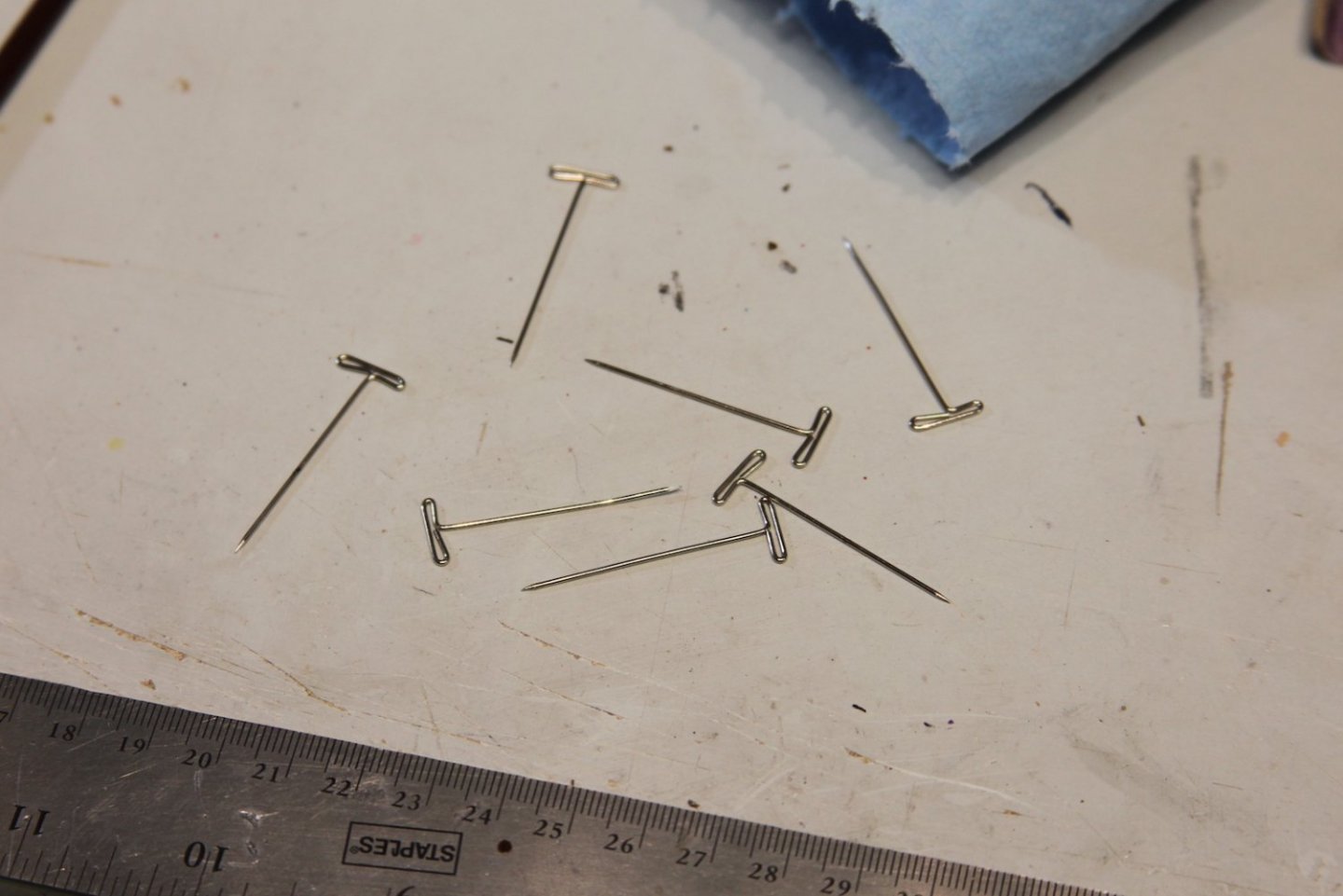

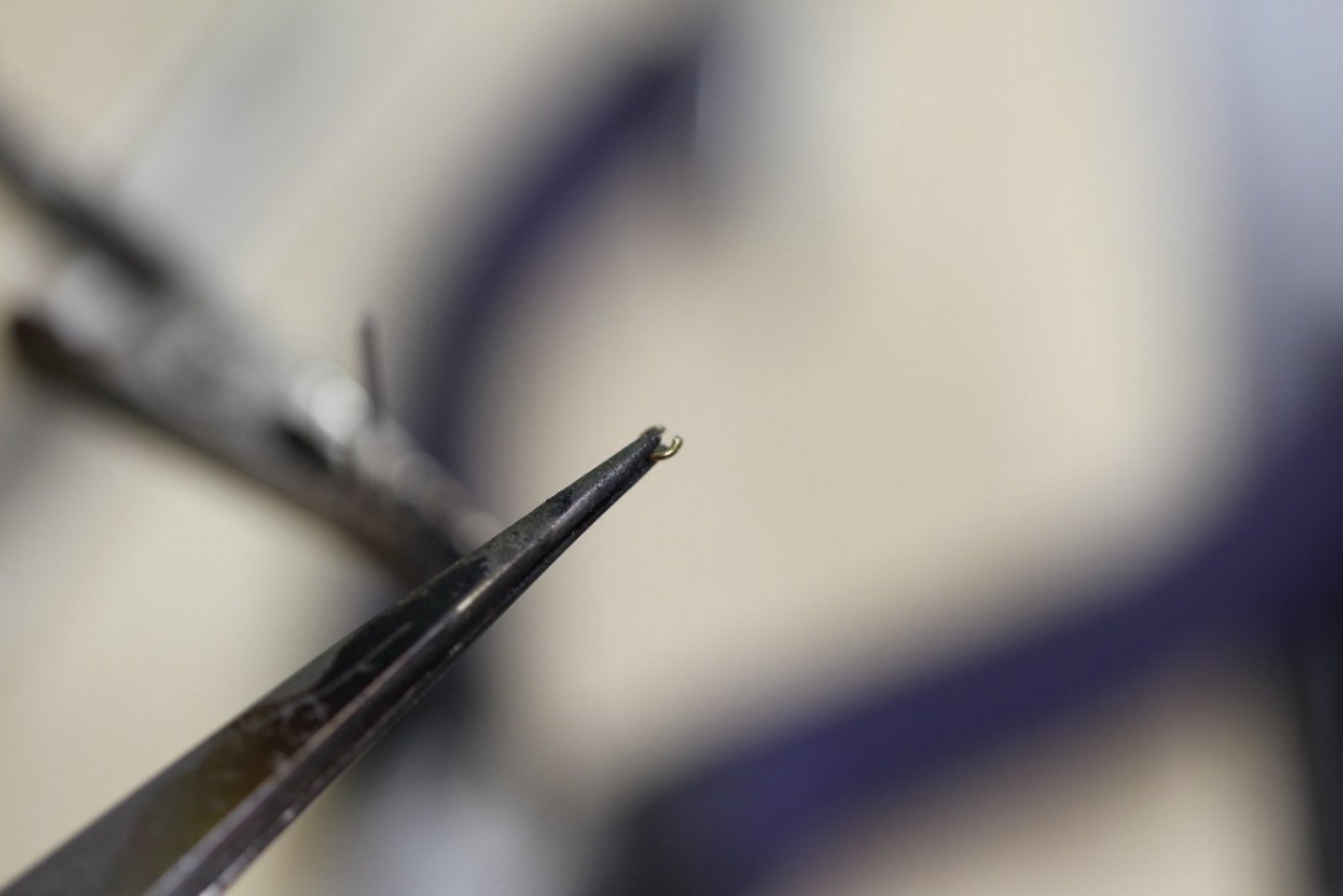

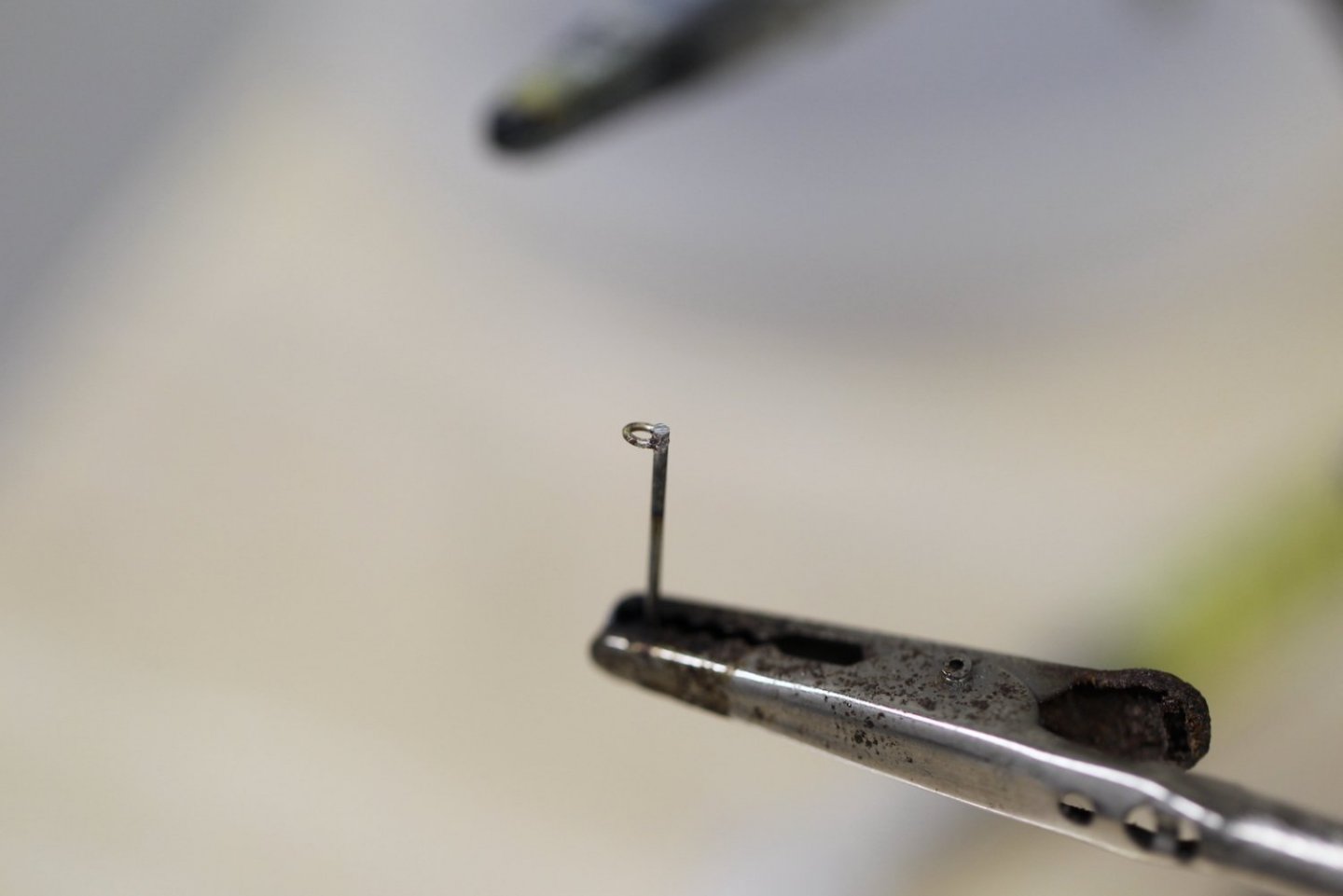

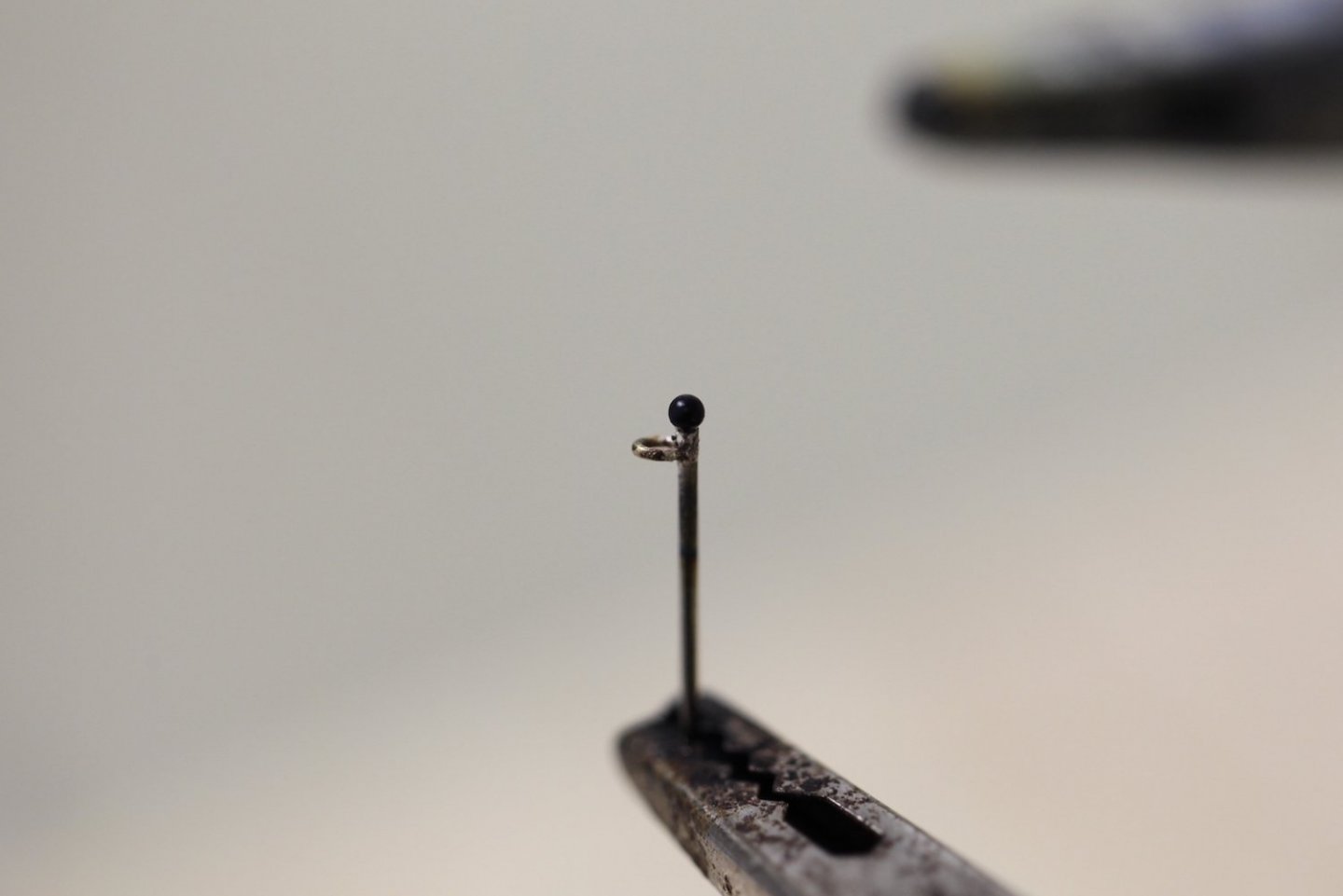

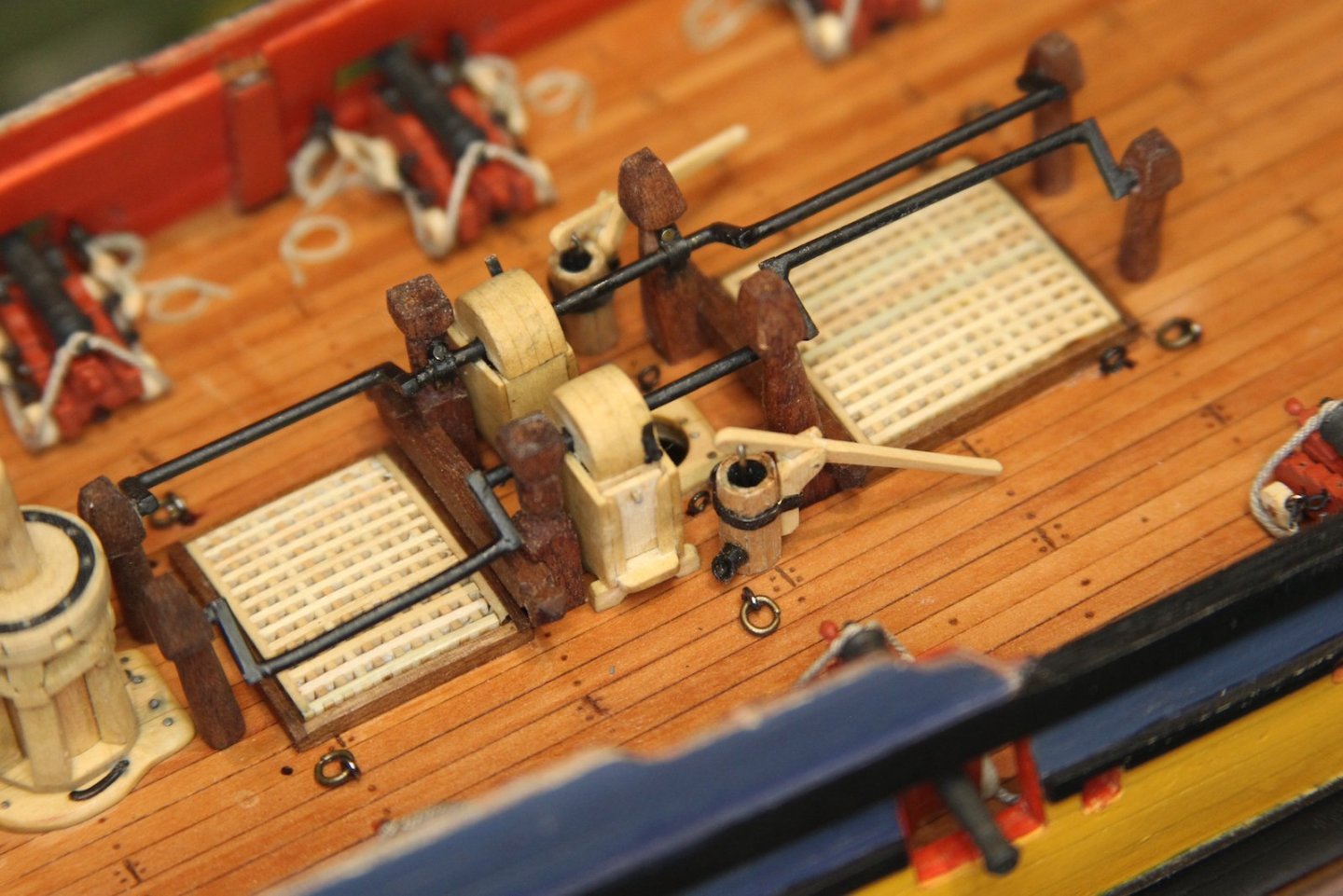

Short post on the stanchions and guard rails around the open hatches. The long eye bolts weren't going to cut it after seeing some of the cool things other folks have done on their builds. So I fabricated my stanchions out of these T-Pins that I snapped off. I wanted something with a pointy end that would facilitate mounting. I then soldered some rings to them.

After running around trying to find tiny little beads or something to serve as railing toppers (including raiding my teenage daughter's stash of beading supplies) - I onIy came up with about half of what I needed. So - I made the rest on my own by using half-dried clumps of acrylic paint, rolling them into tiny balls, and then letting them dry. Then painting over them with Model Master enamel paint. The toughest part was getting all the little balls perfectly round and the same size. Pretty hard to tell the difference if you ask me...For the railings themselves, I've seen metal/wire used and I've seen rope. I decided to split the difference and use this pretty cool little cable wrapped wire I had lying around. Yup - I get this probably isn't accurate; but it definitely falls into category #2 of my aforementioned rating system: "probably not completely accurate but looks cool."

It's been said before - we all strive for a certain degree of accuracy, but sometimes it's also important to remember that these are our pieces of art, and that often calls for some deviation for our own benefit. Anyway - we all also seem to have our own "Mr. To-Scale Guy" with whom we test our sizes, etc. My guy comes from an old S-scale (also 1.64) Train set. He looks like that cuz he was pushing a lawnmower at one point.

On another note - these macro shots remind me that I'm going to have a lot of dusting and cleaning up do do. Sheesh. Either that or I need to just start using a crappier lens. 😆

-

That's a beautiful contrast between the hatches, coamings, and the deck.

For what it's worth - although I also caught the difference between the grating of the aft hatch, I was actually looking for it based on following your earlier adjustments. Had I looked at these photos without that, I'm not sure I'd have really noticed it without it being pointed out.

- mtaylor and Blue Ensign

-

1

1

-

1

1

-

-

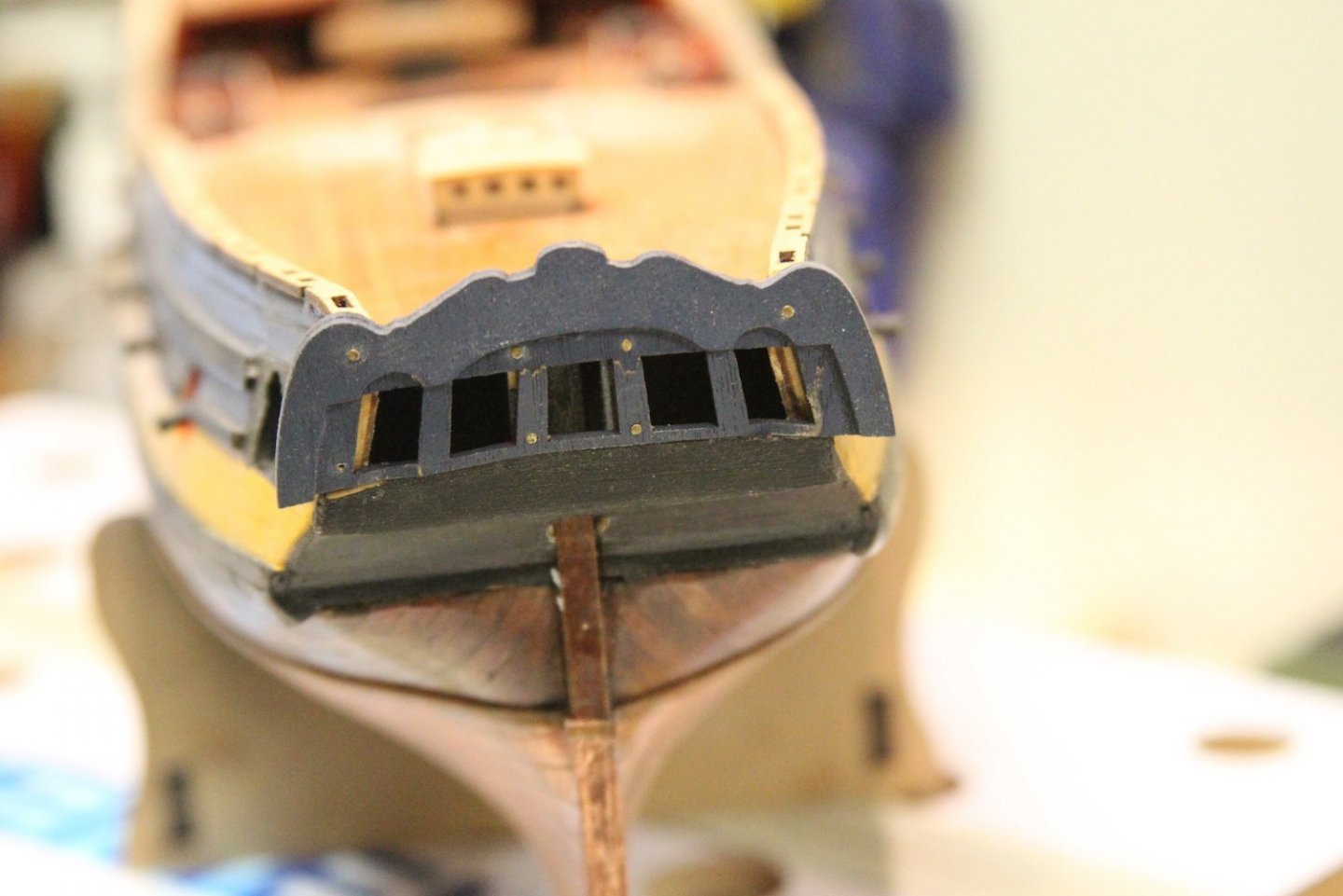

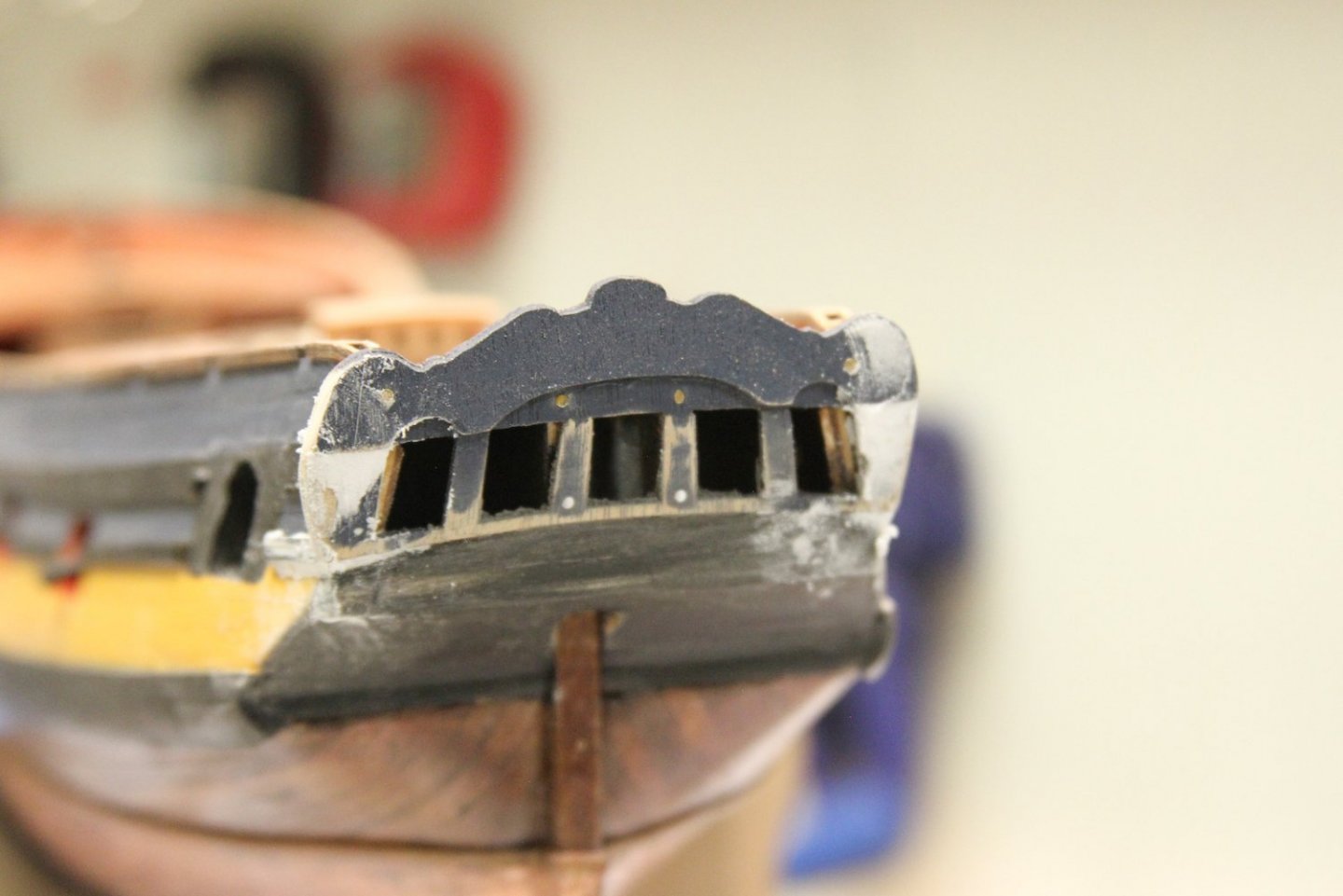

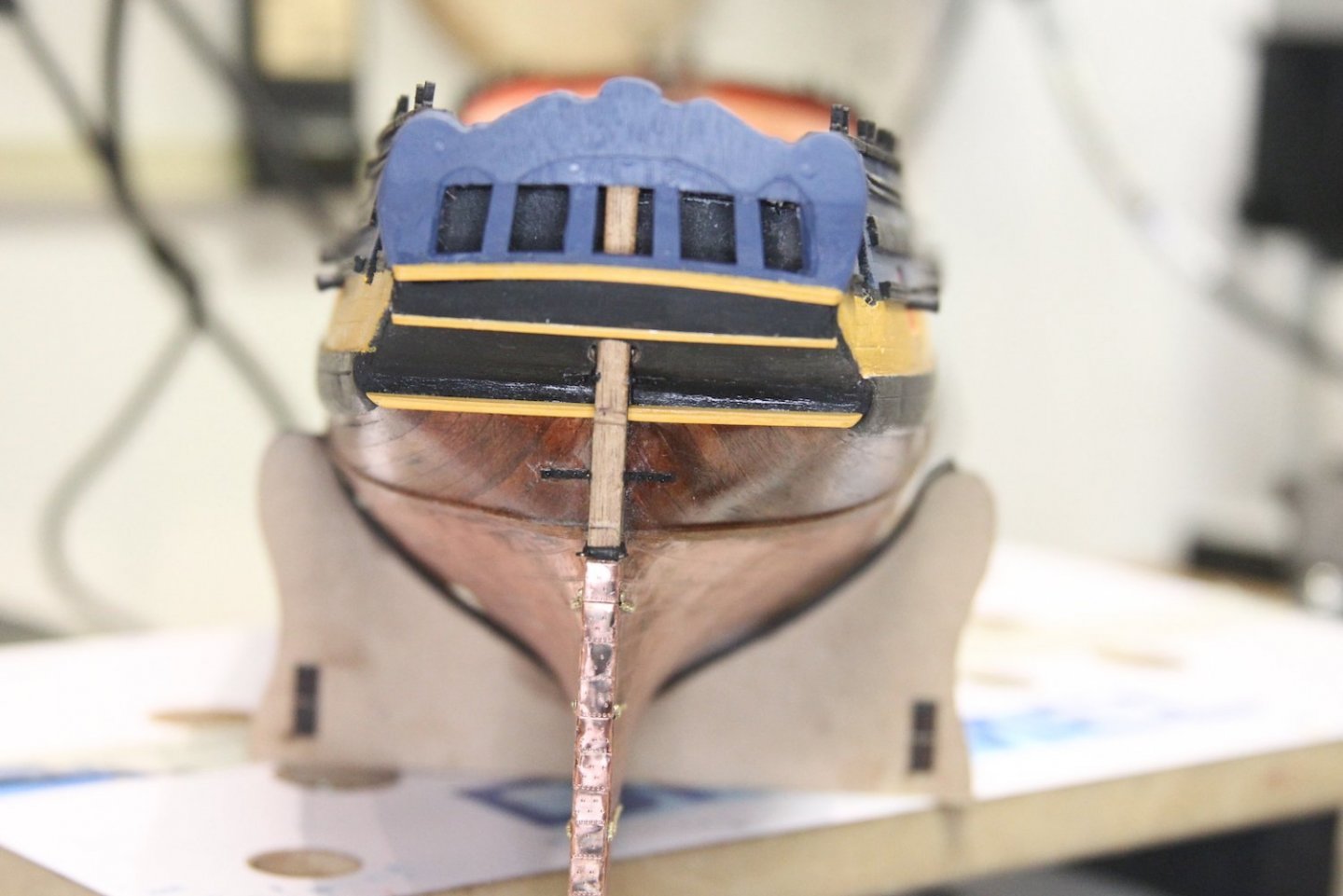

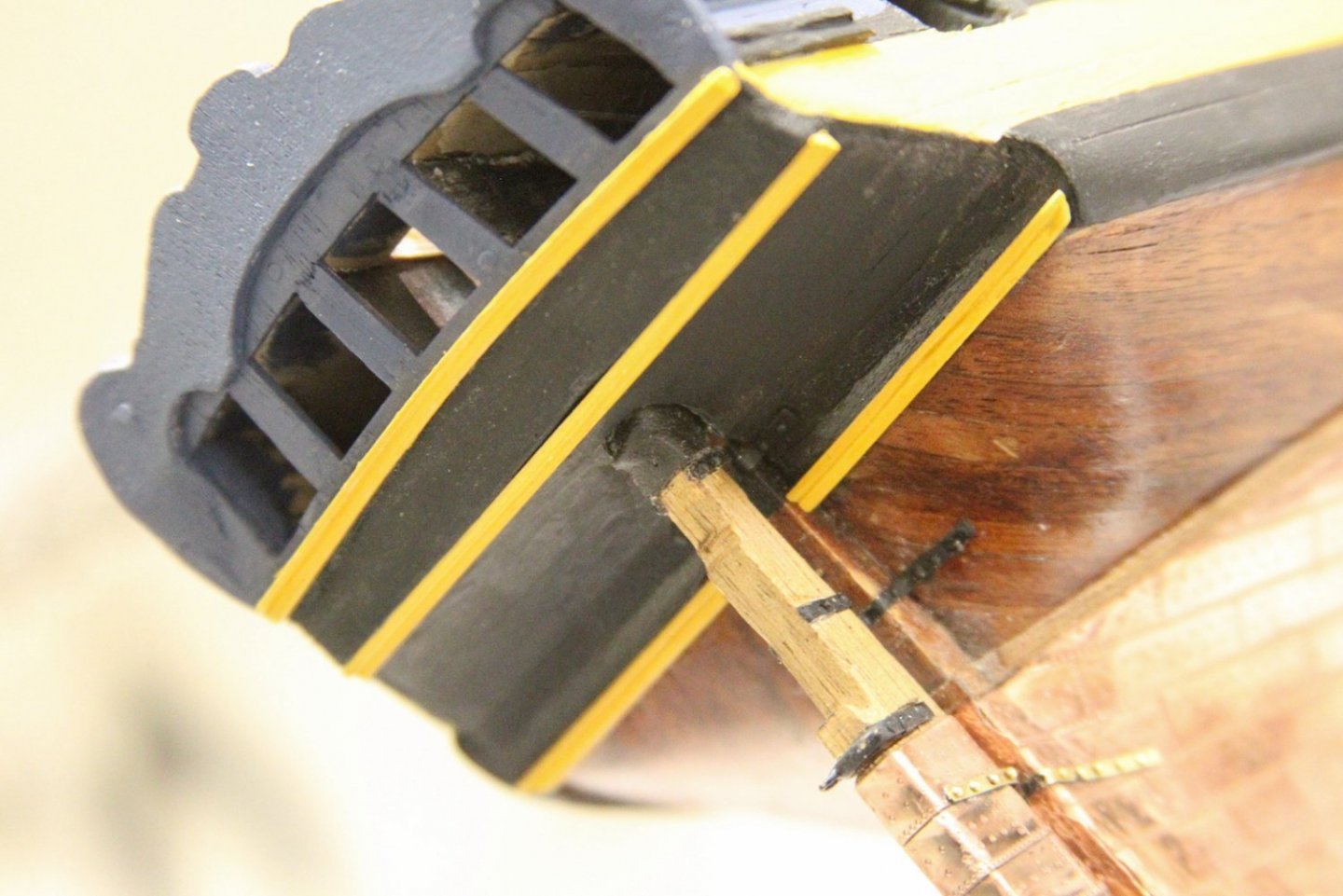

It's definitely worth mentioning that that last couple/few posts represent work that was done simultaneously mostly over the holiday break from work and the last week or so. It's not like I knocked all the stuff out one after another. I'd been thinking about how to handle the transom for quite some time - since like everyone else who's done this built I realized there's a pretty notable design flaw in that the sides of the transom just just out into nothingness with sharp edges. Very strange. The other noticeable different from the NMM plans was the way the stern curved whereas almost every reference (and build) showed it as being straight. So these two things needed to be sorted. First, I straightened up Peg's rear end.

Next up, I addressed the weird jutting edges. I've seen a few different methods in builds - mostly adding a piece to fill in the gap. I decided my best bet would be to reshape the sides to more reflect the plans above. After sanding down and reshaping, I filled in the gaps and angles to smooth it all out. Then I added the moulding to separate the lower stern areas to get an idea of how this would all play out.

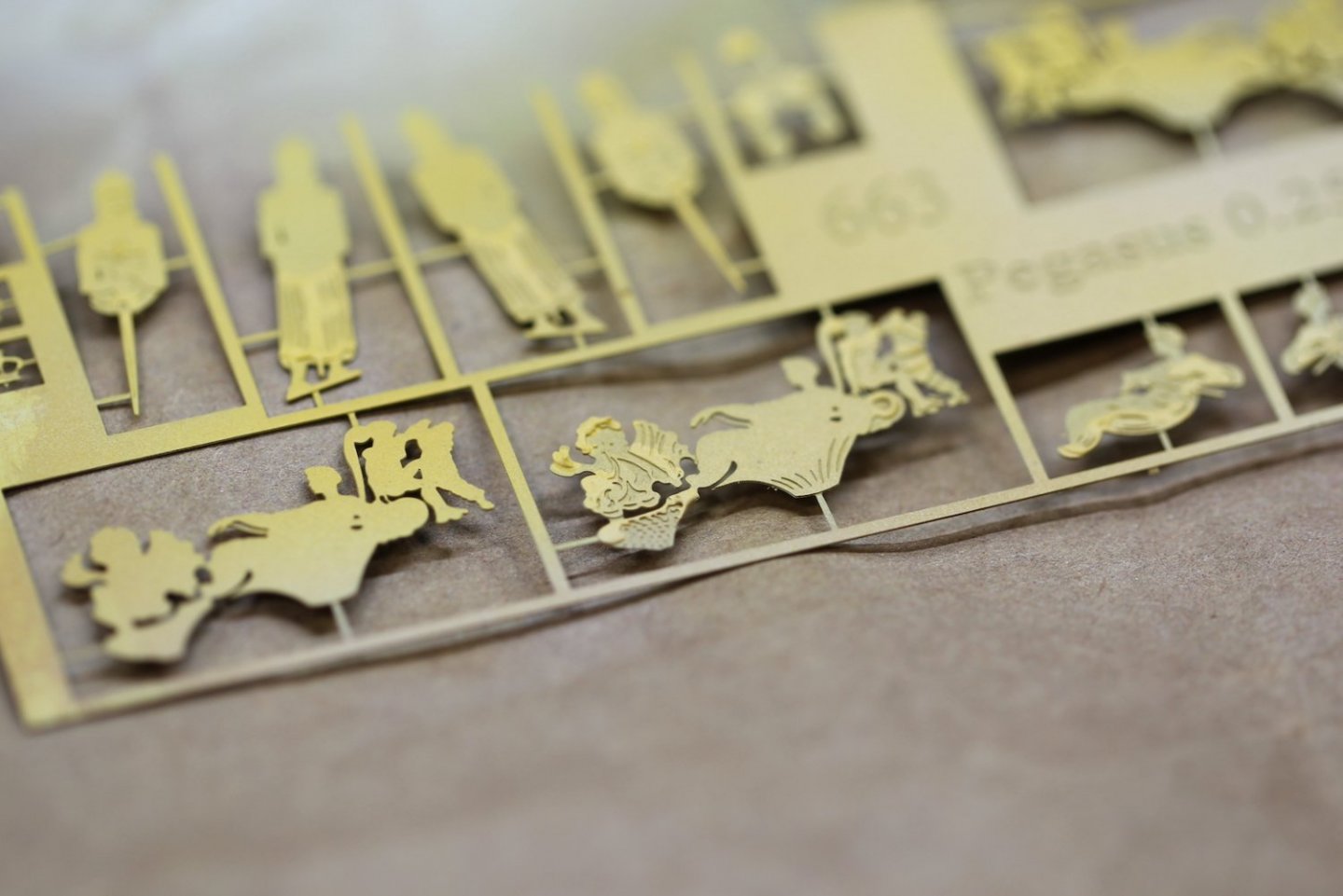

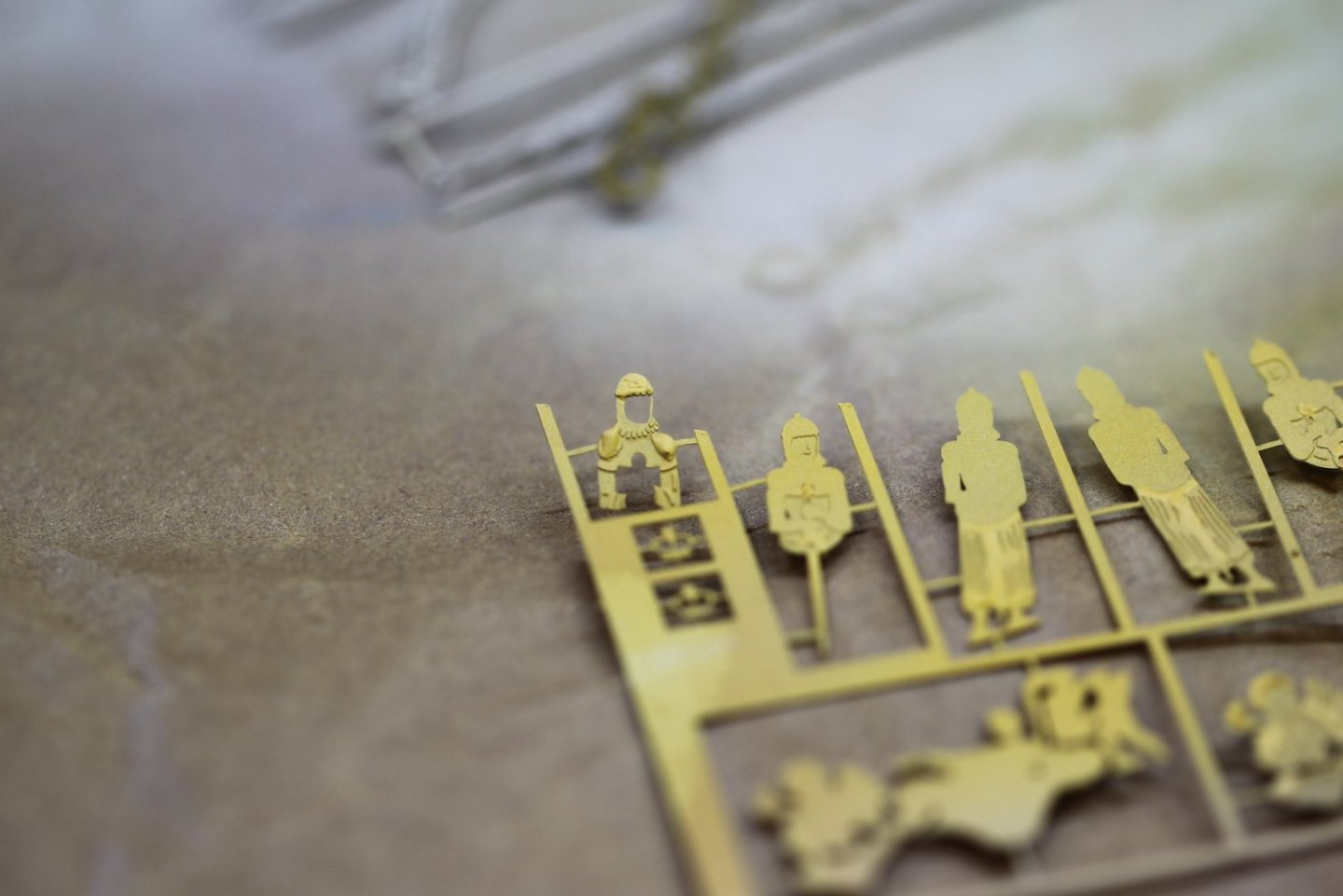

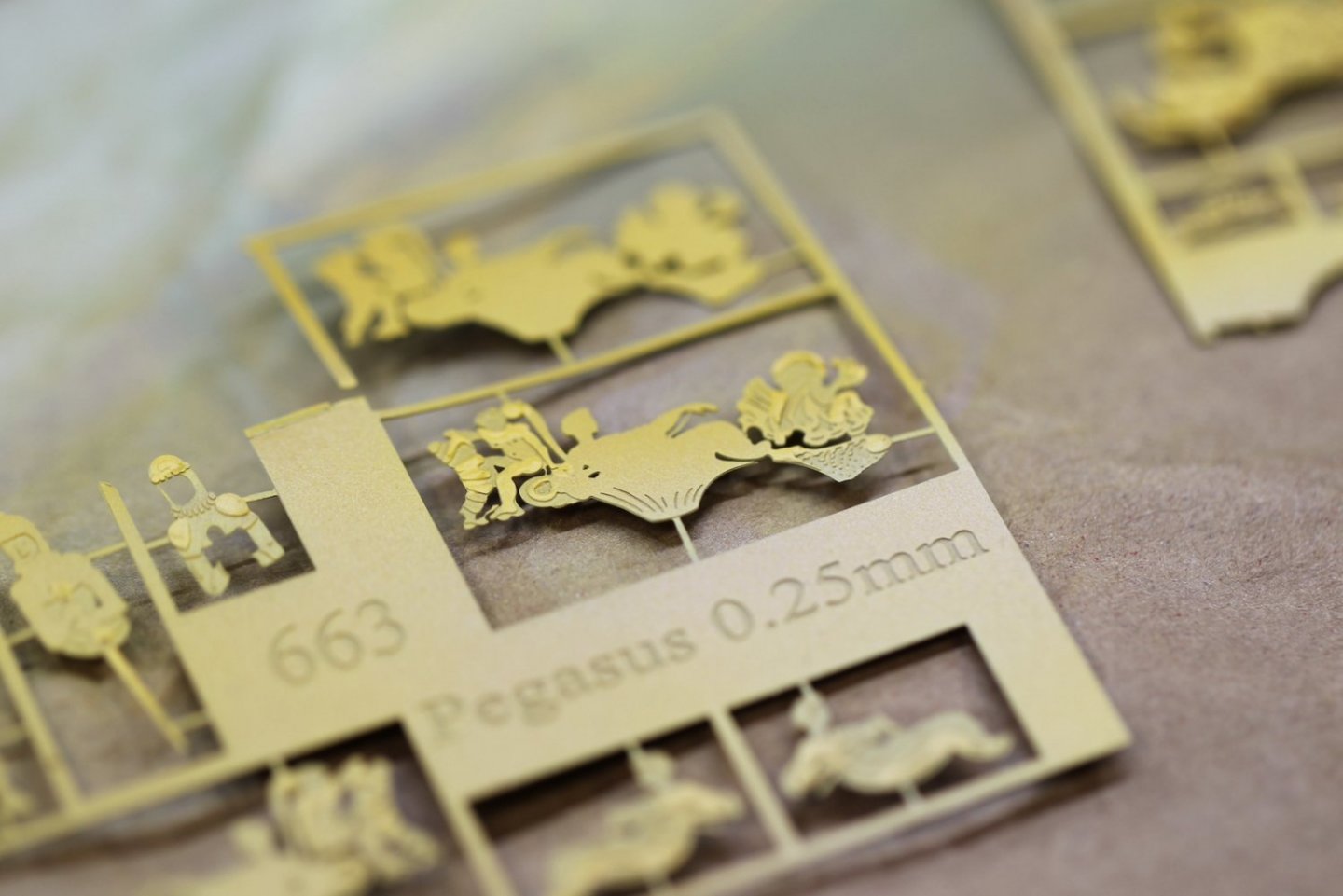

Though the reshaping of the transom looks much better, it does create a subsequent problem that needs to be addressed - the fitting of all the carvings and decorations. Obviously, the kit provided photo-etched decorations are made to specifically fit the kit shaped transom. So - how to fit the decorations into a smaller, differently shaped area?

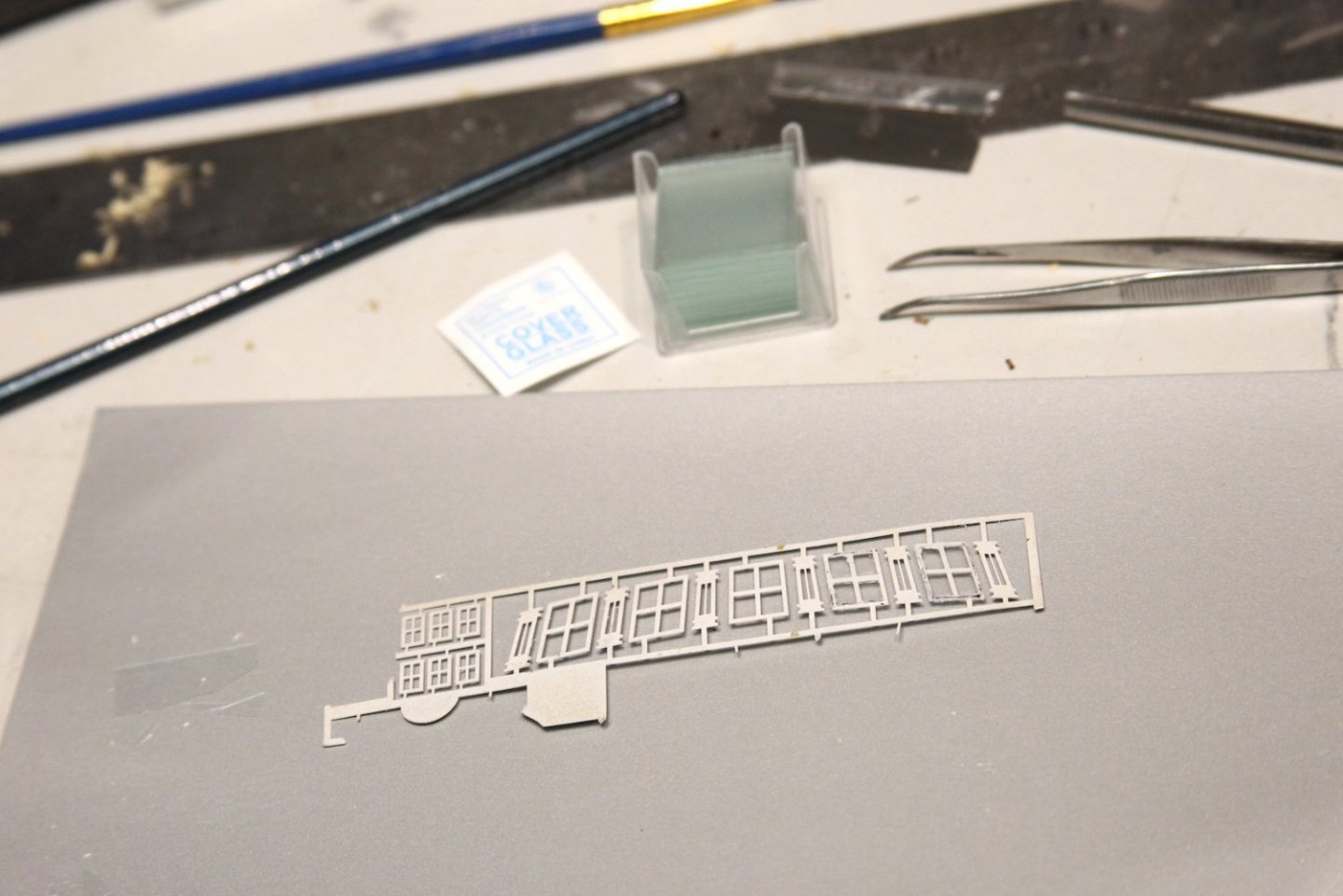

First, I painted them with a few different layers and shades of yellow and yellow ochre to try and create a more three dimensional look - the same technique as I used for the quarter galleries. Then, I installed the windows - because I know that the window locations are fixed and will serve as my benchmark for placing the rest of the decorations. Once again as with the quarter galleries, I am using the thin microscope cover glass as 'real window panes' in my windows.Although the decorations themselves come in layers to facilitate somewhat of a 3D 'carved' look, I used the same technique as with the quarter galleries to to add to that after they were mounted - adding some thicker acrylic paint to bring out the texture. But first I had to get them to fit, so I cut apart each decoration so that it is a separate piece which allowed me to place them individually. I started withe the Pegasus centerpiece, then added the two soldiers on the outsides (the poor soldiers had to be 'trimmed' to fit the different shaped transom) and then individually placed elements to fill in the gaps in between. I even pulled a couple decorations that were intended for other areas of the ship.

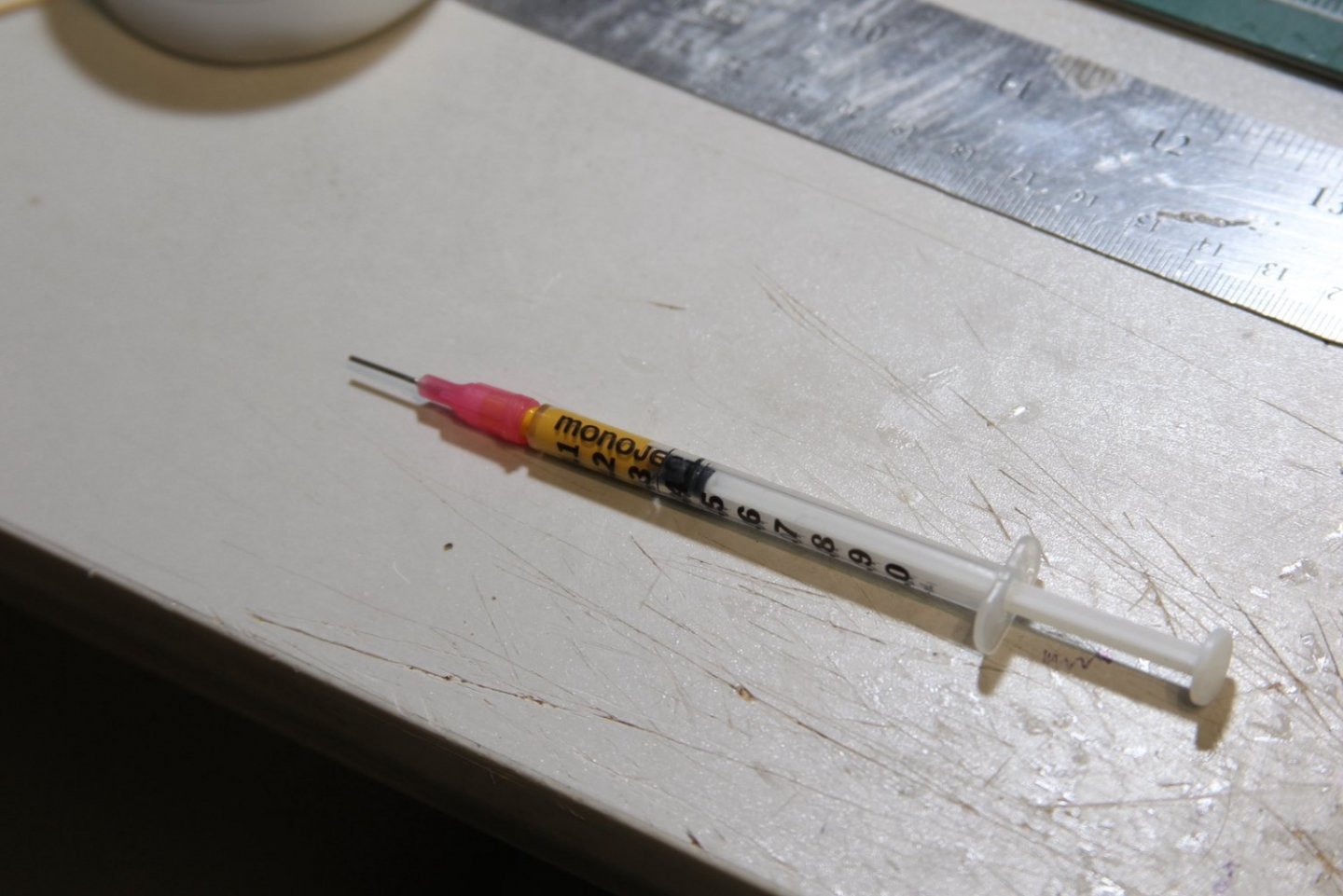

Then, to further enhance the 'carved' effect, I filled in a small syringe with relatively thick yellow ochre acrylic paint and attached the tiny nozzle used for silver soldering. I added the painted to raised areas of the carvings to raise them even further. This took a lot of time and patience and some scraping off of extra painted when my fat-fingers splooged out too much paint on occasion.

Finally, lining up the letters was an incredible pain in the a**. First, the laser cut letters are TINY, and very difficult to remove without damaging or bending them. Then - they were very challenging to paint, and finally- SUPER challenging to line up straight and with proper spacing. It took me almost as long to get the letters on the ship as it did to do the rest of the decorations. Unfortunately, I'm pretty terrible at painting letters or I'd have probably just abandoned the laser cut stuff and painted.

However, at the end of the day (though they're not perfect) I think they're pretty darn close. Of course the macro-lens shots show all the flaws, and I overall, I think it looks better to the naked eye than represented here with the super macro lens.Next step was to create a cap rail along the transom so it would match the rest of the ship. I'd seen builds with and without this rail, and although I knew it'd be a bit of a challenge to get right I wanted to give it a shot. I started by thinning out a 5 x 2 mm strip of basswood and soaking it, then using a hair dryer to bend and mold it along the curves. I used the gel gorilla glue CA to glue it down as I went along.

It was a pretty slow delicate process not to dry it too quickly and snap the wood, but it was worth it in the end. After some trimming of the edges toward the bottom where it meets the wales, a little bit of filler in some gaps, and sanding it was ready to paint. After it's all said and done, I am pretty pleased with the overall results.

-

7 hours ago, datadiscovery said:

What kind of wood are the decks planked with and how did you treat it?

Hey Pete - thanks for the nice comment and asking about the wood. I have to go back and make sure it's in there somewhere. But the decks are planked with Swiss Pear. Long story short - my project just prior to this one was finishing the USF Confederacy - a build started by a wonderful previous member @augie who passed away. Augie used Swiss Pear on the Confed, and I really just loved the way it looked, so I used the leftover for the Peg. I have treated it with a light layer of Tung oil - rub on with an applicator then immediately wiped clean from excess. I'm selective with Tung oil and WOP, but I like what the Tung does with the Swiss Pear as well as the Walnut that often comes with the kits.

Btw - I grew in Lebanon, Oregon - not too terribly far from your and @mtaylor's neck of the woods.

-

Nice looking work BE, especially the binding strakes. As always, I appreciate the ways in which you bring extra accuracy to kit projects. I don't ever see myself having either the necessary equipment or skillset to do a high level scratch project, so being able to 'up-sell' kits will likely be my preferred methodology. You give great kit enhancement tips.

- Blue Ensign and mtaylor

-

1

1

-

1

1

-

I also did some work on the rudder over the holidays. One of my faults as a builder is that I'm a bit erratic. I keep pretty good notes because of course skipping around means one has a tendency to miss things along the way. The rudder's up next so I can finish off the wheel, rudder housing and the rest of the deck fittings.

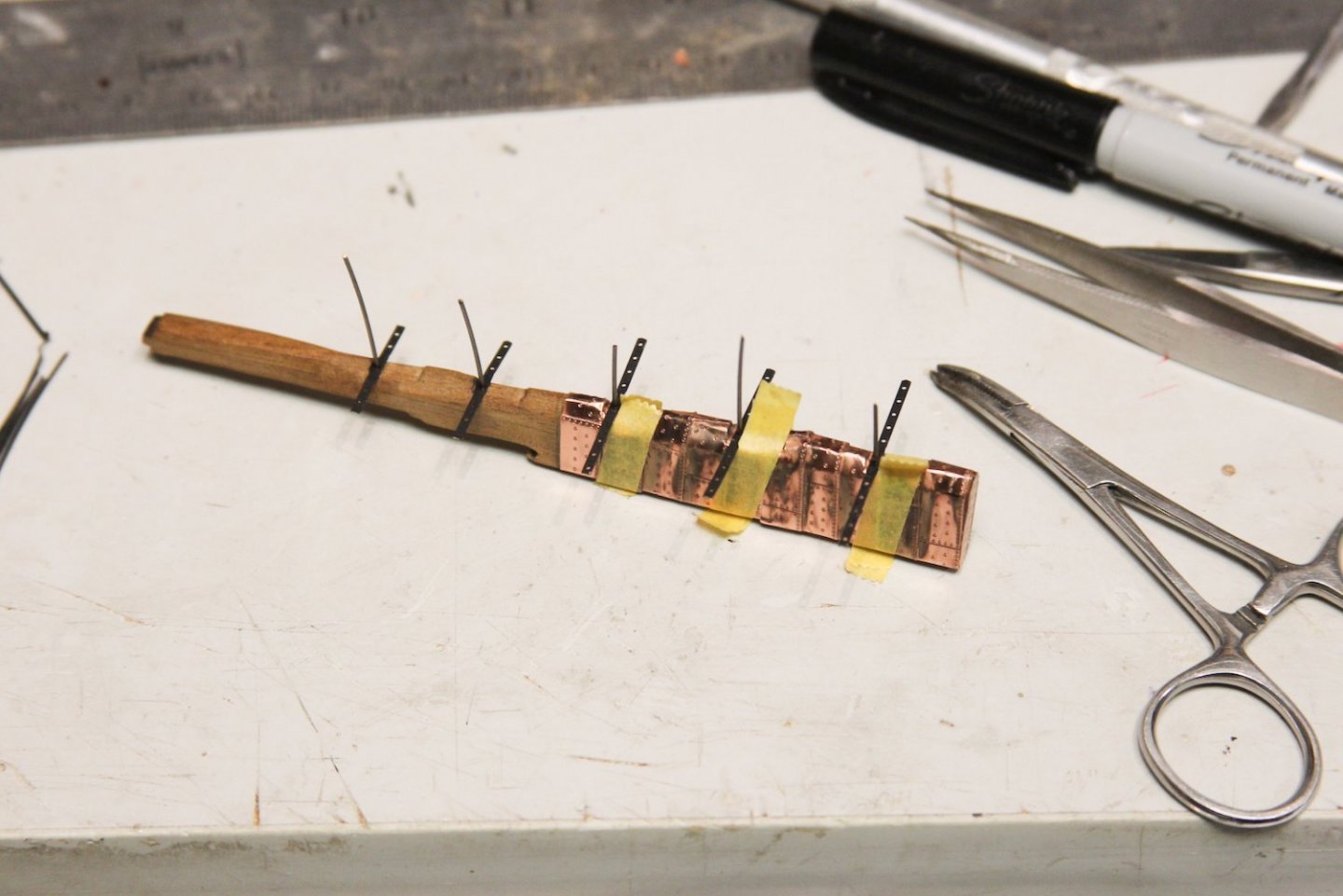

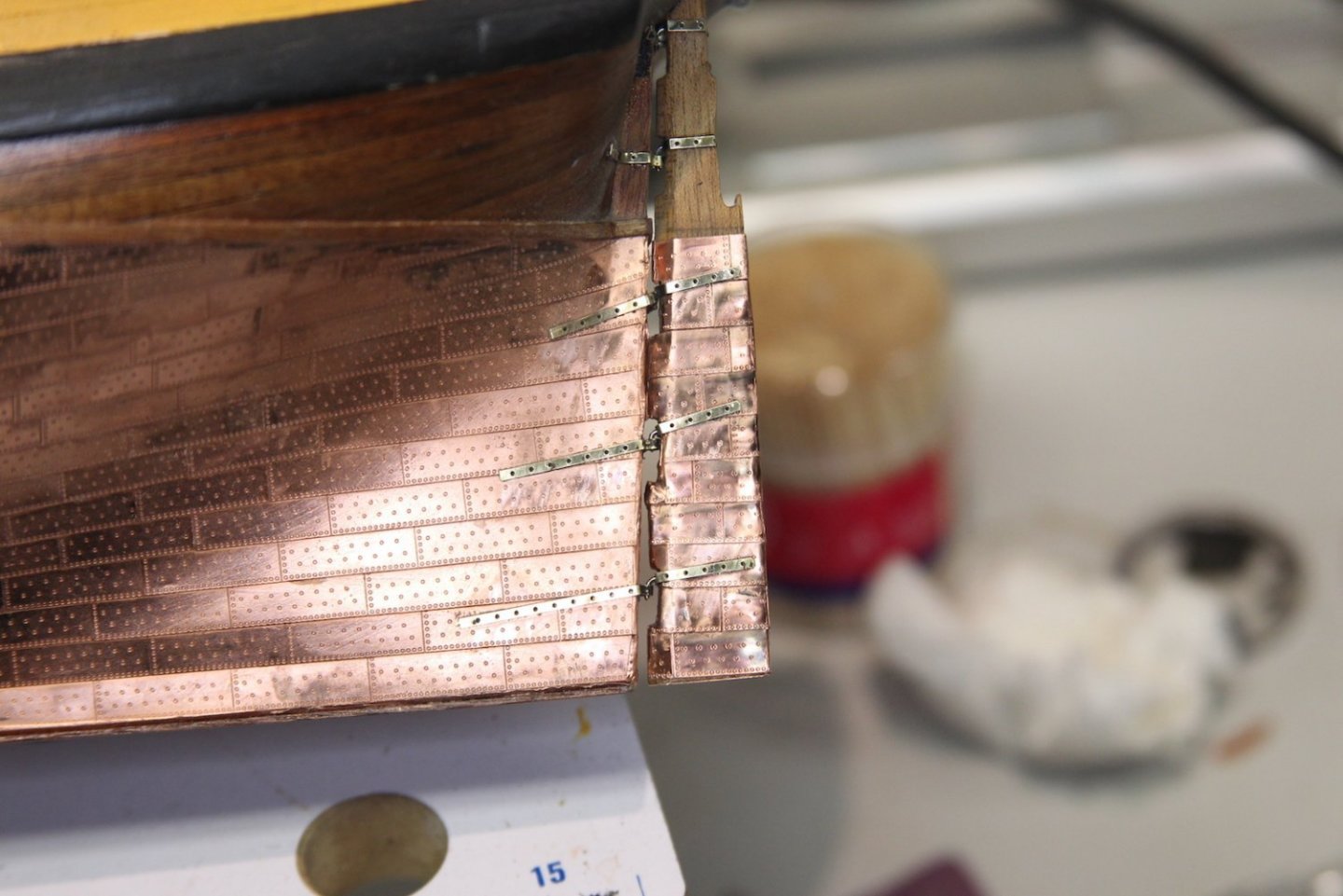

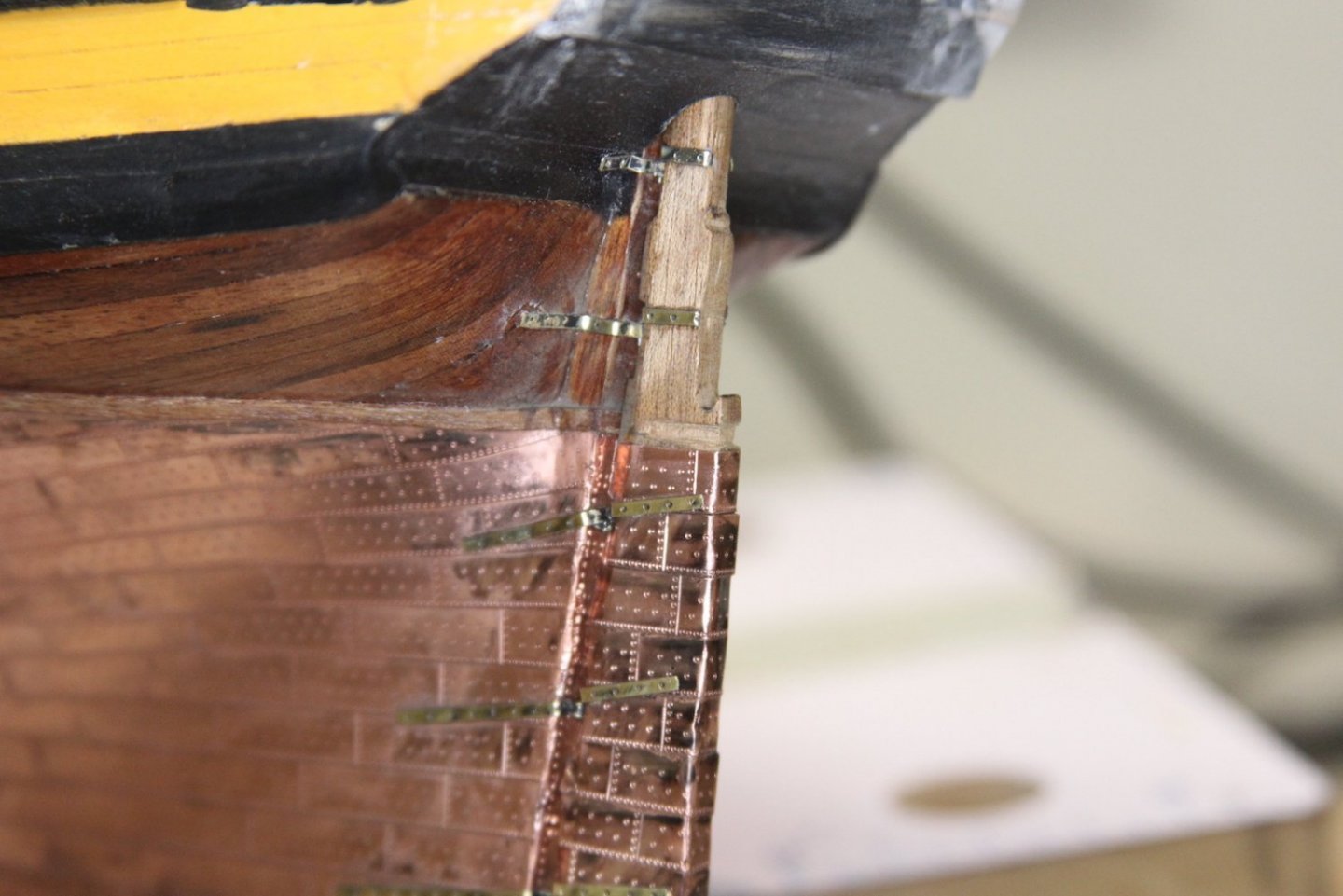

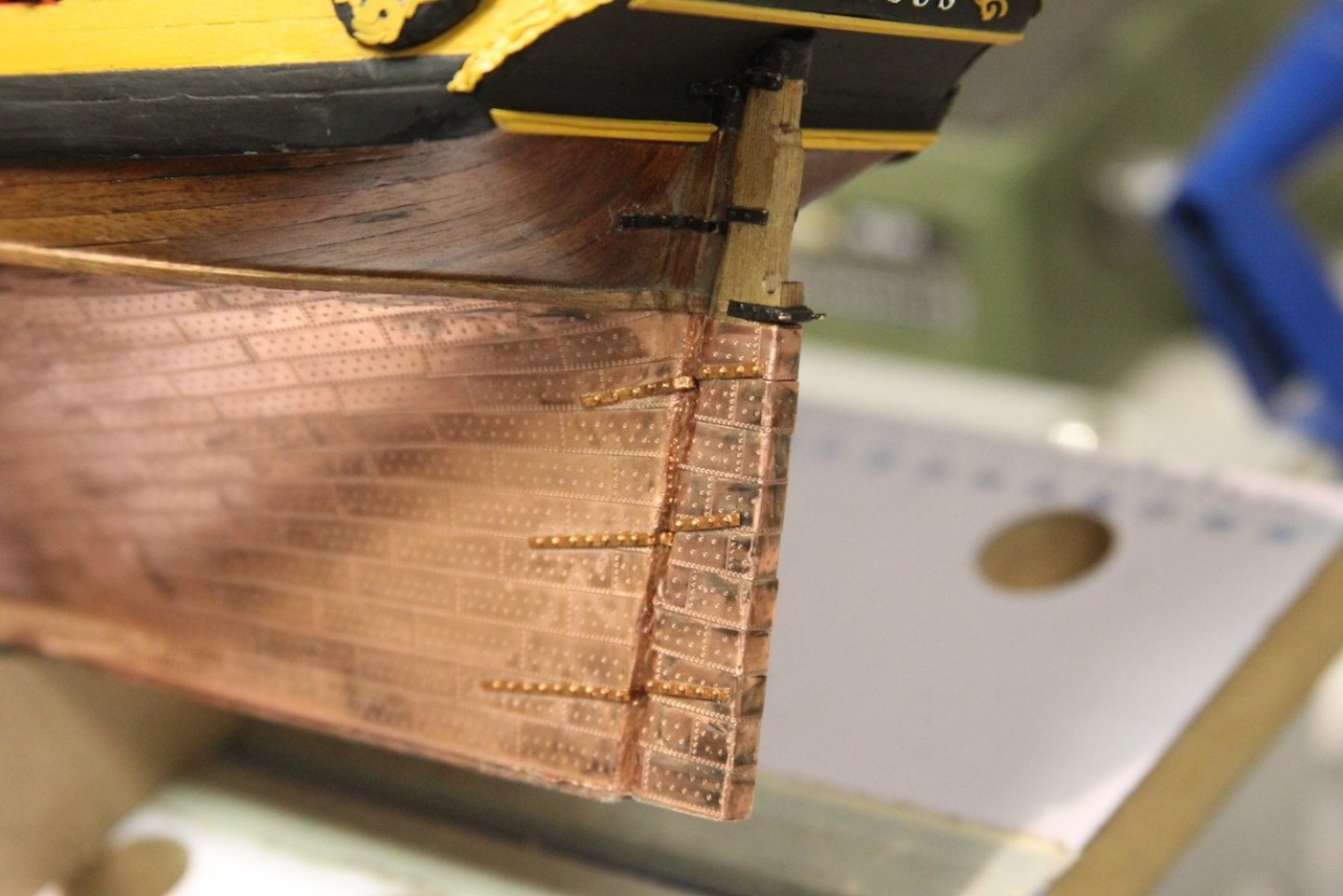

Anyway - on to the rudder. I tapered the insides and then plated the copper. It was a bit trickier than I anticipated, but I stuck with my desire to stagger the plates nonetheless. Then mounted the pintles with a center pin that would bend 90 degrees and serve as the mount to the gudgeons using tape to maintain an even offset and align the pintles and gudgeons along the rudder and hull.

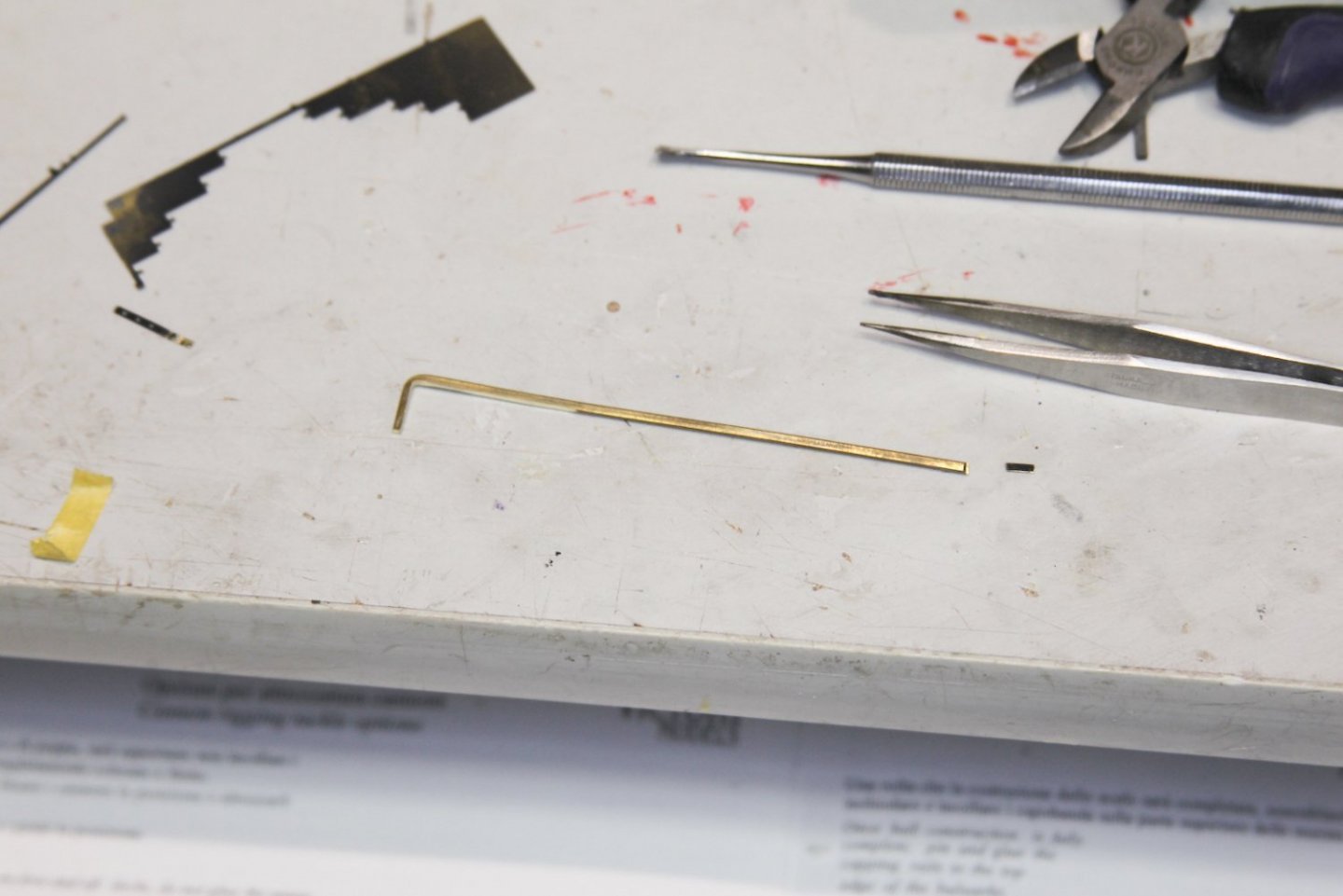

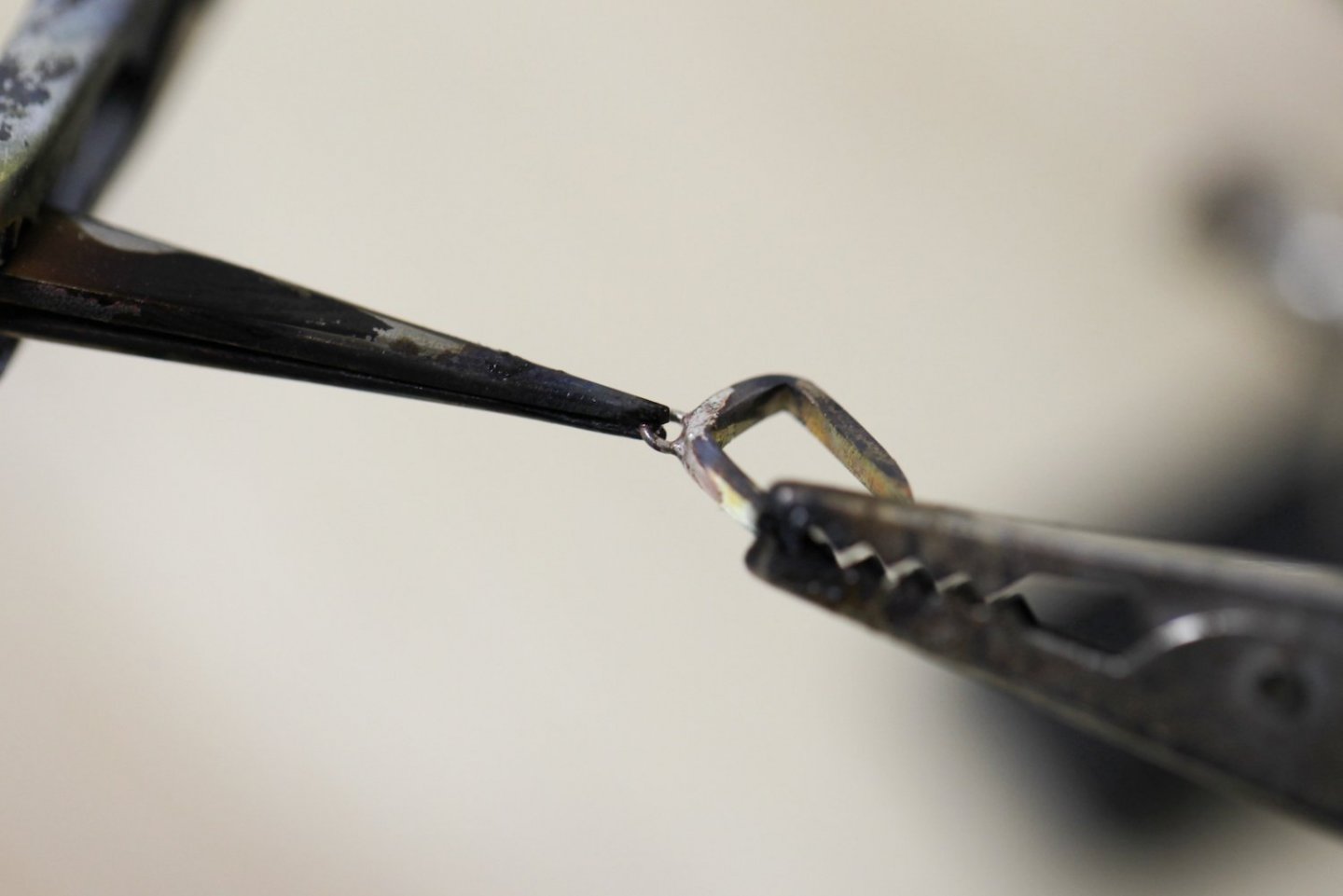

I created the spectacle plate out of a square piece of brass bent at a couple 90 degree angles then sanded thin to fit a complimentary slot cut out of the rudder. I then soldered a couple of brass rings to the corners. Everything is "bolted" with pins from Micro-mark - they're the .020 inch miniature nails. I like them for these applications because they have a round head that looks great for bolts.

The rudder coat is made from an old piece of simulated 'leather' that I had left over from my Artesania Latina stagecoach kit. I think it looks pretty close to the tarred canvas that was used. I glued one side at a time then stuffed it up into the rudder hole. Finally, I painted the pintles and gudgeons copper from "Army Painter" copper paint. These paints are typically used for medieval action figures, etc - so do a great job of simulating metal. I appreciate that the hinge coating is just a slightly different color of copper as the plating.

-

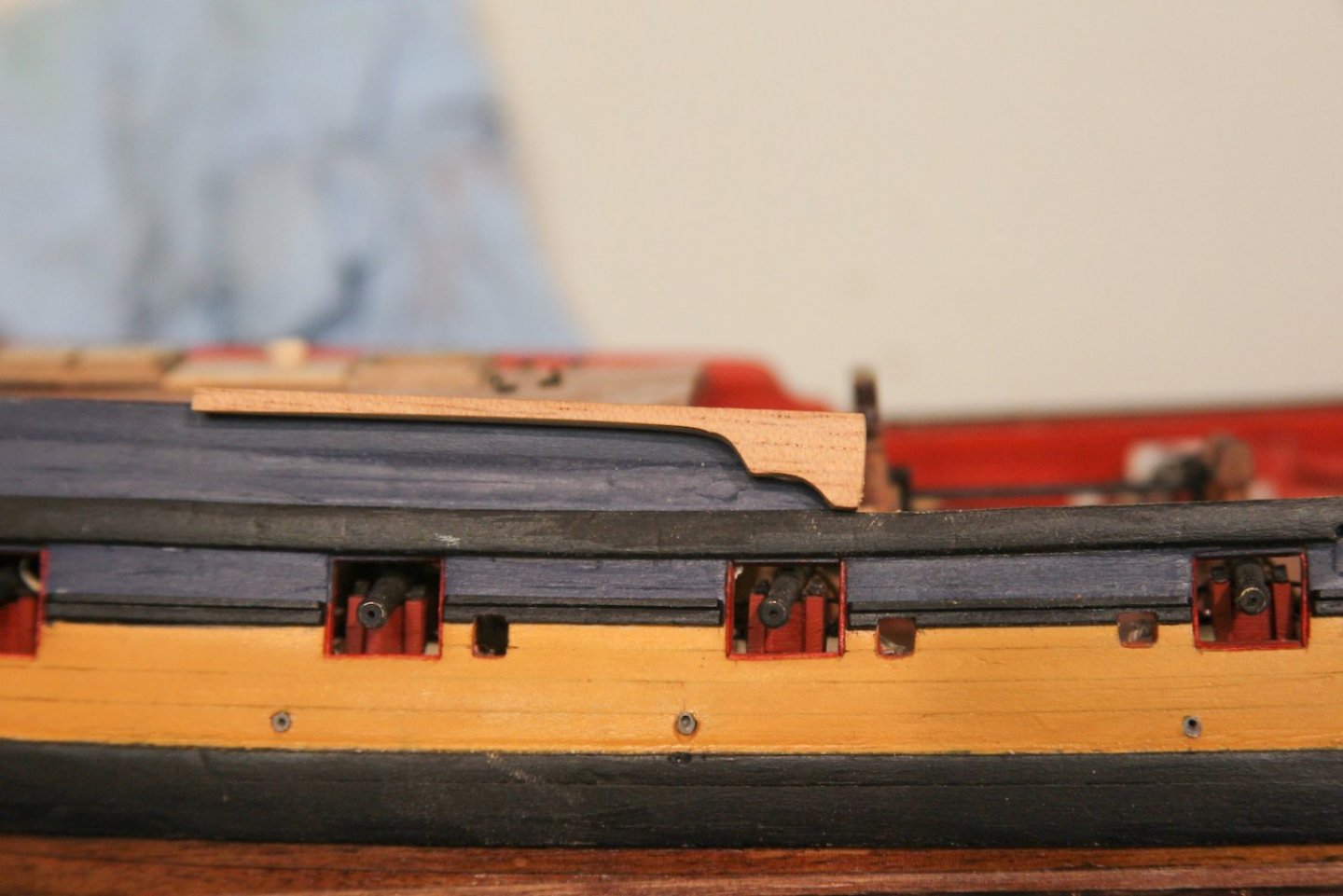

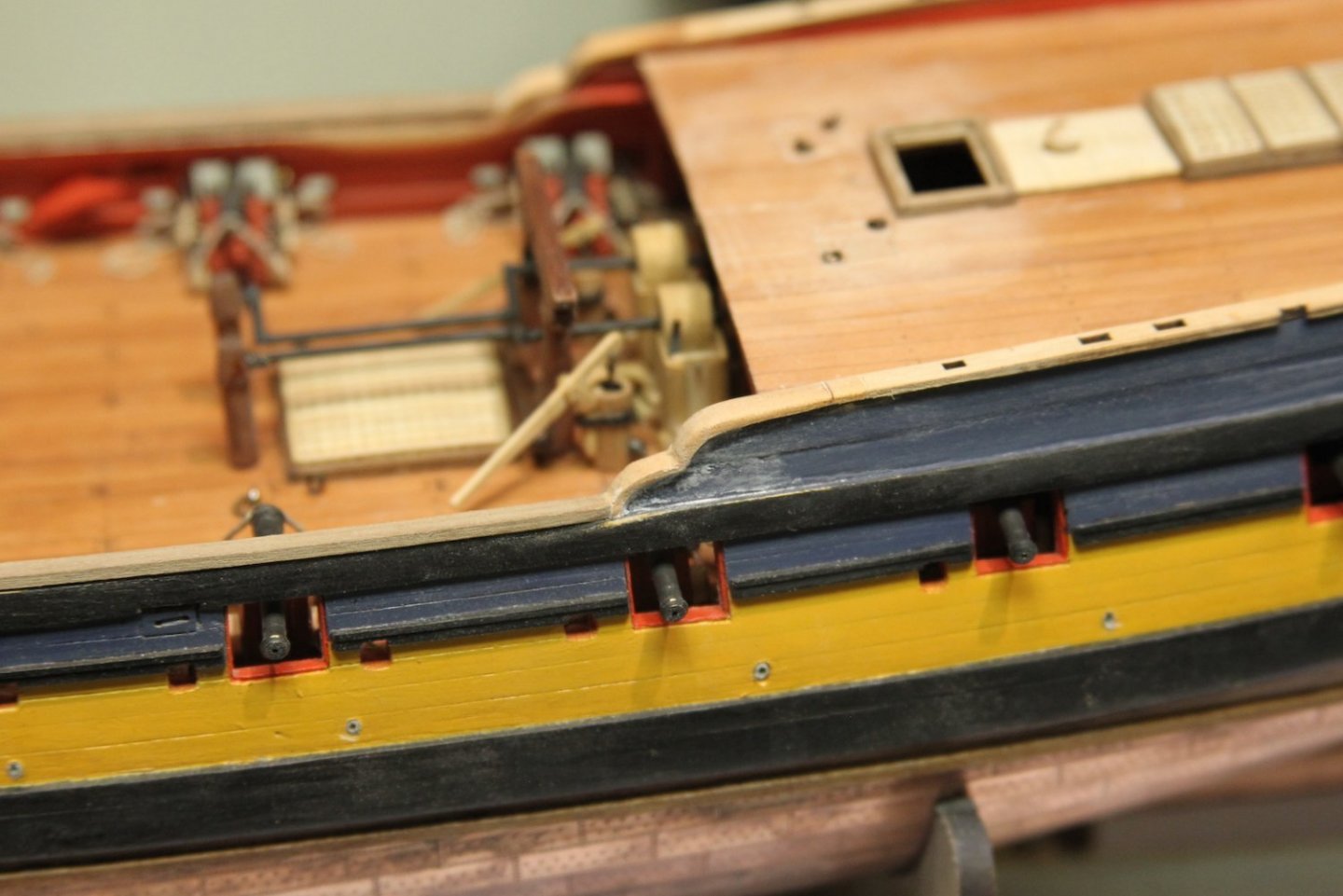

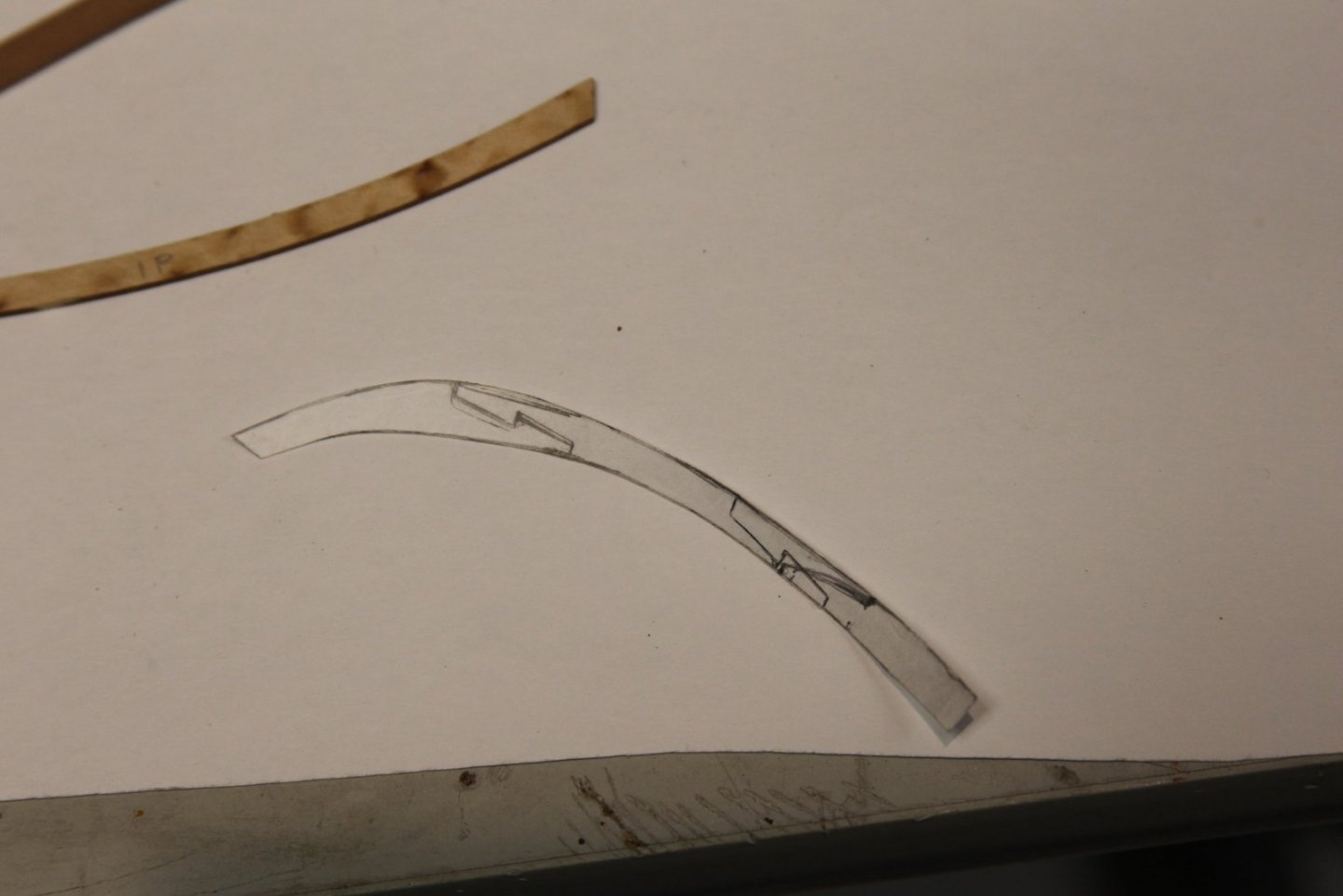

Though I've clearly been negligent with posting, I've been working on a few things simultaneously over the holiday break. I'll have more updates soon on the rudder and transom. But I've also been catching up on some of the miscellany of bitts and rails and other items. As always, everything ties together - so using a thicker deck and increasing the bulwarks affected the roll of top rail that sweeps into the waist. Instead of trying to match it to the plans, or even match it identically to the FFM or other sources, I instead took what the build gave me and worked with that.

I used a solid piece of cedar scrap to draw out what the rail would look like, then carved/sanded the pieces to fit. Admittedly, I'm not much of a wood carver, so my little bit of saving grace is that it'll all be painted black so my inevitable flaws will hopefully be covered.

For the strips along the side I sanded down some make-shift scrapers. The strips themselves are boxwood, split and sanded to match. I sanded them thinner then painted them before they were mounted.

After all the bitts are added along the top rail, I filled in all the little gaps before painting.

During this process I've been keeping the decorative etchings in the back of my head, as I know I'll have to work with those. I realize I painted myself (no pun intended) into a corner by using a full size main wale as per the FFM, etc - which gives me much less space for decorations and other elements. So - I'll likely finish up as much of the sides including the swivel mounts, side ladders and other ornaments (and maybe even the channels) before attempting to decorate the sides.

- BobG, GrandpaPhil, gjdale and 8 others

-

11

11

-

1 hour ago, druxey said:

Interesting variation on a 45 degree holder or jig

Dude definitely has some envious equipment and tools.

- mtaylor, billocrates, Keith Black and 1 other

-

4

4

-

6 hours ago, Blue Ensign said:

Those gratings over the scuttles made no sense to me

Thanks B.E. - these are the kinds of small items where one appreciates the research from those who've done the build before; that way I'm not duplicating effort. Definitely appreciate all your notes along the way, which at the least gives me the opportunity to decide if I want to take the same route.

- Blue Ensign, bruce d, Jack12477 and 1 other

-

4

4

-

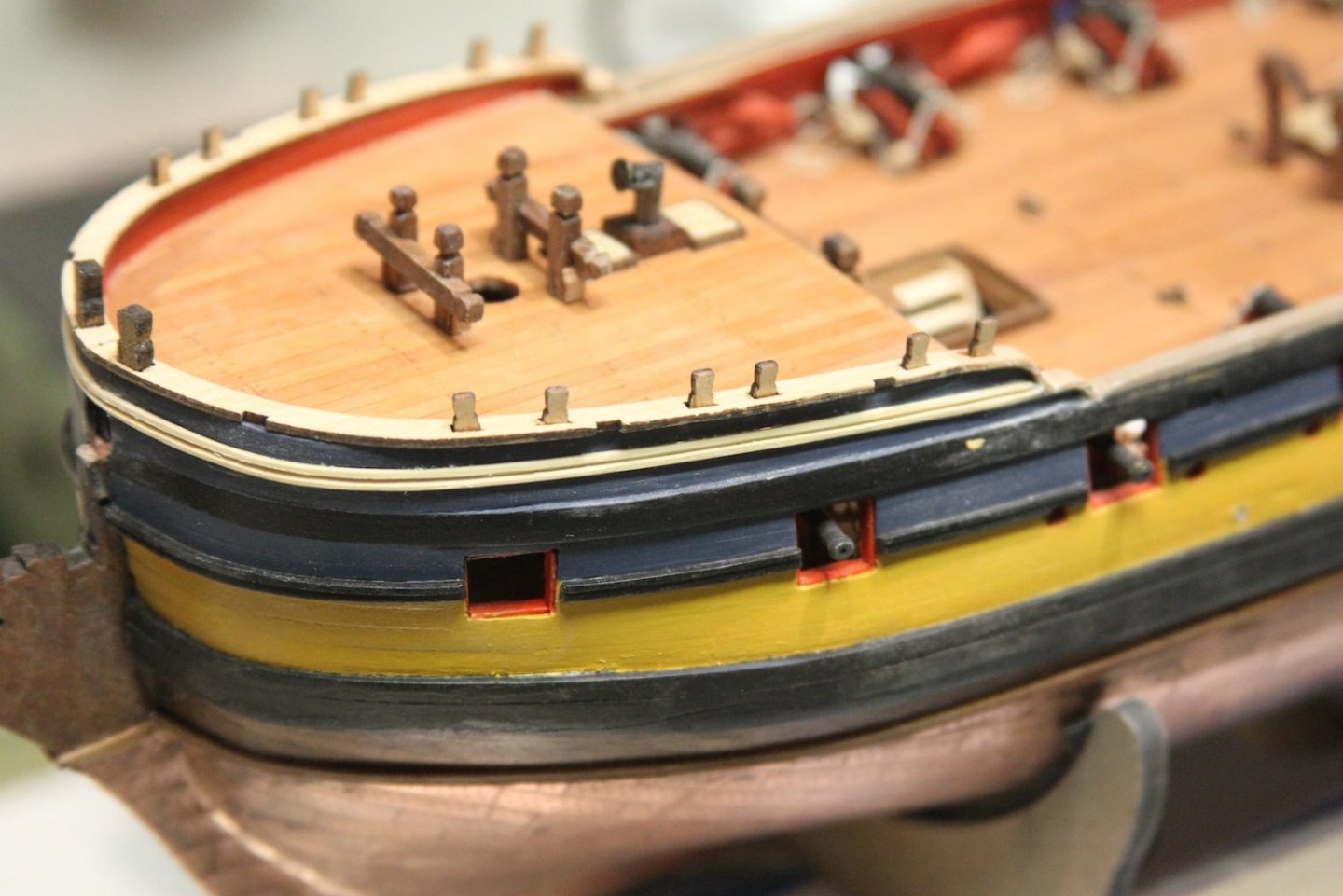

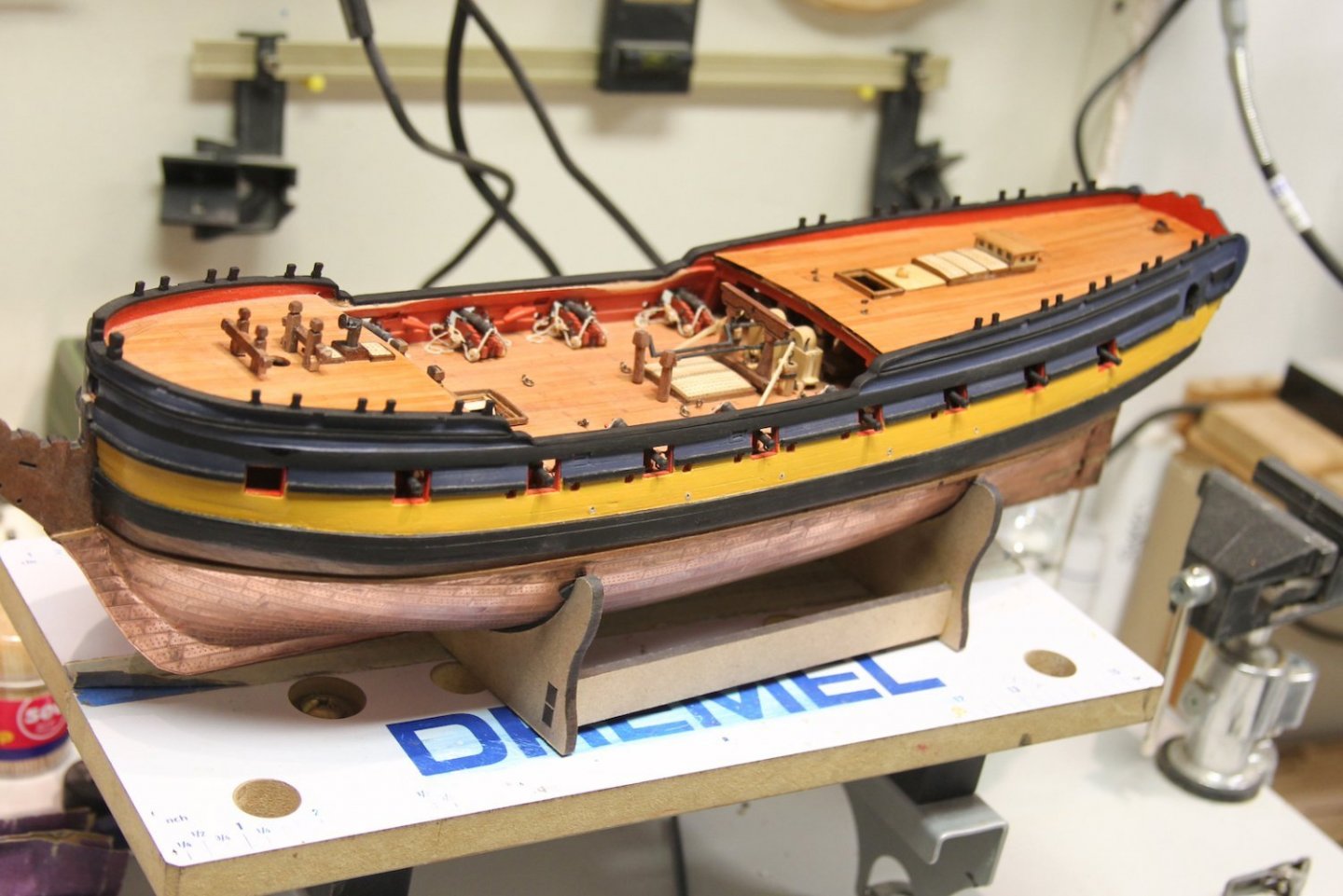

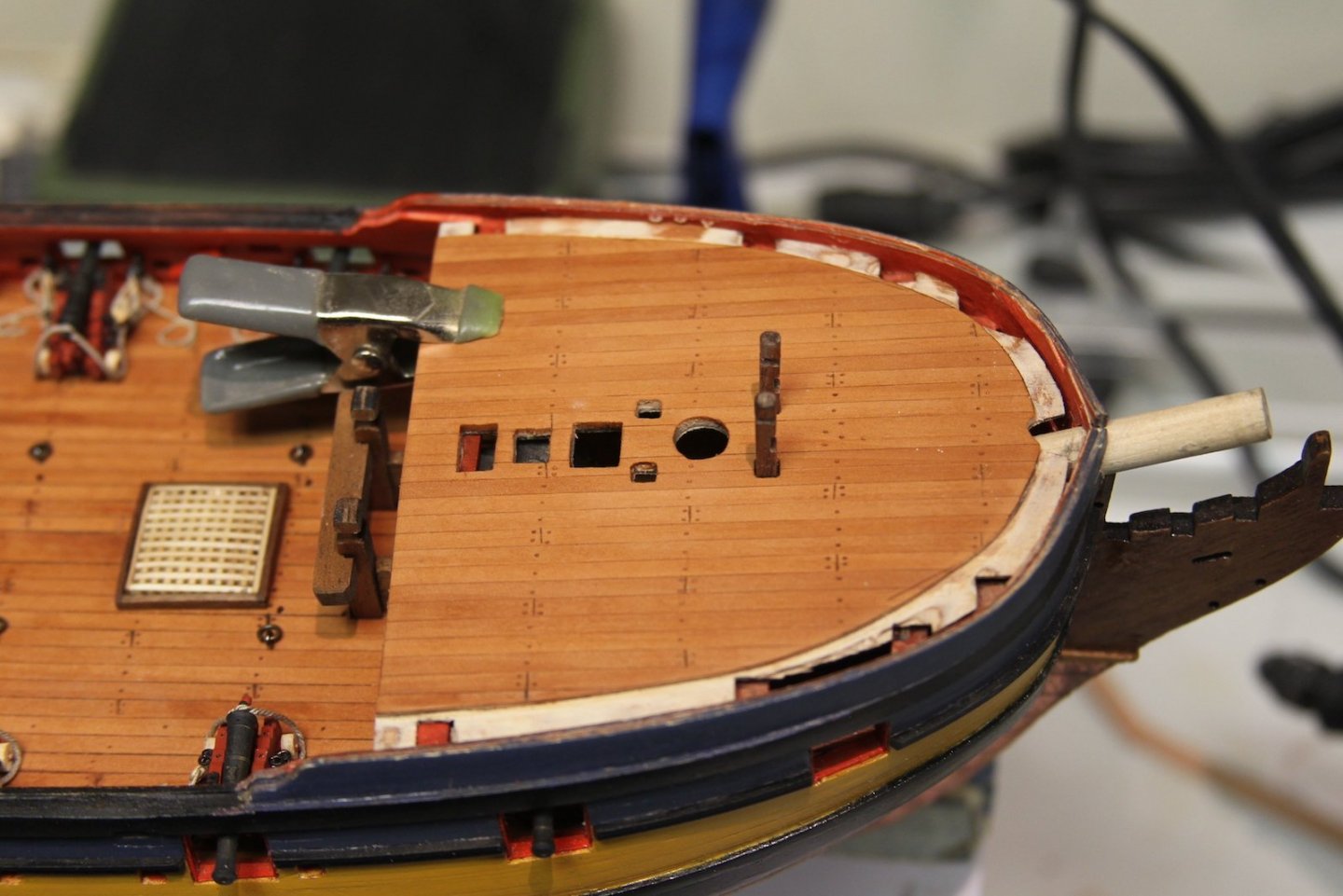

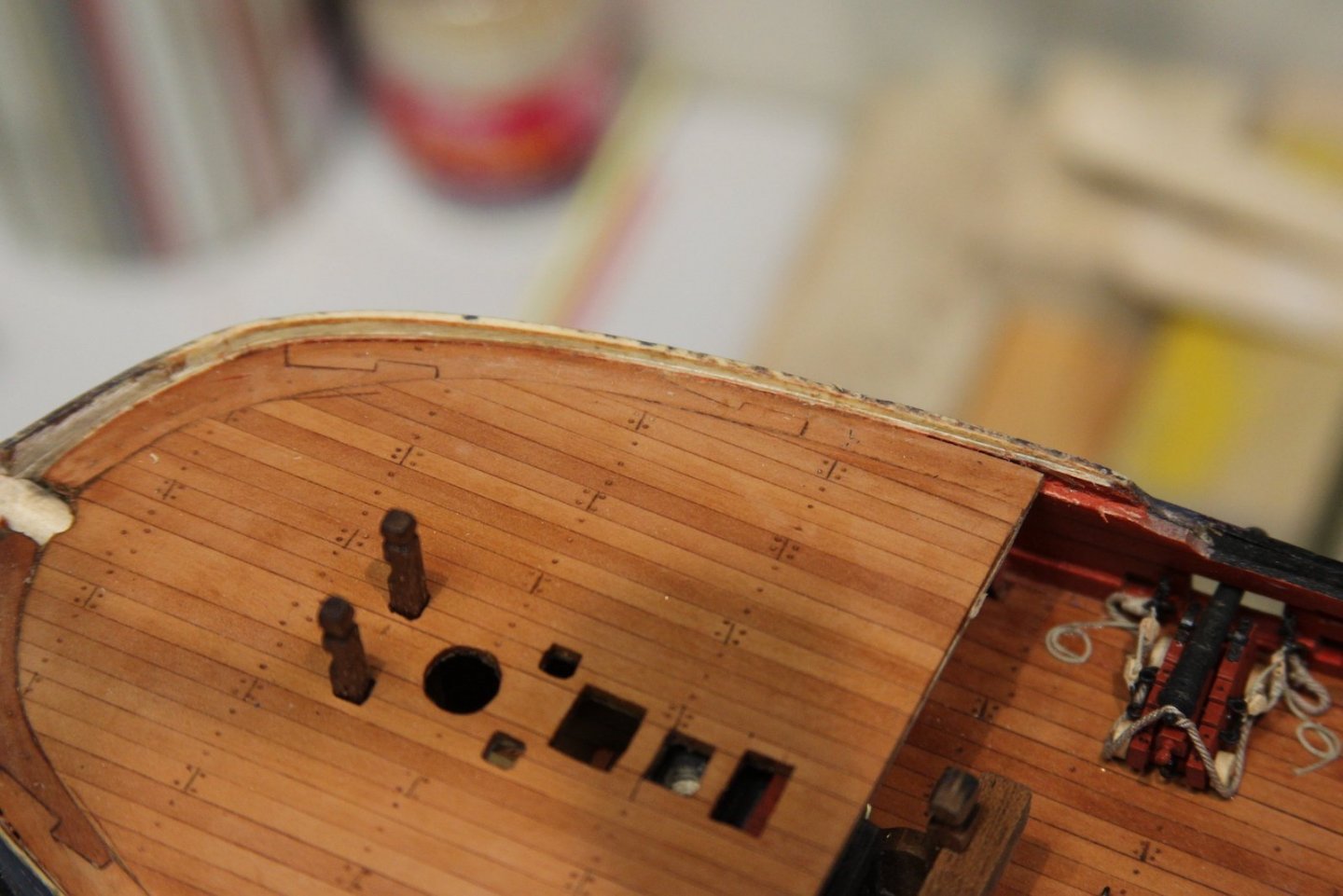

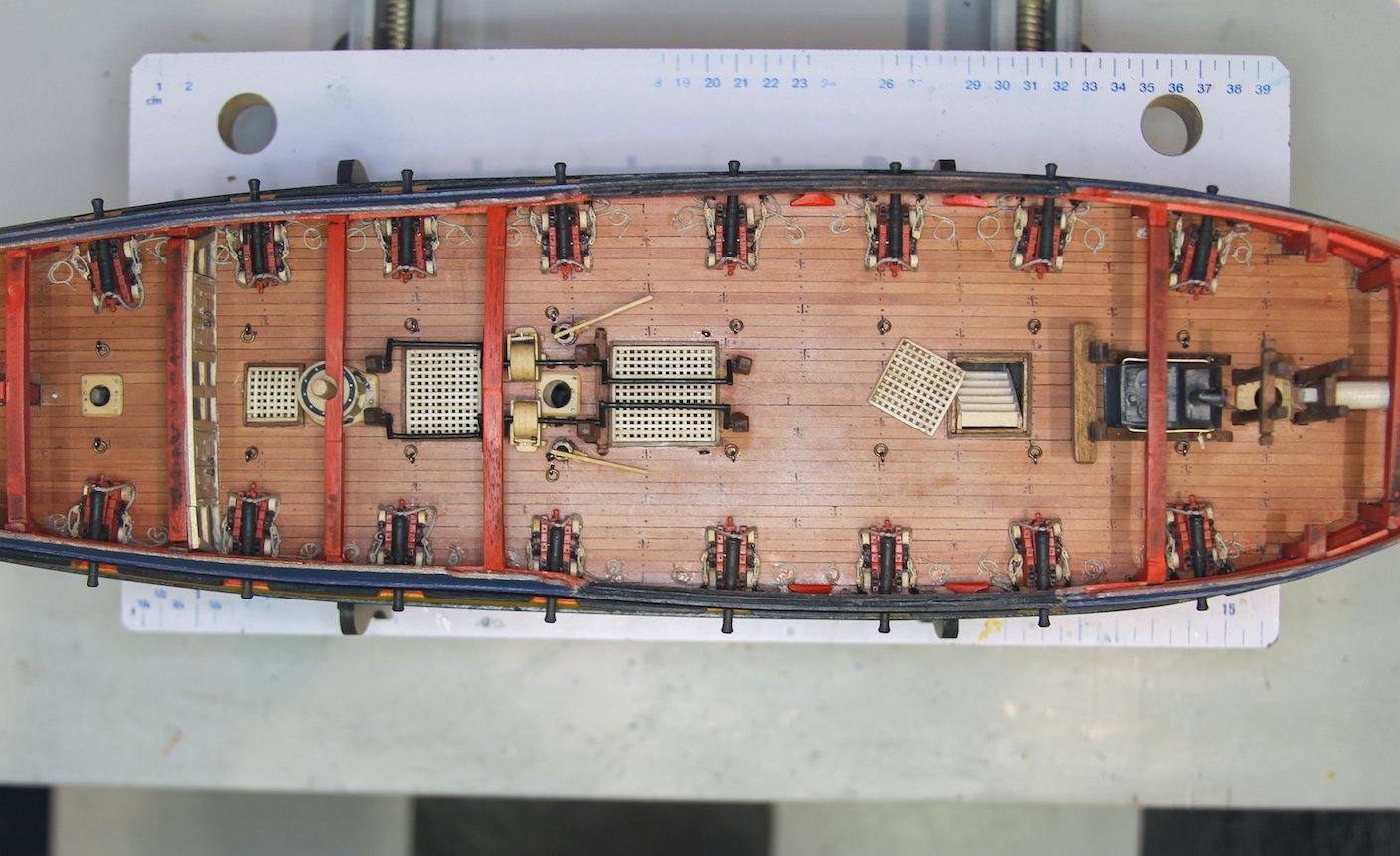

Here are the results of my bulwark boosting. Added inner and outer planking, then sanded it down to provide the proper height both fore and aft. Then I sanded everything flush, and then repainted. For the bow I used one continuous plank bent all the way around rather than butting it at the bowsprit hole. Once again, this is primarily the result of using deck planking that is much thicker than supplied by the kit.

Also - an update to the aft hatchway / stair situation. Turned out to be a successful fix. You'll notice my scuttle lids are flush planking as opposed to grates. I got this idea from @Blue Ensign's build and prefer it. Partly because it's probably more likely how the scuttle lids were - but also because as I noticed with the smaller stove vent grates on the foc'sle - I can't get the grating thin enough to look the way I want. It just looks a little thick and chunky when the grates are smaller. This is all still pretty rough also, and will look much smoother once I finish sanding and give it a coat of tung oil.

- mtbediz, GrandpaPhil, gjdale and 6 others

-

9

9

-

- KARAVOKIRIS, yvesvidal, gjdale and 7 others

-

10

10

-

Nicely done Jack - I remember those little 'half cannons' from my San Juan AL kit. They're pretty handy for the lower deck guns. But I had to be sure and paint the insides of the gun ports black to make sure you couldn't tell they were nubs. Not sure that'd work if one is sticking with the natural brass though.

- Jack12477, Edwardkenway and mtaylor

-

2

2

-

1

1

-

-

-

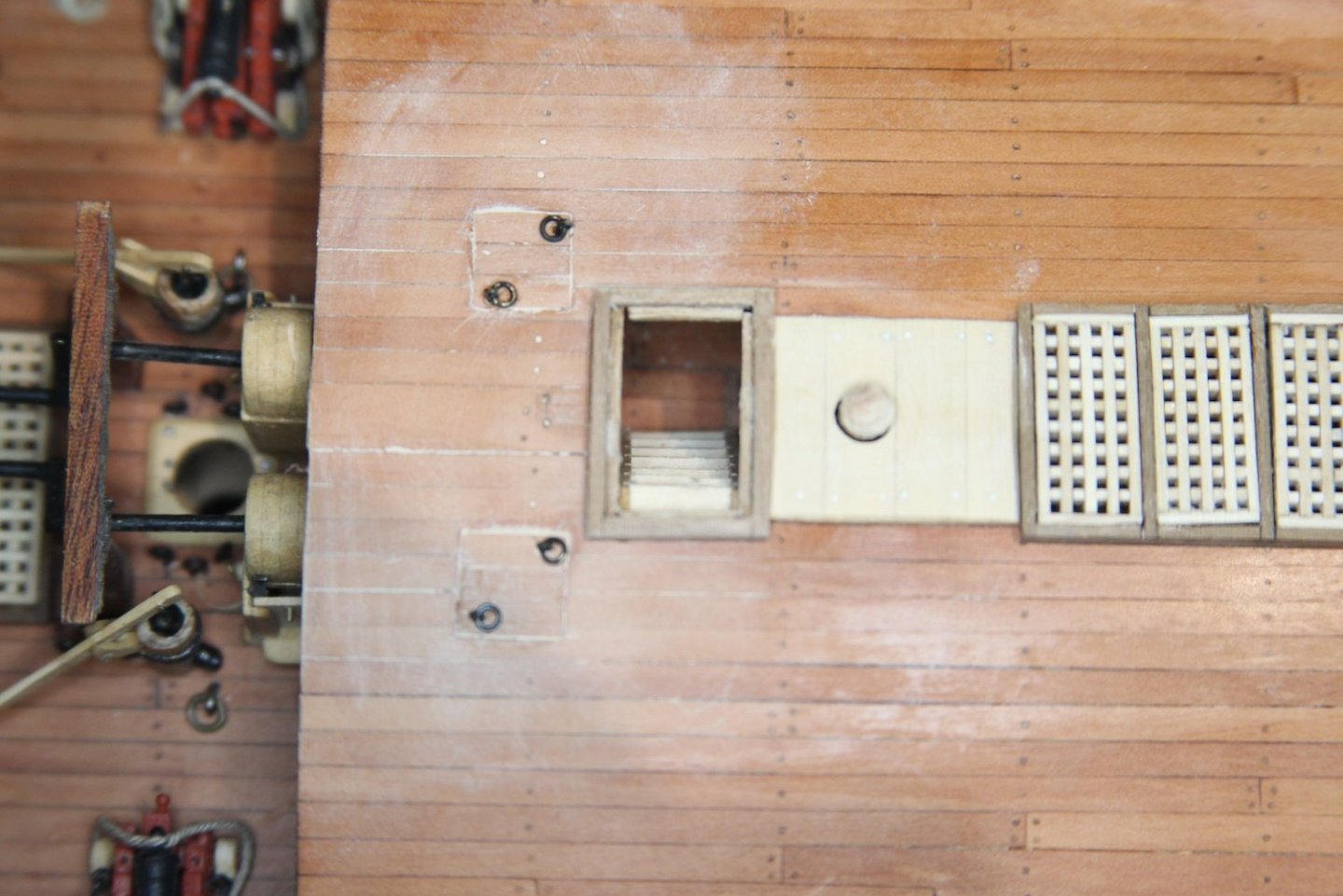

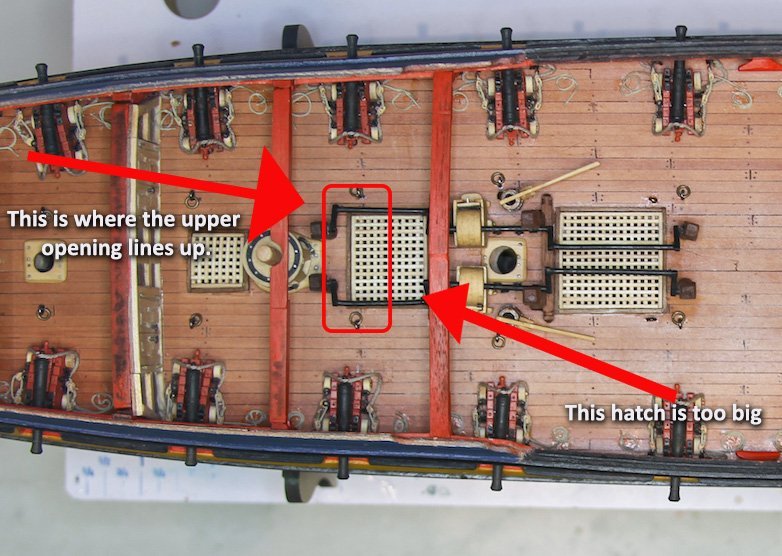

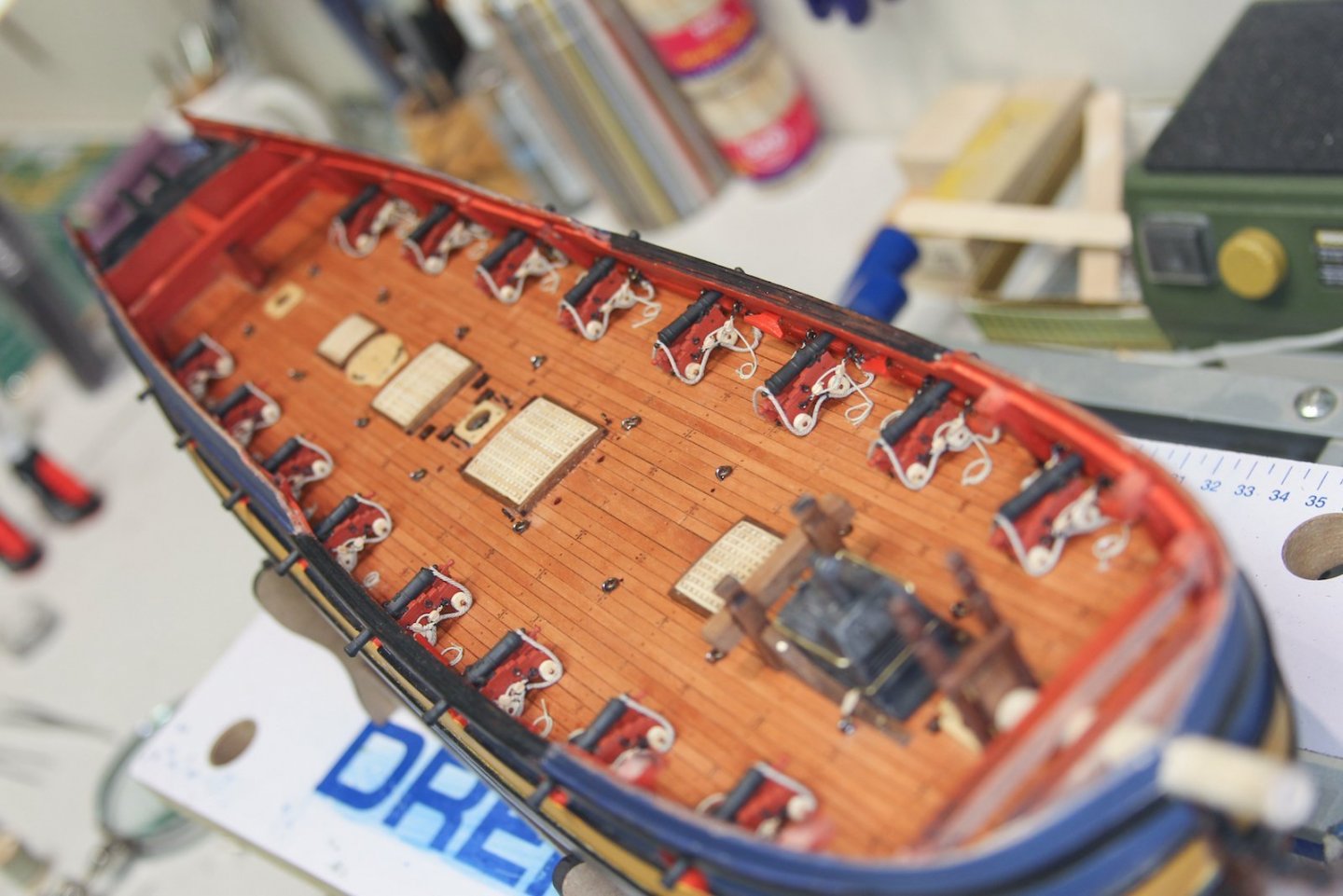

So... remember I said that I tend to do things a little unconventionally in terms of timing, etc? Well - here's the downside: I totally screwed up the spacing of deck elements because I didn't think far enough ahead - an error I discovered when I placed the upper deck in the aft of the ship. As I'm sure most of you know, there can be a pretty big downside when it comes to half following the kit plans and half following the FFM and other builds. My particular problem occurred with the pumps.

My big mistake - was following the kit template / false deck with it came to the locations of all the hatches - but then following Dan's more accurate build/locations when it came to putting in the pumps. I wish I took more 'before' pictures - but I was too irritated and just started fixing. But basically, when I test fit the upper deck in place then looked down through all the holes/hatches - the larger grate just aft of the pumps is about two times too large - so the the pump handles extending over it go RIGHT underneath the upper hatch that's supposed to be fitted with a ladder. Doh. So - even if I were able to fit a ladder in there - folks would be descending right into the pump handles. Many "potty words" were uttered as I tore up deck planks and fittings.

I reduced the size of the hatch by half, patched the deck to fill in the gap, shortened the aft pump handles and remounted them into the posts. The good news is - the view of all of this will be severely obstructed by the pumps, subsequent ladder once it's installed, and various rigging and accouterments. I may even throw in a pump dale or two to further obscure my screw up.

Once again - the reminder here (that we all already know) is - when you're doing a mish-mash of a kit bash that combines the ease and efficiency of a pre-fab kit with other added elements - you can NEVER, ever, think too far ahead.

- KARAVOKIRIS, mtbediz, yvesvidal and 9 others

-

12

12

-

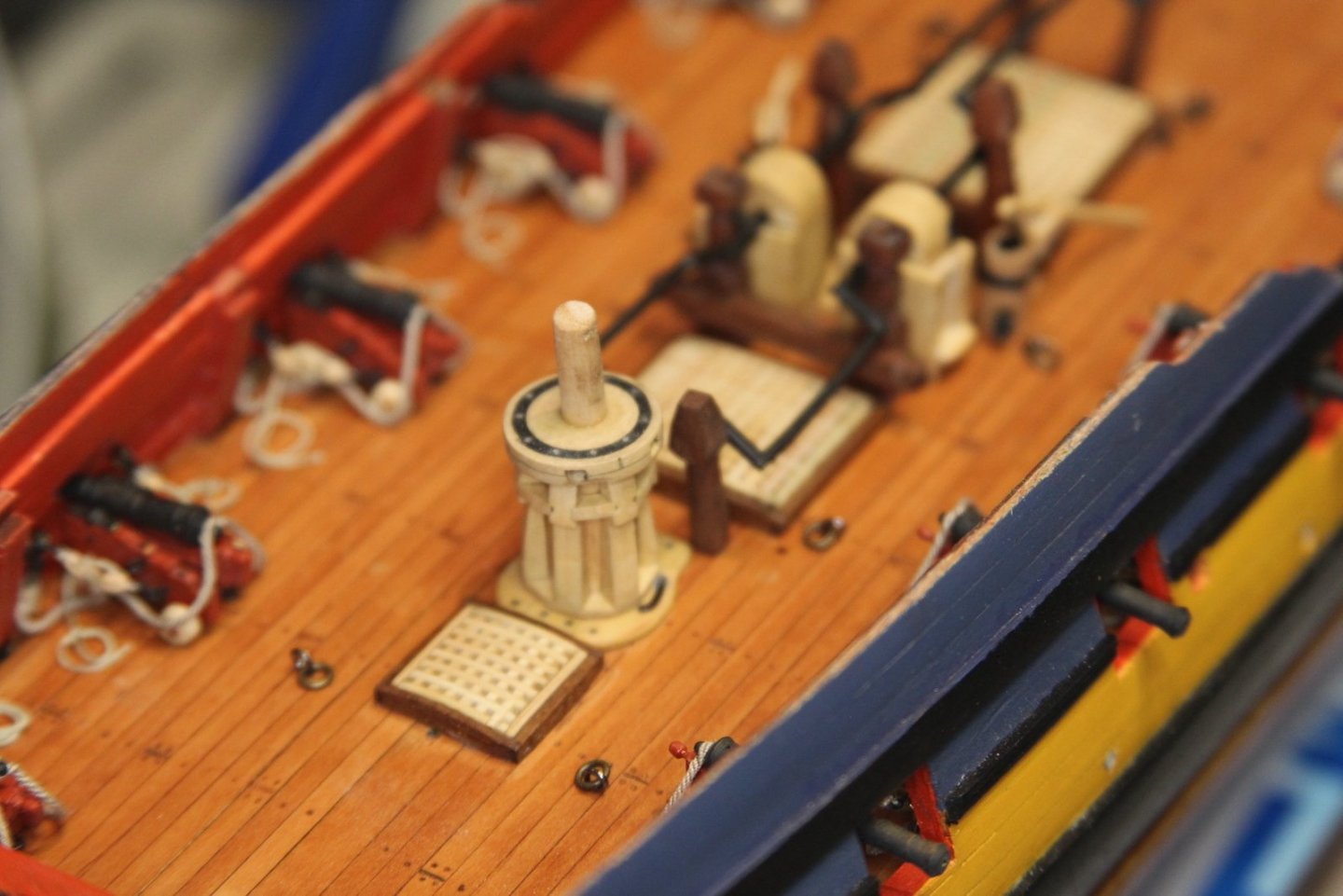

Been doing some fiddling over the holidays to get the upper decks going. First, I knocked out the gallows. I say 'knocked out' - but in reality it took a couple of efforts and a few hours to get the decorations the way I wanted them. I saw it as another opportunity to add a bit of embellishment without (hopefully) being too over the top. This is a piece of scrap mahogany.

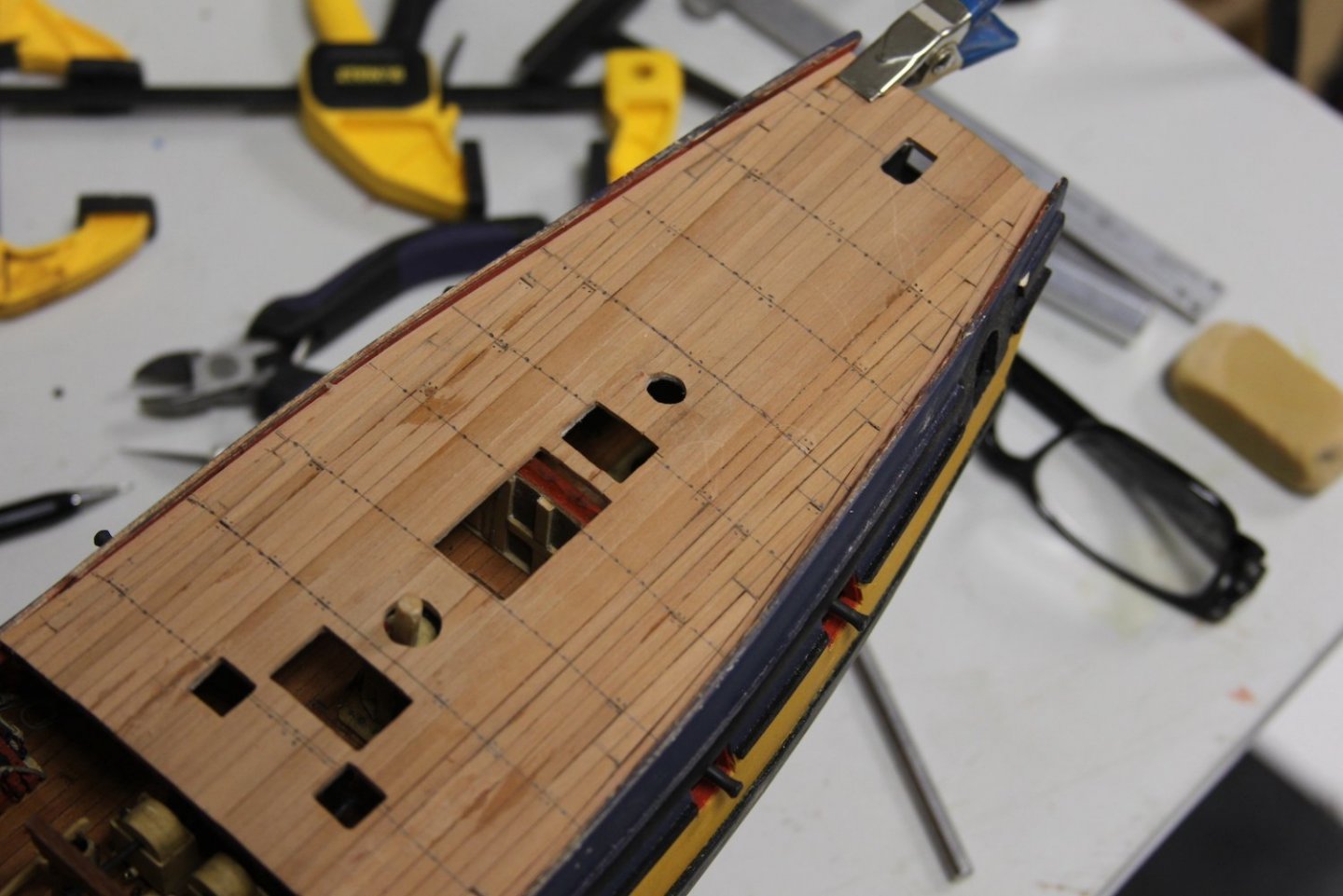

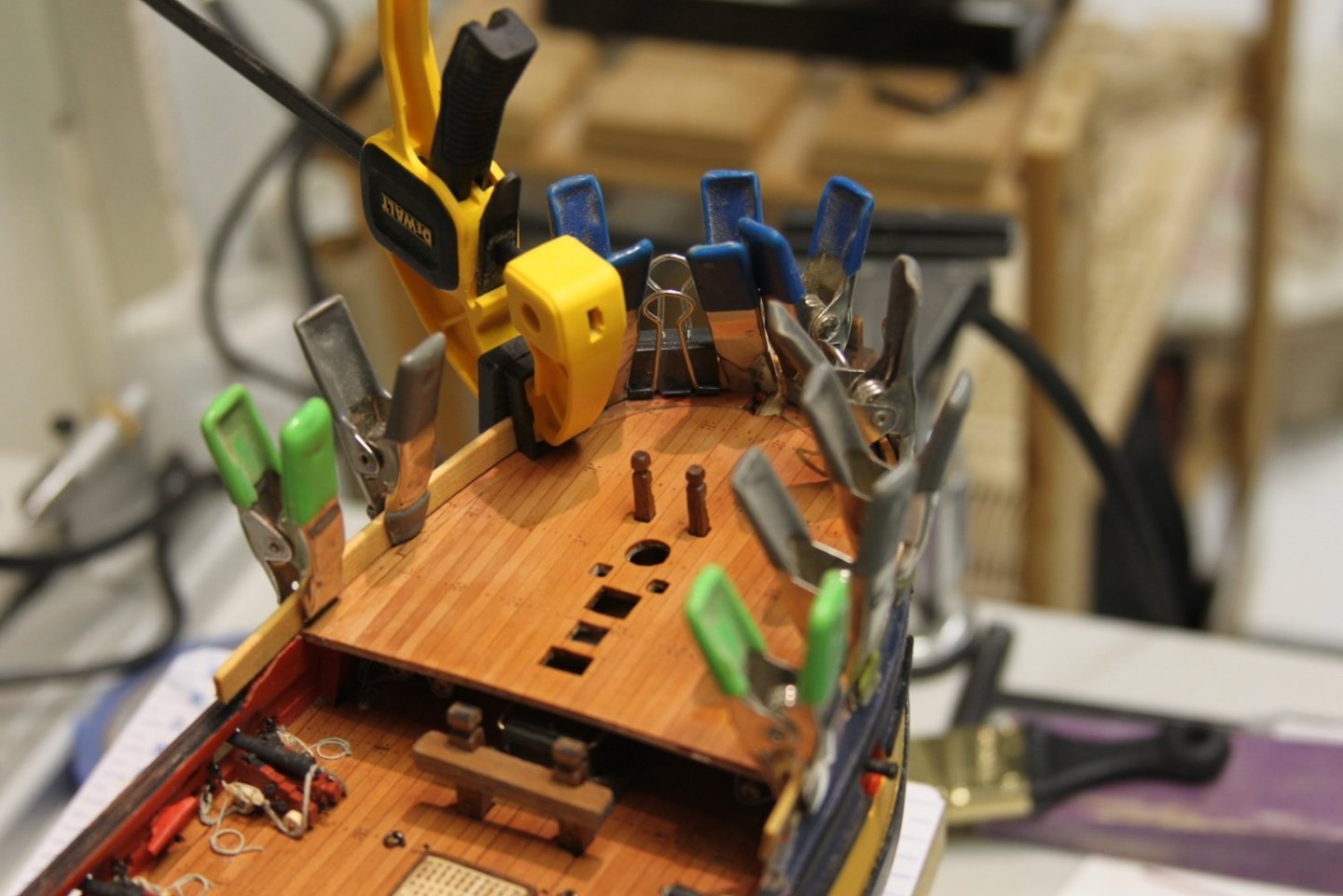

Then I started work on the foredeck. As most of you know - I tend to do things in some unconventional ways and sometimes in unconventional order. In this case, I decided to try and 'pre-plank' the fore deck before I mounted on the ship. My thinking here is that I wanted to drill the treenails with the drill press. I don't have quite as stead a hand as I used to, and although my lower deck treenails look ok - they're not perfectly straight. Hopefully using the drill press would achieve that.

So, I glued my planks to the false deck, and then left some room around the edge of the deck to soak and start bending a bit of Swiss Pear to fit the margin planks. Then I mounted the deck. I missed a couple pictures of measuring and drilling out the treenails, but it's your standard fair - filled in with diluted PVA and sawdust.

The margin plank was fitted by using some card stock as templates, then cutting out and puzzling together the pieces. Obviously this is a bit tedious and requires cutting and sanding at little bit at a time until they fit together snug. After lots of test fitting, I glued/fitted the margin plank together first, then put it in place.

One thing to bear in mind if you're using anything other than the stock planking strips from this (or really any) kit. The Swiss Pear is considerably thicker than the thin planking strips provided. Even after sanding the heck out of it, it's still at least double or triple the size. So I'll need to beef up the foc'sle bulwark inner planking a bit to make up for that.

- AJohnson, mtaylor, shipcarpenter and 5 others

-

8

8

-

Love these old school paint combinations!

- mtaylor, thibaultron, Edwardkenway and 4 others

-

7

7

-

Hi All - I too have had this problem. For what it's worth, I took the photos that failed to load, put them in Photoshop and re-exported them as .jpgs. Similar to BE and Glenn's "twin" technique. I didn't realize this was a site wide problem and thought perhaps it was an issue with my formatting - I mostly use a pretty high end Canon EOS 1D Mark IV.

- Keith Black, mtaylor and Canute

-

3

3

-

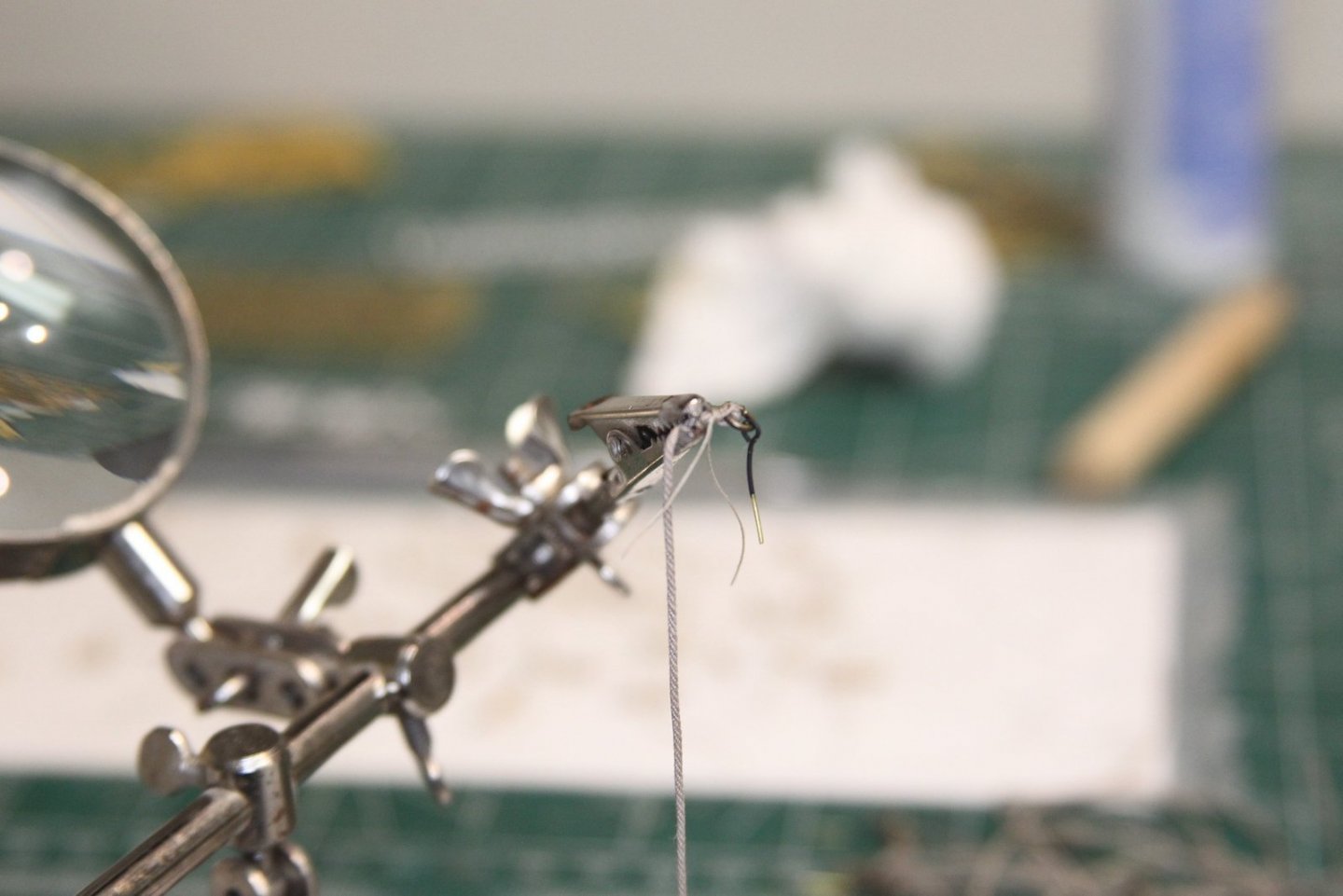

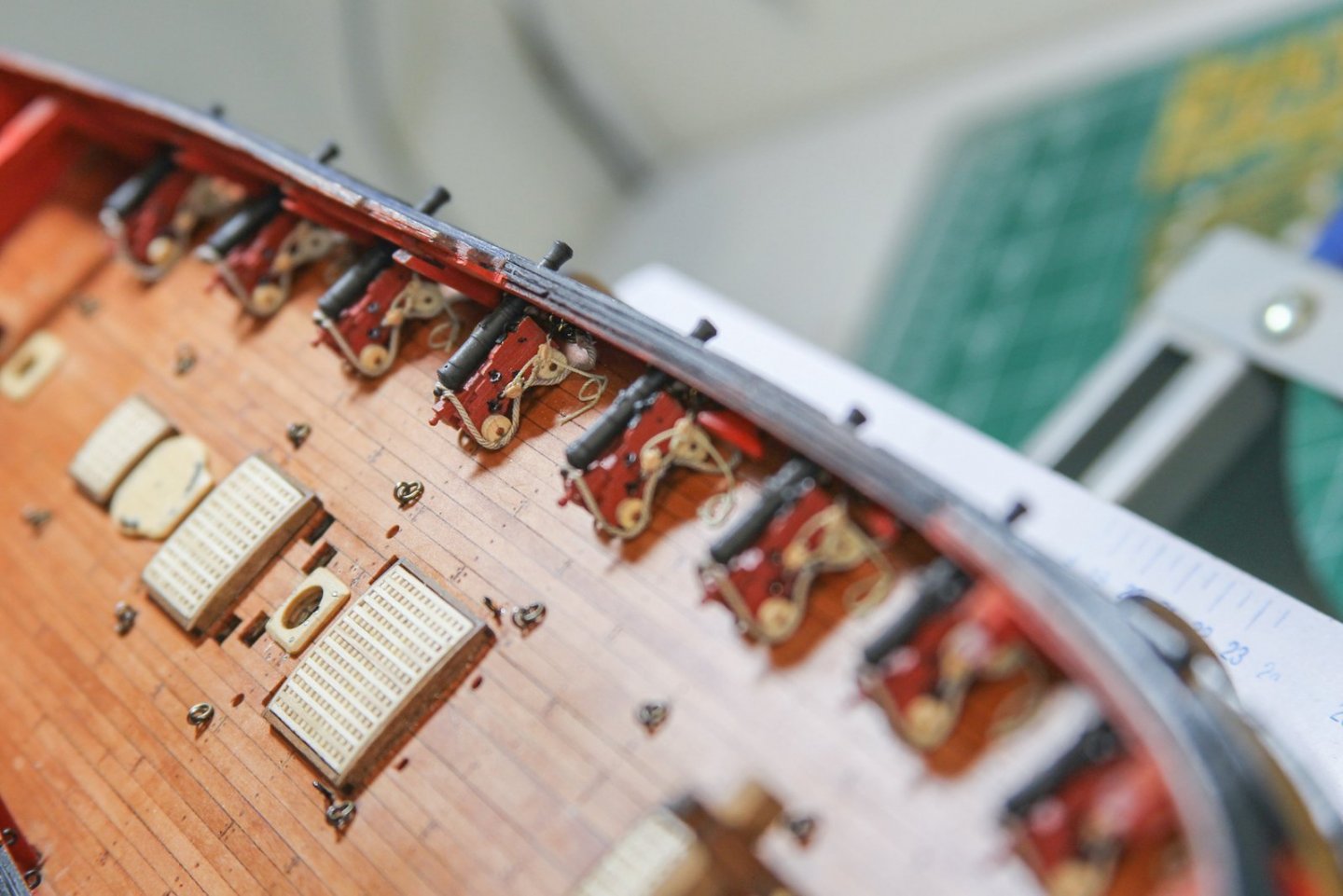

I've been plugging away at the cannon rigging. Everyone has their little methods / jigs, etc, for getting the tackle together, so here's mine. I went through and attached one end of the breech rope to an eyebolt and ring, fed it through the rings on the carriage, then clipped it in the soldering holder to tie up the loose end and clip off the extra bits. I briefly flirted with the idea of feeding it through the carriage bolts/rings, then attaching the entire thing to the carriage - but in a weird way, this actually helped me keep a good measure on the lengths, etc.

I also opted for the "feed the button into the rope" method as opposed to the wrap the breech around the button - even though the latter is more accurate. It just looks SO bulky to me that I don't care for it. After the guns were rigged, I went through and tried to touch up any blackened/painted areas that got scrapped off; a pretty tough gig. I've tried a variety of types of paints and other methods of fixident, but still have a heck of a time getting the black to stay on eyebolts and rings.

You'll also notice that I went with all 16 guns rather than the 14 the Peg calls for. What can I say, I like a full compliment. Getting the guns in place then allowed me to add the lower deck fittings that I had completed up until this point.

- Beef Wellington, gjdale, AJohnson and 10 others

-

13

13

-

HMS Pegasus 1776 by Moonbug - Amati/Victory Models - 1:64

in - Kit build logs for subjects built from 1751 - 1800

Posted · Edited by Moonbug

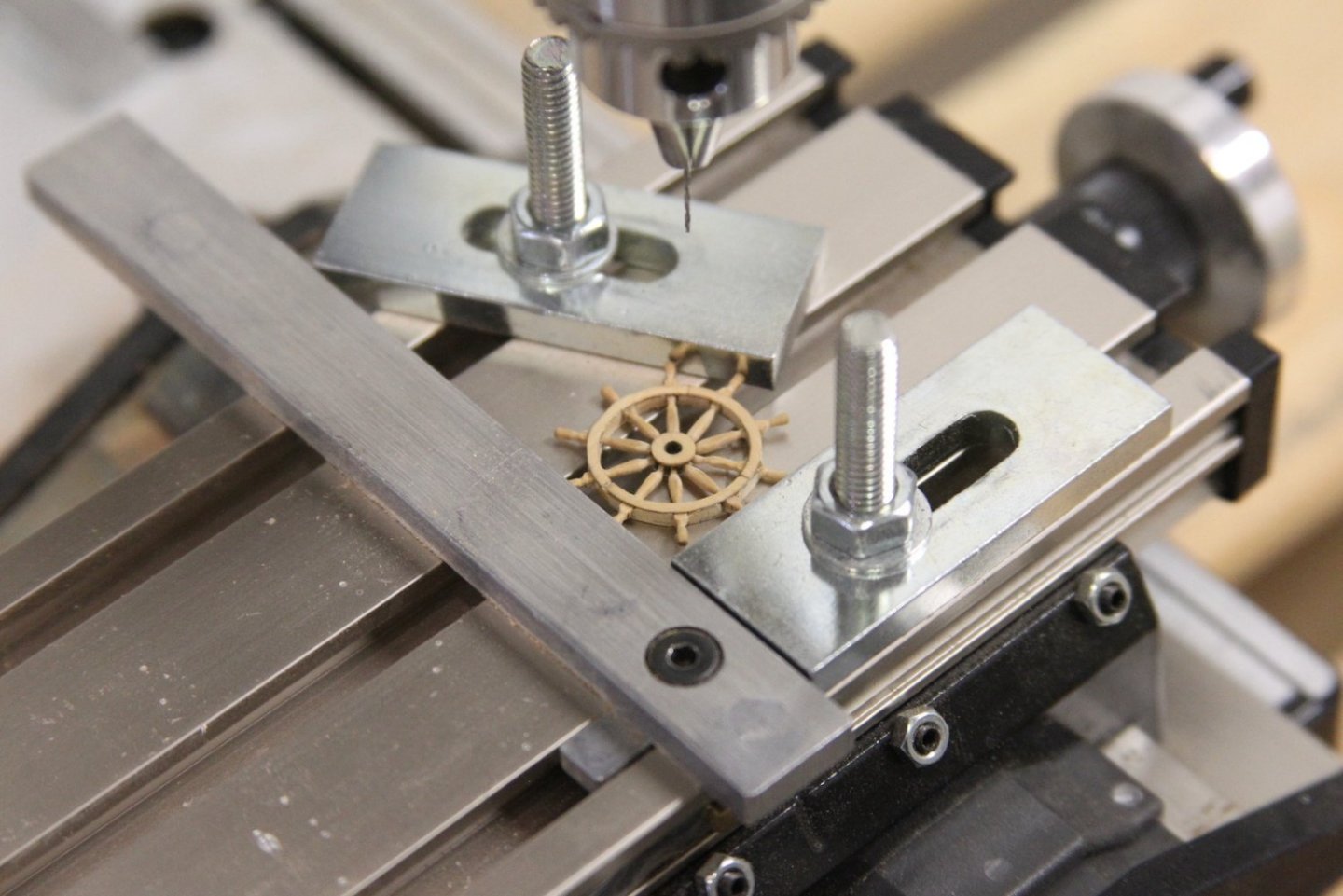

Thanks everyone for the comments. Glenn - They came as an addition option along with the "X-Y Table Attachment" when I ordered the drill press from Mico-Mark. They're pretty darn handy.

Hey Dave - I wish I had a better answer than this, but - I get bored. Hull planking is super challenging and tedious for me, and I much prefer doing deck work and fixtures. So I basically bounce back and forth between the two to keep me occupied. Especially since when I plank, I soak and shape the planks against the hull to let them dry (as opposed to using a bender or heat source). The deck work gives me something to do while I'm waiting for hull planks to dry.

I agree Mike - Chuck does a great job and the boxwood lets you work with it a bit to shape it the way you want. He has two different scales - one that's pretty dead on for 1/64 and a slightly larger one that I haven't seen in person yet. The only challenge for me is getting the laser-cut char off without reshaping it too much in the process.