-

Posts

7,990 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Louie da fly

-

Beautiful work, Chris. That shape is much rounder than I'd ever thought - very suitable for carrying cargo. Steven

- 179 replies

-

- shipyard

- wütender hund

-

(and 1 more)

Tagged with:

-

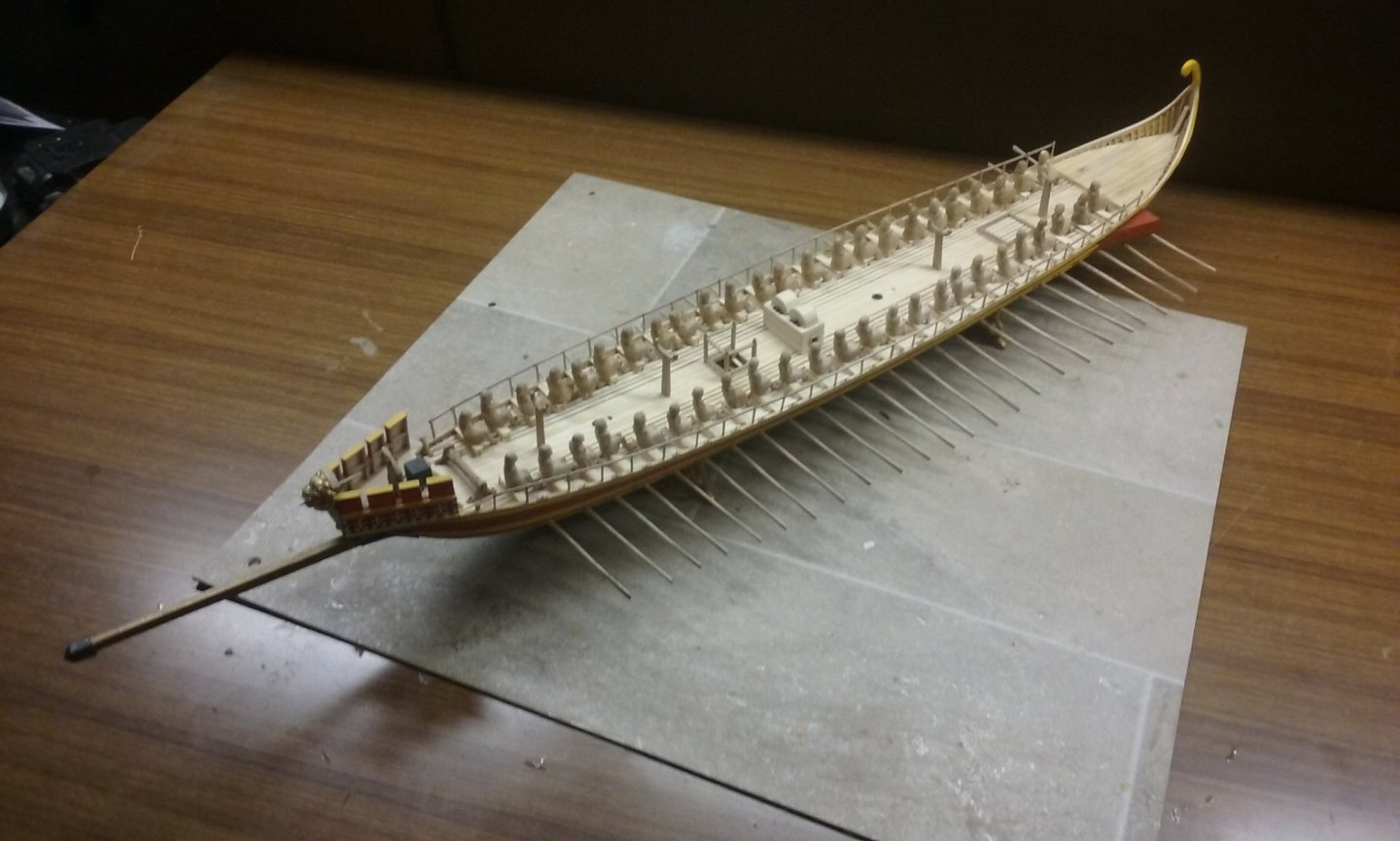

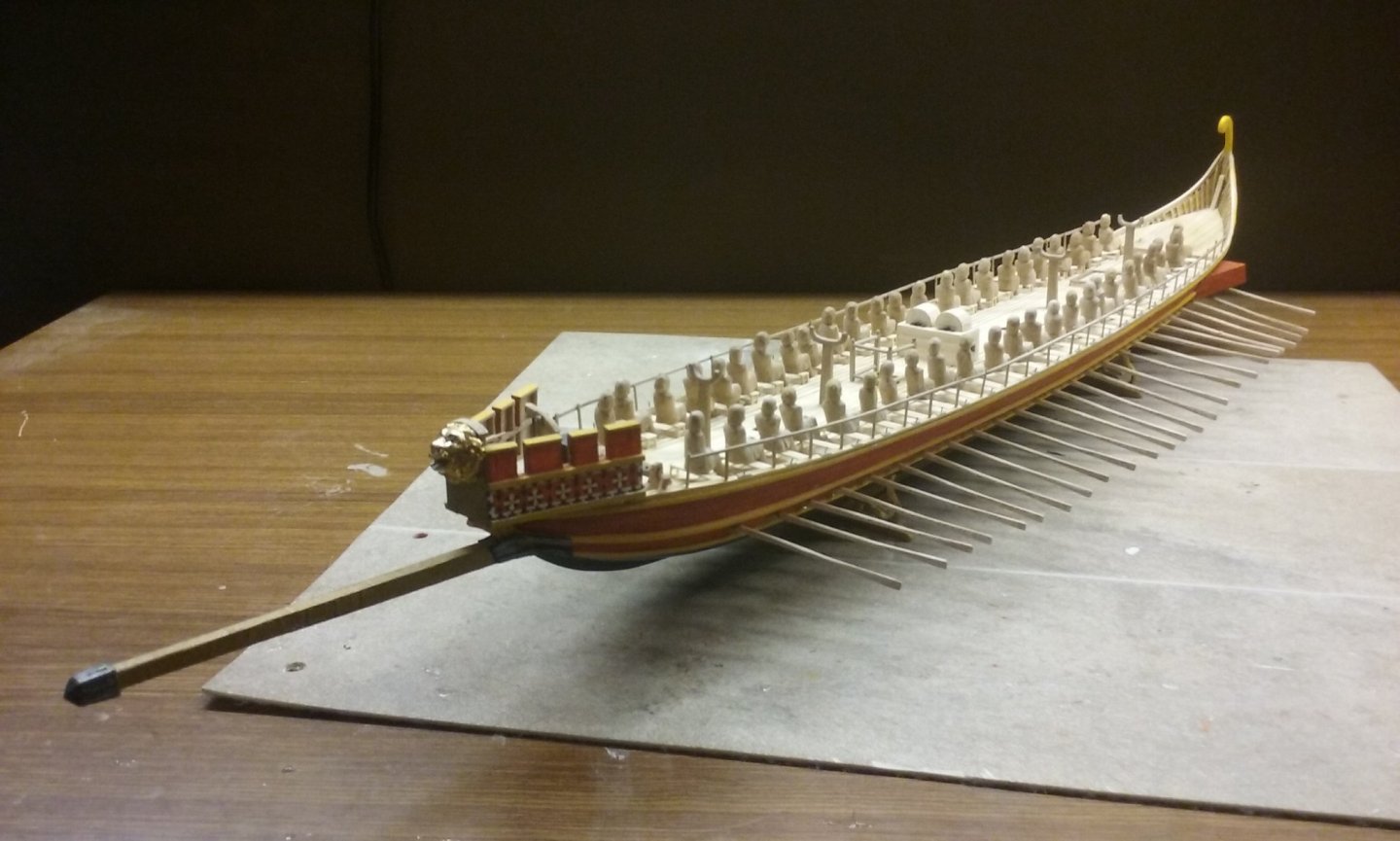

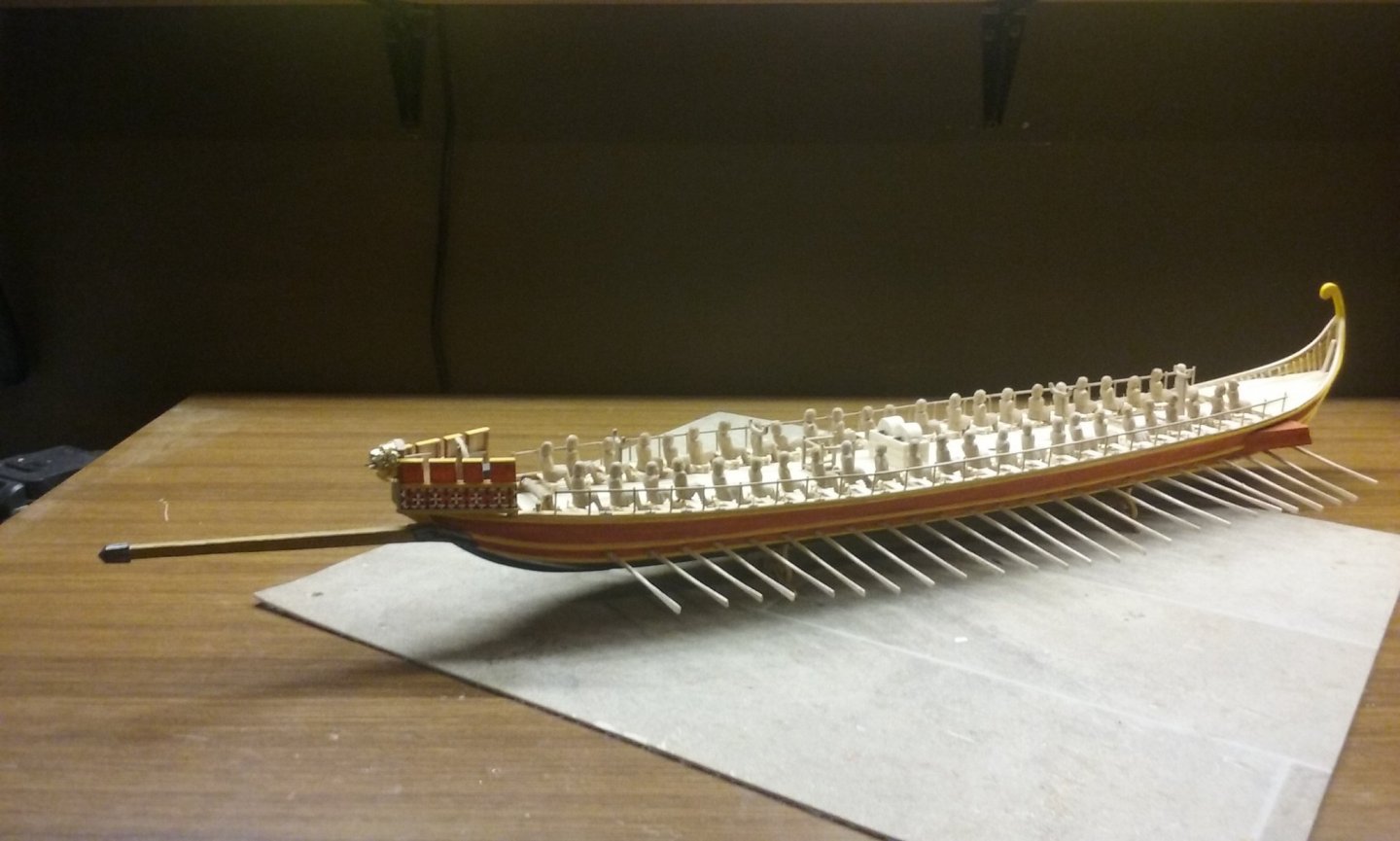

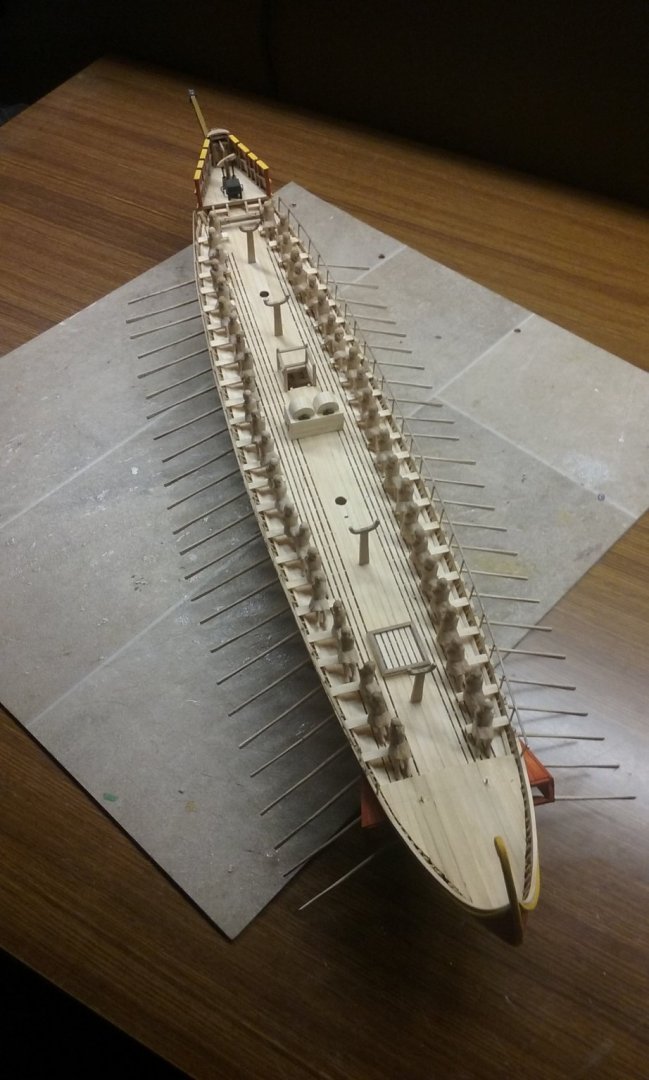

Oh, and you might like to put up some of your painted figures in the "Shore Leave" section of "The Crew's Lounge" (bottom of the Home Page), under "Non-ship/categorised builds." I for one am very interested in methods for painting human figures, particularly on getting the faces right. I have 48 oarsmen I have to paint for my dromon, and they're pretty close in size to your figures. Steven

-

Good to see this build log starting, Boxbuilds. I discovered the person I thought was a part-time volunteer at the Powerhouse Museum in Sydney, where there's an almost identical model, was actually at the Maritime Museum, quite a distance away. I've sent a message to a friend of mine who I think used to be employed by the Powerhouse, but that was quite a few years ago. I'm waiting on an answer. Might be of use - I'll just have to wait to find out. I'm looking forward to seeing your progress on this build. If there's any help I can give, please let me know. Steven

- 71 replies

-

- great harry

- henry grace a dieu

-

(and 3 more)

Tagged with:

-

Yes, Oskar24, disregard our lame attempts at humour. Maritime terminology is a whole new world and it takes a while to get your head around it, but bit by bit it does come. There are quite a few good dictionaries of maritime terms online - I rather like this one - https://www.oxfordhandbooks.com/view/10.1093/oxfordhb/9780199336005.001.0001/oxfordhb-9780199336005-e-48 - but of course (particularly when you're just starting out) you will look up a word and the definition contains new words you also have to look up. But persevere, it does get easier. And ask as many questions as you want. The people here are very helpful and will often give you better ways of doing something that save you a lot of time and trouble. Steven

-

By hand. I think a slip with a power tool could be disastrous. Takes awhile, but much less time than doing the carving. Steven

-

Not quite sure what that means - not even sure I want to know . . . Well the hands will be able to recover now. Oh, and to clarify, it's not that I kept cutting myself as I carved (though that does happen occasionally), but the heel of the left thumb gets painful, almost as though it's been bruised (it hasn't). Probably just holding the hand in a position it's not meant to be in for long periods as I hold the figures to be carved. Steven PS: I'm onto sanding the figures now - a little more than half way through.

-

We have a flute player The others may take some time . . . I feel like resting on my laurels for a while . . . Steven

-

Pat, I was in the sea scouts when I was a kid but I still haven't mastered how to tie a bowline, let alone a sheepshank or sheet bend. I can do a reef knot, and a round turn and two half hitches . . . but I always had trouble with getting my head around knots. Now onto other things. A real milestone - I've finally carved the last of my oarsmen! But wait! (I hear you cry) they still need to be smoothed off and they don't even have arms yet. Crikey, you're a cruel bunch . . . Steven

-

By the way, at the risk of derailing the thread somewhat, I take it you're familair with the 1956 movie "Battle of the River Plate"? If not, much of it's available on Youtube, particularly the battle scenes. Steven

-

HDFC - I like it. I'll have to use that term from now on. (Thus speaks the man who, after the Battle of Hastings re-enactment of 2000 AD was known as H2K (Hastings 2000) - for the 2006 re-enactment coined the term TNBO -The Next Big One - which became the shorthand for the event among the re-enactment community. Of such things is immortality made). Steven

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

Welcome to the Dark Side, Chuck. I have to say I found the comments about the WH's forecastle interesting - they relate directly to a discussion at Maybe I need to re-evaluate some of my thoughts on this. If some cogs were indeed purpose-built as warships, the fact that some cogs had forecastles and "fortified" aftercastles while others didn't might be significant. And I'll be re-looking at some other contemporary pics from the 15th century with ships lacking a forecastle - perhaps purely merchant ships? Steven

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

Very nice work, Chuck. I'm enjoying following this build. Steven

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

Wonderful job, Eric. A result to be proud of. Steven

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Neither could I. It just might be missing - accounting for the titles every so often. Steven

-

I just came across this video with quite a bit of original footage of the Graf Spee: It might have some worthwhile information in it to helpyou with your build (sorry about the intrusive watermark). Steven

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.