-

Posts

9,719 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

Wow...you made it home pretty quick. It was a pleasure to meet you in person Mike. Thanks for the kind words.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You are referring to the rudder port?.......No special technique really. I will just drill a pilot hole as large as my preferred needle file. Then I will slowly enlarge it to shape. Its interseting to note that the stern post should have extended through the counter as well. I designed it so another small piece will be glued inboard to fake it. No one will ever know. In fact it will look like you have the tightest planking joints around the stern post to allow it to pass through so nicely. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

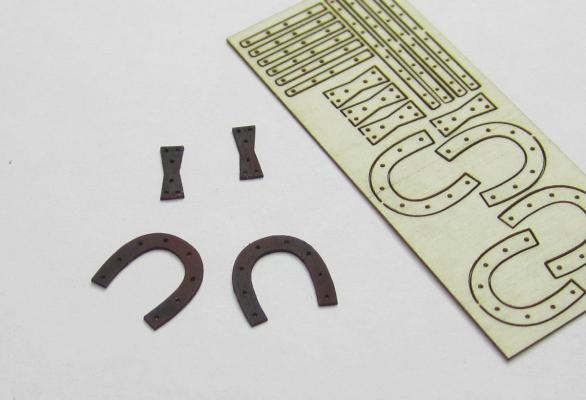

Yes indeed!! This will be used for the port lid hinges as well. I may add them this week just to see how they work. But it will be a while before I add them to the store. I want to include a few other elements like the gudgeons and pintles. Thats a little ways off yet. Sort of a metal-works package. Most of it anyway. But there will be some brass used where extra strength is needed. That wont be included with this. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

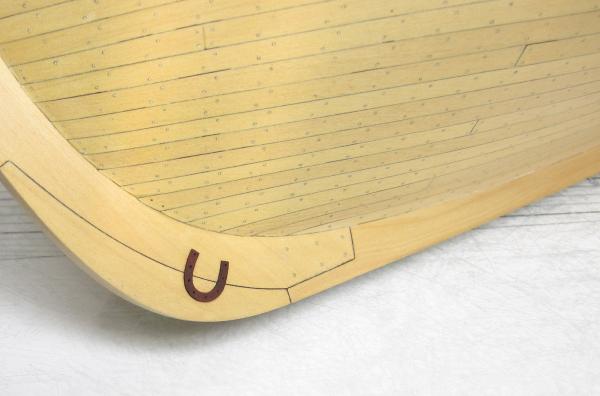

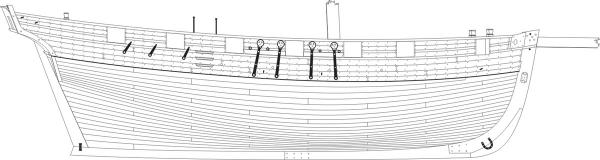

The port side is done and treenailed. I also made the horse shoe plates for the stem and keel plate at the stern. These were laser cut from laserboard. I painted and glued them on. They have little holes cut through them as you can see. The beauty of that is after gluing them with yellow glue and placing them on the model....a little bit of glue seeps through the holes and forms a nail head. But if you dont want to do that, you can drill through the holes with a #78 bit and insert some 28 gauge wire as bolt heads. ....Or just leave it as is. I will be drilling and inserting the wire as bolt heads later on. Also all of the fancy molding is in position that I want to add at this point. Now its time to thin down the bulwarks inboard. FUN ....FUN!!! Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

For those of you who have never seen a complete issue of the Journal.....and if you are considering joining as a full member of the NRG; Click Here to go to the page that talks about the Journal. You will get four issues per year with your full membership. At the bottom of the page I have provided a link so that you can download an entire issue to check it out. See what you are missing!!!

-

Constellation hammock cranes and color scheme.

Chuck replied to Jparsley's topic in Nautical/Naval History

Im moving this topic...be sure to read "how to start a build log" . Since this doesnt constitute a build log I will change the the title to name it properly and move it to the nautical research forum. Be sure to post in the appropriate forums and read the pinned topics for any and all info on what each forum is about. This is really important when posting on the site. Thanks Chuck ADMIN -

John That is looking lovely. Wonderful planking job.

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Just finished planking the port side. I added the stern post. Now to treenail the port side and add the molding... It feels good to have it all planked. It will feel even better when the treenailing is done. I was getting tired of seeing the hull without its stern post. I think it really makes a difference at this point. At least from the starboard side.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

here are some examples....on contemporary models.

-

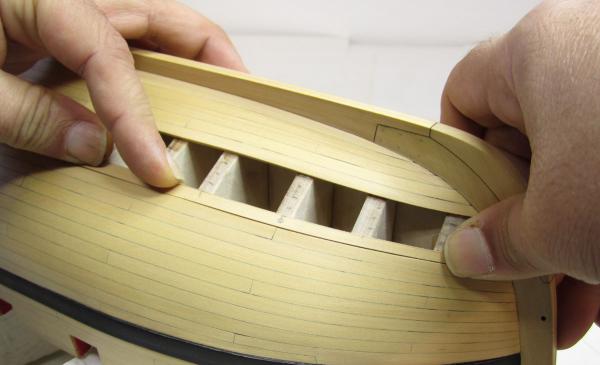

I sand a little bit after every four or five planks. Then I apply one coat of wipe-on-poly. It helps to keep it clean with the wipe on poly. Then after the entire side is planked....its sanded down and finished again. Then once again after treenailing.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Lou, Basically I just sand the heck out of it to remove any CA that may have absorbed into the wood. Using Boxwood is also an advantage as its dense. The glue doesnt absorb very deep at all. So I am not afraid to sand the hull very smooth and thin down the planking. Typical planking is not a scale 3" thick. In fact, the topside planking above the wales on Cheerful was only 1.5" thick. Its actually noted on the planking draft. So using 1/16" thick strips is way out of scale. This is why I actually used 3/64" thick strips and then sanded them down considerably after I was done which thinned them down to about 1/32" or so. This way you get to the nice clean wood that is blemish-free. FYI....The wales were 4" thick and the bottom planking under the wales was 2.25" thick as noted on the original planking expansion. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by Maury S - 1:48 - POB

Chuck replied to Maury S's topic in - Build logs for subjects built 1801 - 1850

Im not sure I understand the question. The uprights are straight up and down....no angles. They are not square to the keel per say because the keel isnt straight. The keel is bent up at the stern which is a typical feature with a rockered keel. So to better explain....they are all parallel to the bulkheads and straight up and down. That is an easier reference. Just follow the plan. As you can see....they will be perfectly straight and even with each bulkhead and even the edge of the paper for the plan. -

Cutter Cheerful 1806 by Maury S - 1:48 - POB

Chuck replied to Maury S's topic in - Build logs for subjects built 1801 - 1850

Good question....Its mid ship. So dont measure up from there to find the height of the port sill. You would be best to measure 1/8" up from your bulkhead (top of deck after planking) and that will be the top of the deck. The false deck is 1/16" and then teh planking is another 1/16" even though I will go with a slightly thinner plank. The top of the port sills is 1/2" from the top of the bulkhead (deck at side). So if your batten doesnt lay across your bulkheads smoothly, it probably means one bulkhead is too high or to low. Especially after you measure that distance up from the top of the bulkhead to the sill. The top of the bulkheads will be faired later so basically.....dont over analize it. Just run the port sill batten so its smooth. Then check that the deck (Top of bulkheads) will be 1/2" below that. If not....the top of the bulkhead for the deck will need to be either sanded down or built up slightly. Chuck -

Medium CA.......Just a drop on each bulkhead. I only glued two at a time and worked my way across the hull. Chuck

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by Maury S - 1:48 - POB

Chuck replied to Maury S's topic in - Build logs for subjects built 1801 - 1850

It looks fine Maury....Another way to get an idea would be to measure from the deck to the batten. It is pretty consistent back there. But most important...make it the same port to starboard. -

Yupp it was included. Just like the original draft I posted. But I knew they were all 3/16" planks at the center of the hull so it wouldnt effect that. So adding them before lining out made it easier to visualize the eight remaining planks in the first belt.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Everything below the wale, I did include the garboard......... I actually have a second planking draft that is slightly different and shows 21....this one is just more clear to post, not to confuse the situation. There are also two deck plans. All original but with slight differences. The important thing to note however is that they are identical in showing no steelers and the one drop plank. When I started planking, I had two versions of my own plans ready to go....I found that after doing the math, the 20 strake scheme was a perfect match to fit 3/16" wide planks mid ship in two belts. Once the hull was lined off and I divided into two belts, below. Each ten plank belt divided up into perfect 3/16" wide strakes at the center bulkhead. The break at the square tuck divided the hull perfectly with ten strakes in each belt. Whereas the one that showed 21 strakes would need a funky smaller fraction. Its a lot easier to rip 3/16" wide planks and its a standard wood thickness to buy, so I went with that one. As a side note....I added the drop plank and the first two strakes in the first belt before I lined off the hull. It just made it easier to do the lining off. Thats why you can see them in the picture while I lined out the hull.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Jan wrote: has nothing to do with actual "real world" planking techniques. In the real world there are no planks wide enough to allow for the amount of spiling required in his method. Of course, Chucks models look absolutely great, but in my eyes more than perfect, where at least my - beginners - strife is for real world authenticity, I mean, whats the point of making everything above the waterline look absolutely real up to the smallest detail, while the other half the ship (the under water section) is a fiction? Jan...Not fiction at all. But I know folks say that steelers and drop planks are just fine and were used historically. That is true....but the huge number of them you see on model ships and explained as the proper way to do it in many books and instruction manuals and practicums. Its just a crutch. So whatever the method.....a hull that looks like this is not something I find attractive or even historically accurate. So I prefer to go for fewer and replicate the way its done on a similar contemporary model or shown in a contemporary draft from the same era. Its just my preference. I have no intention on picking on the fellow who planked this hull below. But its extreme steelers gone wild and if this is the way he (or you) wants to go its OK. But I find many people using them and only because they find an example where one or two were used historically, and it is just a short rationalization further to go ahead and use 5 or six or even more at the bow and as many at the stern. I disagree entirely. Its just an easy fix and a crutch. I just dont think its accurate or aesthetically pleasing. This is in terms of what we were discussing earlier. I will say this. To plank the hull like this fellow did would probably take longer and be more frustrating than it would to just give lining out a hull a chance. Cutting all of those weird shapes randomly etc. One drop plank at the bow at most...and no stealers at the stern. That is what I will always shoot for. I think its more accurate and looks better. Not that you wouldnt be able to scour the web for an example or two that is contrary to my opinion. I just think its an excuse to continue to use them willy nilly and in huge numbers rather than learn how to spile and plan a hull's planking. Again, just my opinion. And its Ok. If folks are happy with that, fine, But I just dont buy the argument that this image above is accurate in any way...even if you could find one example that might look a bit like it. I would rather not get into a lengthy debate about it either because its one of those circular debates. Its just a matter of choosing what you are willing to live with on your project...without trying to force the idea that it must be accurate because one image exists showing something maybe a little similar so...... Then they feel better about using them and wont bother trying to figure it out beyond that. I have had countless discussions on the matter actually. Its more complex than this because it depends on the country of origin, the year, the shape of the bow and hull etc. There is no one size fits all, what kind of ship......... An apple bowed whaler will certainly be planked differently than a sharper cutter or frigate built 75 years earlier and from different countries. Dutch practice vs. English practice. There is just too much to consider for a simple answer.. But I am so lucky because I have this below. Its the planking expansion...just a portion of it so I dont violate any copyright rules...and its for the Cheerful. So I am very comfortable saying its reasonably accurate and the actual ship was closely replicated. Its not fiction at all. The draft shows exactly 20 strakes below the wales. One drop plank only, no steelers. I have no idea how they would have done this in actual practice but there are plenty modeling techniques that can achieve this result. That is if its something you would have fun learning how to do.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The Garboard is almost always in the same approximate area. Once you line off the hull you will see if you have it in the wrong place. I dont have any hard and fast rule or even know if there is one. But after lining out the hull with belts I can isolate the lower belt and its not that hard to determine how many planks and if I have to move the garboard back a bit. Thats why it is so important to plan it all up front. As far as the planking fan goes...I pretty much spell out how I line off the hull and use the planking fan in this tutorial here. http://modelshipworldforum.com/resources/Framing_and_Planking/Lining%20Off%20your%20hull%20for%20planking.pdf It shows everything and also describes the Tape method for finding the curve of the plank instead of the gap method I used above. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Actually not Jan...The results are pretty accurate, and its not fiction at all. Its just the method I am using is one that is for modeling. Those contemporary models are very accurate to what the ship's really looked like. What I meant was that I have no idea how the original ship builders achieved the results. Its not really important to me. Its the end results that I am trying to replicate. Notice the crazy bending below. I am sure they started with wider planks....then they applied some crazy bending as well. but the results are the same....no crazy pie-shaped steelers. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nope...watch the video. All dry bending. Its just the heat. My guess is that you are not bending it enough.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

fortunately I havent had time to finish those last five strakes so I just took some pictures. Here is a staight plank as if I were going to place it on the hull. It could be at the bow or at the stern. Most beginners would try to force this into place and the top edge of the plank would lift off the hull and not sit flush against the bulkheads. Some fight with it using pins and clamps and it gets messy. Holding it without bending like shown reveals the gap . Note the widest point of that gap. Mark this location as the center of the gradual curve you will need. In the next picture, after bending, you can see how nice it fits and how it is flush against the bulkheads. No forcing needed. Its a perfect fit. Note the dot I marked on the plank for the apex of the curve or the widest part of the gap..You could use the compass method or the tape method to find the exact curve, but I prefer to eyeball it like this. Visually its easy to see the curve after a little practice. I always over bend slightly. Now all I have to do is bevel it a bit and darken the seem as I did in the video and glue it on.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The same thing at the stern as at the bow. Basically you hold the straight plank in place without bending it. Because the one on the hull already is curved, there will be a gap between the two. You find the widest point of that gap or the apex of the curve you will need and mark its location on the new plank. That will reference the center or top of the bend you must create. I hope that makes sense. Then you bend it as I did. Bend it a bit more to allow for spring-back.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks...I plan on doing just that. I want to do one on lining off a hull as well as the planking itself. But sadly....it will have to wait until I start another hull. Whenever that will be. I would never sell it. I would just post here on MSW.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.