-

Posts

5,185 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by michael mott

-

-

Hi Druxey, I have been thinking about it the last few days, I will see how it goes.

Joe, yes there is a lot of delay regarding medical situations that are not deemed emergency, here as well.

Michael

- FriedClams, Keith Black, druxey and 2 others

-

5

5

-

I am unable to report any progress at this time, I am still waiting to see the surgeon, I am on a wait list and about 3 weeks ago I was told it could be up to 6 months, I am doing some puttering in the workshop, mostly little things and reading, doing some jigsaw puzzles. computer work is more painful that puzzles or reading. doing some simple stuff learning to use my left hand more.

Michael

- Keith Black, WalrusGuy, Mark Pearse and 3 others

-

6

6

-

Thank you everyone for your kind and thoughtful comments.

Michael

- Keith Black, mtaylor and Mark Pearse

-

3

3

-

I really enjoy the clean brass-work details.

Michael

- FriedClams, Keith Black, mtaylor and 2 others

-

5

5

-

To everyone who is following along on this build. I am unable to do any modelwork for a while, as I am waiting to get some Carpel Tunnel surgery done on my right hand. It has been steadily getting worst over the last 6 months or so, and I finally realized that I need to get it looked at. The neuropathy report used words like severe and immediate in it. My GP has sent letters to three surgeons in hopes that we can get it seen to more quickly.

I am wearing a rigid wrist brace which is helping to keep me from sneaking into the model shop to work, which is detrimental to my future well being in my right hand.

I did have Carpel tunnel surgery in both hand a few years back.

And Rob I have not forgotten your piece of the Lightning.

regards Michael

- Jorge Diaz O, Psyi, Mark Pearse and 2 others

-

3

3

-

2

2

-

Very nicely done, it was good to hear you explaining the process this evening. It is interesting that on my full size Yawl Maria I laced the mast the same way as the gaff using the method you used for your gaff. It worked very well on my boat and never caused me any headaches while sailing.

Michael

- thibaultron and Ryland Craze

-

2

2

-

A great tutorial again Druxey, an inspiration to those of us who have a lot to learn yet on this muckin' about wiv Boat models stuff.

Congratulations on the completion.

Michael

- Ryland Craze, Keith Black, Bedford and 2 others

-

5

5

-

Well I had a meeting yesterday with my GP, he had received the report from the neuropathy tests, and used words like severe and immediate. so it looks like I will be getting surgery sooner rather than later. Doc was sending out three letters to different surgeons in hopes of speeding up the required work.

That said I was a bit surprised that it was so serious, so I will be taking a break, which won't be easy.

A good time to do some gentle tidying up. and reading and smelling the roses so to speak.

Michael

-

Just found this build Mark, funny how we miss these sometimes, A lovely piece of model-work, I was not sure about the stainless, but the effects of the soft reflection will be great. I too find the contrasts in the wood grain to be a delightful way to represent planks.

Michael

-

A very clean looking model, nice planking work.

Michael

- Ryland Craze, JpR62, vladislemm and 1 other

-

4

4

-

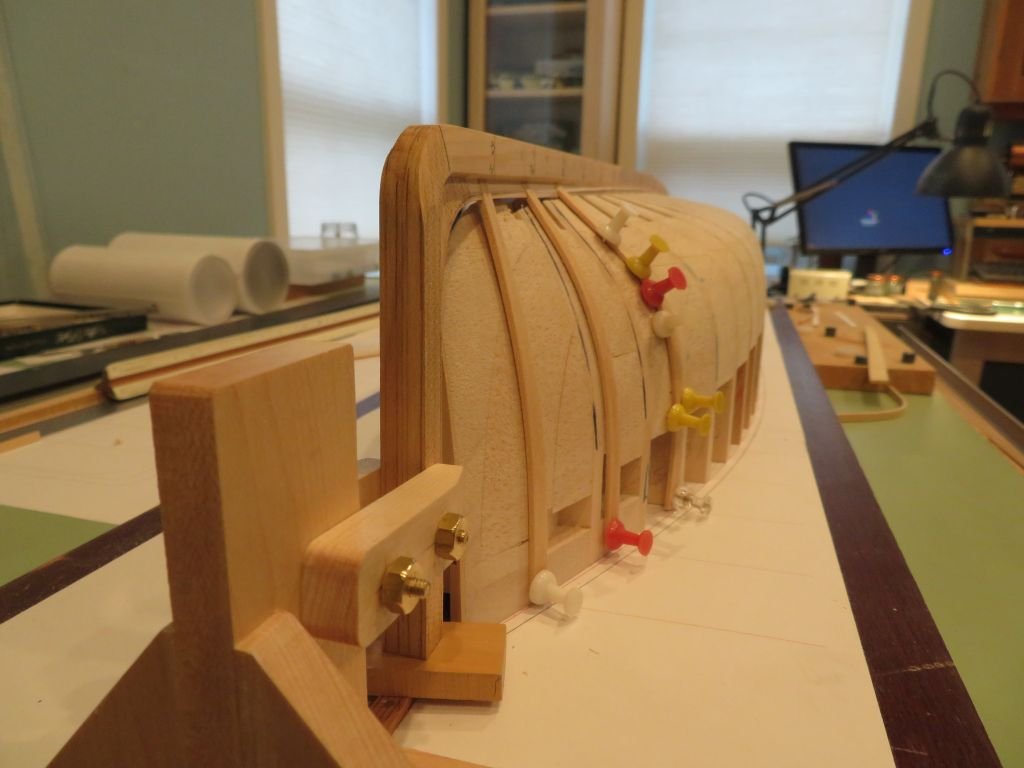

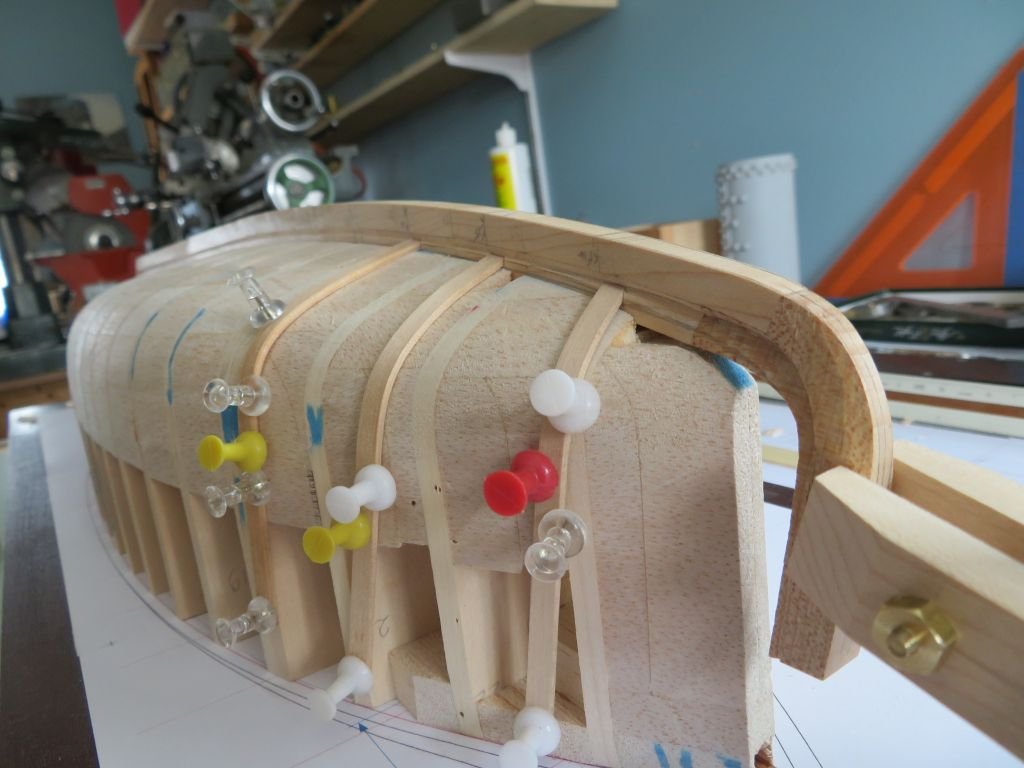

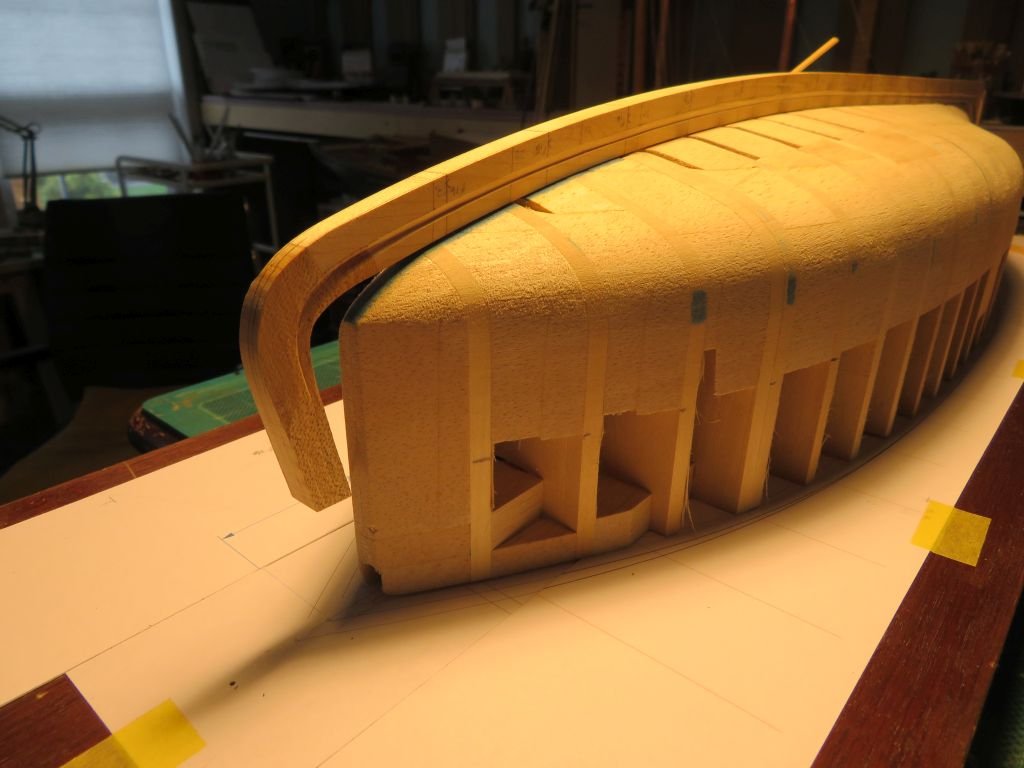

I was only going out to the workshop to do a bit of tidying up but honest! but got a little sidetracked I only worked for a hour and half.

The forward three ribs were a breeze. When I lifted the keel off the form I left the three aft ribs pinned to the form at the bottom.

when I replaced it they slotted right back in.

Then a wet and wrap in a wet paper towel and again on minute each in the microwave.

Now to relax for the rest of the evening.

Michael

- oneslim, mtaylor, Ryland Craze and 15 others

-

18

18

-

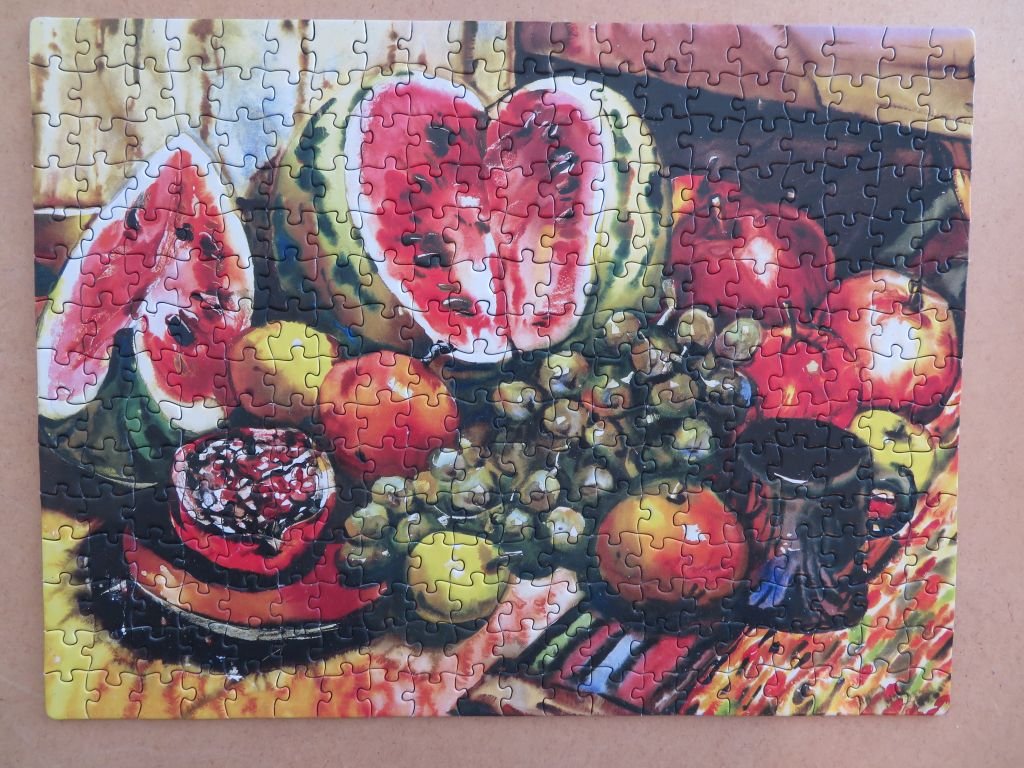

Thanks for all the concern and nice comments about the work. I took the day off today and worked on a jigsaw puzzle of some fruit in a still life.

just a small one but challenging all the same.

and sat in the garden enjoying the flowers. The wrist splint helped with the sleep.

Michael

- mtaylor, GrandpaPhil, G.L. and 8 others

-

11

11

-

-

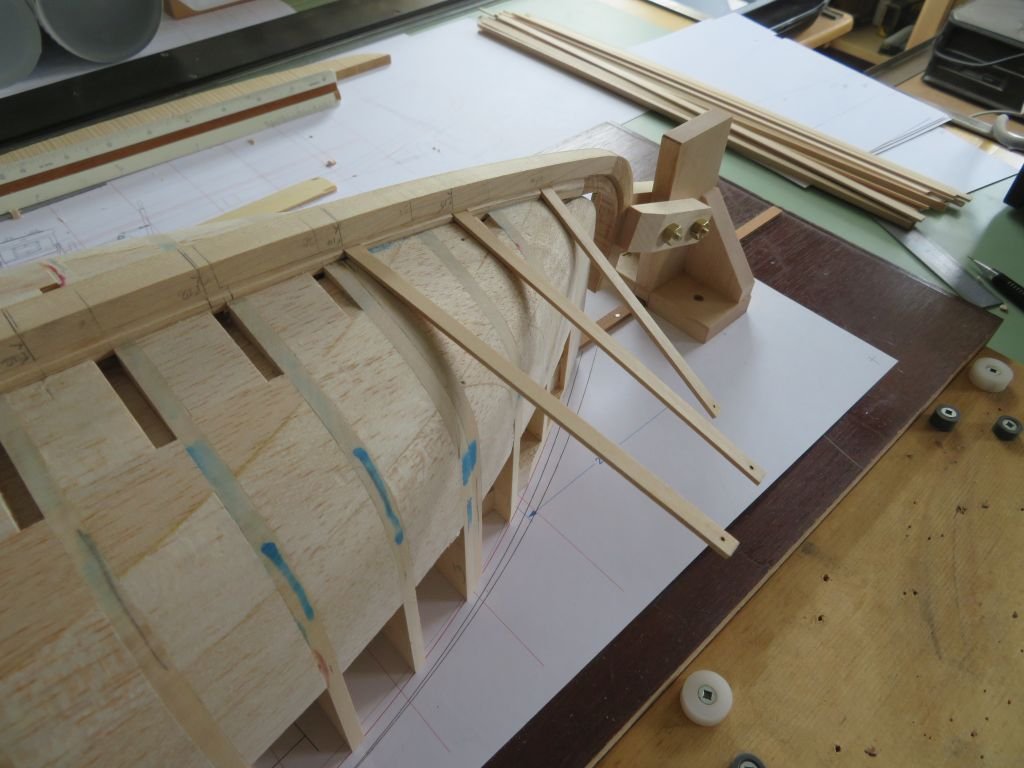

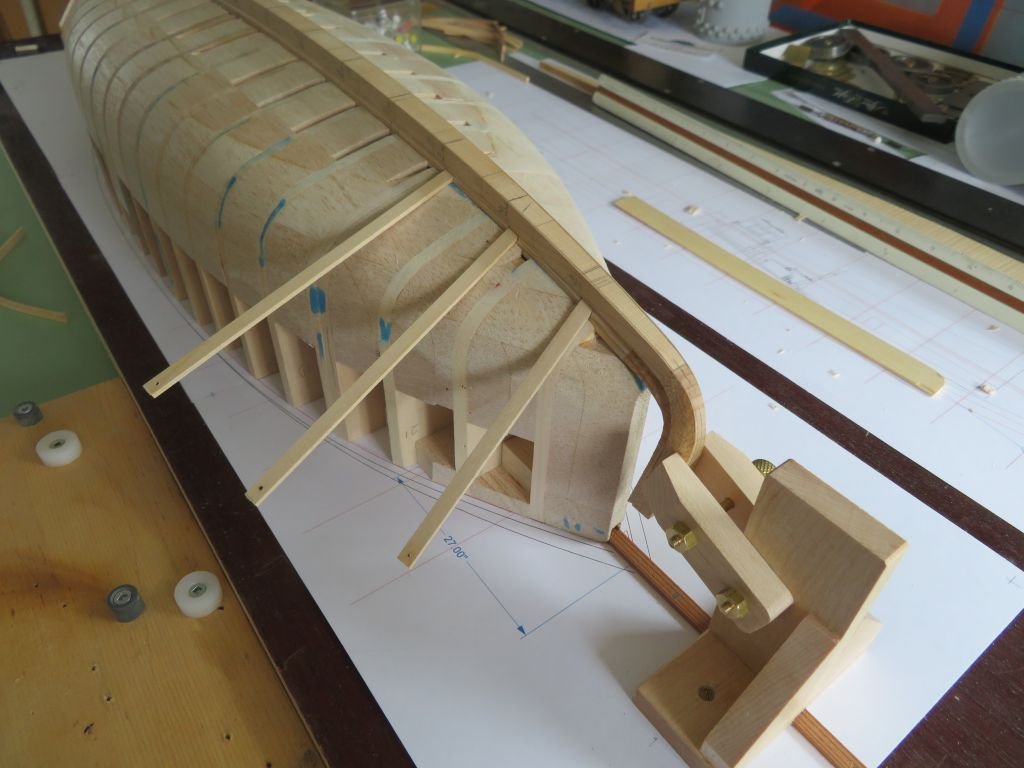

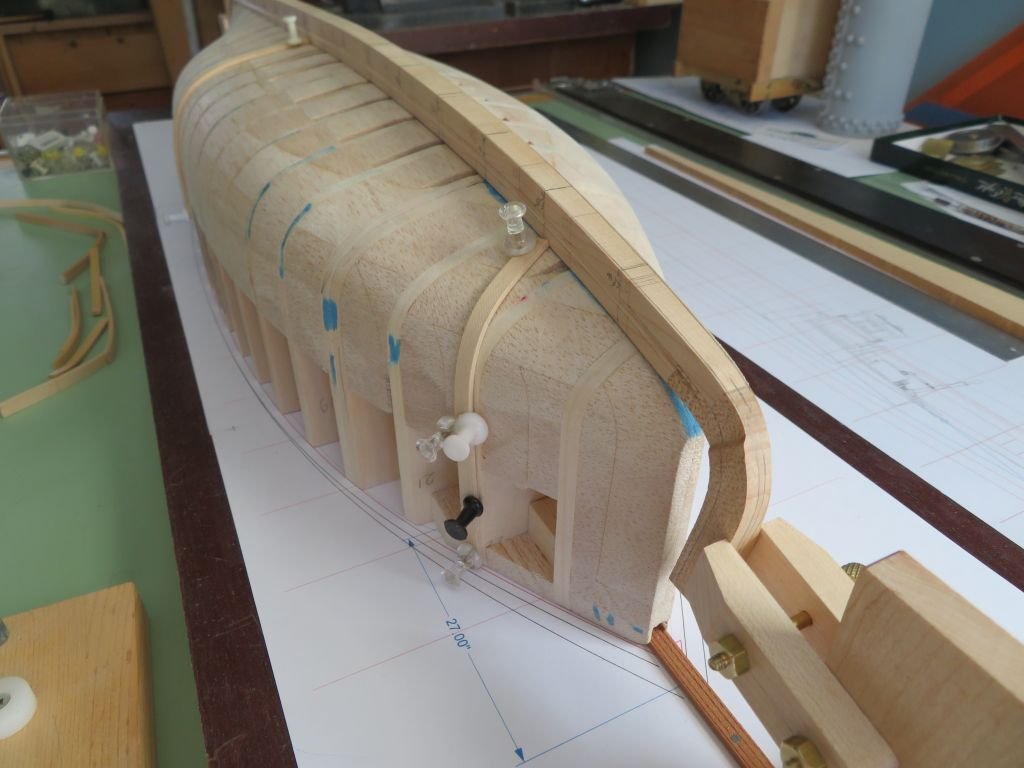

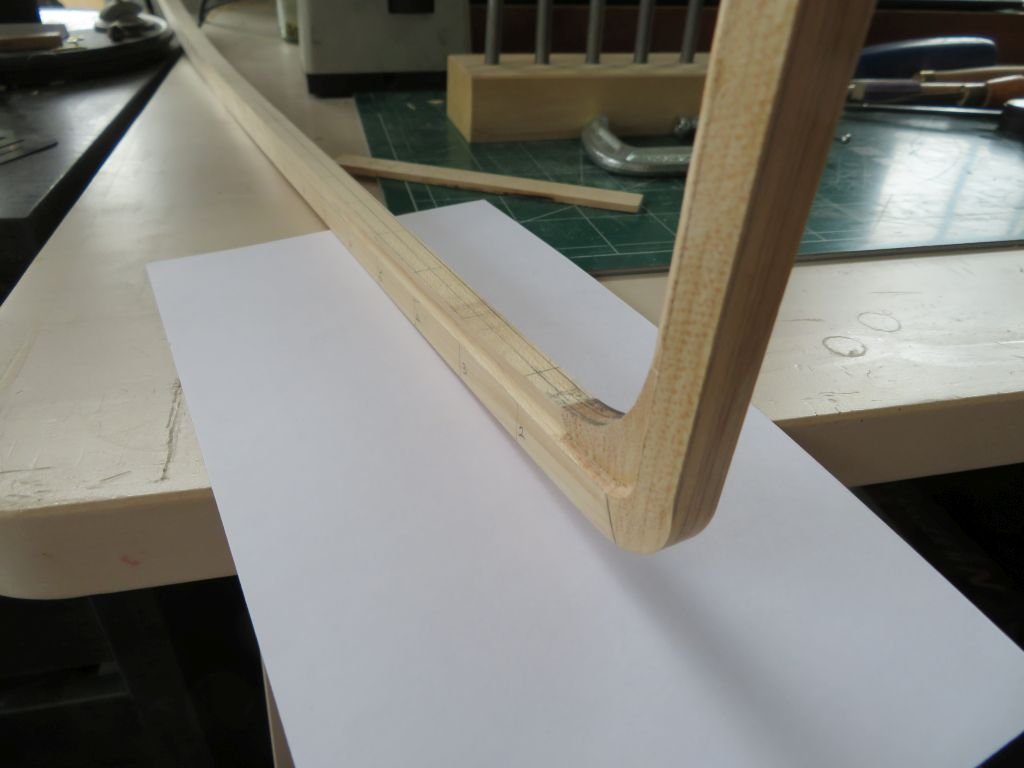

Yesterday and today I notched the area for frames 14, 15 and 16 Then set up the frames to dry overnight.

I decided not to show close ups of the mortises as they were a bit rough to the naked eye so I can imagine how they would look through the camera..... Brutal comes to mind.

I am having to take it slowly because I am having serious numbness issues with my right hand and the nephropathy tests today confirmed that I need to have the Carpel tunnel revisited, so an appointment with the surgeon is in my not too distant future.

Picked up a splint for night time today.

I am happy with the way things are looking with the frames, I laid a plank on the frames to get a sense of what is to come at the stern and I think it is going to work out fine.

Michael

-

There is something very appealing about these smaller models, and it is a testament to your skill and ability to be able to create such a gem.

Michael

- druxey, FriedClams, shipman and 4 others

-

7

7

-

Thanks for support and comments.

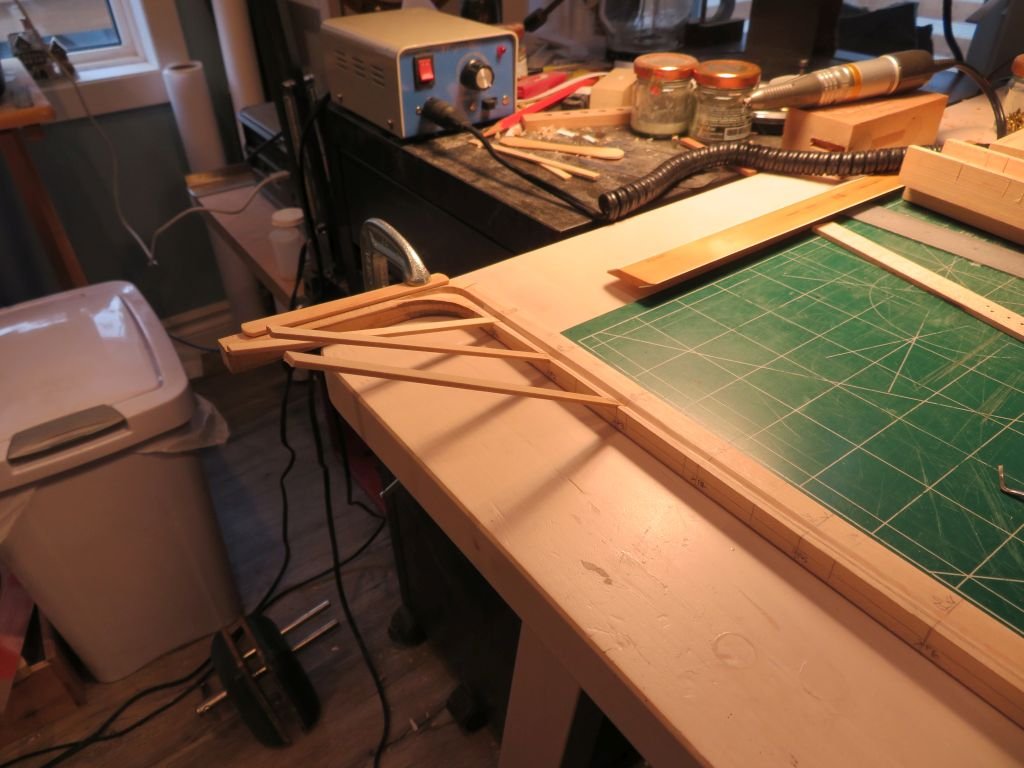

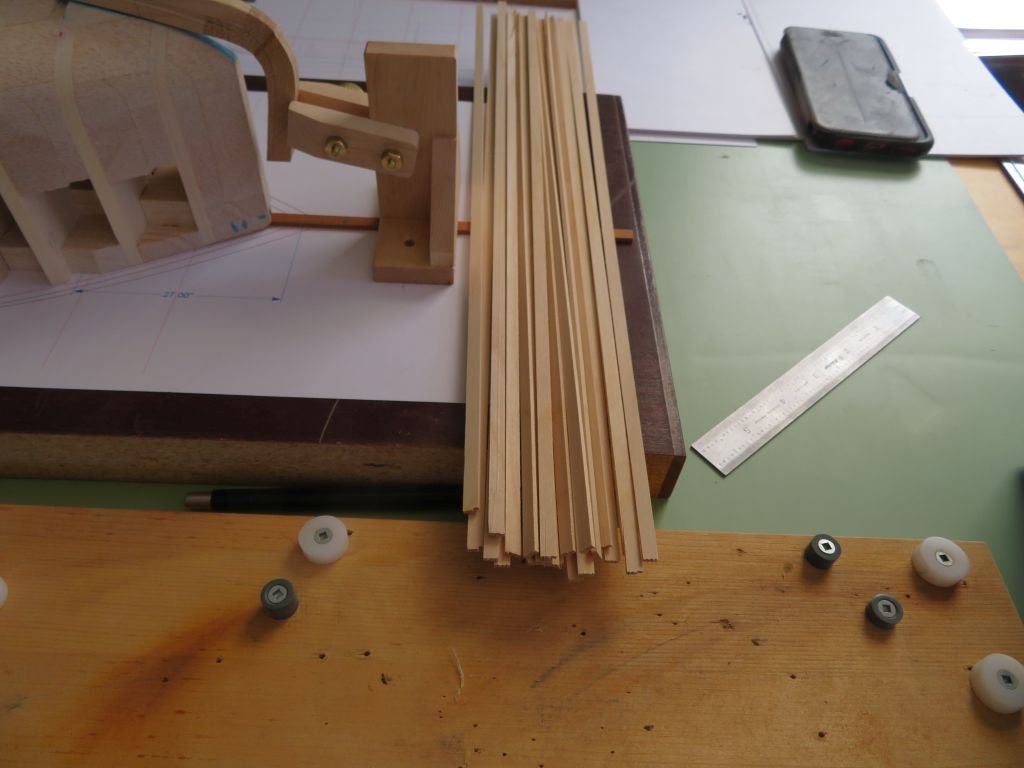

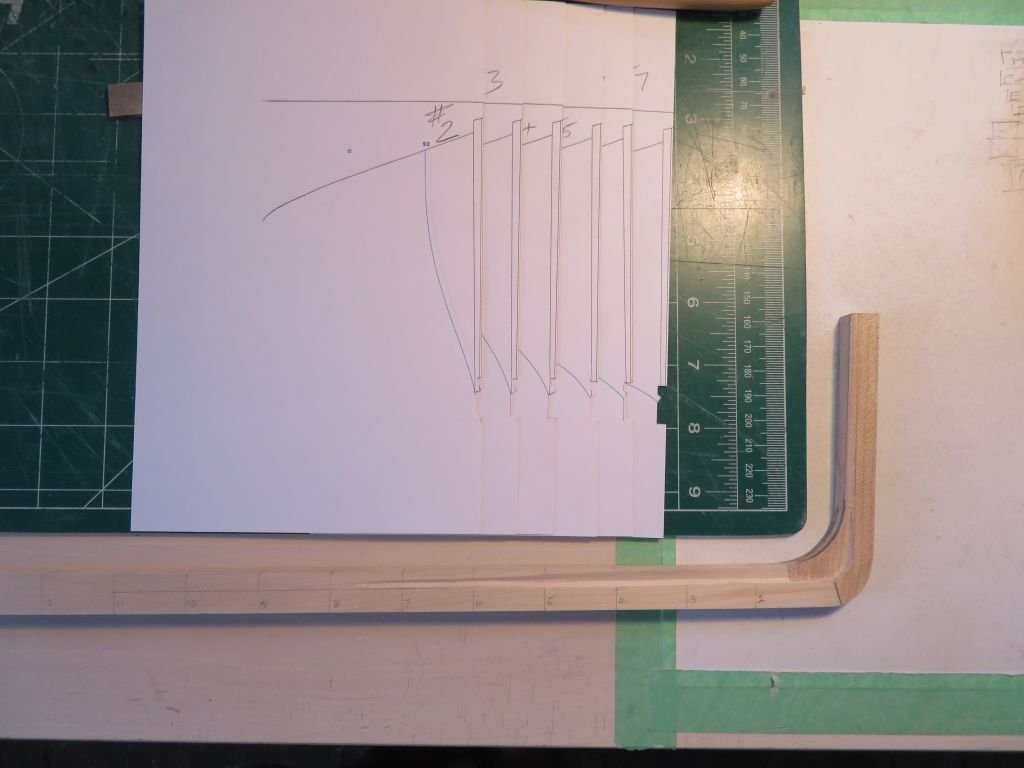

I did some tests today for the ribs (frames). When we lived at the lake we cut some and purchased some Birch firewood A couple of the larger split logs were really clean and straight grained so I split them up a little more and prepared some 1/4 cut billets that were approx 1 inch x 2 inch x 12 inches long They have been drying for about 5 years now so today I cut one up into 1 1/2" x 1/2" scale ribs (3/16 x 1/16 actual)

I had done some bending tests with other woods as well, left to right Birch, Yellow Cedar, Castello, Maple, and Beech. The air dried Birch bent the best.

So a couple of test bends on the form to see how they are overnight. I wrapped the frame in a wet paper towel and popped it into the microwave for 1 minute then used the hot air soldering station to add a little more heat as I bent the frame in the bending jig before pinning it to the form.

These are just some preliminary tests.

Michael

- Keith Black, BANYAN, GrandpaPhil and 11 others

-

14

14

-

Mark, thank you for the detailed explanation, that helps me understand the nature and size of these little carvings.

Michael.

- Old Collingwood, mtaylor, EJ_L and 2 others

-

5

5

-

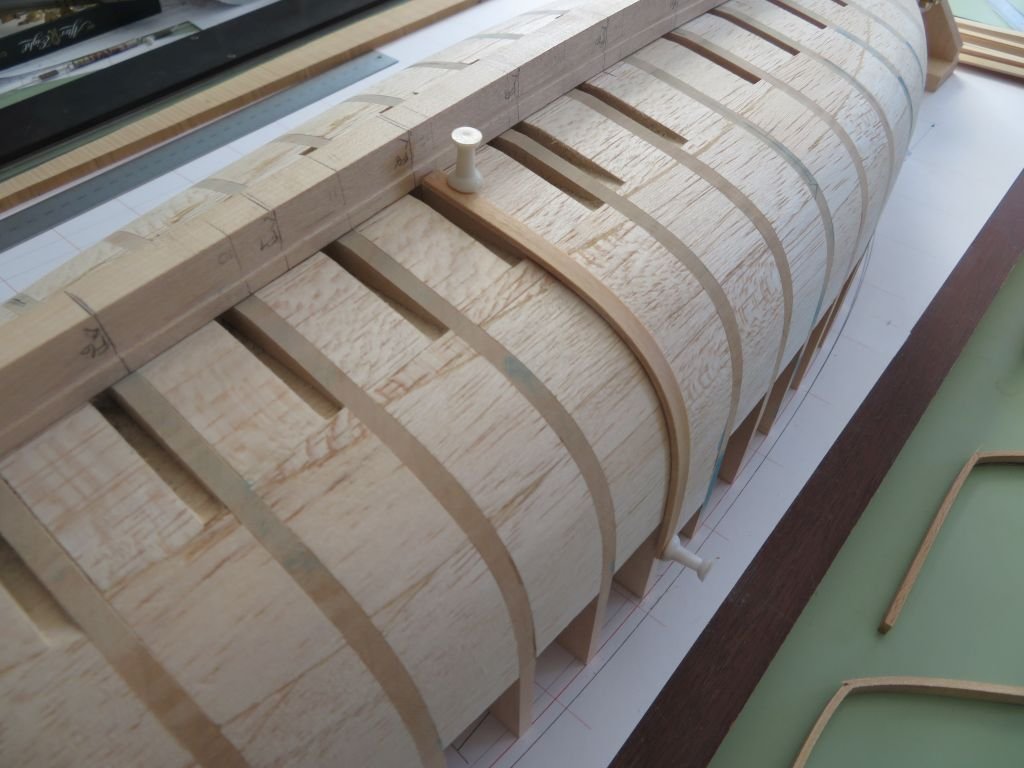

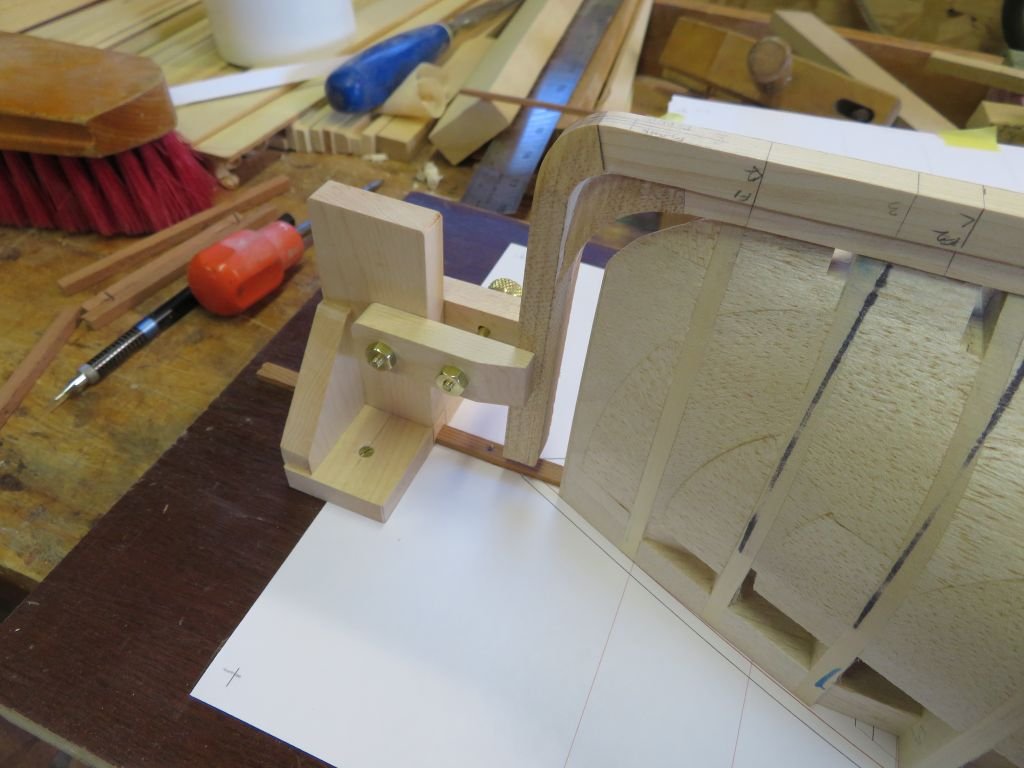

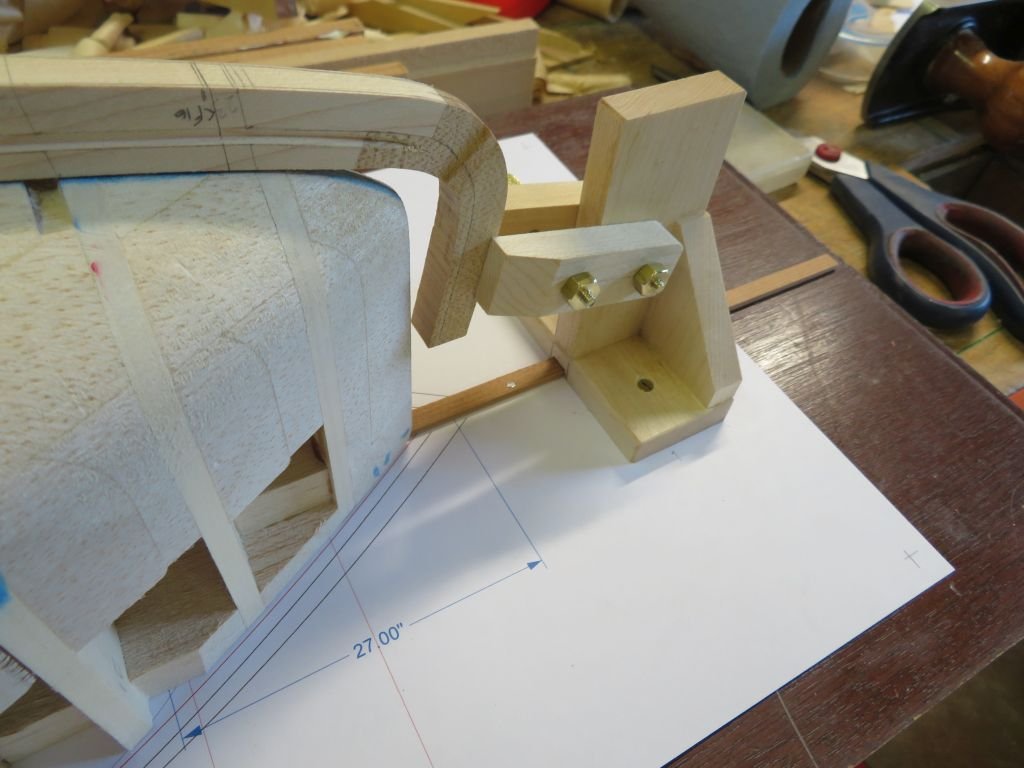

Had a chance in between a few other commitments to get the new clamps made and mounted, I also remade the location strip in order to align the clamps, and so did up a new print while I was at it.

Now I can finish the rabbet and get on with the frames and floors.

Michael

-

Well said Bob.

Michael

- Keith Black, thibaultron, mtaylor and 5 others

-

8

8

-

The carving looks good Mark How are you holding the small angel as you carve?

Michael

- Canute, Keith Black, FriedClams and 2 others

-

5

5

-

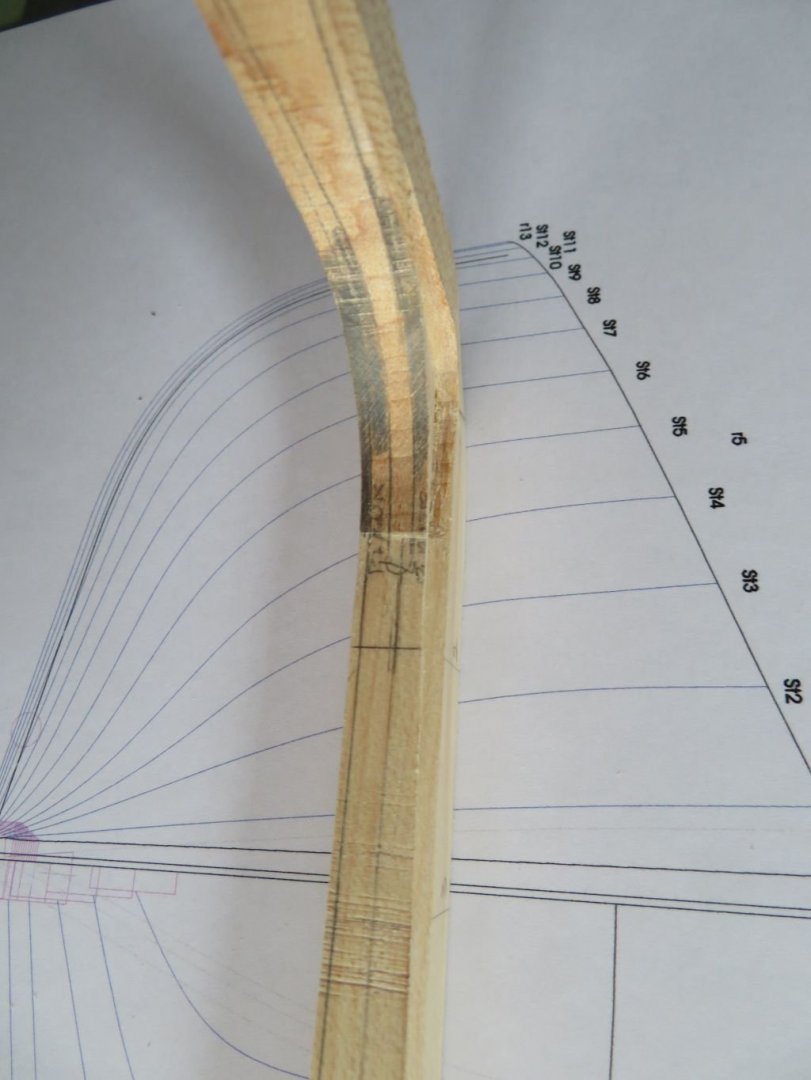

Continued work on the rabbets.

I am going to make a couple of clamps to hold the keel in position while the frames are shaped and fitted there are 15 frames in all so when it comes to adding the floors I will need to cut the slots in the base form. Nothing will get glued until the frames and floors are sorted. The Maple is a little more difficult to work than the Castello, but I am pleased with the results so far.

Michael

Michael

- dvm27, Mark Pearse, Bedford and 12 others

-

15

15

-

I began the slow work of carefully carving in the rabbet A big thank you to Druxey for comment about the rabbet following the line of the hull less the planking, and to Mark Pearce for the comment about the thickness of the wood at the stem. Obvious to many of you who have built several or more models of boats and ships, but was not to me.

This time I have left the bow at the full dimension of the mid-ship as 3 inches and am working the taper down to the given by Roger as 2 3/8 inches just aft of the bow proper to allow for the clamping while carving.

I am following the templates for each station point along the new keel, and checking it with a small piece of 3/4 inch plank to ensure that the plank fits properly at each station. I am confident that this time I will achieve the results I am looking for.

Once I have the rabbet cut the whole length on both sides I will finish shaping the bow and stern posts.

Michael

- bruce d, Keith Black, wefalck and 12 others

-

15

15

-

Looks like you want to get this finished before next week😉

And I have not forgotten the bit O' wood I promised you.

Michael

-

So the keel gods spoke to me in a dream (that's my story an' I'm sticking to it) Turns out that they were not happy about using the foreign exotic wood called Castello.... I know it is a beautiful wood to use and work with. However they suggested I use some of the Maple that I cut from the 24 inch log way back in 1976 and that has been thoroughly air dried for the stem and stern

and the nice piece of rock maple that was in the storage for the long part. So I agreed

Michael

Brass piano hinges

in Metal Work, Soldering and Metal Fittings

Posted

(Chariots of fire)? You could try something like this.

Michael