-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

Mark I have to echo everyone else again on your work. A few years ago our regular sheer operator was on vacation and there was some jobs that needed to be done. I was busy on another project at the time so they put another guy on it. However, he was soaked. The parts were on the large side so instead of attaching the extension that was made he used a sheet of steel instead. The sheer was designed for paper etc not for metal. The steel slid under the blade and he was so out of it he never noticed when the blade hit the steel. By the time we got over there the blade was destroyed along with one of the retaining bolt and the sheer pin needed to be replaced as well. He had made 4 hits by that time. Needless to say he was canned on the spot. David B

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

dgbot replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Jealousy, envy, ego breaking need I continue? Your work is superb. One of these days I hope to be in the same class. If you were in the states and could come to WI you would win best of show, modelers choice, and judges choice. What more can I say? David B- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

I rarely see enough models of working boats. I love the way your trawler is coming together. David B

-

If you get Seaways Ship in Scale Kurt Van Dahm did several articles on building the Philadelphia. David B

- 308 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

At work QC uses Mititoyu digitals for the final inspection. For handcut we use a less expensive model. The reason is if you drop the QC version it has to be calibrated for final inspection. You pay for what you get. For what we do a .0001 readout is all you will ever need and that can be overkill at times. David B

-

You are almost there Mark. Only a few more to go then the fun begins. What will you use for the hull? David B

-

It has been years since I used a vernier. I use a digital and it makes my life and my eyesight easier. Plus I can convert from decimal to mm with a touch of a button. And you can always take a wider plank and narrow it down. Whenever you plank the hull always try to use the widest planks possible, that way you can modify them as needed. David B

-

I am alot older than I look. Geritol does wonders. David B

- 259 replies

-

- Gunboat

- Philadelphia

-

(and 1 more)

Tagged with:

-

Nice metal work. Fortunately there is a ton of information out there. David B

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

It has been years since I was in Minn. Northerns, Walleye, and Large Mouth Bass. I bet that fish gave you a good fight. But you enjoyed yourself and had a great meal. Pan fried with flour or grilled with lemon and butter? David B

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I had the pleasure to be there when it was built. I wish I had a video of those meetings. David B

- 259 replies

-

- Gunboat

- Philadelphia

-

(and 1 more)

Tagged with:

-

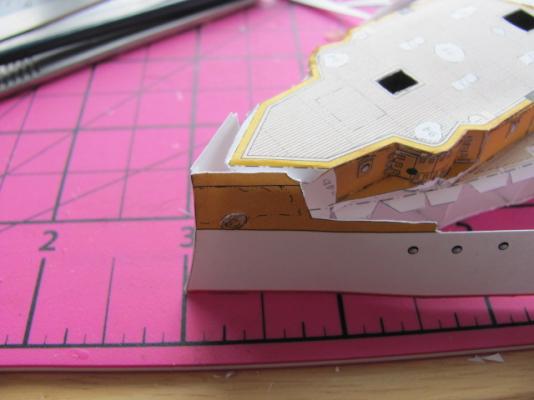

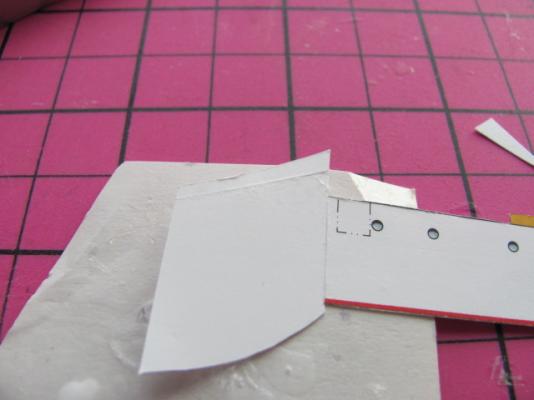

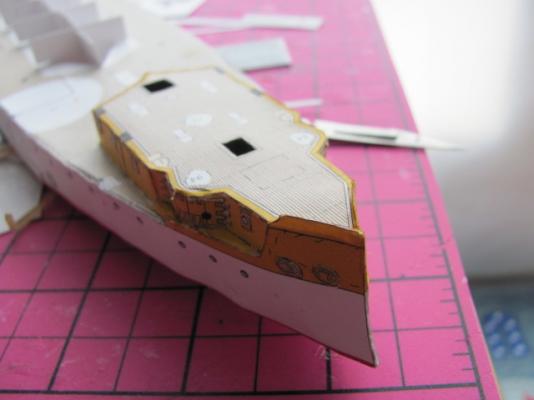

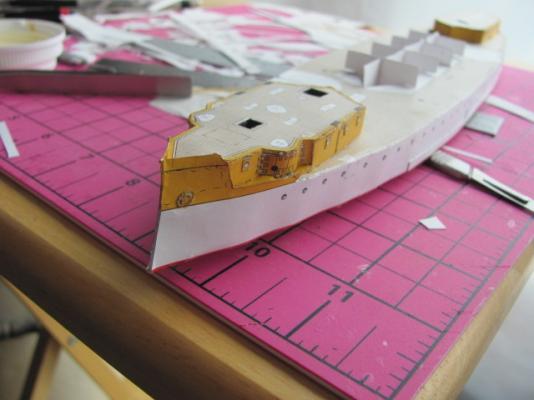

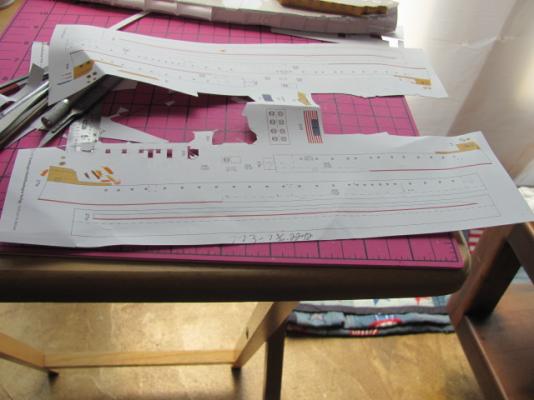

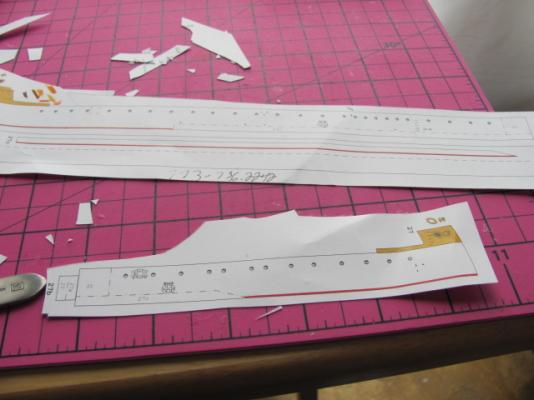

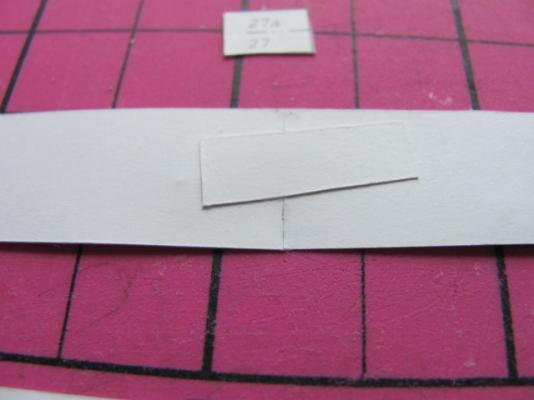

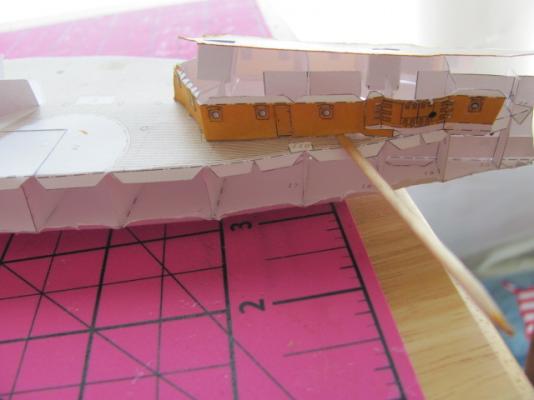

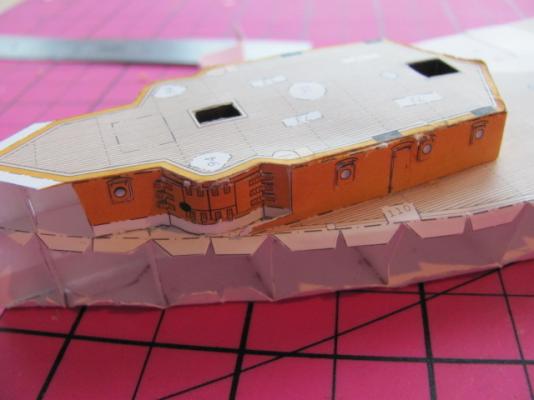

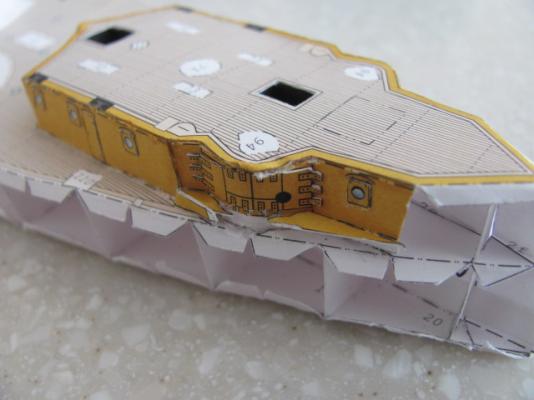

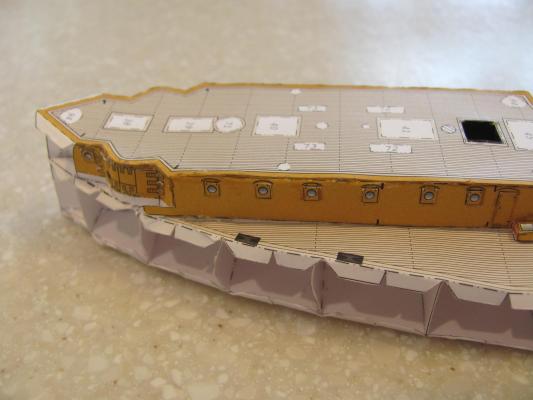

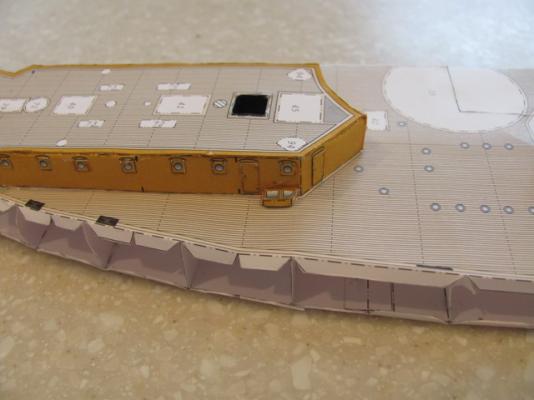

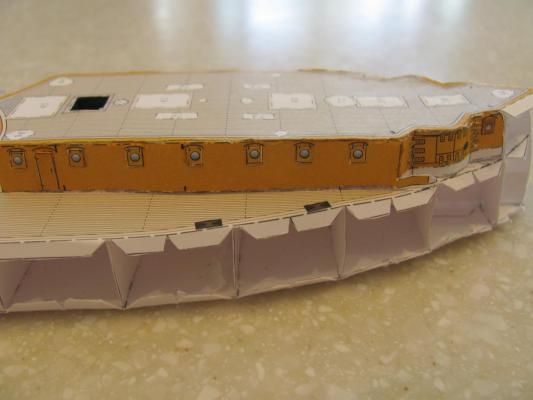

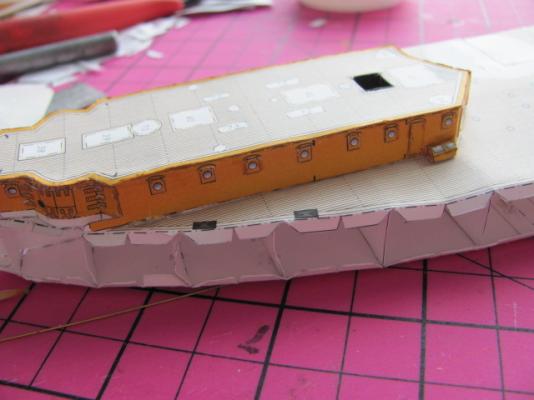

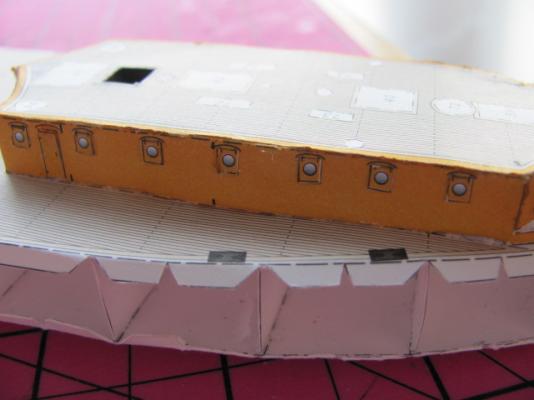

Once everything was added to the side panels they were glued into place. The first thing I did was to tack the bow sections in place so I could make sure everything was even on both sides. And glued the sides to the hull. I then noticed that one side was about a 1/16 to short. So I cut a section and added a strip to make it fit. A little pressure and the seam is hardly noticable. I will proceed to hide it as I proceed with the model. David B

-

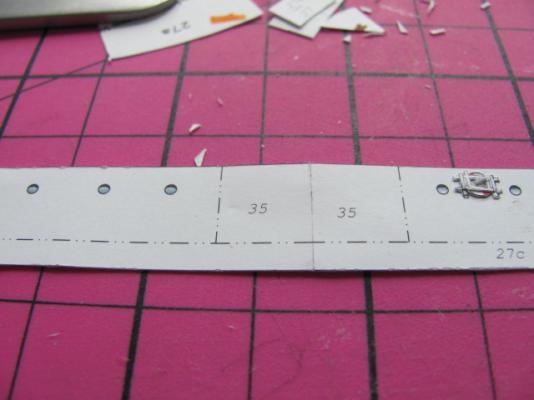

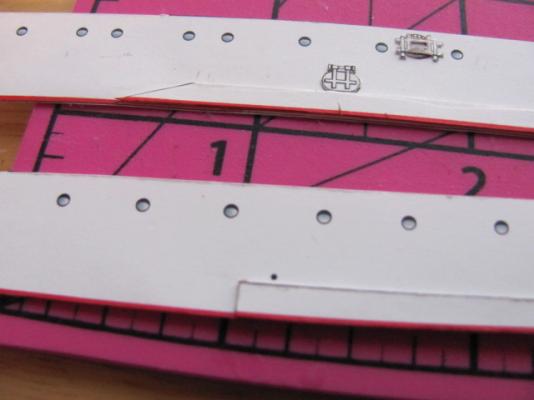

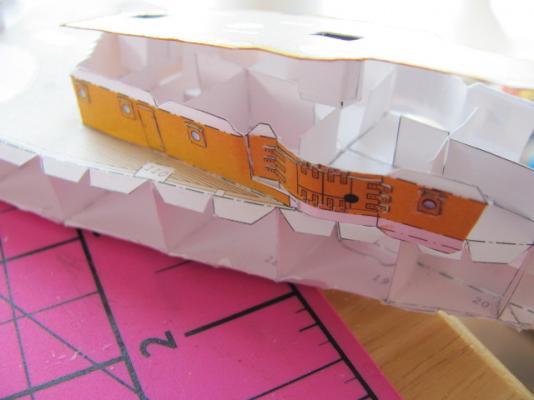

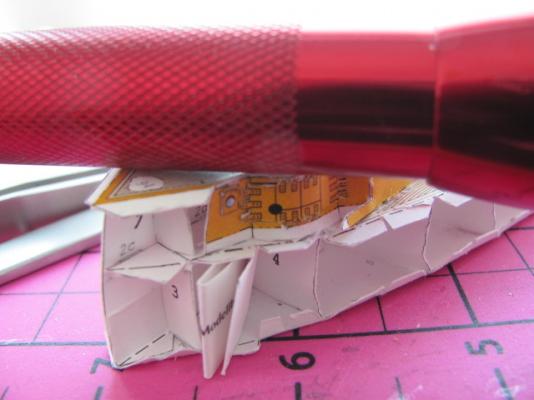

The next item was the hull. The sides were two parts each. The first thing was to cut them out and glue them together. I used a piece of scrap on the back at the joint and a straight edge to make sure it was lined up properly. Then I cut out and applied the accents. This part was the nerve racking part where a steady hand and a sharp scalpel came in handy. David B

-

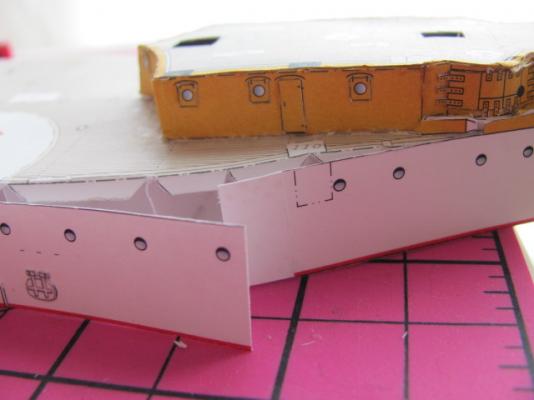

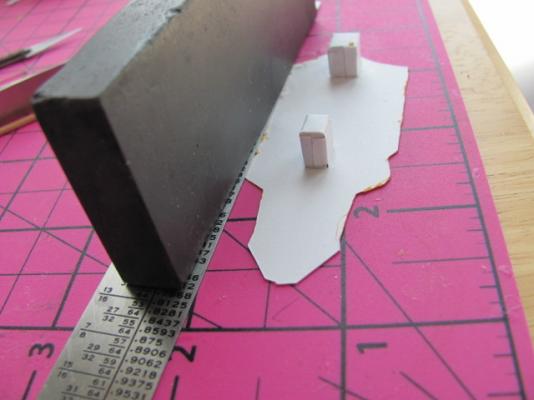

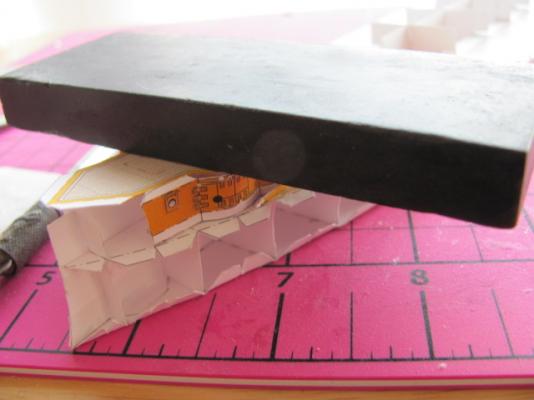

The aft deck was pretty much the same way but once more the alcohol saved the day. One of the items I found usful for applying glue is a dental pic. Not only will it apply glue it helps to put pressure on the joint as well. On the aft deck to help with the tabs I used a ruler and some weight to get an even edge Then after reworking the cabin sides I started to fit the roof. Dry fitting it first. And once more a weight was used to help keep everything straight. Then I proceeded to touch up the edges. David B

-

I have been able to get some more into the Maine and was able to finish off the two cabins. And here is where I found that rubbing alcohol can be your best friend. While fitting the roof of the forward cabin I noticed that the walls were not fully aligned. By using a brush and a drop of rubbing alcohol I was able to reposition everything for a better fit. Plus the alcohol evaporated quickly and did not stain or damage the material. Once the roof was placed to my satisfaction I glued it down using a weight to hold it until the glue dried. Then a little touch up with a brush and it is about as good as I can make it. . David B

-

Omega your workmanship is incredible. If you live in the midwest I would love to see your model at the Wisconsin Maritime Museums annual Model Contest. We do not get enough miniatures with this quality of craftsmanship. David B

-

Ed, I could almost feel the ankiety undoing some of that great work you were doing but will be for a greater good. As for sharpening, in what you are accomplishing a well honed chisel is a necessary tool. And I would have to agree that Dave no longer looks like a bucaneer. But he could be a very dangerous card player. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

The Whaleboat is an excellent kit. I have it. You are doing a fine job. David B

- 43 replies

-

- new bedford whaleboat

- model shipways

-

(and 1 more)

Tagged with:

-

Your battens should lie naturally but that is not an iron rule. It gives you a base line to start. The end result should also look pleasing to the eye as well. This will help to insure that your planking is running true. That one batten should be repositioned in the bow to even things out. If you have 5 strakes at the mid section then you want 5 planks at the bow. Especially on the first run. David B

-

What you have sounds like a crimper. It crimps the wood with little breaks. For the veneer you are working with you can soak them in a container of hot water for a few minutes then tack them to the hull until they dry. I have also made a fixture with the curve I want and clamped the plank to the fixture. If your wife has an iron take a wet towel and put the wood in it cover and run the iron at the highest setting over the towel. This will steam the plank making it pliable. Then tack it to the hull until dry. On the full sized vessels they used a steam box to do the same thing. David B

-

You need help. I think we are going to have taken in for some therapy. Or I am going to face the fact that you are just that good. Excellent work. David B

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.