-

Posts

2,007 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

HMS Euryalus by egen -

Trussben replied to egen's topic in - Build logs for subjects built 1801 - 1850

Got to agree, looks excellent. Ben -

Sweet guns mobbsie! I'm just starting the same job on my Confed. Wish I was as fast as you. Ben

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

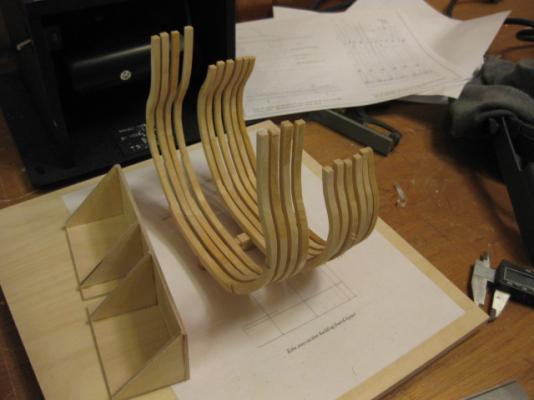

Hi and thanks. @ Bob - As my old gran would say " Variety is the spice of life ". @ Druxey - I'm still raising frames slowly @ Rusty - thanks man. Here is frame 1 fore raised. ben

- 147 replies

-

Nice work Rusty, Funny how you remember things from the Confed build, I'm not installing my trim until much later on as I don't want to waste my boxwood. Ben

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Hi Sjors, don't worry as I don't know what I'm doing half the time! I look forward to seeing Anja's dark side career begin, believe me it is a steep learning curve but its extremely enjoyable, I'm sure you will get hooked while you watch her build Hannah, what wood did she decide to build it with? Ben

- 147 replies

-

Nice to see some build updates Andy, your log does seem to have the tendency of wandering off the beaten path, but it normally comes back. Enjoy the lake mate. Ben

- 1,148 replies

-

It was a bit strange to be looking at a swamp donkey again, I had enough of those meetings when I lived in northern maine. Keep going Augie. Ben

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Hi JP, The sheer of the wales is a little off but damn it looks good to me!! I think you may have a munity in your hands if you paint the hull, I really think you should wait to make that decision until you get the bulwark planking on, you may change your mind when you see it in its overall state, just a thought. Ben

-

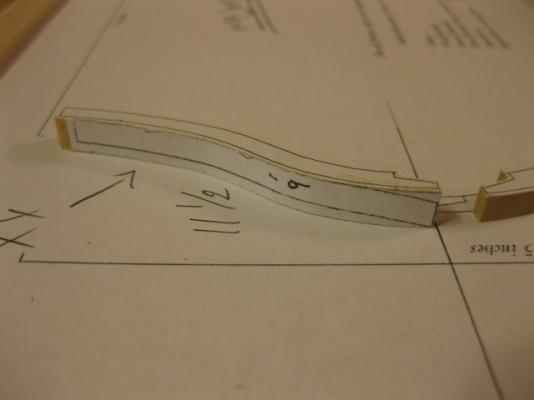

First pic shows all frames made except 3rd. Second shows how I made the 3rd top timber which has the big cast. third shows frame treenailing completed. four and five show dead flat frames being raised. I will maybe get some more done this weekend but I want to switch back onto the Confederacy for a little while. ben

- 147 replies

-

All frames are completed and treenailed, I will post some pictures tomorrow after I get the dead flat frames raised. I am going to use boxwood scrap to use as spacers between the tops of the frames and I will also treenail the frame into the rising wood for more strength. Ben

- 147 replies

-

He who has no name will be waiting I'm sure! Ben

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Glad the damage was not extreme! Murphy was not with you I guess! Ben

-

Augie - that rigging looks SWEET, really well done! Have you put in the order for the Essex yet?? Ben

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Hey grant, it seems like you and me both have issues with painting, I'm having issues with acrylic on my Confed carriages, hope to figure it out next week with a new tube and different dilutions. But my cannons turned out well. Hope you get over the hump more easily than me. Ben

-

Congrats Tony, As a recent Byrnes Saw owner I can only say you made the right choice, you will adore it. Only things I think you should maybe of got were the slitting blades and zero inserts, I find I dont use the carbide blade a lot, more the 0.040 slitting blade. You should try the Disc sander next - an absolute wonderful machine as well. ben

-

The new transom looks great Sjors and happy birthday. Ben

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.