-

Posts

2,007 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

Congratulations on passing the finish line, she looks awesome, please post some pics when the case is finished and she gets in her final resting place. Confederacy Eh?? Who would of thunk it! I shall of course be around to watch that build, contact me before you start her, I have some small experience with that particular ship. Enjoy the break buddy and see you in the fall. Ben

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks for the comments Bob, Sjors, Greg and Aldo. This version will not be fitted out, just the framing as I said on first page of log. I have still got half the wood left from the package as I didn't make too many mistakes and Jeff supplied plenty, so I will make another which will be fully completed when Greg and David finish the entire practicum and offer a wood package for it. Ben

- 147 replies

-

Well Done Rusty, Looks great. Almost time for you to start up on the Echo again. ben

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Very nice work on the seizing Robbyn. Ben

- 773 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Very well done Aldo, looks like your cad work has paid off, I agree its a little difficult and time consuming redoing the entire plans, I'm currently drafting and lofting a set of plans for the US brig Eagle and I have spent many hours so far but I'm enjoying learning how to do this for future scratch building. Ben

-

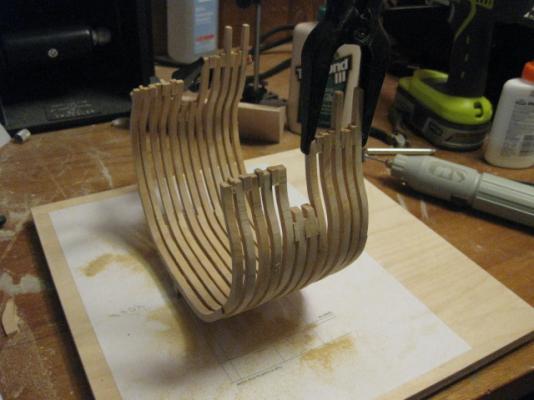

Thanks Druxey. Rusty - just send em on down and i'll get them done for ya! Well I just raised the last frame and thought I'd post a pic of it drying, hopefully sometime over the next week I will get the sweep and gunport sills and lintles installed and start to sand and fair it all up. ben EDIT - reposted missing pics 4-2-14

- 147 replies

-

More frames have been raised, up to 3 aft which is cast against the gunport. I hope to finish raising the rest over the next week. ben

- 147 replies

-

Very nice work on the brackets Rusty! Did you use normal solder or silver solder? Ben

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

If anybody is interested a guy called Kevin Crissman did his dissertation on the eagle and its the most comprehensive info I could find in her, he actually took measurements from the wreckage and that's what I'm using for lofting my plans. He also has a book about her that has some plans and other info, proberbly still get it second hand! It's a free download from Http://nautarch.tamu.edu/anth/abstracts/crisman.htm It's got tons of info about her and sister ships and the war of 1812. Ben

-

Hi JP, Not having built the Rat I am unsure wether the gunports should follow the sheer of the wales but I would guess so, does the deck follow the lines of the wales? If it does then I would use a temp batten to get the correct shape at the correct height above the deck and then mark each bulkhead and then install the sills/lintels to those marks. Also maybe use thicker wood and fair it back to the bulkheads inside and out, that will get rid of those strait lines. Take a look at my Confed log first few pages and you will see me doing exactly that. Hope that helps somewhat. Ben

-

Hi Ed, I started reading your entire log again and noticed that Part 5 is missing, did you know that?? ben

-

10 coats looks plenty good from here Rusty. ben

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Hi Chris, what size of ships wheels did you buy from Cornwall models boats? They have 2 sizes available. And your right about expensive! Ben

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Nice to see those pics again Chris, that's the area I'm working on now and I just completed the stern decorations, not as good as yours though! Ben

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Have there been changes to Model Expo Support?

Trussben replied to rtropp's topic in Wood ship model kits

Thanks for the official update Eric. Ben -

Have there been changes to Model Expo Support?

Trussben replied to rtropp's topic in Wood ship model kits

Frank was the parts guy, sorry to hear he retired. ben

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.