-

Posts

946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by mbp521

-

-

Eric,

So sorry for your loss. What a beautiful dedication to him. It sounds as though he was a great man who lived a wonderful life and will be dearly missed.

Your build is progressing very nicely, glad to see that you have been able to overcome all of the obstacles the build and life have thrown your way.

Very nice job on the decking, much better results than the kit provided “scribed” planks. Definitely adds a touch of realism to it.

Do you plan on repainting the hull, or are you going to leave it as it is currently. Personally I think the way it looks right now gives it a very nice “weathered” look as though it has seen many beaching and days along the docks.

-Brian

-

-

Keith,

Thanks for the additional pictures. What a plethora of puzzling Parrot problems.

-Brian

- Canute, mtaylor, Keith Black and 2 others

-

5

5

-

4 hours ago, Keith Black said:

Brian, beautiful work. I am enjoying your build and look forward to each new installment.

One thing if I may, while your turning of the 30 lb Parrott rifle is beautiful, it looks like there is too much muzzle swell. I've seen photos of 30 lb Parrott rifles that have no swell as per the attached photo but then other 30 lb photos show a very slight swell. I once had tons of Parrott rifle photos when doing research for the Parrots on the Tennessee but have since deleted them when I finished the guns.

Please don't take this as criticism, merely a small point that you may want to look at more closely......Keith

Keith,

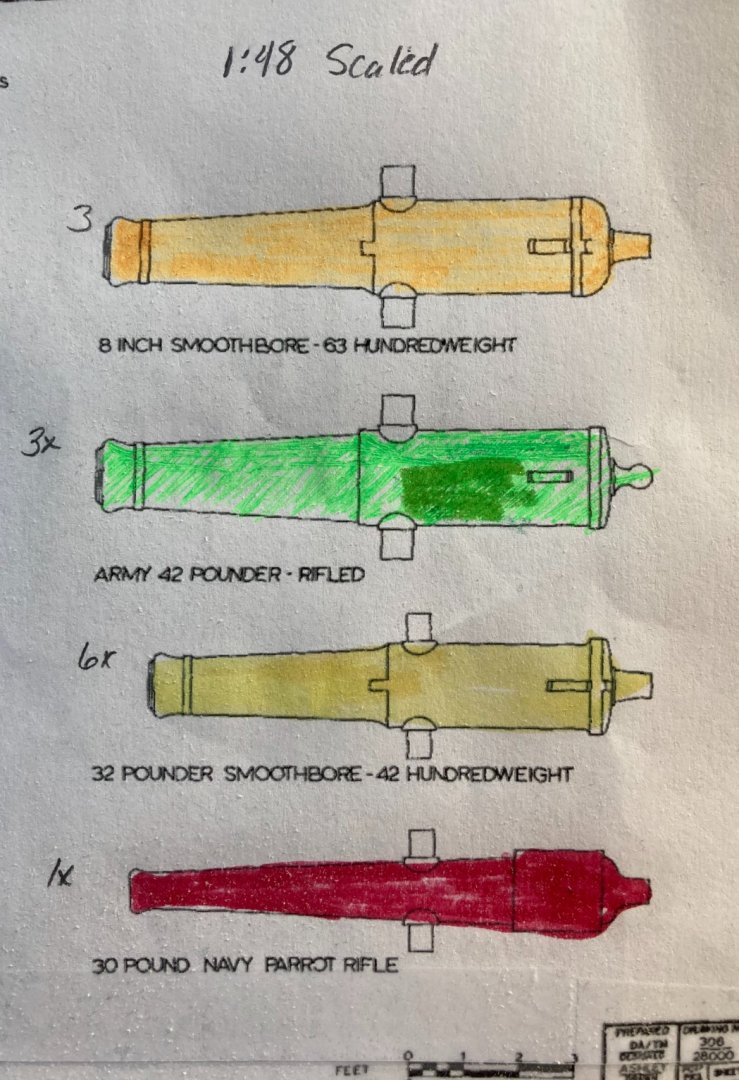

No worries about the criticism, I openly welcome it. Any tips, guidance or pointers I’ll gladly accept. To be honest, I really didn’t do a whole lot of research on the guns for Cairo, I just took it for granted that the HSR document was correct on her armament. I based the guns off of the below sheet that was part of the HSR. This drawing has a significant muzzle swell on it. However, now you’ve got my curiosity up again on how they really looked. Time to do a little investigation. If you do happen to run across any other pictures of the Parrots that you may have, please feel free to share.

Please pardon my coloring. I color coded them for positioning on the deck.

-Brian

- mtaylor, Keith Black, Canute and 1 other

-

4

4

-

5 hours ago, Cathead said:

Looks wonderful, so crisp and even on the framing. Nice fix using the toothpicks to strengthen those joins. The guns look nice to me, though I'm hardly an expert.

Thank you Eric. That toothpick method has come in handy more than once on this build.

-Brian

-

Hello Again Everyone,

I have finally hit the six month mark on my build and figured it was time for another update. It has been slow going and I realized that it has been several weeks since my last posts, so I guess it is about time to get something out there. I am still chickening out on building the engines. For some reason, I just cannot get my head into them (not sure if it is mental or what). So instead I worked on the casemate framing for the gun deck.

To start the framing, I set me up a jig that would allow me to keep the frames in a straight line and equal height. I use a couple of scrap blocks glued to both ends of by build frame and some 3/4" aluminum angle for this. For the top beam, I marked out the framing positions to also line up with the build frame and set that into place on top of the blocks. Then the beam and aluminum angle were lined up and clamped into place. The two middle blocks were left loose so that I could slide them next to the frames as they were going in to maintain a consistent height. Even though I use a solid piece of angle there was still some flex in the four foot span and I didn't want to risk my frames drooping in the middle.

First few frames going in on the port side.

More frames going in.

Looking pretty straight.

Starboard and port frames in place.

After the side frames were installed, I started work on the forward casemate frames. These were twice the thickness of the side frames for added protection on a frontal assault. On the real Cairo, the side frames were about 12" thick, the forward frames were 25" thick. This was not counting the armor plating that added an additional 2 1/2" of thickness.

While I contemplated how I was going to form the curve of the top beam at the forward end. I started work on one of the deck features. I built up a couple of water/beer/wine casks (not sure what the preferred drink of the day was) and got them into place next to the stove.

I went ahead and temp installed the stovepipe since I wasn't sure that I would be able to get my drill down in the deck once the forward frames and ceiling beams were in place.

Then the fun began where the top beams started to curve in at the bow. I built up one of the ceiling beams to keep the port and starboard casemate frames equidistant apart while I made the bend in the beams. The ceiling beams have a slight bow to shed the water from the hurricane deck. I calculated these to be about 4mm in rise to the center to give them the correct radius. I glued the pattern to the beams and sanded them down on my disc sander.

With the first ceiling beam in place, I then cut out a pattern and form to use for a consistent and even bend on the forward frames.

A second and third ceiling beam were added to keep the curve in place, along with the forward casemate frames.

I was having some trouble keeping the top beams from going back to their original form. My attempt at steaming them with a steam iron was not working all that great, not to mention the look the Admiral gave me when she caught me using her iron for something other than what it was intended for. So I drilled some holes through the side beams and into the ends of the ends of the ceiling beams and epoxied some toothpicks into them. I also added a small piece of scrap wood to the bottoms to hold it all together. The scrap wood should be out of the way where it is not seen on the inside.

Once the epoxy was set, I trimmed the top beams and finished out the port and starboard casemate frames to tie into the forward ones.

Next I finished out the aft frames. Again, I temp installed a ceiling beam to keep the sides at their proper distance then installed the framing.

With all the framing in place, I have now removed her from the building frame. This makes it a whole lot easier to work on not having the bulky jig to deal with. Here is where she sits right now. She is starting to come together.

Finally, with the framing completed, I tried my hand at some more wood turning. I wanted to see if I will be able to make my cannons from wood. I think I have the concept down, just not sure if I can make them consistent. Here is my first attempts on the 30lb Parrot Rifle and one of the 32lb Smoothbores. I'd be glad to hear any thoughts on them.

That is all for now. Hopefully I can get more done since the colder weather is starting to set in. Of course the holidays are also around the corner so that may put a delay on some of it. In any case, thank you for looking and all of the kind comments and likes.

-Brian

-

3 hours ago, yvesvidal said:

I have resurrected the Emma C Berry by Model Shipways.

Quite the contrast to the sub. Looking forward to watching that build.

-Brian

- lmagna, mtaylor, popeye the sailor and 3 others

-

6

6

-

On 11/22/2020 at 3:22 PM, vaddoc said:

Just catching up Brian, the stove came out great. What paint did you use and did you use any primer?

Vaddoc,

Thank you. No primer, I just used an ordinary rattle can of flat black. I then dry brushed the highlights with a gray acrylic and finally coated it it all with satin clear lacquer. I used the same technique on the paddle wheel and boilers. Seems to work fairly well.

-Brian

-

Yves,

I still sit here in amazement at the beauty And detail of this build. So sad to see it end. Can’t wait to see what hits the bench next.

-Brian

-

3 hours ago, KeithAug said:

Brian, isn't it annoying when life intrudes.

Great job on the stove, I particularly liked the aluminium tape technique.

Thank you Keith.

I definitely agree, the aluminum tape technique works great for giving wooden parts a metal look and provides an easy way to simulate the rivets, especially after painting. I wish I would have used it on my Chaperone build, it would have given my stacks and boiler a more realistic look. Oh well, all part of the learning experience.

-Brian

- J11, Keith Black, Canute and 2 others

-

5

5

-

Bob,

Thank you so much for the kind comments.

I started building model ships back in my tweens, graduating to full rigged plastic models in my later teens. For a while I had abandoned ships altogether and moved over to planes (a direct result of serving in the Air Force). It was only until about seven years ago that I got into building the wood ship models. With each build comes new experiences and learning. I look at my first wood build HMB Endeavor, while proud of how it turned out, I still see many flaws and things that I should have, could have, done differently. But, it gives me something look back on and see how my skills have progressed. While I am not in nearly the same league as some of the builders on this site, I’m happy with my results so far. Along with this it’s helped me gain the confidence to tackle a scratch build like this.

In the end though, it's not totally about the end result, but rather how much you enjoyed getting there.

-Brian

- Keith Black, Canute, Cathead and 2 others

-

5

5

-

Hello again everyone,

Progress has been a little slow for this update, my focus has been on projects around the house trying to get many of the outside things taken care of while the weather is nice and before it gets cold.

A couple of things that I did get accomplished were the cookstove and some of the lantern wiring. I am still shying away from the engines for some reason, mainly because I still haven't found enough photos of it to get a good representation of them. I had hoped that a friend of mine who was passing through Vicksburg a few days ago could have swung by and taken some pictures for me, but unfortunately the Cairo display and museum are still closed. So for now I'll work on other parts.

So on to the update.

Starting with the cookstove. This was just cobbled together with a few pieces of leftover wood sprues from a previous build (I throw away nothing). I then covered the whole thing in aluminum tape.

The basic form of the stove.

I then covered the box with aluminum tape and scribed the cook plates and top.

I then added then added the fire doors, hinges and handles.

Next I added additional features. Not sure what all these features are, they just added to detail.

Finally added the chimney flue.

Once the assembly was complete, I gave it a coat of flat black.

Followed by a dry brushing of light gray paint for highlights and a final coat of clear satin lacquer.

After the stove was completed, I started work on running the wiring for the lanterns. This is some time consuming work, soldering all the connection points. I plan to install about 20 LED's to light major features that will be visible. Some will be disguised as lanterns, others will just be hidden to light other features such as the paddle wheel and engines (if I ever get them built). The central connection point will be hidden under the boiler and I haven't quite figured out where I'm going to put the battery compartment and toggle switch. I still have time though to figure that part out.

Well that's it for this round. I am going to continue with dressing in the wiring and getting them painted up as well as completing the smokestack for the stove. I think I'm also going to either get started with the cannon carriages or possibly the casemates. Haven't decided just yet.

Until next time, thanks again for all of your encouraging comments and likes.

-Brian

-

-

Eric,

Sorry to hear of your woes both with the model and life. Here’s hoping that things get better on both fronts soon. 🥃

I do agree with your decision to go with individually planking the deck, personally I’ve never been a big fan of pre-scribed decks anyway. I do believe the results will be much more life-like and you’ll be more satisfied with the results.

Although this type of boat is way out of my wheelhouse and I’m not real sure how the original ones were built, I do like your idea of building the oar locks. If you are going for more of personal preference and not authenticity, then go with what makes you happy. I think you have said before, this is not going in a museum, so as long as you can get the satisfaction of visitors viewing your work in awe, then go build it as you like.

-Brian

- Canute, FriedClams and Cathead

-

3

3

-

Yves,

Absolutely stunning build. You are a master of your craft. I have thoroughly enjoyed this build and look forward to your next endeavor. Also, your photos are nothing to balk at at all. They truly do your model justice.

-Brian

-

Greeting everyone,

Small update this week. I managed to get the paddle wheel and pillow blocks completed this week.

Here is the wheel assembly painted.

Buckets cut, sanded drilled and stained. I used a mixture of Ipswich Pine and Golden Oak stains for these. I wanted something that would contrast the black ironwork of the wheel assembly, yet not blend in with the rest of the surrounding wood.

First bucket going in.

More buckets being installed. I threw together a little jig to hold the assembly while I worked on it. This jig made it a little easier to rotate the wheel, and by inserting a scrap piece of wood between the spokes, kept it from rotating it while I was installing the buckets.

All of the buckets installed and assembly temp installed in the wheel housing.

Finally the strings holding the buckets have been trimmed up, a little dry brushing with some light gray to highlight the details of the rivets and a final coat of clear satin and the wheel assembly installed in place.

Then it was on to the assembly of the pillow blocks. This part was a piece of cake compared to the paddle wheel.

Pillow block installed.

Here is the wheel assembly sitting in the pillow blocks. I still need to make the pillow block caps, I'll have to hunt around for some pieces of brass or aluminum for this part. Something that is the correct width and thickness and will also bend around the shaft, but I'm sure I can come up with something.

I tried to research on how the buckets were attached to the wheel spokes but couldn't find a whole lot on it. Apparently iron paddle wheels were not the standard back in these days or my search methods were just not up to par. At first I was going to make some simulated iron stirrups to attach them with, but I wasn't sure if this was correct or not. So I went with my gut, and off of the reasoning that the builders of the St. Louis model may have used for theirs in that tying the buckets to the spokes made for ease of quickly changing damaged boards. After all, these were war vessels and I'm sure they took their fair share of damage and in the heat of battle they could not afford to be sitting in the open while maintenance was performed. That and a portion of the paddle wheels on these boats was not protected by the armor plating and could be susceptibly to a fair amount of damage during periods of heavy gun and cannon fire. Just my thoughts, and since there isn't a significant amount of documentation on these, I took my "builders liberties" with it. Also, I think the group building the St. Louis know what they are doing, so I'm going to go with their expertise.

That's all for this update. I think I am going try and revisit the engines this week and see what I can come up with. First go-round just didn't come out right. Hopefully this time will be better. Wish me luck.

As always, thanks for looking and all the likes and kind comments.

-Brian

-

Eric,

Nice job on the figurehead, that’s one of the skills that I have not attempted yet is carving. Not sure that if I gave it a shot that it would resemble a dragon at all, probably look more like a worm.

I’m with Louie on the eye. Protruding would most likely have a better effect.

-Brian

- Canute, Louie da fly, mtaylor and 1 other

-

4

4

-

Roger,

Winchester has some truly beautiful weapons. One of the guys I hunt in Wyoming with uses a true Winchester 1894 38-55 black powder cartridge and is deadly accurate with it. I am more of a traditional cap and ball black powder person. I have way too many hobbies to start reloading. Not to mention the Admiral would blow a gasket if I picked up another one.

Funny you mention flying saucers at Devils Tower. I was 10 years old when I first saw Close Encounters and wanted to see Devils Tower every since then. Sad that it took over forty years to cross that bucket list item off. Hopefully you can get to Cody soon, it’s well worth the trip.

Gary,

Thanks for the kind words. The paddle wheel had definitely been a challenge. Totally different take on the traditional packet steamer paddle wheel.

-Brian

- Canute, Roger Pellett, mtaylor and 2 others

-

5

5

-

Keith,

Thank you for the kind words.

You are so right about that being some of the best scenery (minus the smoke of course). I was a little disappointed that we didn’t make it to Yellowstone, but I’ll definitely hit it on my next trip up there. Nice to have friends up there to go visit every so often.

We spent most of our trip in Cody, WY where, if you are a gun enthusiast like I am, they have one of the best collections in the world. The Buffalo Bill Center of the West has over 7000 guns dating from the 2000’s back to the invention of gun powder. They actually have the entire Winchester collection from every model they ever made, experimental and production, to ones the Winchester family collected and traded for. We spent about five hours perusing just the gun section alone. The museum also includes other exhibits from the natural history of Wyoming and Yellowstone to artifacts from Buffalo Bill’s Wild West Show. Truly a must see if anyone is ever in Cody, WY. You may have to set aside a couple of days to see the whole thing, that’s why your admission ticket is good for two days. I would also suggest the exclusive tour of the gun museum, the cost is quite a bit more than general admission, but they take you to the vault where you get to handle some rare guns that are not on display (with white gloves of course). Truly an experience.

This was just one of the rooms in the museum. Each of the pull outs has rifles and all of the drawers below have hand guns.

-Brian

- Canute, Keith Black, mtaylor and 1 other

-

4

4

-

Hello again everyone,

It has been a while since my last update, but I have finally returned from my hunting trip and vacation. Needless to say it was well needed and I saw some of the more beautiful parts of this country that have been on my list for a long time. Unfortunately, the wildfires that have been plaguing California, Oregon and Washington halted my trip to Yellowstone. The smoke was so bad that the air quality and visibility would not have made for a very fun trip, so I'll hit it next time. I did se a couple of other fascinating places though, as you can tell by the pictures the smoke was even bad in eastern Wyoming and South Dakota.

Devils Tower was a little cloudy, but you can tell from the haze that the smoke was still a factor.

Mount Rushmore was just a smoky haze, but at least it was visible to. The farther west you traveled the worse it got. Even North Texas had a smoky haze to it when I got home. I do have to give an immense amount of credit and praise to the firefighters working their tails off and putting their lives on the line containing the wildfires to protect as much as they can.

We'll enough of that, on to my update. While most of the past week was spent playing catch up at work, I managed a little work on my paddle wheel.

Having assembled the remaining three wheels, it was time to start building up the hubs. To simulate the hubs I used a couple of different size flat washers, stacked on top of each other to give them some depth.

I used a piece of brass tubing filed to an edge to help center the washers around the paddle wheel shaft.

Once the glue had dried I had eight perfectly spaced washer "Hubs" .

Next I placed each of the wheels in the assembly jig and with the sharpened brass tubing installed the washers on the wheel assembly.

Once that was done they were all ready to install on the paddle wheel shaft. I used the same brass tubing cut into 1" pieces as spacers for the wheels assembly and notched out a few scrap pieces of wood to keep the outer edges of the wheels spaced evenly.

Wheels installed on the paddle wheel shaft.

Outer spacers installed.

And everything held neatly in place with rubber bands.

Then it was on to one of the more complex assemblies that I have done so far on this build. Installing all of the cross bracing between the wheel assemblies.

My first attempt was to use 24 gauge wire for the bracing, but I couldn't get the wire to bend one way and then the other and still remain straight. Given the tight quarters between the wheels, it was next to impossible to work the wire back into shape. So I decided to use .20 black rigging thread instead. I managed to weave the tread between the wheels, applied a dab of CA on one end, let that dry, then pulled it tight and placed a dab of CA on the other end to hold it in place. Once the CA had dried, I brushed the entire string down with a coat of CA to stiffen in up and the end result came out looking a little bit like hammered iron. Couldn't have asked for a better result.

While the CA was drying on my cross braces, I went ahead and cut out my buckets and sanded them to length.

Taking some tips from the St. Louis build, they have four buckets that are double the thickness as the others and spaced every other spoke for the counterbalance of the cranks. These will be installed on the opposite side of the cranks to keep the paddle wheel properly balanced. I am going to have to do a little research on how the buckets were attached to the wheel arms though. Normally they would be nailed in place, but since these wheels are iron, I don't think that was the way these were mounted. On the St. Louis build, it looks as though they tied the buckets in place, but I'm not sure if that was just temporary or if that was how they were actually done. I'll do a little digging to see if I can come up with how they were fastened.

Anyhow, that is where I am for now. This week I will work on trimming up the cross bracing string, cleaning things up a little bit on the paddle wheel assembly and getting the whole thing painted.

As always, thanks for for looking and all the comments and likes.

-Brian

- G.L., CiscoH, Andrea Rossato and 13 others

-

16

16

-

Eric,

Finally catching up on your build. It’s looking like you are overcoming the hull obstacles very nicely. It won’t be long before you can put that part behind you and move on to hopefully less frustrating construction.

Love the figures. Your choice of colors is very realistic. I wouldn’t worry too much with the scale difference, from here it looks as though Sihtric is somewhat crouched in a stalking position so he would appear a little shorter than Ragnar who looks to be posed ready to launch his spear.

-Brian

- Louie da fly, Cathead, FriedClams and 2 others

-

5

5

-

Very tedious work, but she’s looking great. Love the chisel jig as well, perfect way to keep an even edge. Pretty ingenious.

-Brian

- FriedClams and mtaylor

-

2

2

-

Vaddoc/Don, Thank you both for the kind comments.

Vaddoc, these boat were actually fairly sturdy for being built on a short schedule and a shoestring budget. Their flat bottoms, triple keels and heavy framing helped support their heavy armor. Thankfully they only had the western rivers to contend with and not the seas, so they weren't tossed around that much, just swift river currents and enemy bombardments.

Time again for a brief update.

While I still contemplate work on my engines, I started working on the paddle wheel frames. I was having a difficult time deciding on what types of material to use for them. At first I wanted to use brass strips for them, but I was having a hard time finding strips of the right size and length. The thickness and width weren't as difficult as trying to find strips longer than 12". While walking around the house looking for ideas, I happened upon the Admiral's sewing supplies. In her spare time she makes face masks for the elderly and donates them to local retirement communities. While I was looking at her her supplies, I discovered the aluminum wire that she uses for the nose pieces in these face masks. This had the correct dimensions that I needed so I borrowed some from her. I did order more to replace hers though, so hopefully she won't be too upset with me.

I then made a couple of simple jigs to wrap the wire in to get the proper sizes for the inner and outer frames.

I started with alternating the spokes, bending them around the rings as I worked my way outward. For the center hubs I found some 1" brass discs and drilled out the centers for the axle.

All of the spokes and rings were held in place with 5 minute epoxy at the cross points. A second disc was placed over the top of the spoke ends and epoxied into place. I again simulated the rivets on the hubs with aluminum tape and my ponce wheel.

Once the pieces were dry they were removed from the jig and the ends of the spokes trimmed off and filed down.

Next step is to drill all of the rivet holes and fill them in with brass nails. That and three more wheels to go. Slow progress, but I'll get there.

Also this week I received my lanterns from Shapeways and decided to throw one together to get an idea of how it was going to look.

Lanterns on the sprues.

The three part that will make up the lanterns. Globe, reflector/base, and micro LED.

The three pieces together.

...and lit up.

Painted up the bases.

Finally one mounted into place. I think I nailed it. I may take a small disc of aluminum tape and put it on the reflector to give it a little better look, I just need to find my hole punch to do this.

Things will slow down for the next couple of weeks, I'm off to Wyoming this weekend for a much needed vacation. Going to attempt to decrease the Antelope population by a few and while I'm up there I'm going to knock off another bucket list item and visit Yellowstone NP.

Thanks everyone for looking and all the kind comments.

-Brian

- KeithAug, Moab, Keith Black and 15 others

-

18

18

-

Yves,

Difficult decision indeed. You could place one on the sub itself and the other as it’s own static display since they are both beautifully crafted.

-Brian

USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

in - Build logs for subjects built 1851 - 1900

Posted

So after a little more research, I determined that you were right Keith, The muzzle swell on the 30lb parrot rifle was a little bit much.

I found some pictures I had taken a few years ago when I visited Vicksburg NMP. Now given the assumption that these are the original guns that were brought up with the rest of the USS Cairo then the 30 pounder has a slight swell at the muzzle, a little less than what is shown on the HSR.

Compared to the HSR drawings, the real guns have less muzzle swell.

So with that all being said I decided to turn it down a bit. It might not be perfect, but I do think it looks closer to the actual gun than the drawing.

Thankfully there was only one 30 pounder on board. Now to build the carriages and figure out how to duplicate the other guns.

-Brian