-

Posts

4,894 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

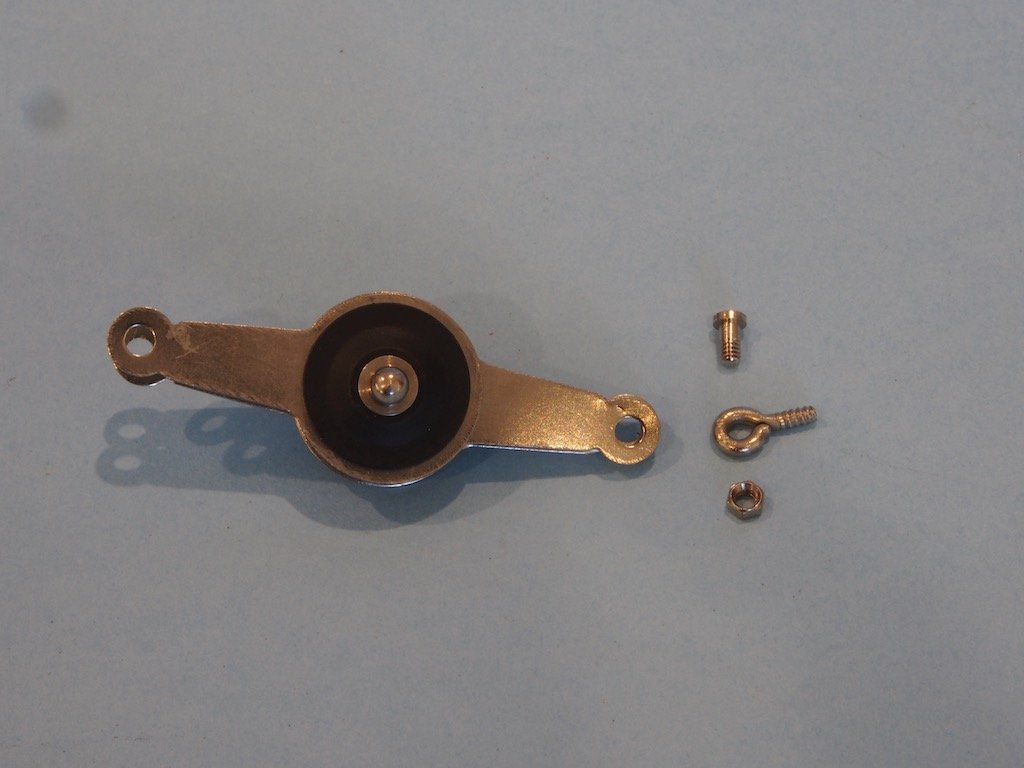

Thanks for all the likes folks. Bob, to answer your questions: I’m using Vallejo Metal Colour paints, sprayed with my airbrush (Harder and Steenbeck Infinity with 0.4mm needle). I used Dull Aluminium for most of the engine and associated parts. I used Steel for the radiator and for the drive shaft and rear axle. And I use Gun Metal for hand painting the highlighted bolts where appropriate. I used thin CA for this. It forms a pretty much instant bond between brass and the rubber, so it needs to be done carefully. I applied a small amount in the mid section, then worked outwards a little at a time.

-

NIce to see you back at this one Kevin. I’m in!

- 273 replies

-

- panart

- amerigo vespucci

-

(and 1 more)

Tagged with:

-

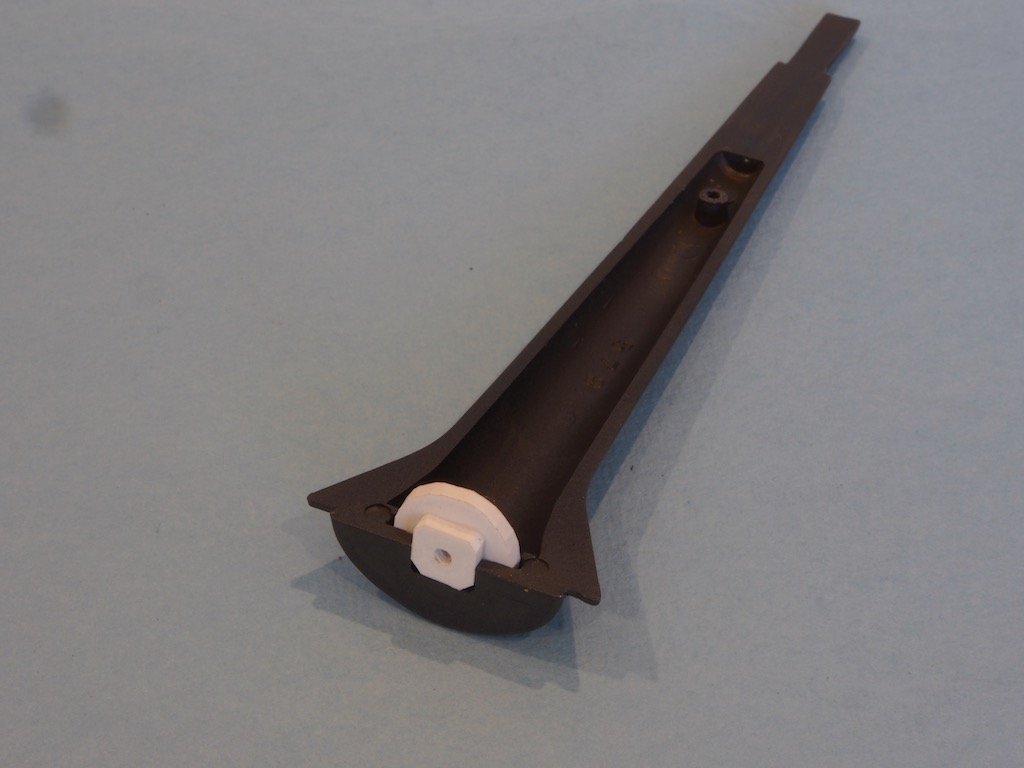

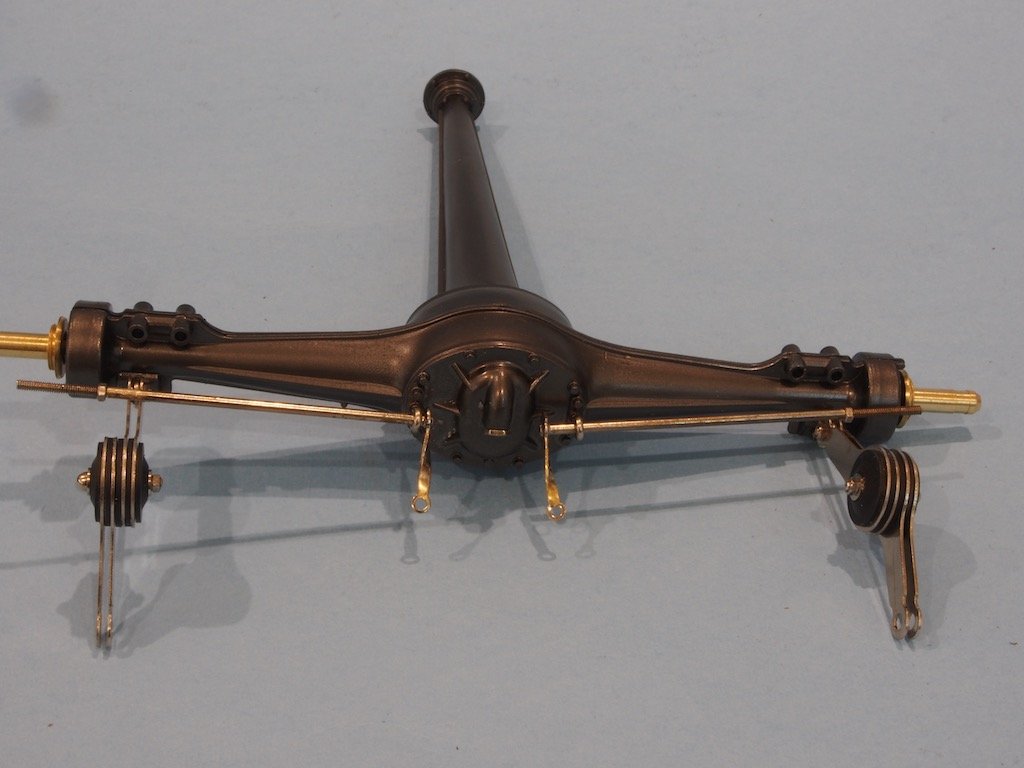

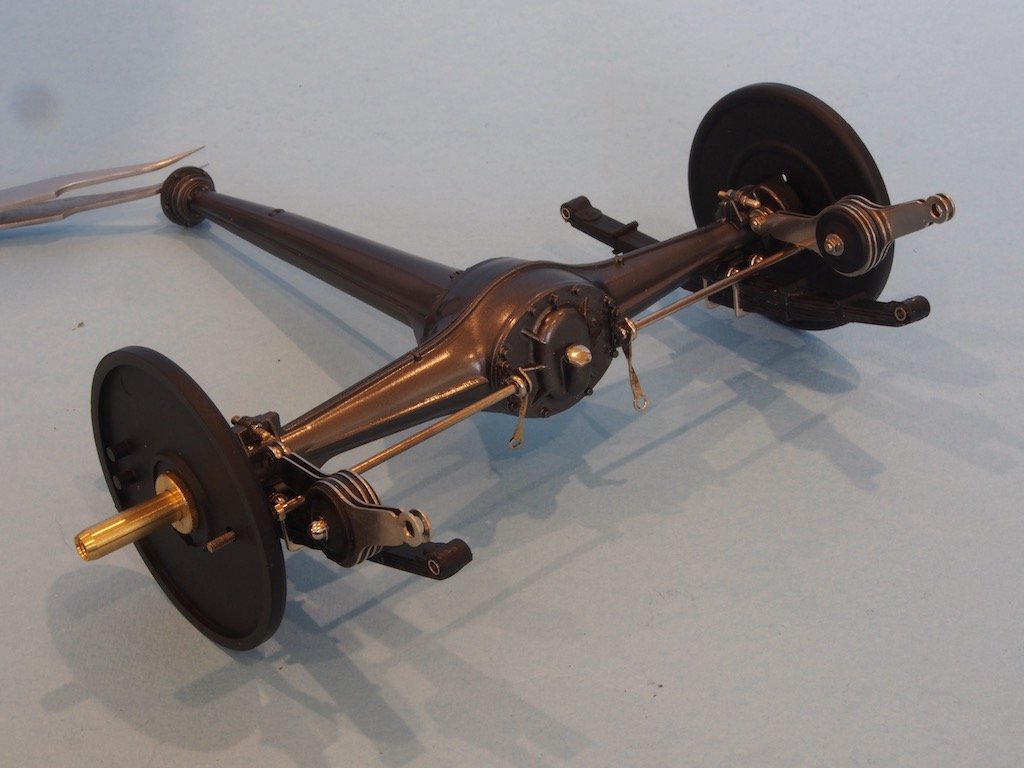

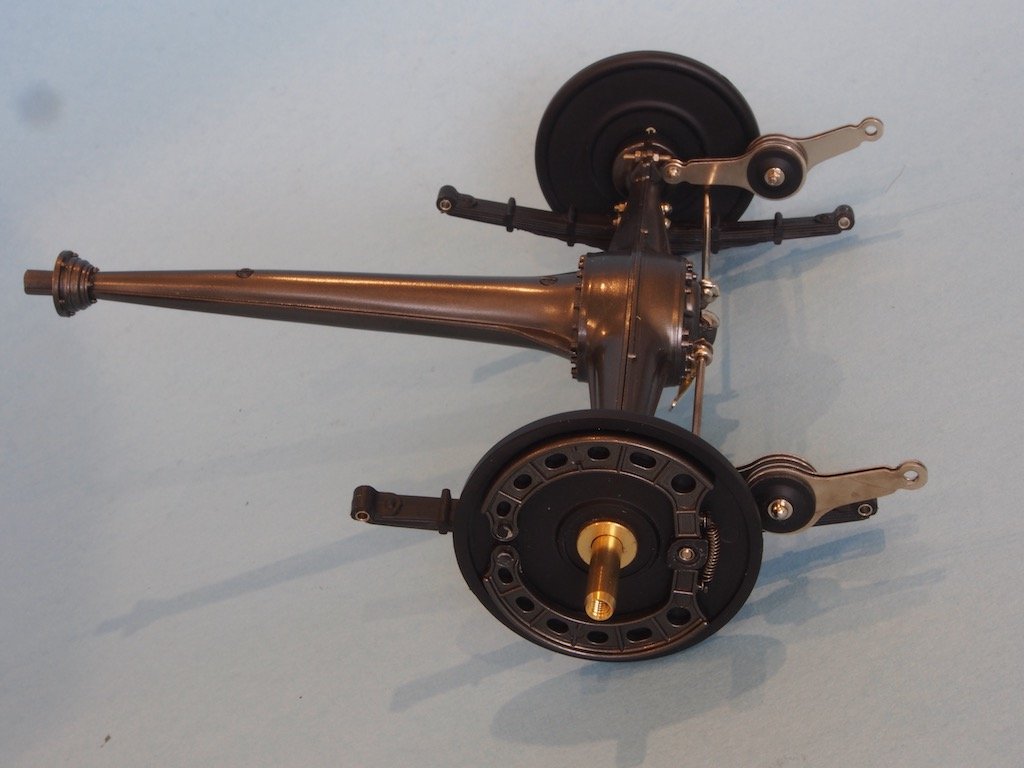

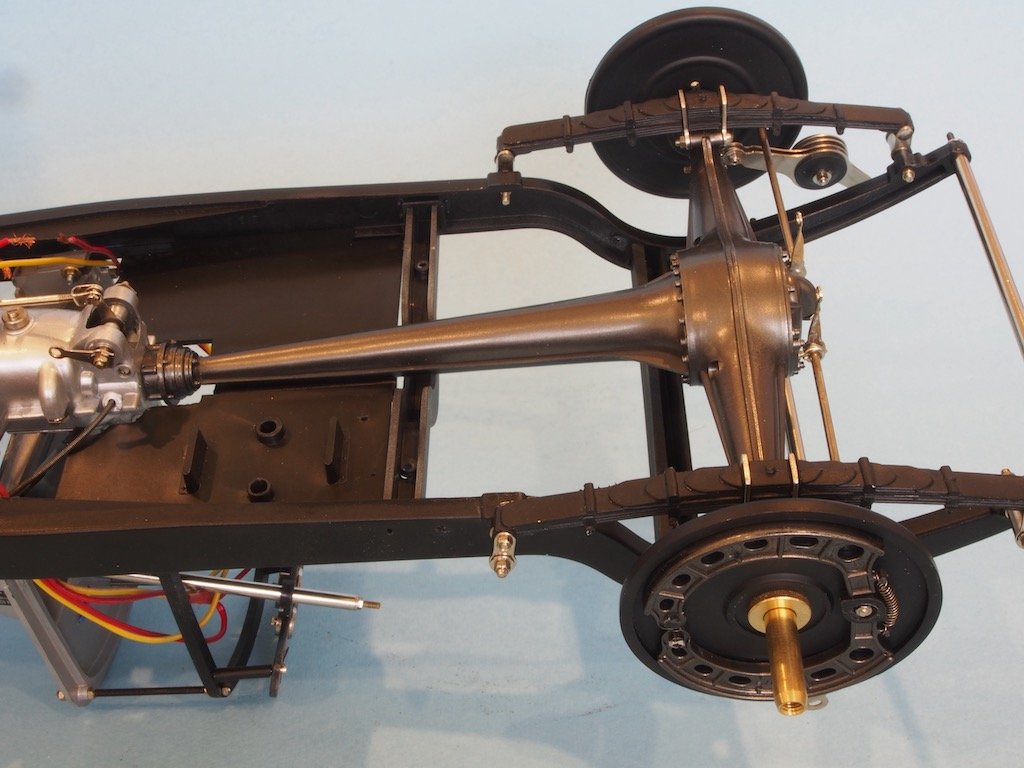

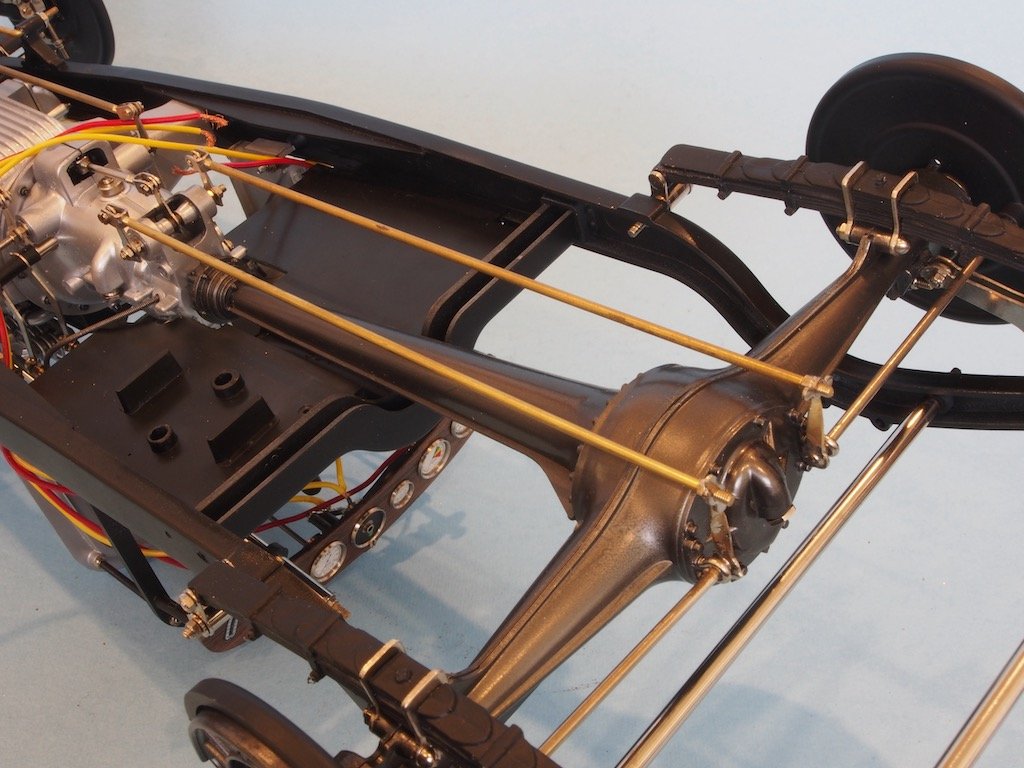

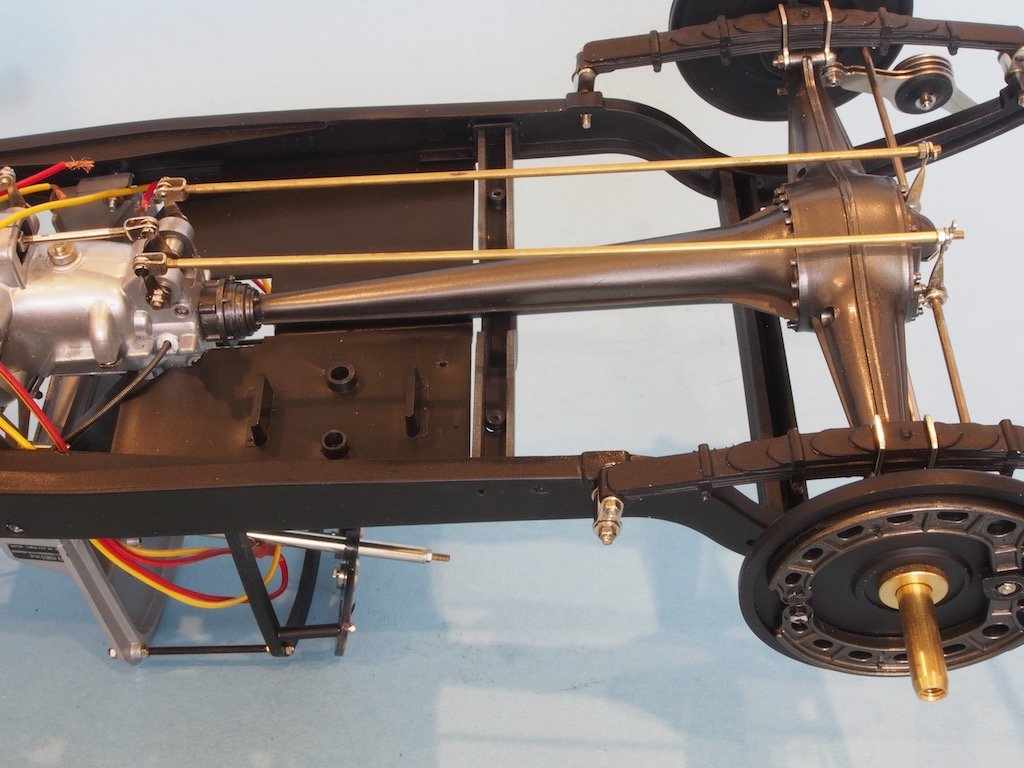

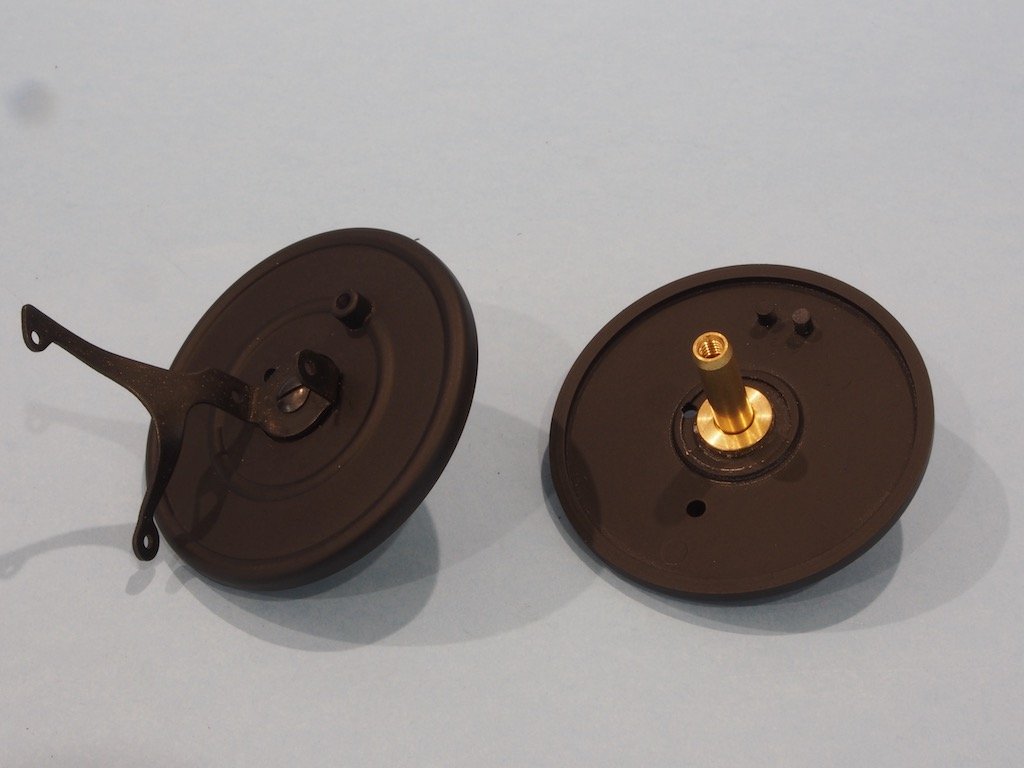

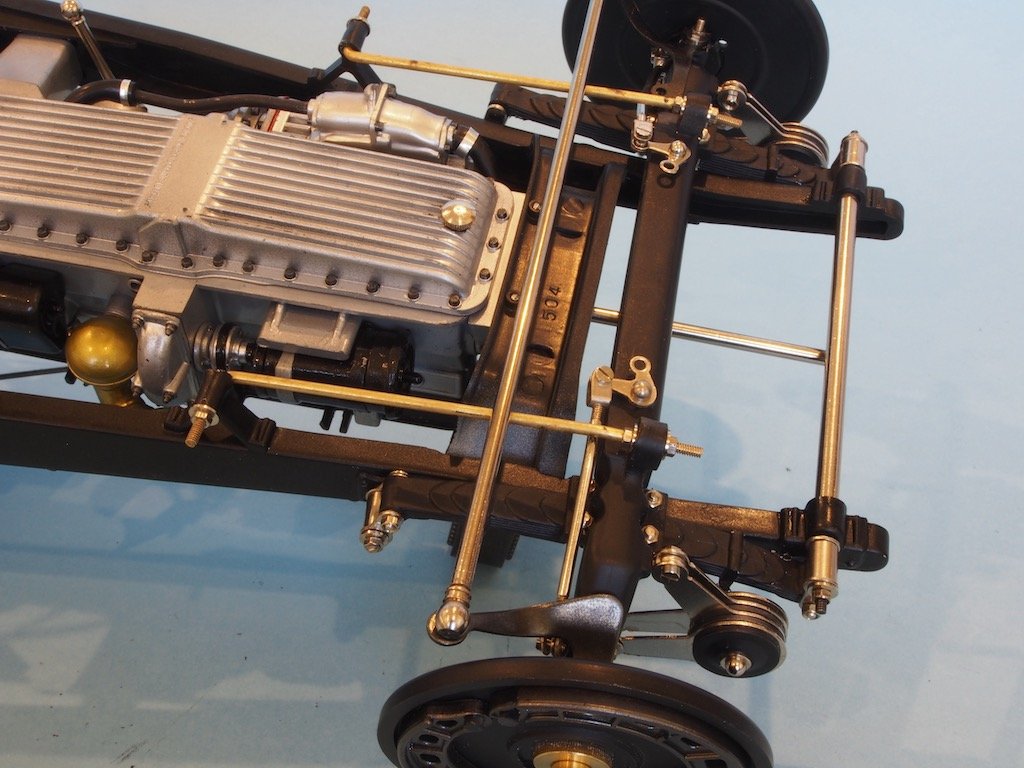

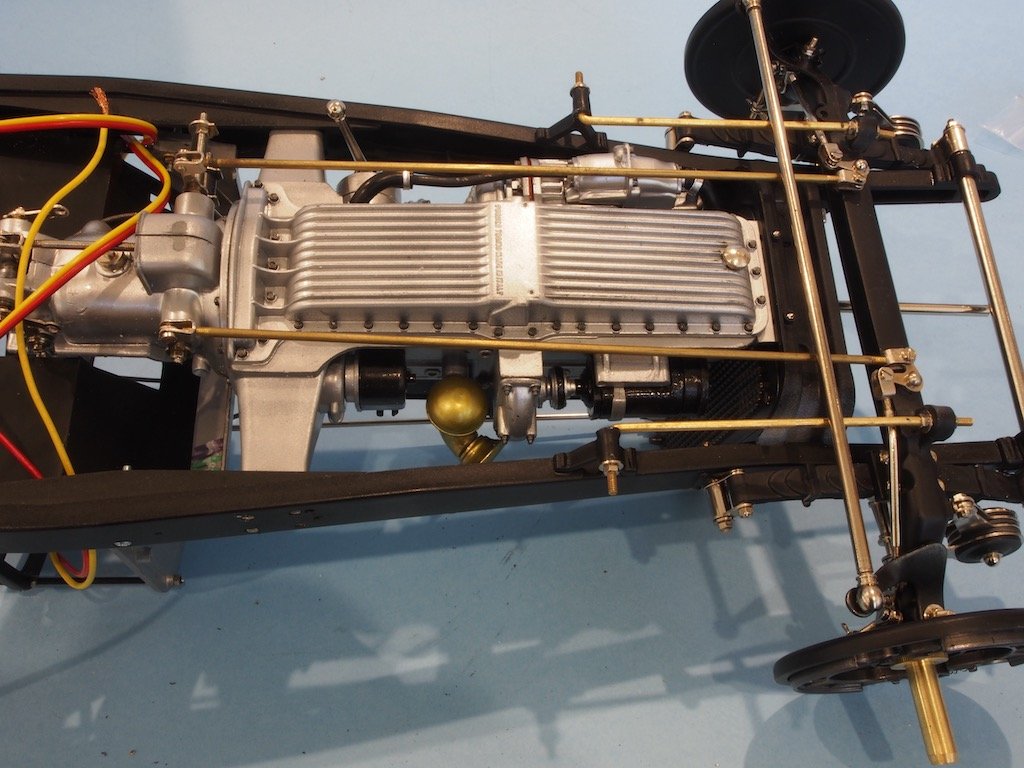

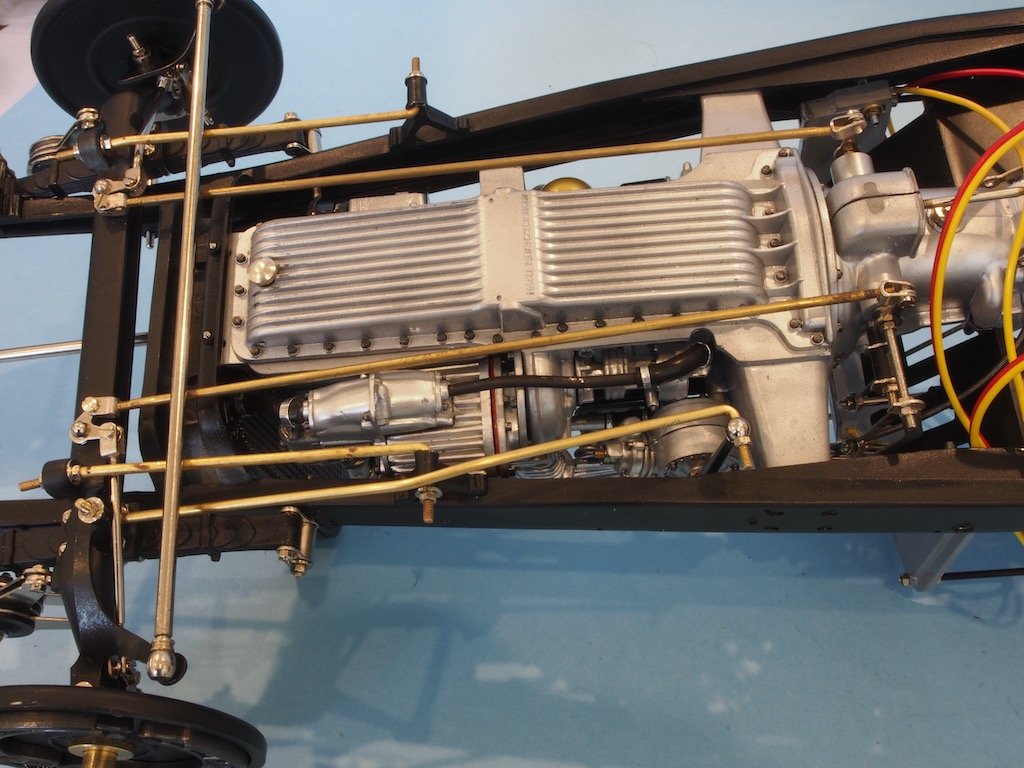

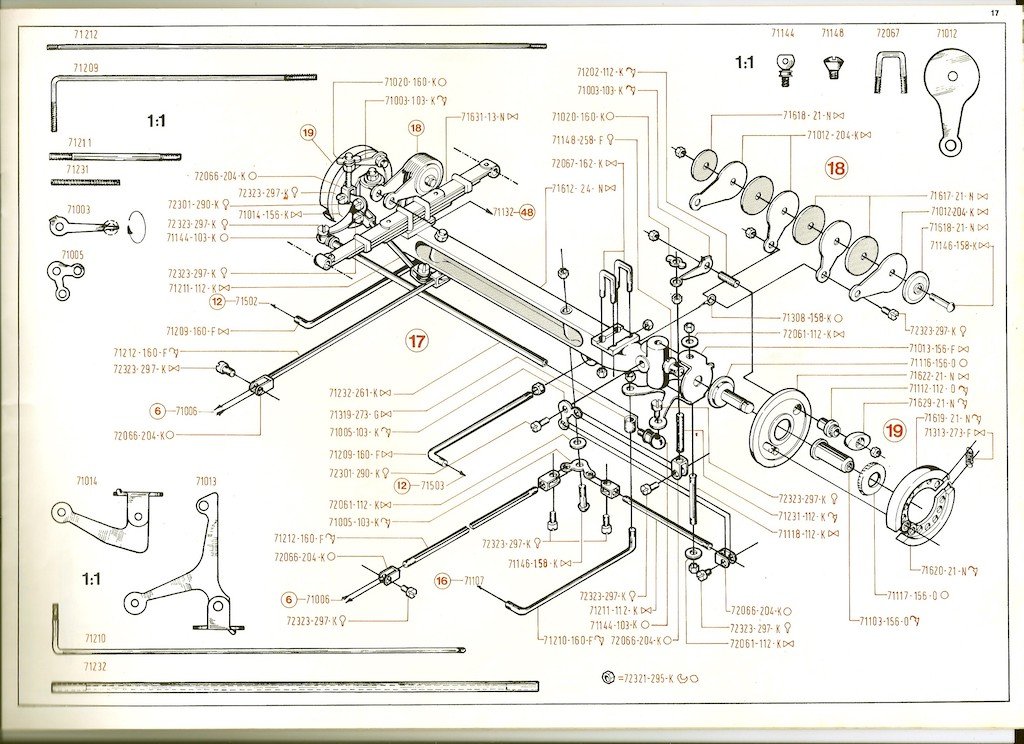

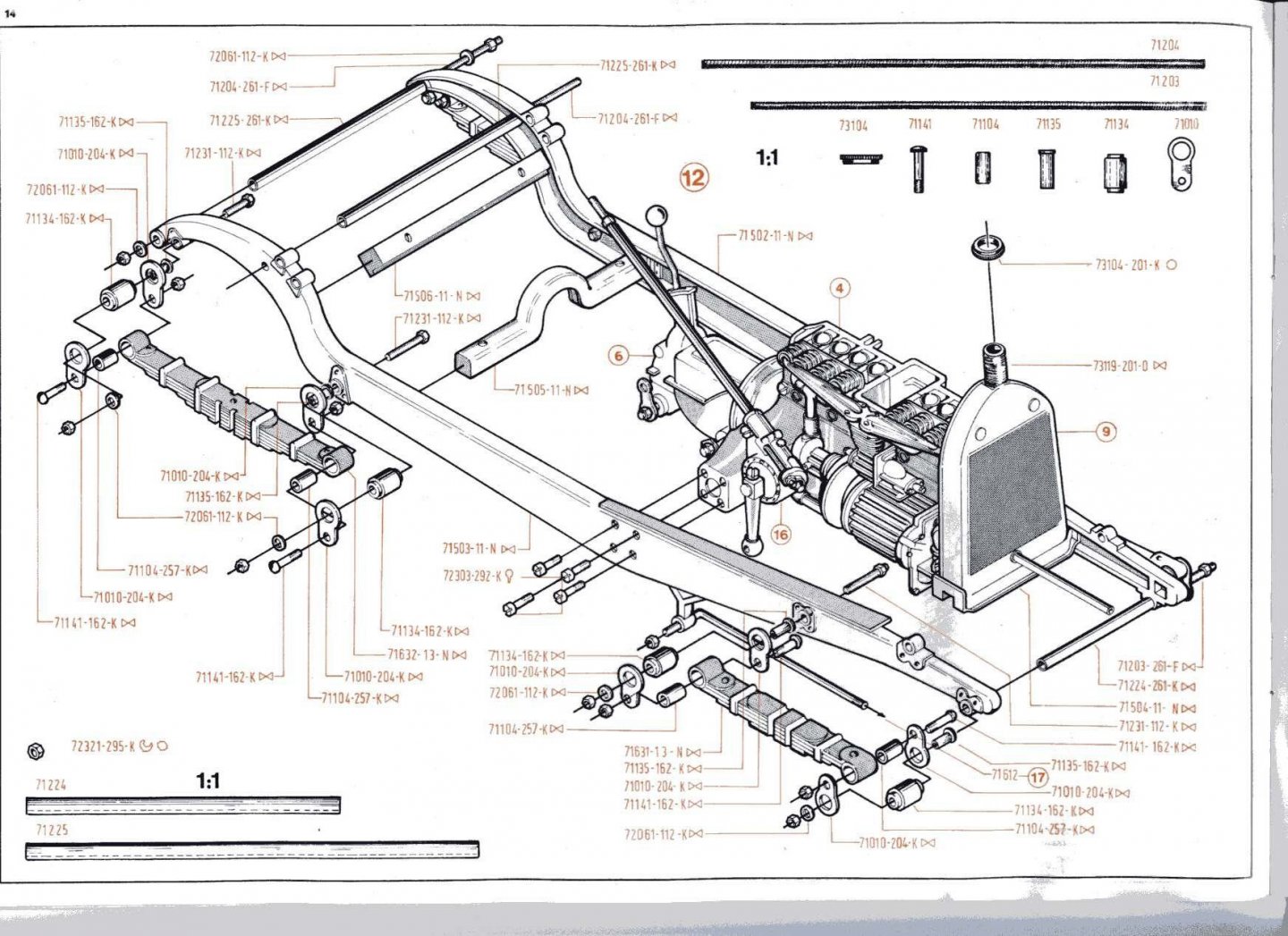

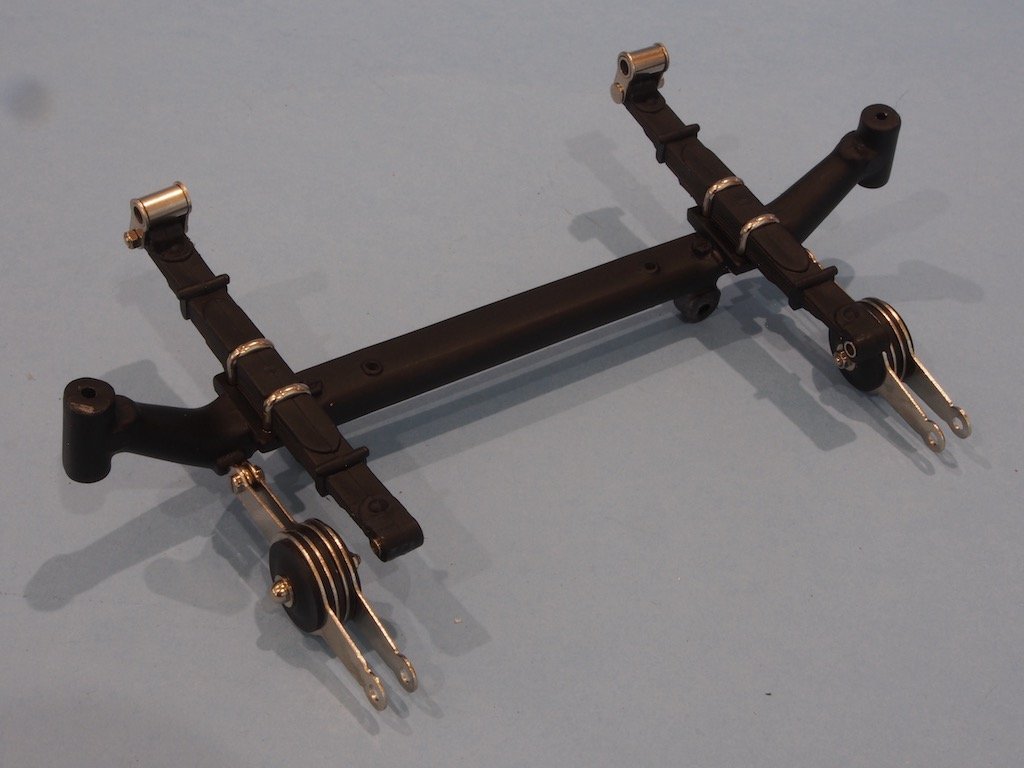

The Rear Axle Once again, some test fitting, modification, disassembly and re-assembly are required. Another 88-page photo essay from Paul supplements the one-page Pocher diagram. Assembly commences with the drive shaft. It comprises two main components, two rear spacers, and an internal part that receives a screw for attaching the rear axle to the drive shaft. As the internal part did not require painting, it was set aside while other parts were painted. Of course, when I went to commence assembly, it was nowhere to be found! Fortunately, it is not a complicated part and I was able to manufacture a scratch-built replacement from a couple of pieces of 2mm styrene sheet. The photo below shows the new part glued in place in one half of the drive shaft. The other half of the drive shaft was then put in place (held in place by two screws) and the first half of the rear axle housing was screwed in place using the new part to receive the screw. The actual rear axle is then put in place with its two wheel hubs. The front half of the axle housing was then attached and the rear dampers assembled and added in much the same way as for the front axle. The rear brake linkages were also added at this stage. At this point the rear leaf springs are required. All of the leaf springs are made of a soft rubber compound rather than hard plastic. Paul notes that while these are okay for the front axle, they are too soft for the longer rear leaf springs and suggests modifying them. Although Model Motorcars does offer some very nice after-market photo-etch leaf spring assemblies, at USD $130 per set plus the exorbitant postage rates from US to Australia, plus the eight week plus current postal delay, this was not really an option. Paul’s second option is to modify the rear leaf springs by cutting them in half length-wise and inserting a piece of 1/32” x 1/4” brass strip to act as a stiffener. I chose to go with this option. The hardest part was cutting the original leaf springs in half. I did this using by Byrnes table saw and very dodgy holding jig. Here is the leaf spring cut in half and the pre-bent brass inserted. Matching notches were cut in the brass using a cut-off wheel in my Dremel-type tool. Then the top half was reattached and the entire assembly re-painted. The completed leaf spring was then attached to the rear axle. The wheel plates had the brake cams installed and these two were then attached to the rear axle. Brake shoes and springs were then inserted as per the front wheels. The entire assembly was then test fitted with only one of the two rear spacers fitted. The gap between this and the transmission was then measured and the second spacer sanded down to this thickness prior to final fitting. The brake linkages were then fitted between the brake connecting rods and the transmission levers. Another view. Final attachment of the rear axle requires the dampers to be attached to the chassis. However, a couple of extra parts need to be in place prior this. These parts are now in the paint shop and will be fitted during the next phase of construction.

-

Dave, If you want to see how the Spar varnish comes up over woodgrain and a painted bottom, have a look at post #280 on page 10 of my Chriscraft Runabout log: I finished that build almost 3 years ago now and it looks as fresh today as it did then.

- 51 replies

-

- miss unlimited

- dumas

-

(and 1 more)

Tagged with:

-

That’s looking great Dave. If you are going to maintain an option for RC, then you might want to consider Spar Marine Varnish as it has UV protection built in to protect the finish from yellowing over time.

- 51 replies

-

- miss unlimited

- dumas

-

(and 1 more)

Tagged with:

-

Ingenious modification BE, but that shouldn’t really surprise us now should it? 👏👏👏

- 195 replies

-

- lady eleanor

- vanguard models

-

(and 1 more)

Tagged with:

-

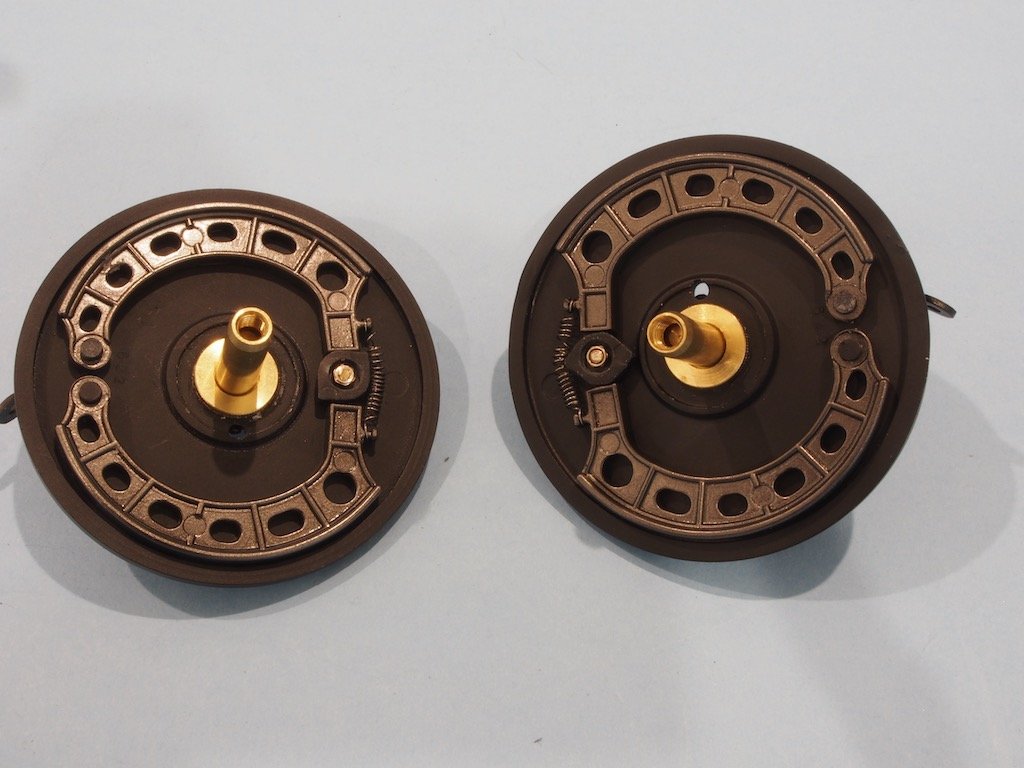

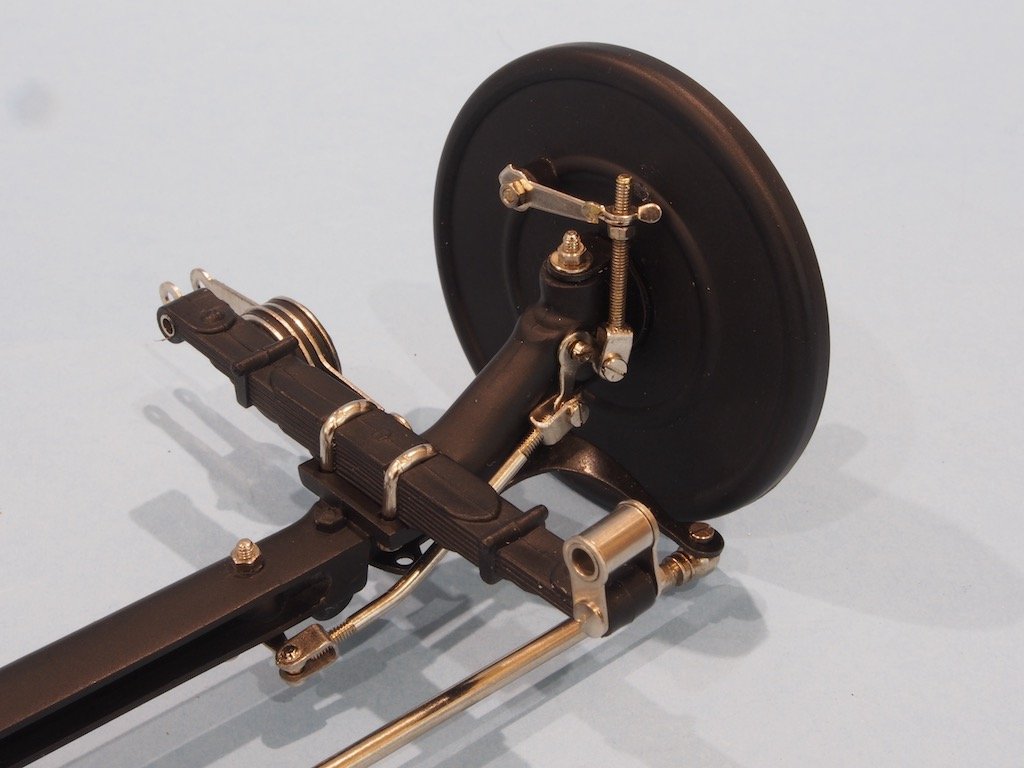

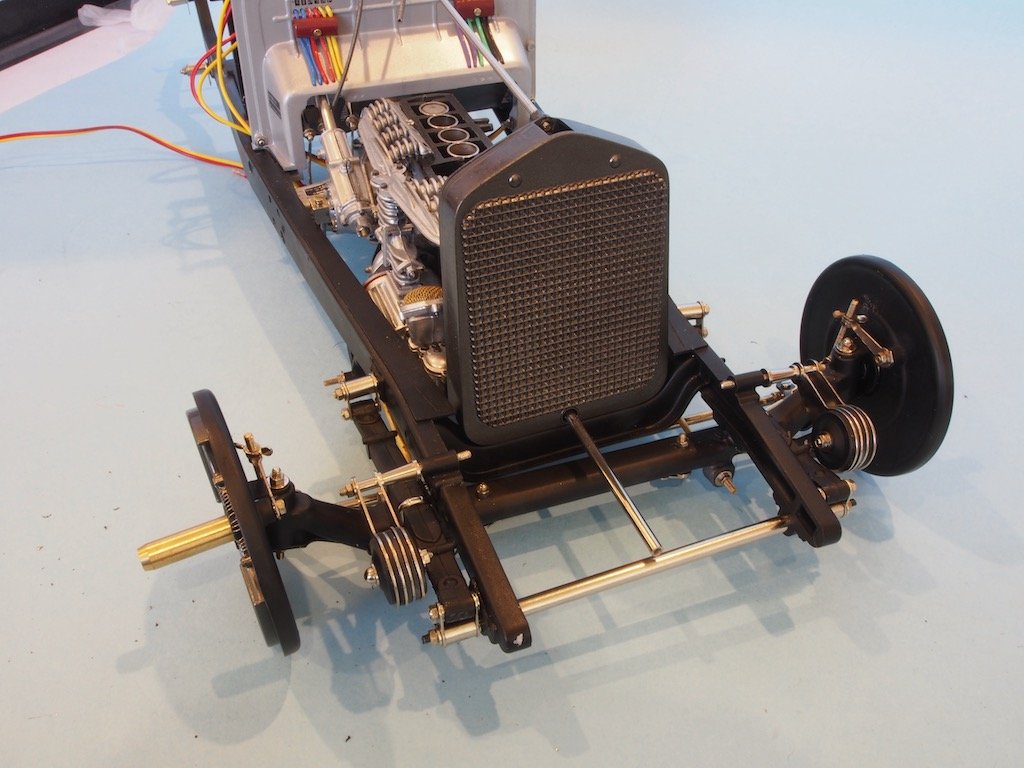

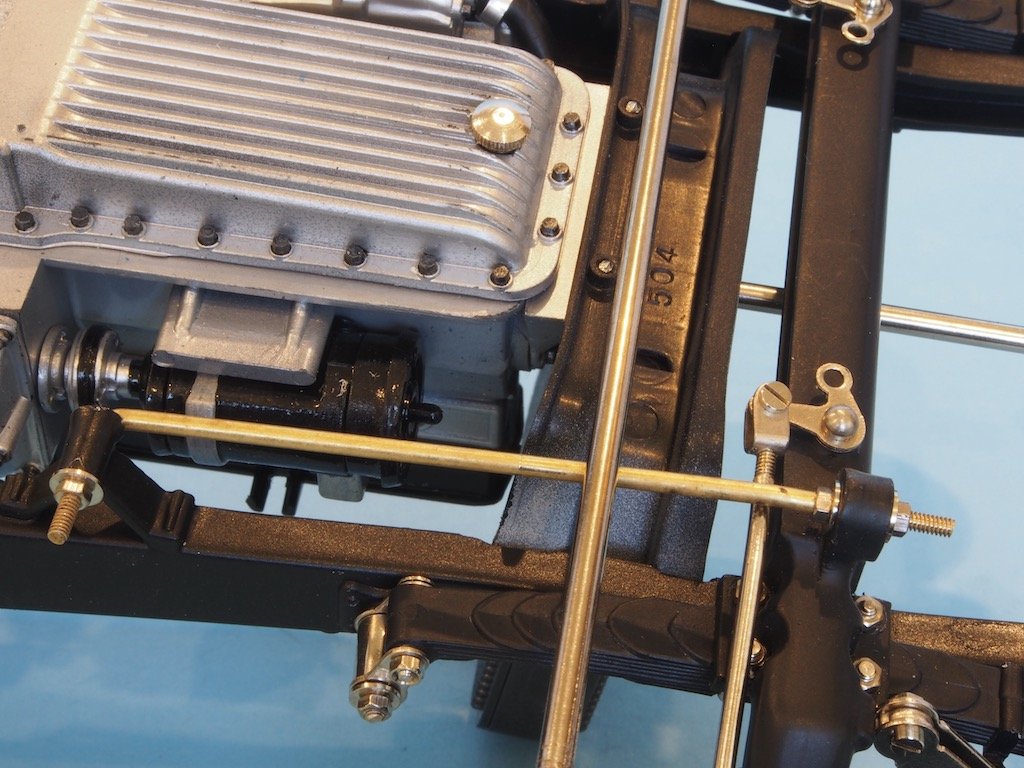

Next up are the front wheel plates. These get fitted with the rotating axle hubs and a strange looking metal piece that I have no idea of the name. I forgot to take a pre-assembly picture, but here is what these look like assembled together: The front brake cams then need to be fitted to the wheel plates. Here are the components and pre and post assembly: On the other side of the wheel plates, the front brakes themselves are fitted: If you look closely you will see the spring joining the two brake shoes running over the top of the brake cam. The brakes are supposed to be fully functioning, but the springs are a little too strong and the cam a little too weak. It is supposedly possible to fix this issue, but it is not easy and I’m not going there! The wheel plates are then fitted to the front axle: And here is what the front axle looks like so far: The tie rods, brake linkages and front axle braces are fitted next, with some judicial additional bending of the front axle braces and some extra threading added to them as well: The front axle brake linkages are then added back to the transmission brake levers: And finally, the steering control rod is added back to the control arm on the steering gear box. Again, this needed to have some judicial bending imparted and in this case was inserted from the opposite direction at both ends to that shown in the Pocher manual in order to provide a better fit: The rear axle assembly is next...

-

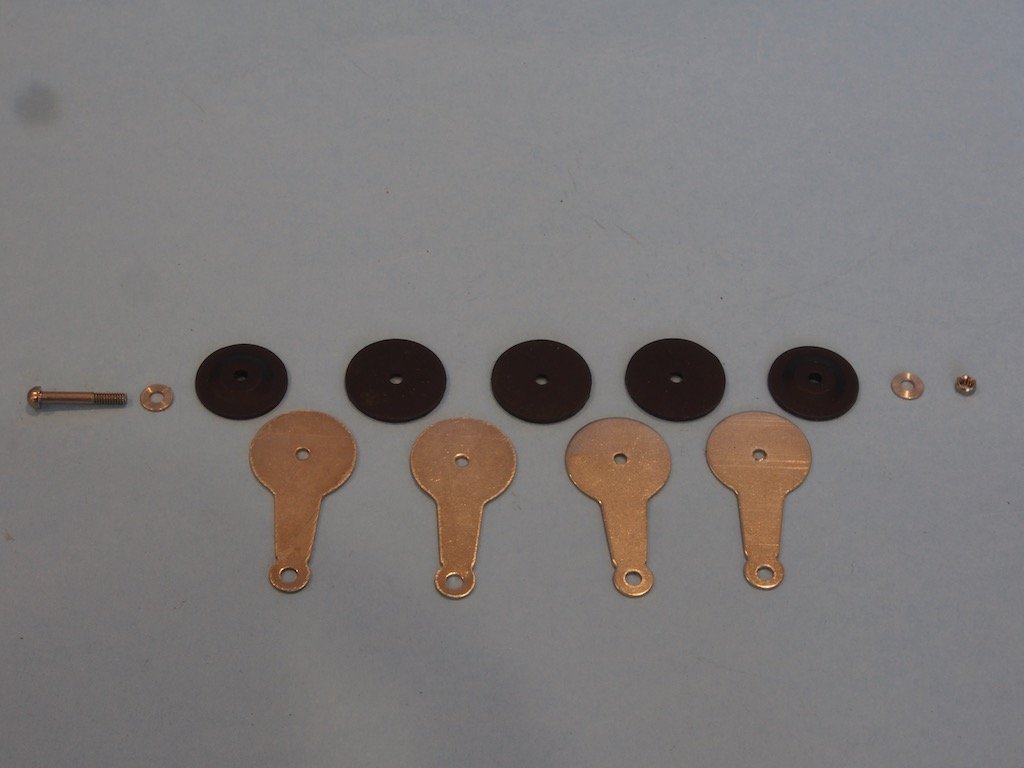

Some progress was made last weekend, but I didn't get to update the log until now... The Front Axle The approach to the front axle is the same as for previous sections – ie test fit and adjust where necessary the plastic parts, then disassemble, paint and re-assemble. This is a quite complex assembly. The Pocher instructions are nothing more than an exploded parts view – with no information about the order of assembly. A second page deals with the leaf springs, both front and rear, but these need to be addressed in conjunction with the front and rear axles respectively. In contrast, Paul’s photo essay on the front axle is 96 pages long, with detailed explanations for both parts fit and sequence of assembly, as well as offering alternative methods for some parts to make the fit better and/or easier. Assembly commences with the front dampers. Here are the initial components (there are two lots of these of course): And assembled: They then need to be affixed to the front axle: The front leaf springs are next. Part of the leaf spring shackles were fitted to the main frame in the previous step. Here are the components for one of the rear shackles: And the front leaf springs attached to the front axle: Continued next post...

-

Happy Birthday Gary and thanks for giving us the present of an update on your lovely work.

-

Welcome to the forum Rick. Please do start a build log once your kit arrives - this one is on my “bucket list”.

-

Looking good Spider. I’m only just catching up with your progress. I used the little green tiles on my Victory and then painted them over with copper paint and then lightly sanded the copper paint to allow some of the green to show through, then sealed all with a clear finish. I think it came out okay. You are certainly taking it to the next level by applying copper tape over the top of the tiles.

-

Welcome to the forum from the Nation’s capital Jii. You’ll find there are quite a number of us Aussies here. Regarding first kits, although I’ve not built one, there are some nice offerings from Vanguard models available that are specifically designed with beginners in mind. There are also a couple of reviews of these kits here on the forum, and a few build logs underway. Although UK based, so postage will take a while in the current COVID environment, they could be worth waiting for. I don’t think you’ll find better sets of instructions anywhere.

-

Change Theme

gjdale replied to cog's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Reminds of an Admiral once quoted as saying, “I’ve been in this outfit for 40 years. I’ve seen a lot of changes in that time. And I’ve opposed every single one of them!” Keep up the great work Mods/Admins - I’m sure any minor glitches with the changes will be overcome (or forgotten) in time. -

I view cleaning the airbrush much the same way as sharpening a chisel - keep the tool clean/sharp and it will serve you better. Once you get used to stripping down, cleaning and reassembling the airbrush you’ll find it’s not that big a deal and you’ll become very proficient at it - much the same as gaining proficiency (and speed) at sharpening a chisel. If you get lazy about either task, the tool will not perform at it’s best and you’ll end up taking longer over the main task and likely with more re-dos.

-

He has an ebay store: https://www.ebay.com/str/pocherphilesforum But if you are after a kit, you’re probably better off contacting him direct via email as he doesn’t necessarily put these up on the web. He can usually source particular kits for you as well. If you’re interested I can PM you his email address.

-

You'll just need to be prepared to do a little bit of experimentation with air pressure, paint viscosity (ie thinning ratios), and air:paint mix through the brush. It sounds complex, but the only way to really get the hang of it is to just do it. After a while you will "just know" that you've got all the variables right.

-

Thanks for the friendly kick in the pants Chuck! 😀 Although my replacement parts all arrived safely a few weeks ago, I have been so absorbed in my non-ship project that I haven't gotten around to re-starting this one yet. I have been studiously reading others build logs though, and will re-start this one soon.....I promise.......I just need to get a round tuit. 😉

- 109 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

If you are using an airbrush Bob, why not use it for the primer as well? If you are using Vallejo paints, their primers are also very good. I have found that thinning them 3 parts paint to 1 part (Vallejo) thinner works pretty well. Although acrylic paints don’t have the “nasties” in them, they are still atomising the paint, so lung protection is always a good call.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.