-

Posts

4,890 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

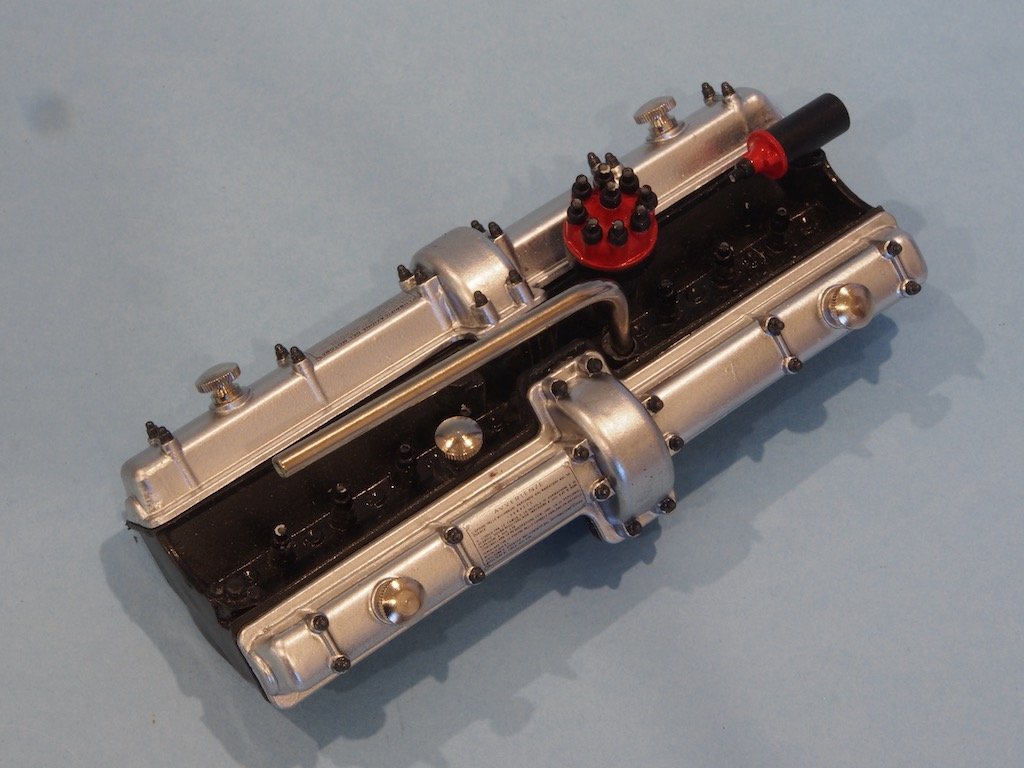

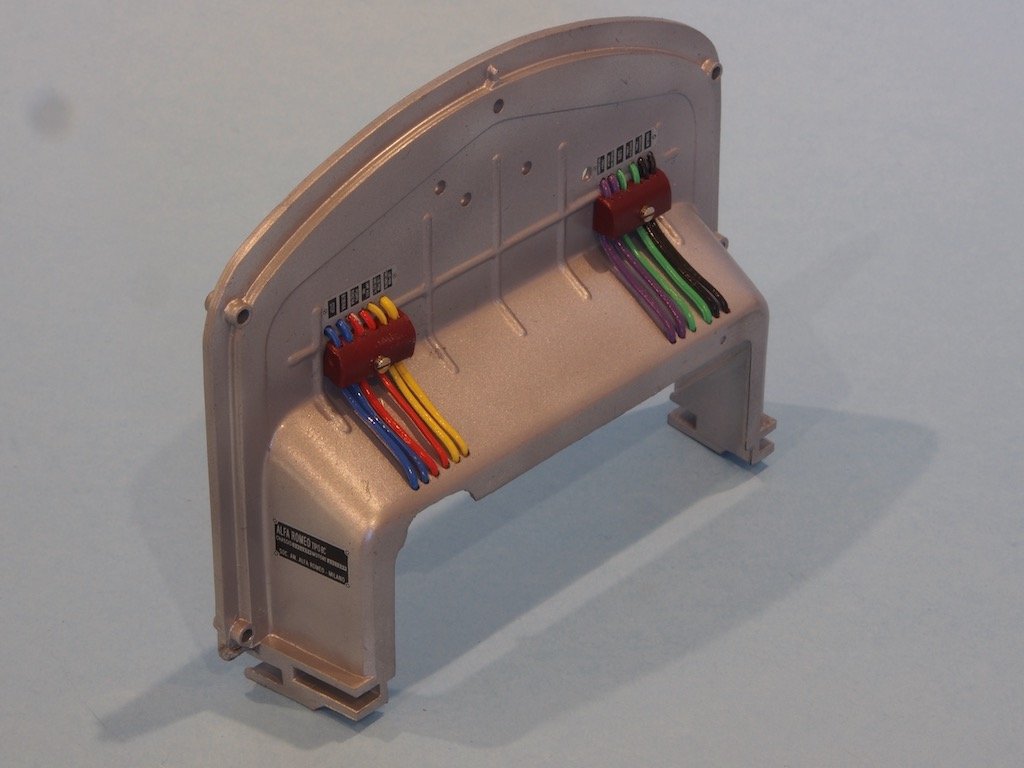

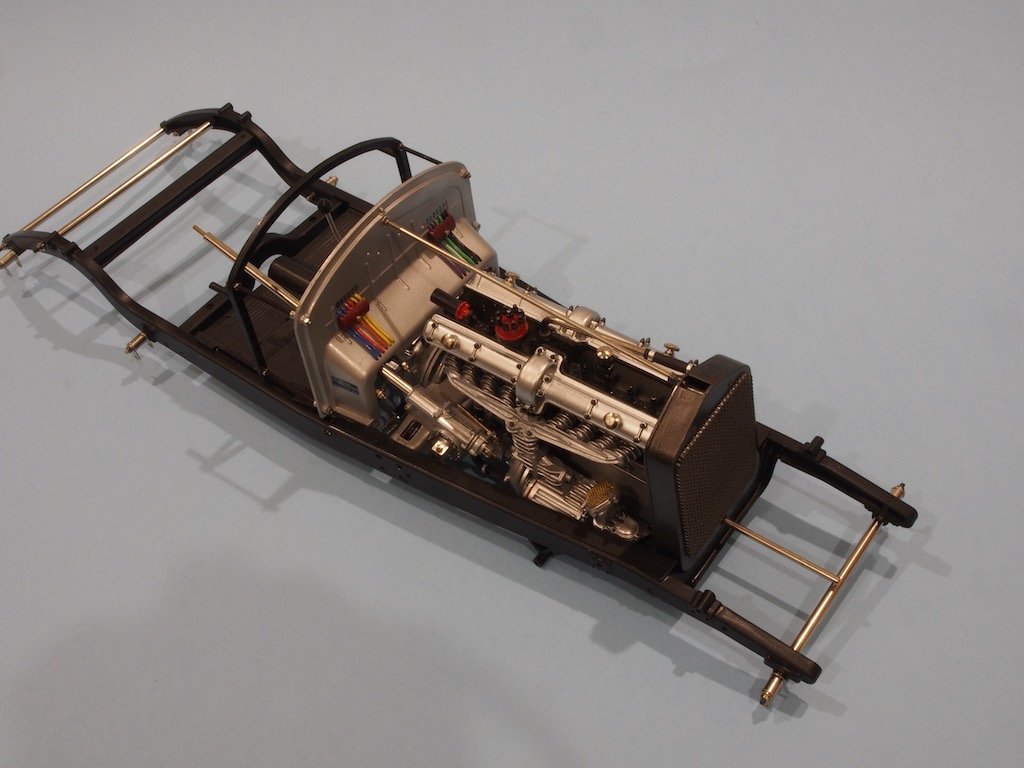

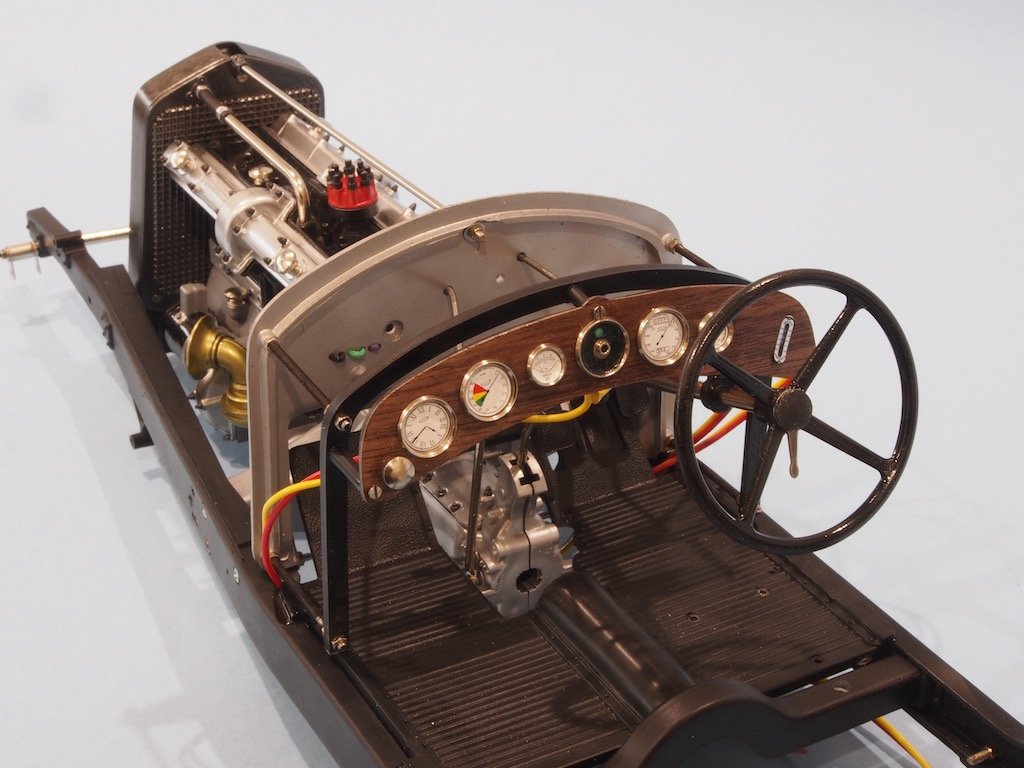

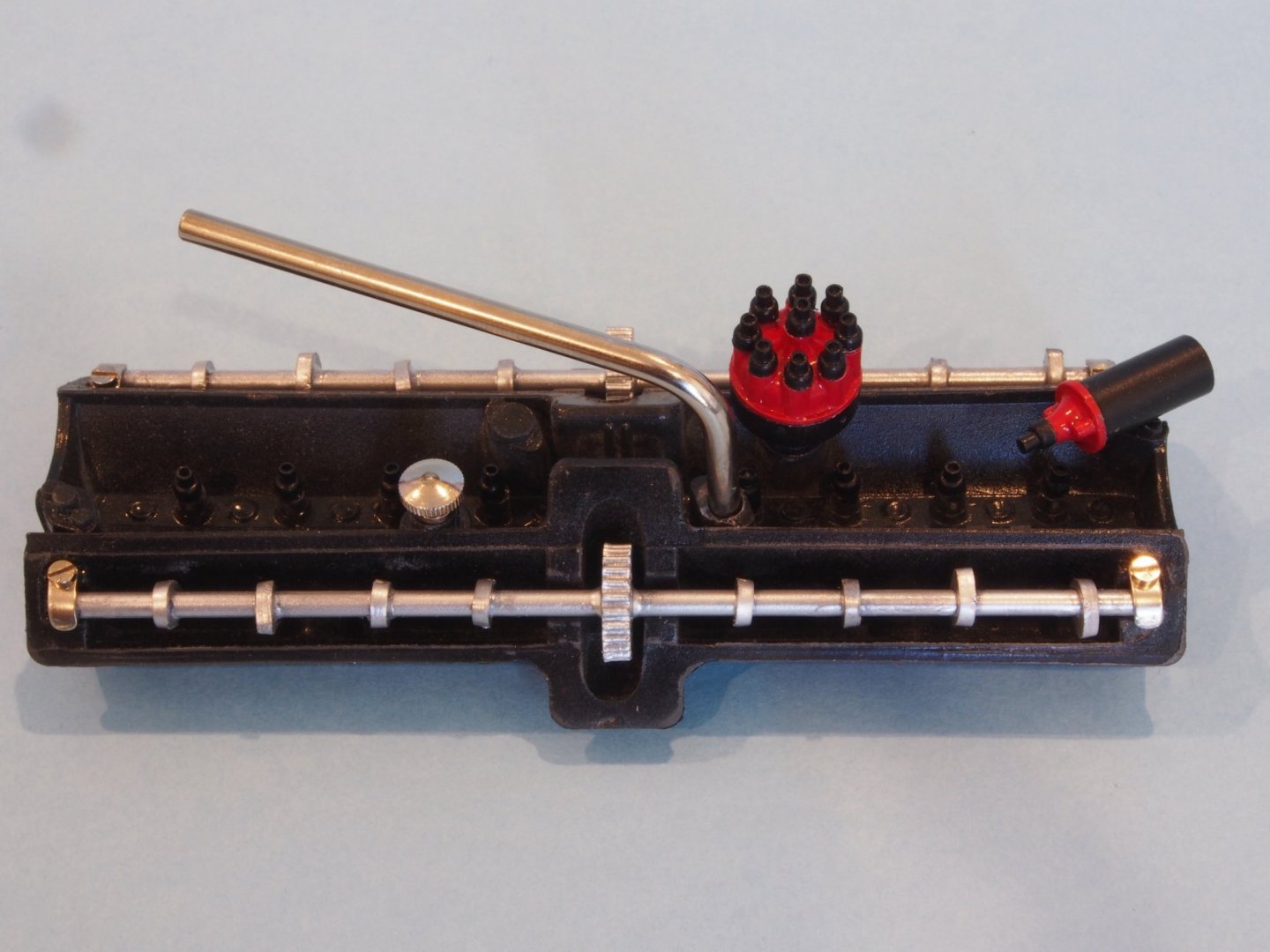

Thanks for all the kind comments and for all of the 'likes' as well. The replacement Cam covers finally arrived. After painting they were fitted to the Engine Head and two decals applied. These are aftermarket replacements for the stickers provided in the kit. Here is the assembled Engine Head – I have yet to fit the ignition wiring, which will be left until much later in the build as the Engine Head is still removable at this stage. The firewall was also painted and then re-assembled with the modified wiring arrangement: Once the remainder of the Main Frame had been painted, it too was reassembled – a relatively easy job thanks to all the test fitting and adjustment previously completed: The Dashboard The Dashboard presents no particular problems, although I opted to dress up the provided plastic piece a bit by making a real wood dashboard veneer using the plastic part as a template and some 1/64” thick walnut I had in my stash. Again, I replaced most of the kit provided instrument faces with aftermarket decals from Model Motorcars. While the decals look a lot better, they are very fragile and I think just about all of them broke in at least one place while fitting them. Not sure if it was my technique at fault, or the very, very thin decal material. Anyway, I managed to get the pieces re-aligned with a minimum of colourful language! Here is where we are at to date:

-

I definitely agree with everything Mike has said about Sherline. Although I’m in Australia, I bought mine through Mike’s Tools in the US - good prices, great service. The only thing I would add is think about what you want to do with the machine/s. I personally think I get more use out of my mill than I do the lathe, although I do use them both. There is an option to buy a combination mill/lathe set-up from Sherline, but I would counsel against that in favour of two separate machines for slightly greater initial expense - otherwise you’ll invariably be set up for the opposite of the machine you need at the time! As MIke said, accessories are likely to cost you more than the basic machines but you can add these as and when you have a specific need. Sherline do offer some very good package deals with the basic accessories - and you can buy these packages through somewhere like Mike’s Tools as well. (No affiliation here, just a very satisfied customer).

-

Looks like an interesting build. I’ll pull up a chair too.

- 51 replies

-

- miss unlimited

- dumas

-

(and 1 more)

Tagged with:

-

Thanks Rick and Mike. That’s a lovely looking finished model you have there Rick. Yes, that tail fin is going to be a challenge from what I’ve read so far! MIke - I am not an experienced modeller in plastic by any stretch of the imagination. What is allowing me to do a half way decent job is the amazing instructions and photo essays from Paul Koo. I say, “go for it”.

-

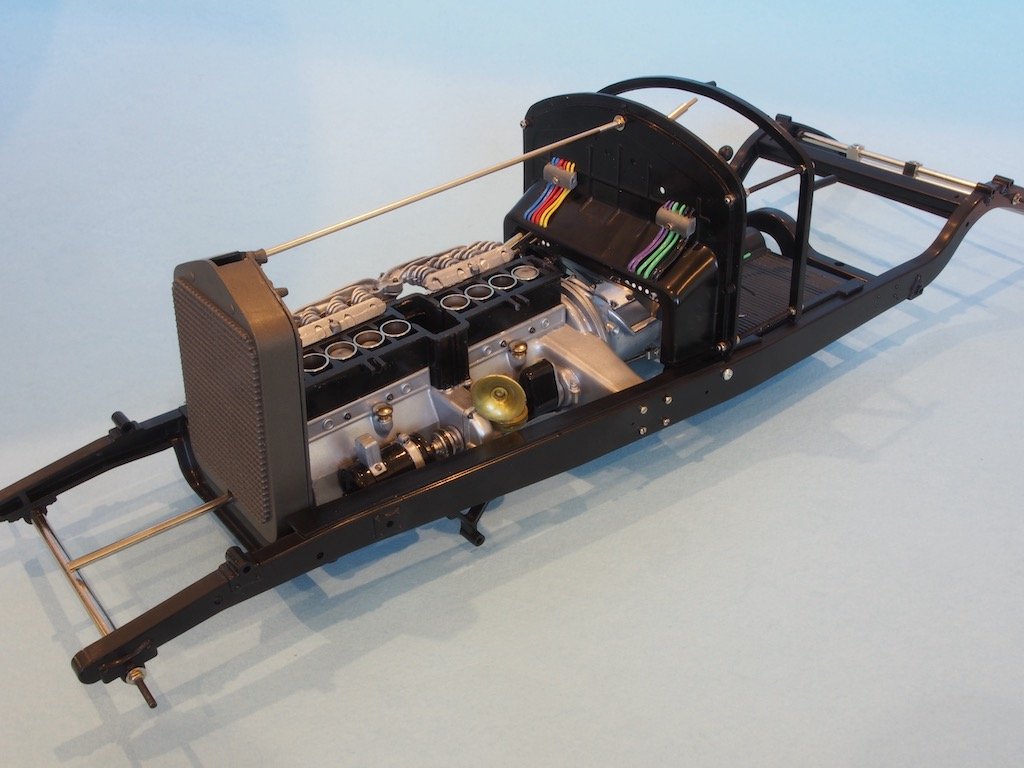

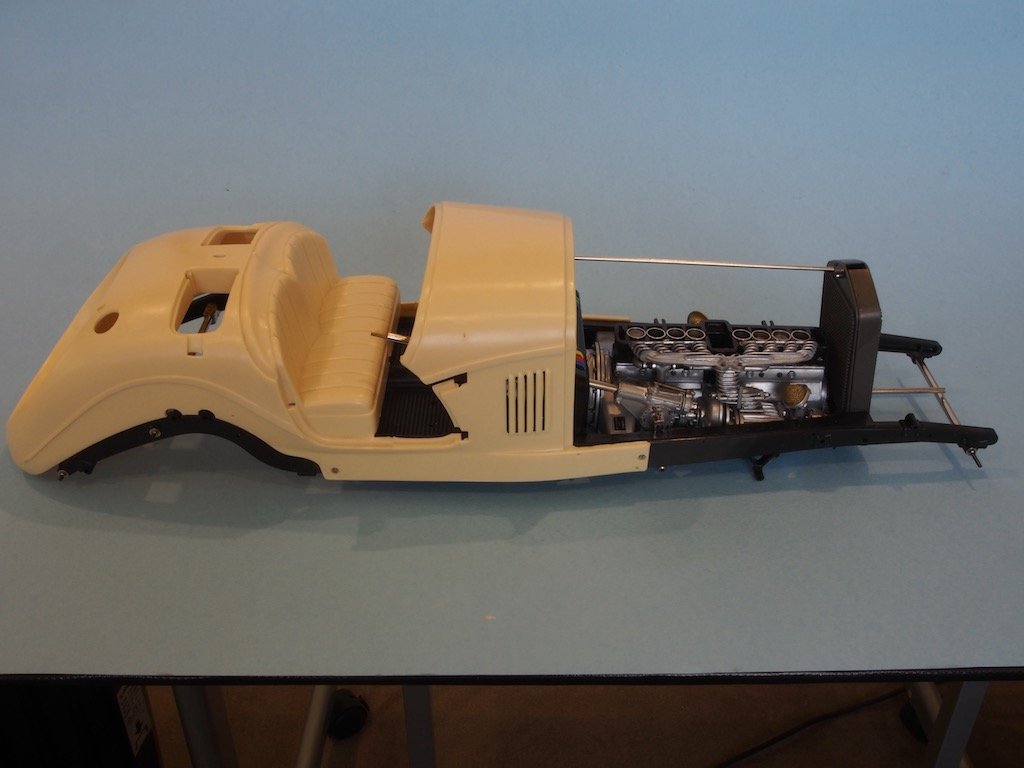

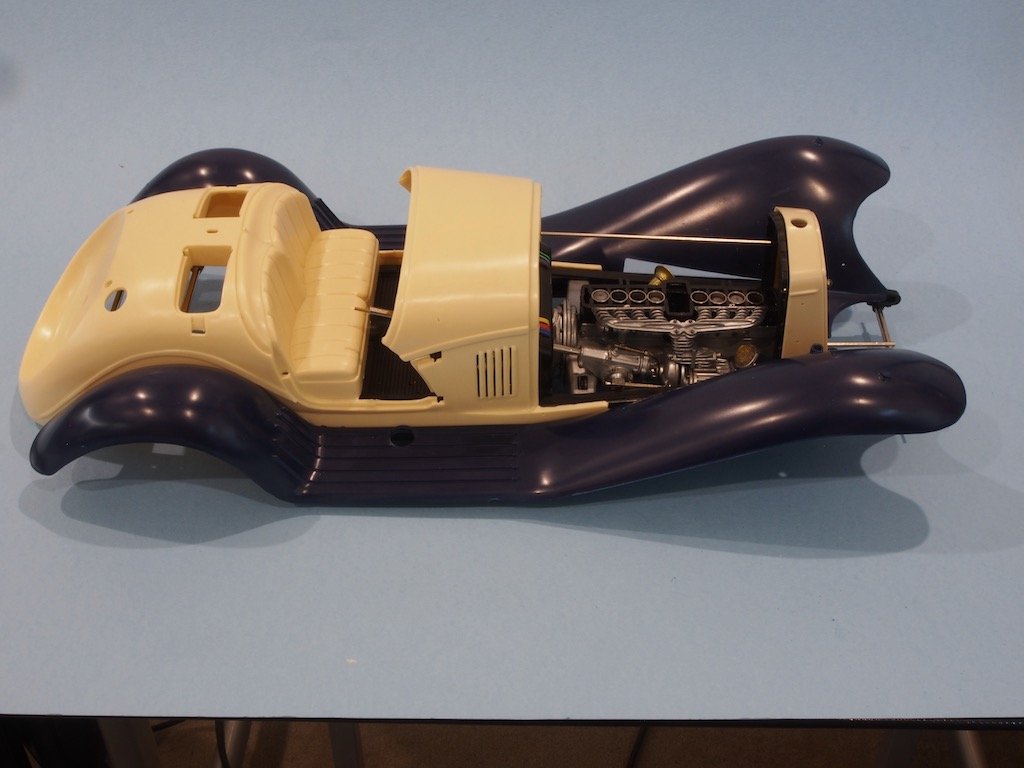

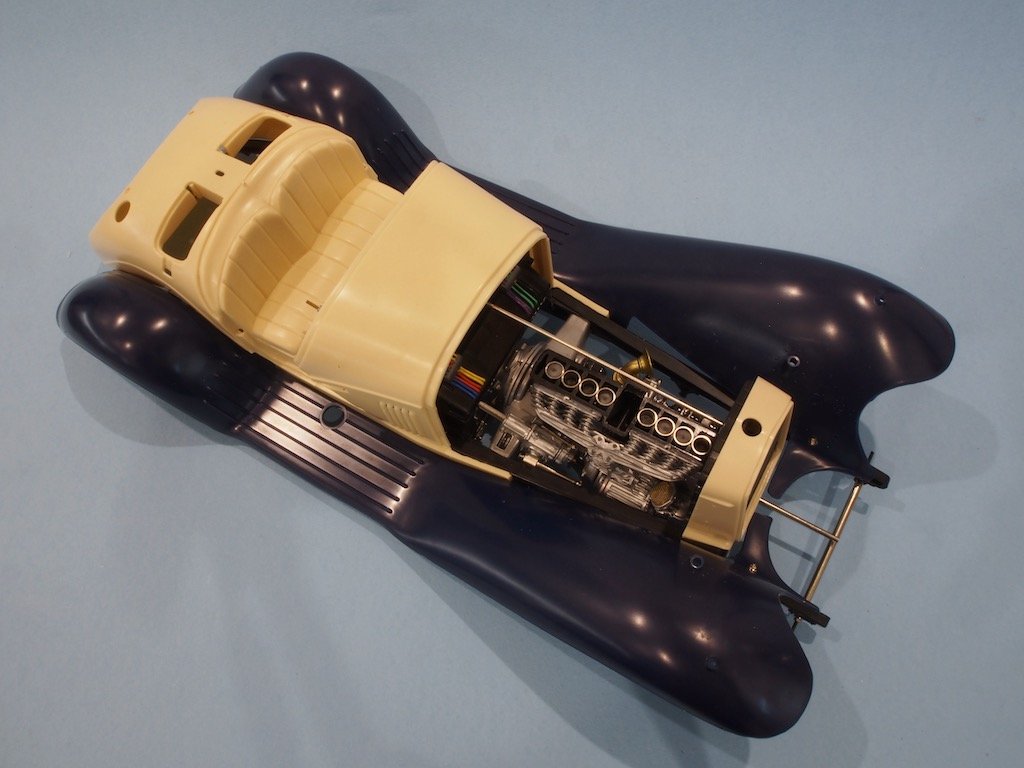

Thanks ken, Yves, Keith, Denis, Michael, and Mark for the kind comments, and to all of the'likes'. The replacement Cam covers have at last arrived in country – they arrived in Sydney on 26 May. A week later and they still haven’t made it out of Sydney…. In the meantime, progress continues… The Chassis The basic sequence of assembly for the chassis is: · Main Frame · Radiator assembly and test fitting · Test fit body parts · Check engine position and decide whether to relocate the engine · Paint the main frame · Assemble the chassis components Note that the above list involves a lot of test fitting, which implies a lot of adjustment, and the almost ‘throw-away’ line of deciding whether to relocate the engine! The journey begins with the main frame itself. A number of adjustments are needed to allow the radiator cross member to fit properly. Failure to get this right will result in the front end being too wide and the body and suspension parts not fitting properly. It’s a relatively simple fix but once again, without Paul Koo’s guidance here this could end up a real mess! The next issue to be addressed is the mounting arrangement for the firewall. On older kits (like mine) the firewall is attached to the mainframe by two screws accessed from inside the mainframe, making access extremely difficult because of the presence of the transmission. On newer kits, this problem was remedied by making through-holes in the frame and placing the bolts from the outside – a whole lot easier! Needless to say, Paul provides instructions for how to convert the older style kit to the new mounting arrangements. The firewall is also modelled incorrectly in that only four wires for each of the two fuse boxes are used, and their routing is also incorrect. Following Paul’s advice, two new (slightly larger) fuse boxes were scratch built and holes drilled for the correct wiring. I bought some rainbow ribbon wire from my local electronics store and stripped this down to provide some different coloured wiring. The next issue is the fit of the radiator and the cross brace. An incorrect radiator position will affect the fit of the front nose. When properly positioned, the radiator must be slanted to the rear when viewed from the side. The radiator brace, which joins to the firewall, must be horizontal (ie parallel to the main frame) however the brace is tightly fixed to the radiator at an angle of 90 degrees. If this is not fixed, when the brace is attached to the firewall, it will push the radiator into a vertical (incorrect) position and once again cause fit problems with the front nose and hood. The fix for this is to attach the brace to the radiator, and then apply heat from a soldering iron to the metal brace. The heat will then start to melt the plastic surround at the radiator mounting point, which allows the brace to then be lifted up about 20 degrees and held there while the plastic cools. Now, experienced plastic modellers are probably quite familiar with this type of technique, but it was a first and somewhat nerve-wracking time for me. It did however, work exactly as advertised. The next issue is the hole in the bottom of the radiator for the engine hand crank. With the radiator mounted correctly at a slight angle, the hand crank will not pass through the hole in the bottom of the radiator assembly. This one is an easy fix, requiring only that the hole be slightly elongated on the rear side. Once all of these issues had been addressed, the engine and firewall could be assembled to the main frame. With these issues addressed, it was time to test fit all of the body parts, starting with the main body. The first issue to be addressed is that the main body must fit flush against the main frame. However, there are a couple of (unnecessary) raised moulded details that prevent this, along with the presence of the bolt heads for the engine mount and firewall (see photo above). The moulded details are easily taken care of by sanding flush. The bolt heads on the other hand require a different approach – enter the soldering iron once more. In this case, a hot soldering iron is touched to the bolt heads and once the plastic starts to melt, the bolt is pushed into the plastic until it is flush with or just below the surface. As it goes in, the plastic moulds itself around the bolt thread, forming additional threading inside the now longer hole. It’s a brilliant technique! There is still some additional tweaking required to the main body plastic, although mine didn’t seem to need as much as some others clearly do from Paul’s descriptions/pictures. With the main body in place, the fenders can be test fitted. There is a fair amount of clean-up required on these, and the two of the mounting holes are misaligned on the main body, requiring new mounting holes to be drilled and threaded. Two additional mounting points are also created by drilling and using the “melting method” to drive screws right through the main body and into the main frame to close up some residual gaps. Again, this method worked really well. The front nose was also adjusted to allow it to fit properly over the radiator. Then further adjustments to the fenders were required, including removal of a significant amount of material from the front ends, to allow them to fit properly around the front nose. Once the fenders were fitted correctly, it was time to remove the fenders and main body again in order to test fit the engine hood panels. Paul’s instructions suggested that quite a bit of finessing would be required to make the side and hood panels all fit together with the main body. I must have gotten lucky here as mine needed only a very slight adjustment to allow them to fit properly. In the photo below, they are held in place with masking tape and placed back on the mainframe to check for overall fit. As you can see, all seems to be well with no significant gaps around the front nose. The final tasks in test fitting the body panels included the two covers (just behind the seats), the doors, and the rear end (moulding line). Of these, the only tricky part was the doors, which required quite a bit of very fiddly adjustment. I forgot to take any progress photos of these, but they do fit now. Once all of these adjustments were made, the whole lot was disassembled again, including removing the engine and fire wall, so that the main frame and firewall can now be painted. The issue of relocating the engine is one of considerable debate. According to Paul Koo’s notes, the problem arises from part of the model being designed with the engine in its current placement, and part being designed with the engine approximately 10mm further to the rear. Paul offers four options to remedy this – a 10mm rearward move, a 5mm rearward move, a 2 mm rearward move, and no move. Of these, he recommends the last option – no move. Any move of the engine rearwards will result in significant further changes being required as the model progresses. The no move option involves omitting one part and accepting that the hole in the top of the radiator will not be aligned with the hole in the top of the front nose (a detail that will not be visible on the completed model). The part is a threaded base that attaches to the top of the radiator and passes through the front nose. If it is inserted with the engine in the current position, it will pull the radiator into a vertical position again, causing subsequent fit problems. By omitting this part, the radiator can stay as is, the radiator cap then subsequently gets glued to the front nose, rather than being attached by a threaded component. I’ve decided to go with Paul’s recommendation of ‘no move’ – this build is hard enough as it is without adding further complications! Next up, painting the mainframe and re-assembly.

-

You might also like to check out Vanguard Models. Chris Watton, who is also a member here, has just added two nice little models to his range, that are specifically targeted towards beginners. His kits use quality components, are exceptionally well designed, and come with probably some of the best instruction manuals going. His express desire in creating these offerings was to provide newcomers with a positive experience that would encourage them to stay with the hobby. You will find some excellent build logs on the site here if you want to preview what building them will look like.

- 14 replies

-

- hours

- build time

- (and 4 more)

-

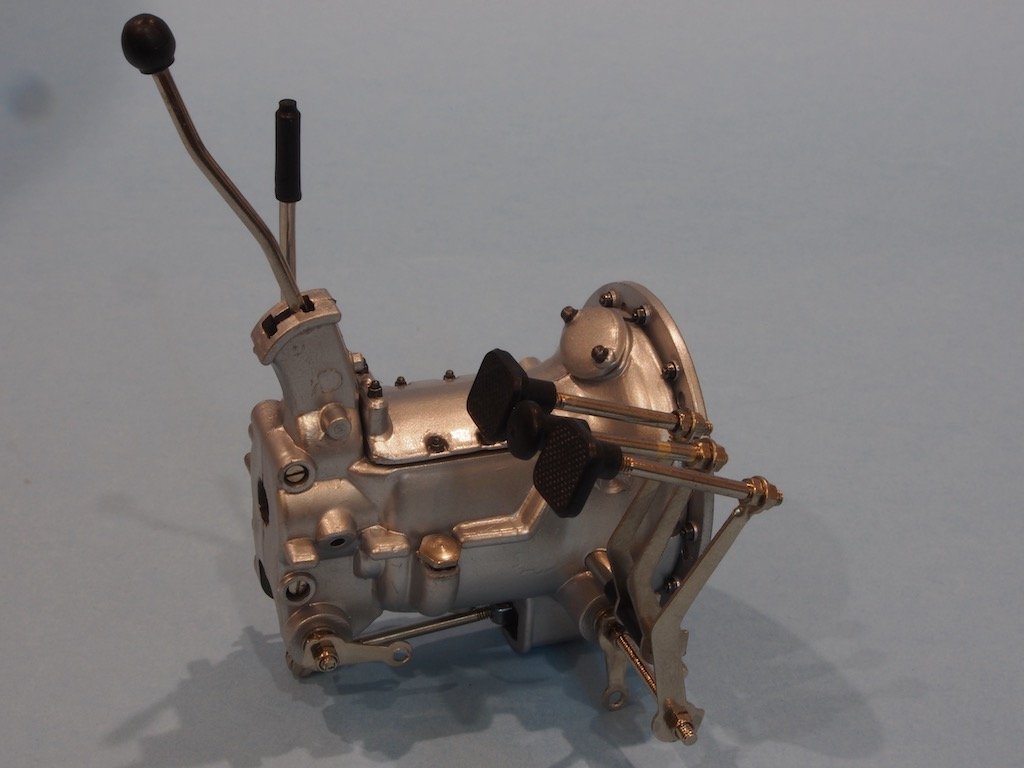

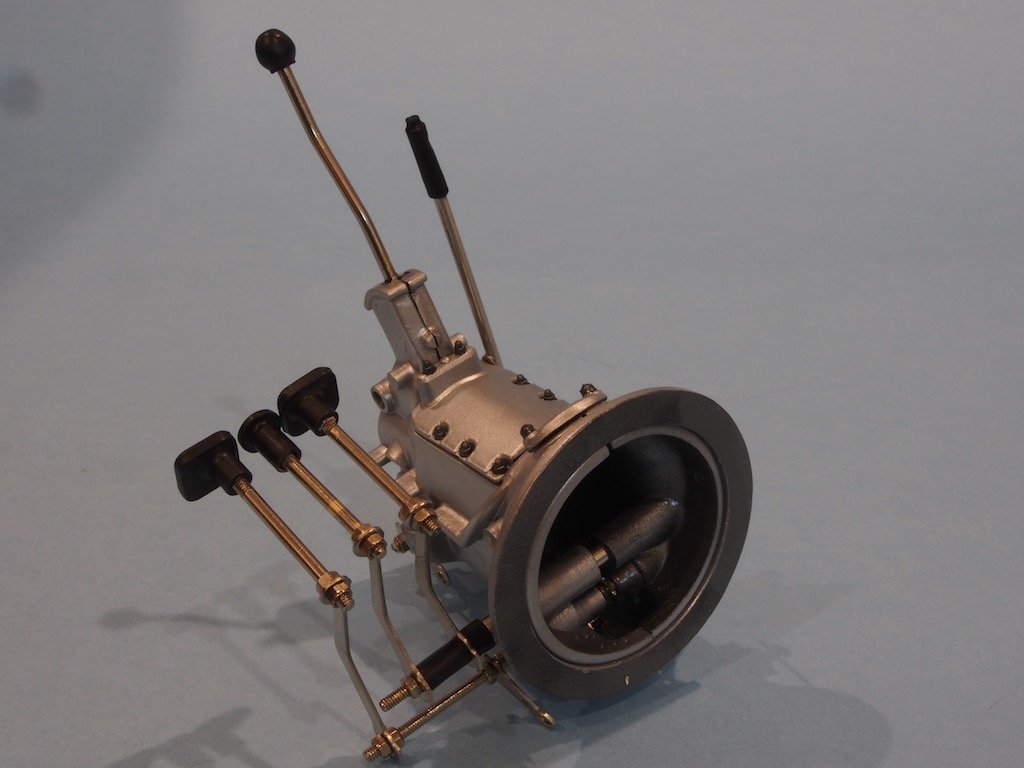

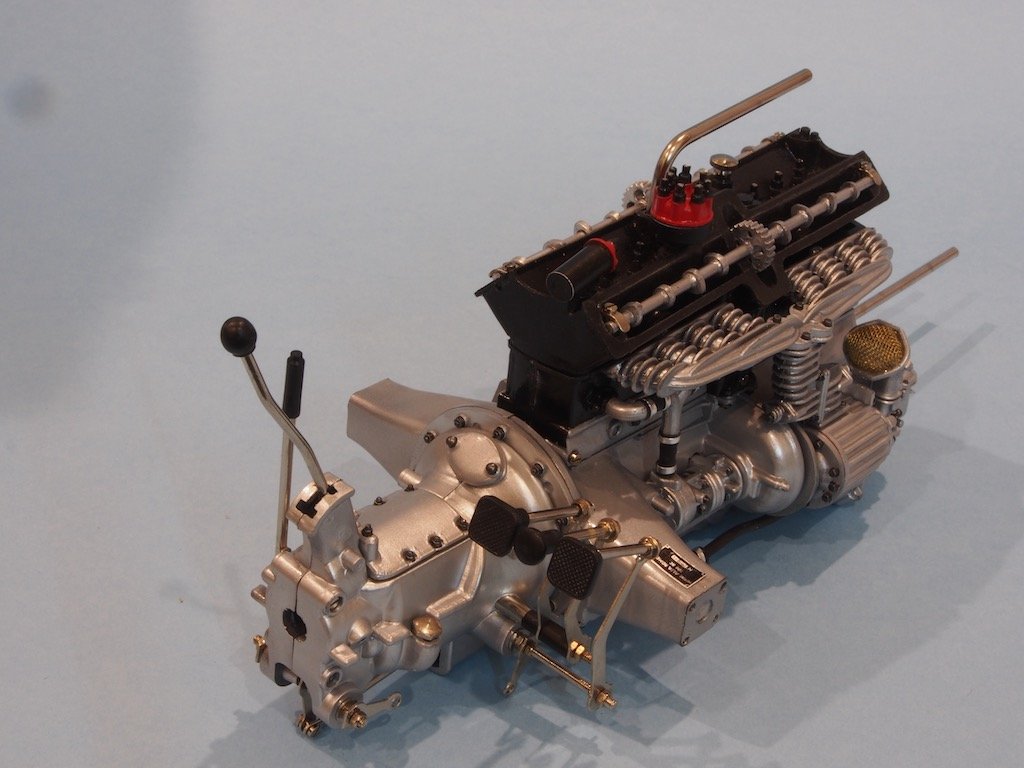

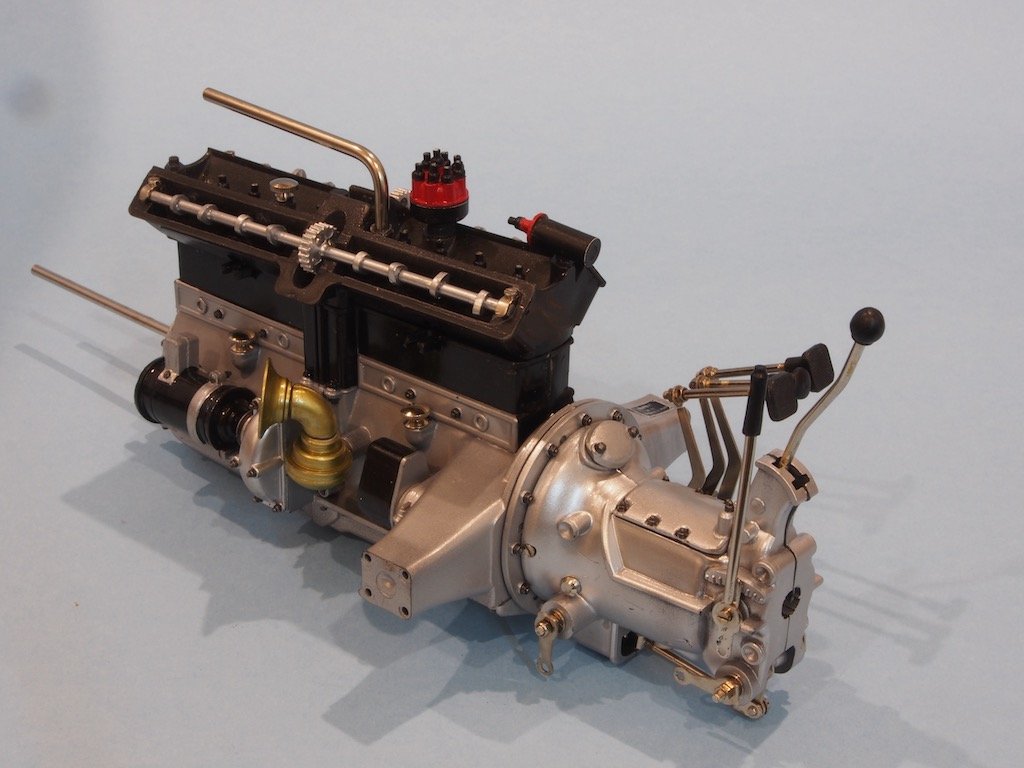

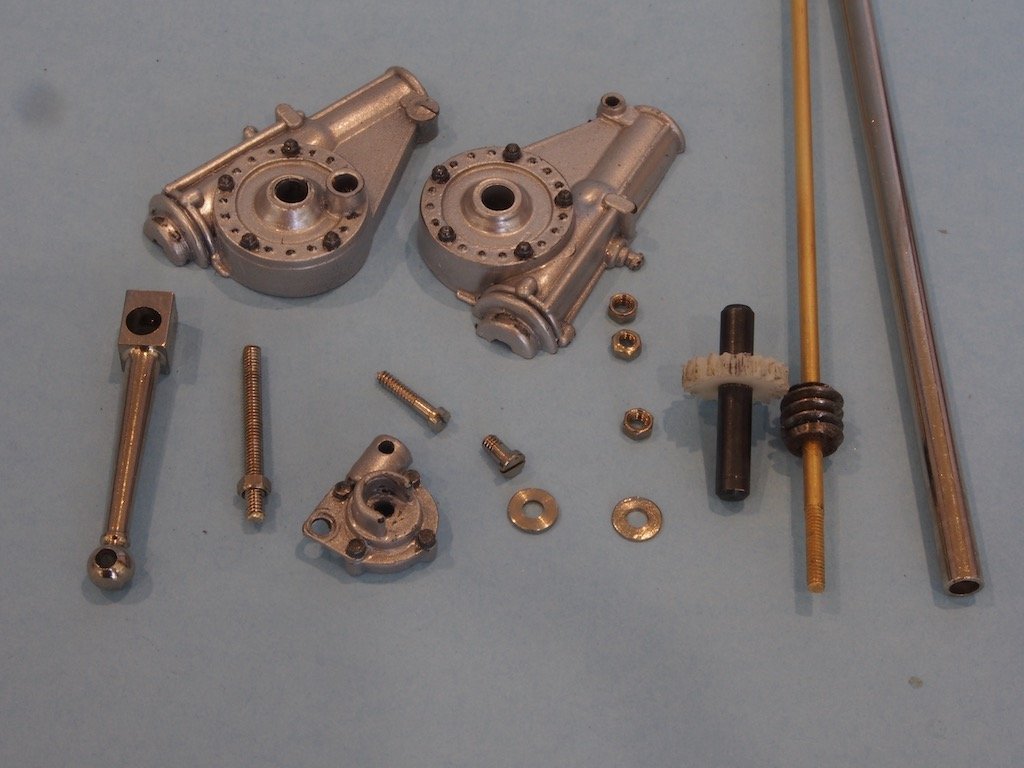

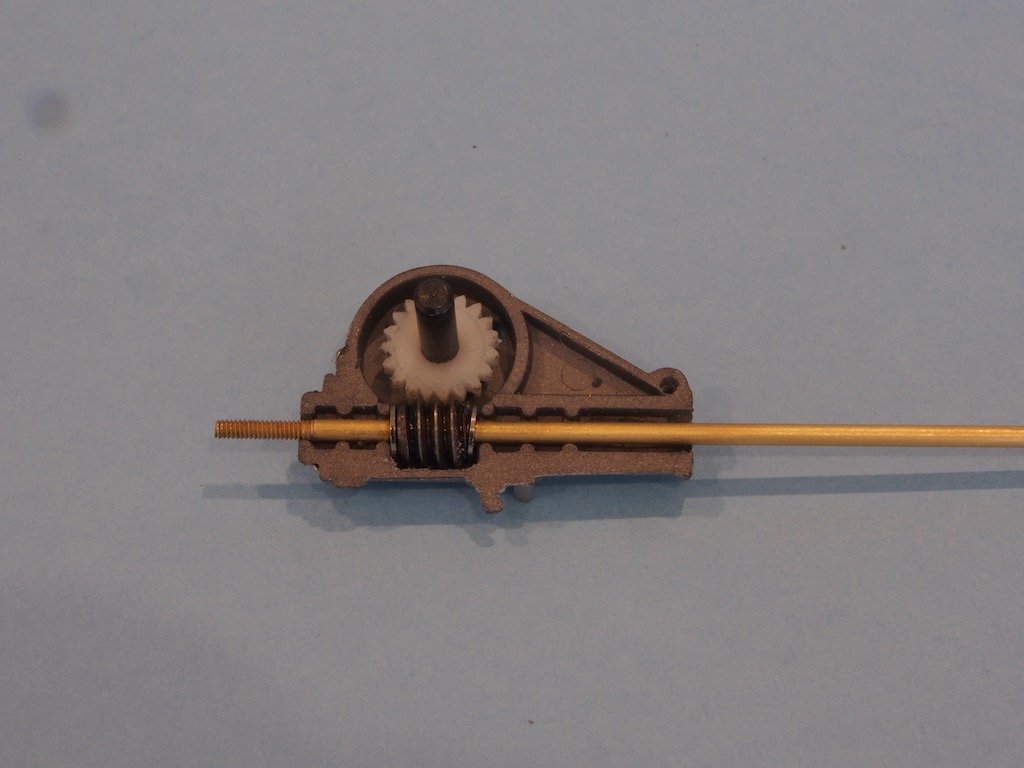

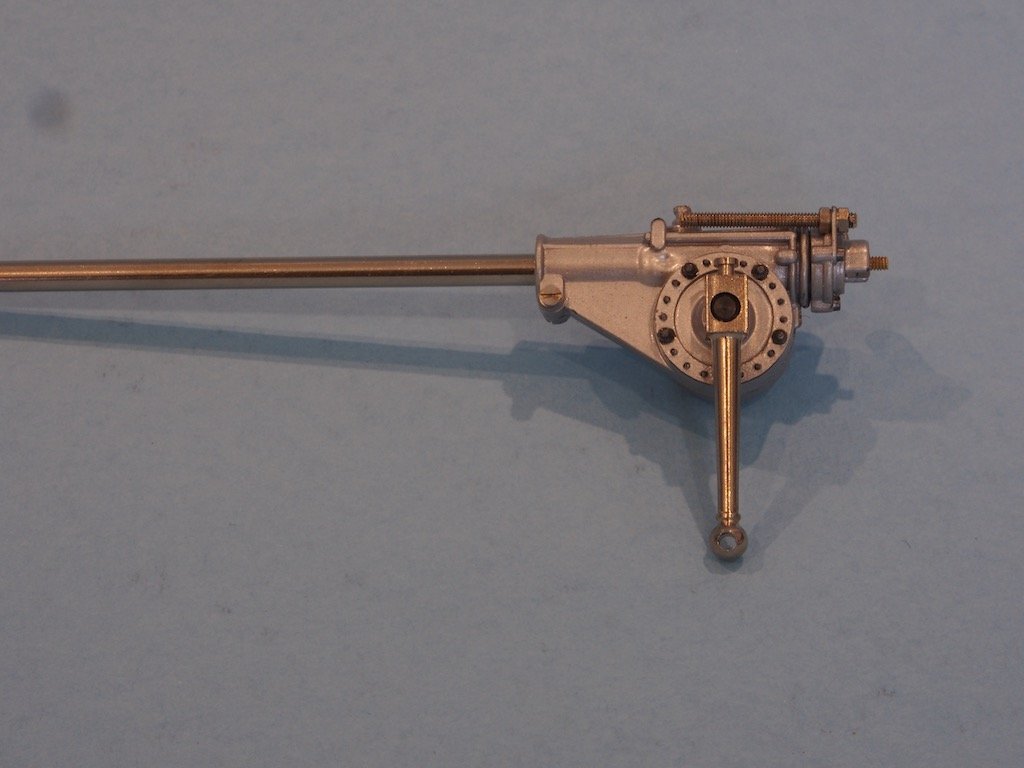

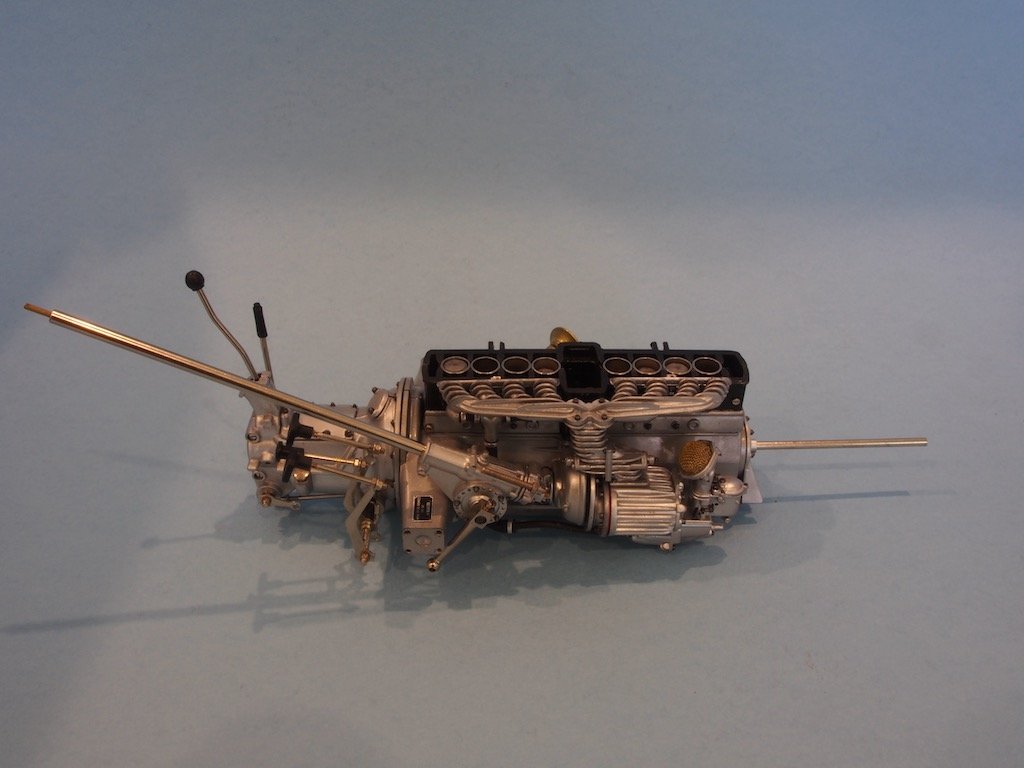

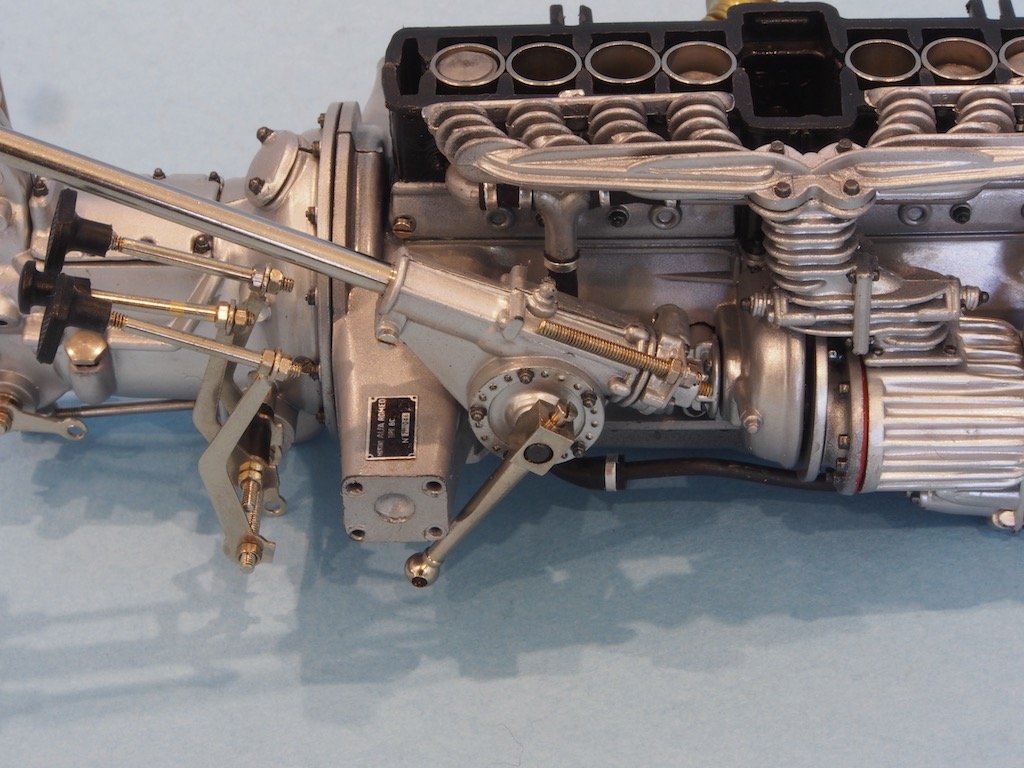

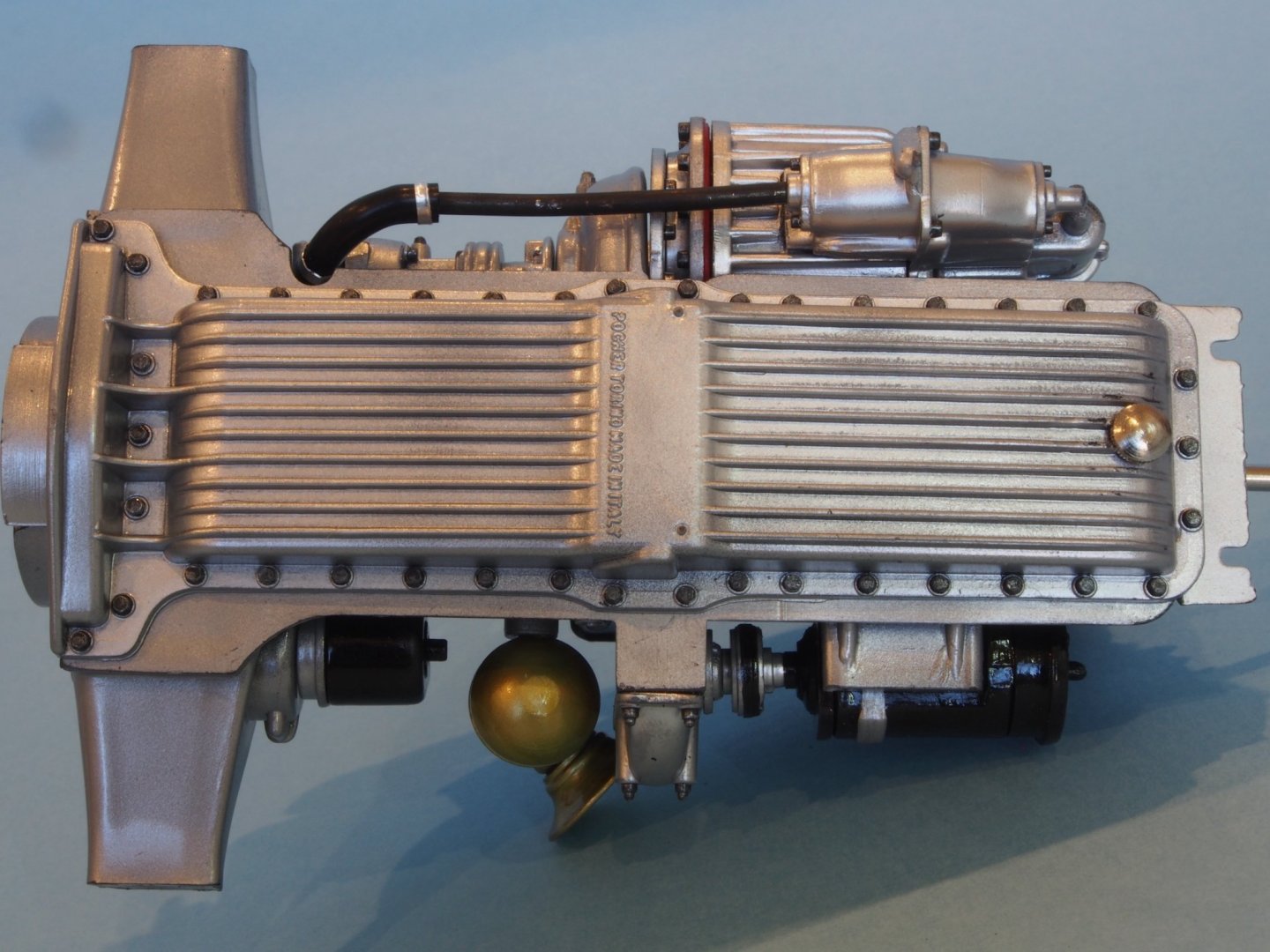

USPS last tracked the replacement Cam covers having travelled from the USPS distribution centre in LA on 16 April to LA International Airport on 18 May (32 days to travel that far!). Hopefully they are now finally boarding an aircraft on the way here. In the meantime, I have decided to proceed with the next phase of construction. The Transmission Building the transmission follows essentially the same procedure as building the engine – ie, test fit and adjust all parts, then disassemble, paint, and re-assemble. Sounds straight forward but Paul Koo produced a photo essay of some 48 photographs to supplement the Pocher drawings, illustrating clearly where the problem areas are and how to fix them, as well as some good advice on assembly sequence so that you don’t “paint yourself into a corner”. Here are all of the parts after test fitting and painting. Some sub-assemblies here have been pre-assembled (eg foot pedals and gear knob/handbrake handle). Once all of the fit issues are taken care, the remainder of the assembly is fairly straight forward. The only part glued here is the tiny access hatch on the top forward end of the transmission. Here are some pictures of the completed assembly: And here is the transmission fitted to the engine block. Again, no glue, the whole transmission is held in place by some tight fitting joints and two screws. The Steering Gearbox The Steering Gearbox is tackled next as it needs to be fitted to the engine block prior to installation in the chassis. Once again, the sequence of test fit, adjust, paint, re-assemble is followed. Another 28 photos from Paul Koo to show this relatively simple assembly! Here are the parts after test fitting and painting: The steering system actually works, however some fettling is required to ensure that the gear will actually turn. I had to adjust the teeth on the cog gear with a file, clean up the worm gear on the shaft, and adjust the clearance in the housing to enable it to all turn freely once assembled. Here is what it looks like inside the gearbox: And here is the completed steering gearbox: And finally, here is the steering gearbox installed onto the engine block: And a close-up: The next phase will see the Main Frame assembled...

-

Justin, Chuck made his original post before he started his retail business if I recall correctly. Once he began commercial production, he quite reasonably removed his original post and personally asked me not to divulge any of his “trade secrets” that he had shared with me. So, I’m sorry but I must honour that commitment to Chuck. Having said that, I can tell you that there is a fair bit of trial and error in getting things set-up, and even then it is a tedious business. Not to mention that you need a Mill, miniature table saw (eg Byrnes saw) and a Drill press PLUS a separate size of roundover bit for each size of block. That is a not insignificant investment. For most people, I’d advise “just buy them from Chuck”. It’s probably more economical, and you know you are buying a quality product. Unless of course, you are masochist like me that is!!!

-

Wonderful work Danny. It’s great that your grandson will be able to continue your work.

- 29 replies

-

- hmw

- Hamburg Harbor

-

(and 2 more)

Tagged with:

-

Ah, another B.E. build to follow. My day is complete. 😊

- 195 replies

-

- lady eleanor

- vanguard models

-

(and 1 more)

Tagged with:

-

It's been a while since I updated this log - the reason will become apparent shortly! The Engine Bottom Pan was painted with the airbrush and the bolt heads hand painted. It is meant to be removable to provide access to the engine parts, being held on by a clip on the other side of the oil drain plug. I decided to add a small dab of CA glue to the opposite end to make it a little more stable (I won’t be taking this apart!) The Engine Head The Engine Head is a fairly straight forward affair – at least it should be. All that is required is to assemble and install the Cam Shafts, Distributor, Ignition Coil, Oil Filler Cap, Water Pipe, and Cam Covers. As with the rest of the Engine, it is a case of test-fitting, adjusting the fit, then dis-assembling, painting and re-assembling. I had a bit of an oops when trying to adjust the fit of the Cam Covers. Let’s just say I got a little too enthusiastic with a heat gun and am now waiting on replacement parts to arrive! This is why I haven't updated in a while. In the meantime, I decided to upgrade the kit a little by adding some aftermarket ignition wire boots from Model Motorcars. I believe these are 3-D printed, though I’m not certain. They are supplied on a plastic card base and need to be cut free. Here is the remains of one card. These needed to be painted black prior to installation, so after cutting them free individually, I then put some double-sided tape on a wooden stirring stick and placed all of the boots on the tape. This gave me a “handle” as well as securing these tiny items while they were sprayed with the airbrush. I finished them with a satin clear coat and then attached them to the cylinder heads, distributor cap, and ignition coil. Here is a picture of the Distributor Cap and Ignition Coil, complete with boots. And finally, here is a picture of the engine head with all parts temporarily in place, bar the Cam Covers. The ignition wires / spark plug leads will be added at a later date. I can’t finish off the Engine until the Cam Covers arrive. They were posted from California on 15 April and were last tracked by USPS in Los Angeles on 16 April. With the current postal situation due to COVID19, it may take some time for these to turn up. I may move on with the Transmission while I’m waiting for these.

-

Thanks Bob. This was a fun build and it is fun to be able to take her for a spin once finished as well. There is plenty of scope for making your own mods to the kit too - plenty of rabbit holes to disappear down. Go on, you know you want to........😈😈😈😉

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

-

Congratulations Bob on completing a truly fine model. She really is beautiful and a credit to your skill and dedication. Well done!

- 170 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

What a fantastic build Jan. The RC is the icing on the cake. Just beautiful. Congratulations and well done, Sir! 👏👏👏

-

Italari 1/12 Mephistopheles by kpnuts

gjdale replied to kpnuts's topic in Non-ship/categorised builds

Looks like a fascinating build - I’m in. 😊

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.