-

Posts

4,891 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

Such a treat to see another of your updates Doris. A truly remarkable work and an absolute joy to watch. Thank you for taking the time to share your art with us.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Can i live without a BYRNES TABLE SAW

gjdale replied to shihawk's topic in Modeling tools and Workshop Equipment

Thanks so much for posting these details Keith. 😊 -

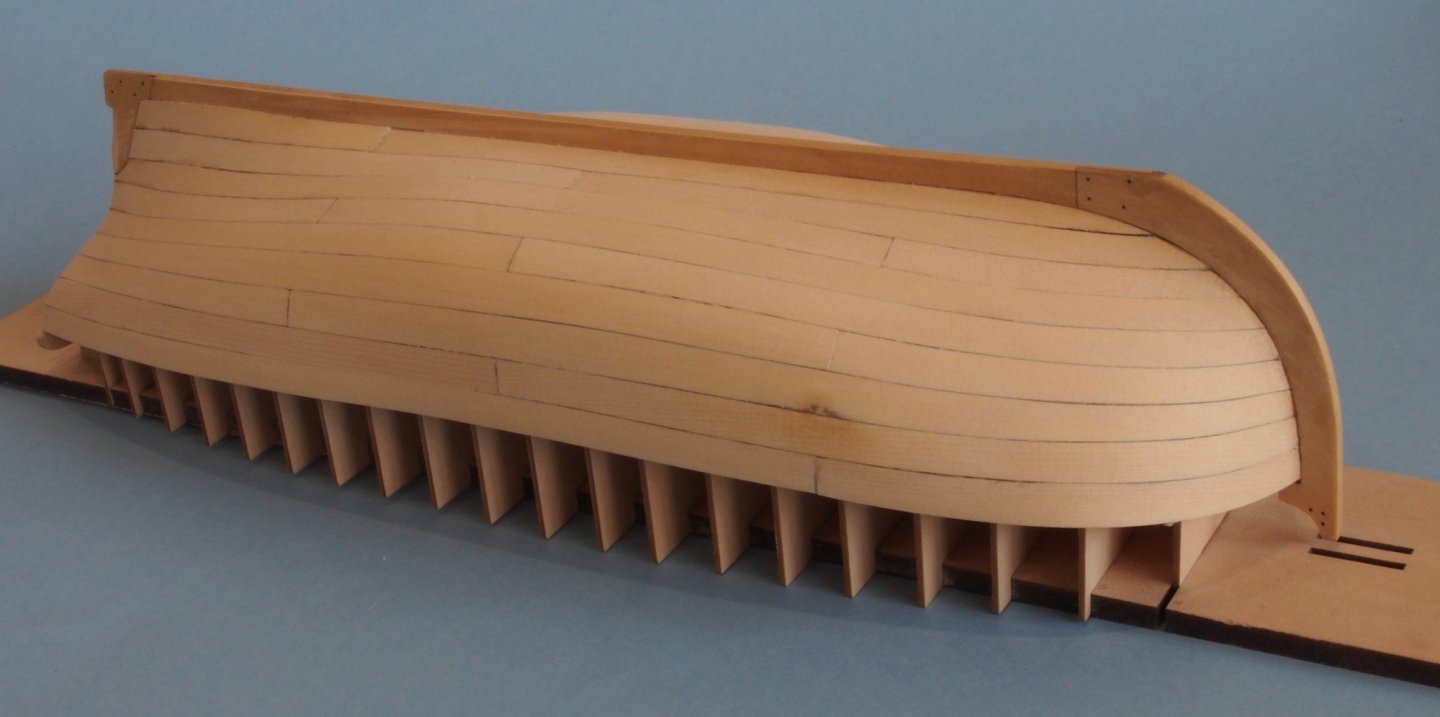

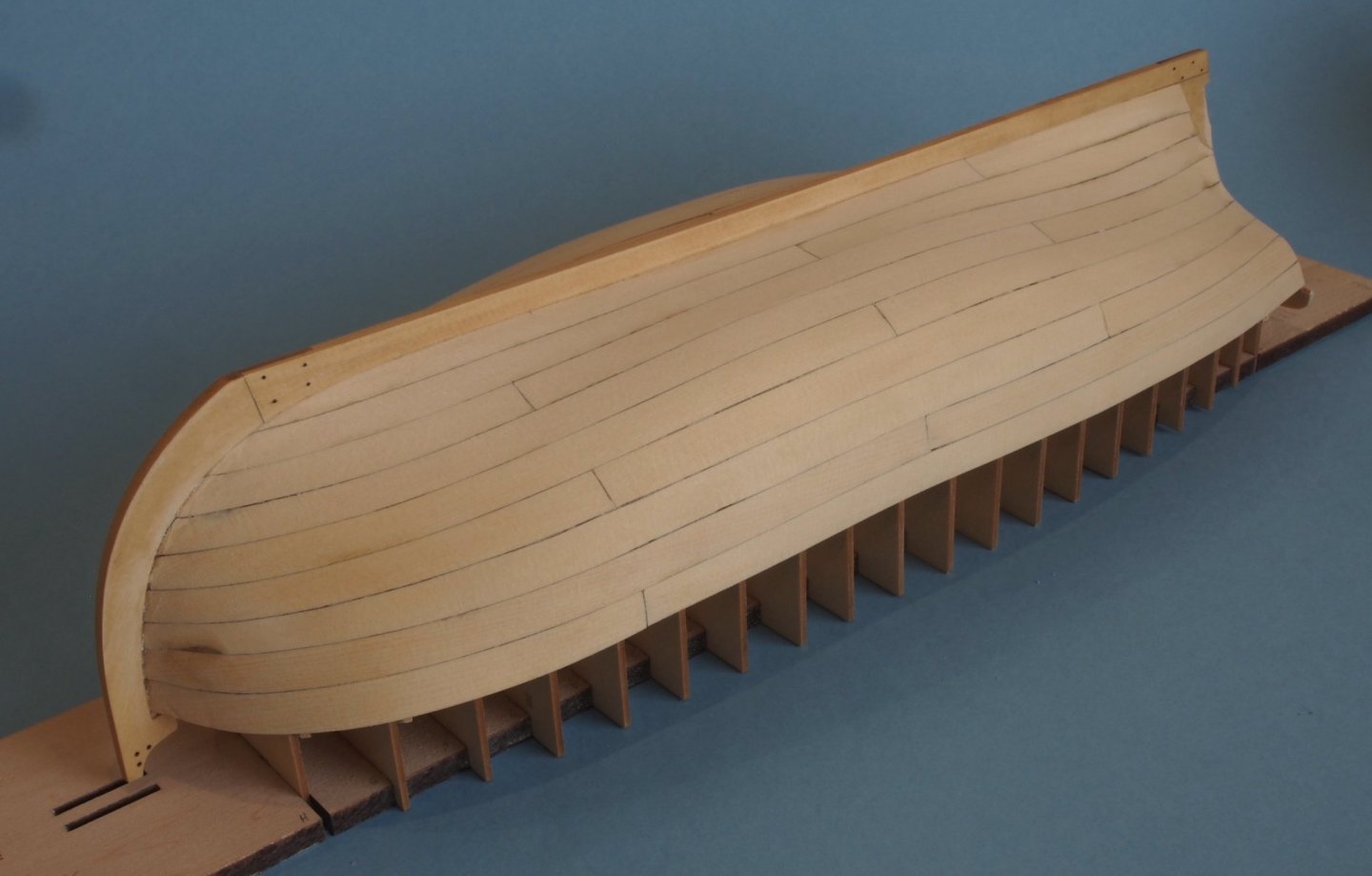

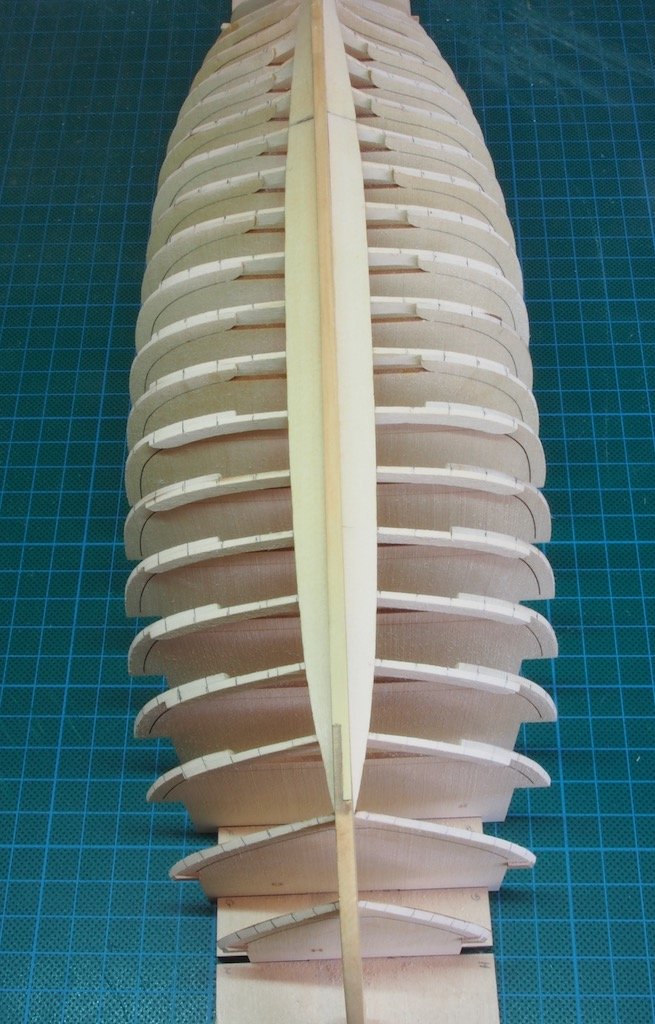

I quickly discovered that using PVA glue for this planking was going to be problematic in terms of clamping. Reluctantly, I started using CA glue and completed the first layer of planks. The next day, I started suffering flu-like symptoms. As I’d been wearing my respirator while using the CA, I wasn’t sure if this was a virus, or was in fact still a reaction to the glue. I checked the date I’d last changed the filters and let’s just say that I went straight out and bought some new ones! It has taken a couple of weeks to get over the resultant symptoms, and then of course the usual excuses that keep one away from the shipyard! I was not terribly happy with the outcome of the planking. Despite Chuck’s best efforts to make this build fool proof, I managed to prove that it’s still possible to get it wrong! Although I did pre-bend and twist all of the strakes, I still managed to get a considerable “staircase” effect at the bow. I also ended up with dirty marks all over the hull as my fingers, graphite from the pencil “caulking”, and CA glue, combined to make quite a mess. On the plus side, I found that taking the trouble to line off the hull iaw Chuck’s instructions was a big help in monitoring the evenness of the planking on each side. There was one strake that “got away” a bit, but I was able to correct that with the next strake. Today I finally got back to addressing that mess. I spent quite a lot of time sanding out the "staircase" as well as the other irregularities and the dirty marks. Overall, it has come up to an acceptable level, though not even in the same league as some of the other builds here. There was one place in particular where I had done such a bad job that when sanding I ended up with a hole in the planking. I made up a filler of sanding dust and PVA glue to patch the hole and fortunately both it and one other “untidy” patch will eventually be hidden by the frieze. The hull is now ready for the additional layer of planks for the upper two strakes. That is going to have to wait for a couple of weeks as I’ll be away this week for work, and then taking a short trip up to Brisbane for my niece’s wedding. Will be nice to catch up with family for a few days. Here’s a couple of shots of the planking as it stands today.

- 109 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well, that just cost me a pretty penny! I’ve been wanting some decent files for a while and I can resist anything except temptation!!!!😮🤑😀

-

Lovely job Bob. Shame about the missing deadeye - that must have been quite frustrating for you!

- 78 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Can i live without a BYRNES TABLE SAW

gjdale replied to shihawk's topic in Modeling tools and Workshop Equipment

Congratulations Derek - prepare to fall in love! I recall when I bought mine, shipping to Australia added 50% to the price. Now, I couldn’t even tell you how much it actually cost me - only how much I love it. As the old adage goes, quality is remembered long after price is forgotten. -

Congratulations on the new addition to the family Mike! Now you will have even less time for modelling. 😮 Maybe you should enlist Daria’s help now that she has so much experience with her own build......🤗

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

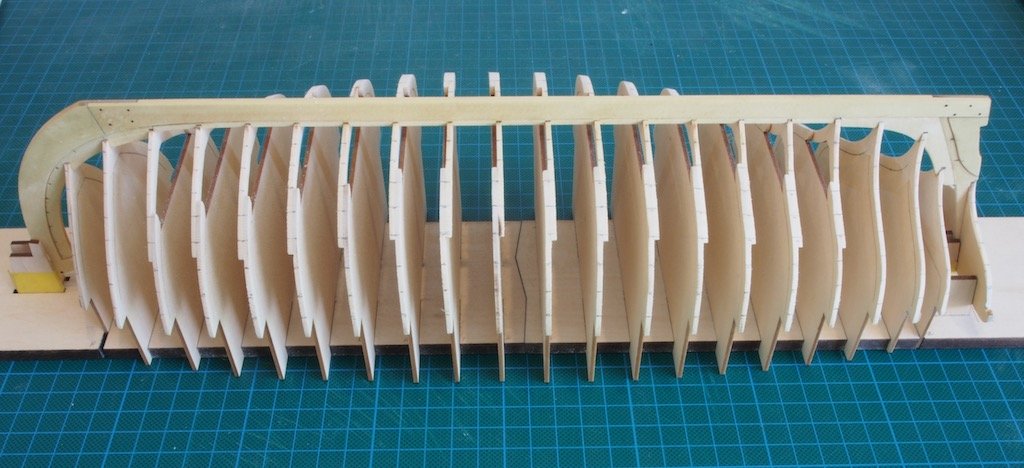

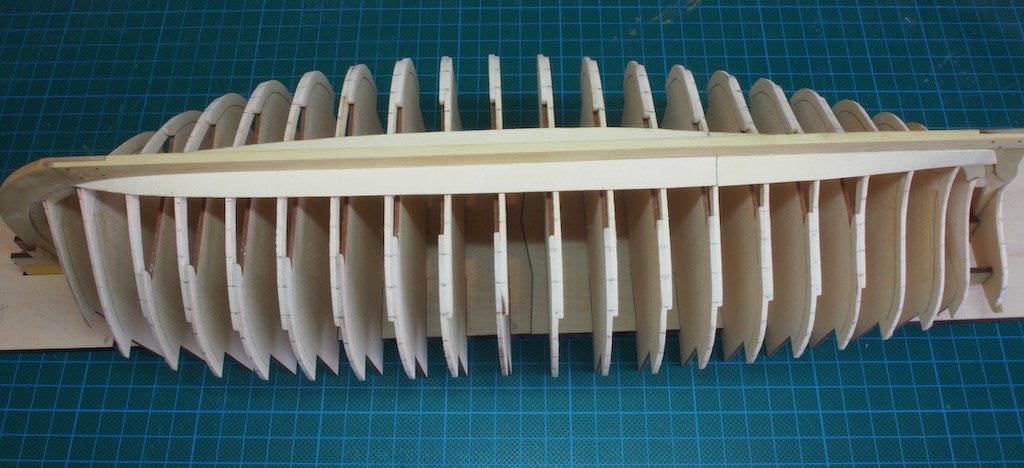

It has been six months since this log was last updated. It seems that the usual culprits of work, life and other projects and priorities have conspired against making progress. I did at last return to the build last weekend, although did not update progress as there was nothing really to show. The frames have been permanently attached to the keel, and then faired ready for planking. I then lined off the hull following Chuck's excellent instructions. Planking commenced with the Garboard strake, per the instructions. A small travel iron was used to provide the twist and bend required for these strakes. I cut one of the aft sections too short and so had to cut a new plank – no problem thanks to the extra material provided and the laser cut outline providing the template for the new plank. Then, when attempting to place the second (forward) plank, I discovered I’d made the new aft one too narrow. Fortunately, I'd used PVA rather than CA (which I have an allergic reaction to), so out with the isopropyl alcohol and off it came. Third time is the charm as they say, and so it was. Both Garboard planks on both sides now fitted. Hopefully it won't be another six months before the next update!

- 109 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Congratulations Ben - lovely work, as we’ve come to expect from you!

- 64 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Dust port - hoover connector

gjdale replied to Matrim's topic in Modeling tools and Workshop Equipment

I found this in the local hardware store for AUD $9.98. It’s a reasonably soft rubber and you just cut the section to fit both the dust post on the saw and the vaccum hose. I use a Festool CTL 26 and it works like a charm. -

Lovely work Bob - just what we have come to expect from you!

- 78 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Sorry to hear of your health problems Ryland, but glad to hear that you are on the road to recovery. The build is looking is looking lovely.

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I can’t say it any better than Pat has Mark, so I’ll just add my support and best wishes through these troubled times. We’re here for you whenever you’re ready.

-

Congratulations on finishing a fine model - she looks superb on that display base - what a great idea!

- 366 replies

-

- granado

- caldercraft

-

(and 1 more)

Tagged with:

-

Congratulations Danny! No surprise to me, but nice to see you get the recognition you so thoroughly deserve.

-

Congratulations on completing a truly fine model Vince. You can be justifiably very proud of your achievement.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

For Landlubber Mike, Paul Budzik, who is an occasional contributor on this forum, has his own website and has produced a number of very useful videos about airbrushes (and other aspects of modelling), how they work, how to use them, and which one is right for you. The videos are really well done and worth a look. Here’s a link to his site: http://www.paulbudzik.com/tools-techniques/Airbrushing/airbrushing_for_modelers.html

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.