-

Posts

4,888 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

Converting a Backyard Shed into a Model Workshop

gjdale replied to Hank's topic in Modeling tools and Workshop Equipment

You know what they say Hank - if there’s no photo, it didn’t happen...........just sayin’............... -

I’ll pull up a chair for this one too Tom - I’ve fond memories of several trips to Venice over the years.

- 54 replies

-

Converting a Backyard Shed into a Model Workshop

gjdale replied to Hank's topic in Modeling tools and Workshop Equipment

I want to see the scars from the cat Hank! -

I have to agree with Bob - that looks fabulous. Well done!

- 53 replies

-

Converting a Backyard Shed into a Model Workshop

gjdale replied to Hank's topic in Modeling tools and Workshop Equipment

ROFLMAO! 🤣🤣🤣 The floggings will continue until morale improves!!! -

Converting a Backyard Shed into a Model Workshop

gjdale replied to Hank's topic in Modeling tools and Workshop Equipment

Noting Roger’s comment above Hank, you could justify the A/C as “necessary preventative maintenance” rather than creature comfort. I’m sure the Admiral will understand.........😉 The shop is looking superb BTW. -

1930 BENTLEY 4.5 LITRE by MadDogMcQ - AIRFIX 1:12th Scale

gjdale replied to MadDogMcQ's topic in Non-ship/categorised builds

Nice work MadDog. I don’t think anyone is going to notice your “oops” unless you point it out to them. -

Nice job on the frames Sea Hoss. Looks like you’re tackling the challenges in your stride.

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

1930 BENTLEY 4.5 LITRE by MadDogMcQ - AIRFIX 1:12th Scale

gjdale replied to MadDogMcQ's topic in Non-ship/categorised builds

Yep, more than a few skills retained here..... Looking good MadDog. -

Thanks for all the nice comments folks but let’s not forget that I’ve been mainly following the advice of Paul Koo with this model. He is the true master modeller and deserves the credit for the work he has done to make these models accessible to us mere mortals. I would have been lost without his guidance.

-

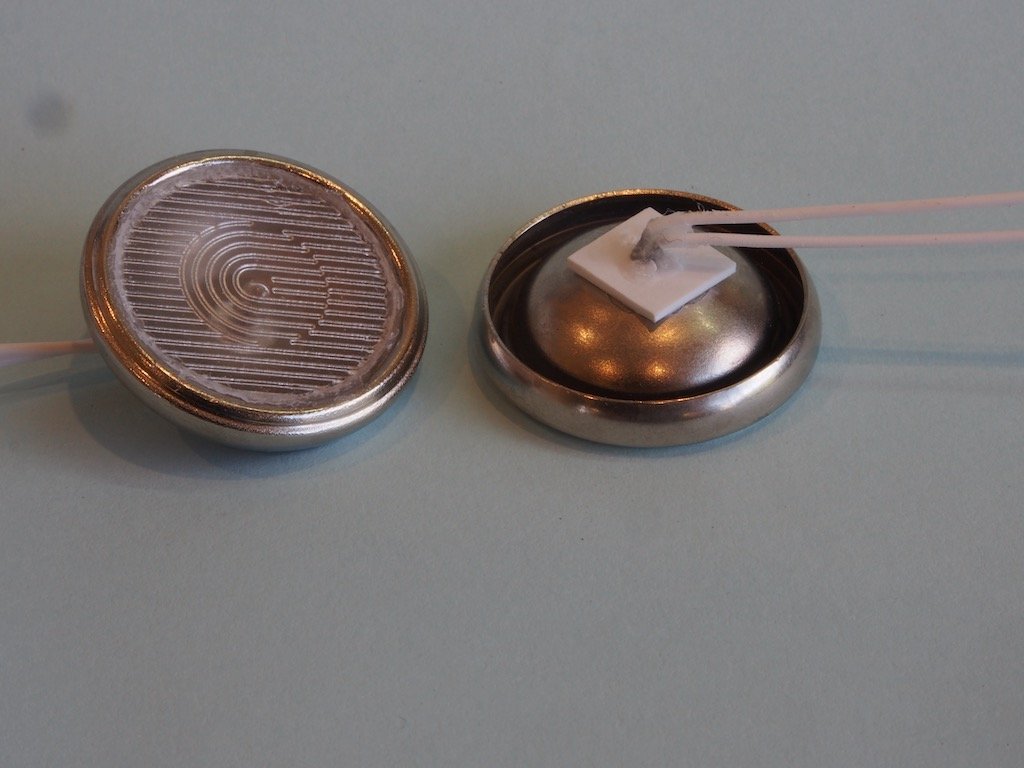

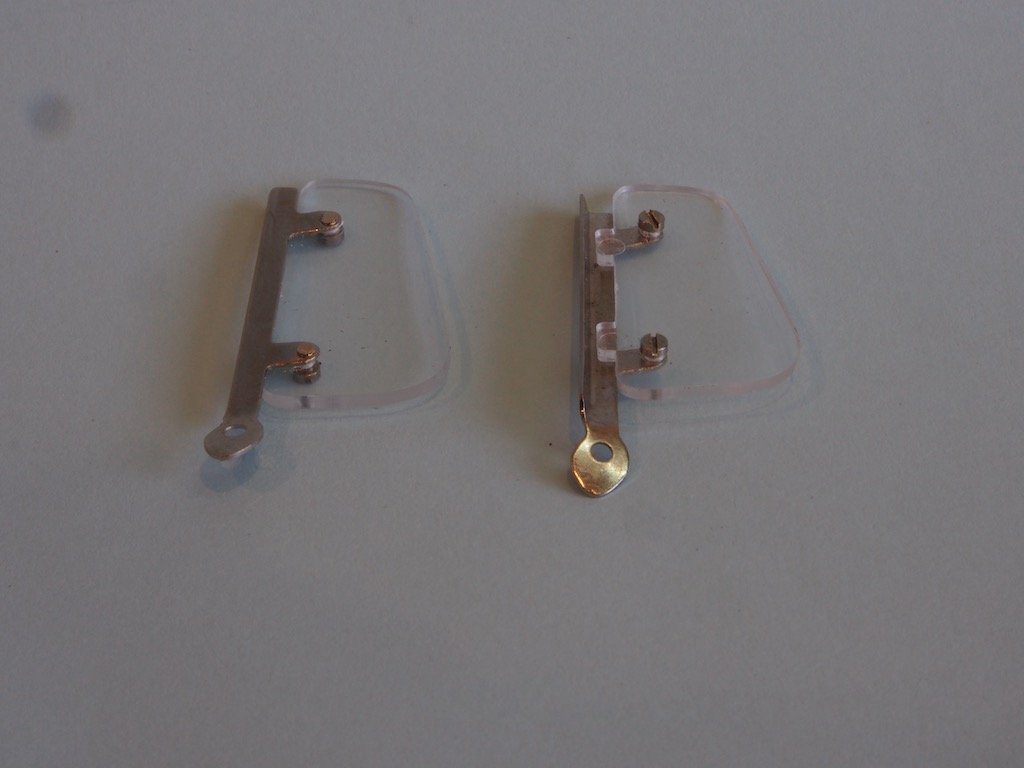

Minor Update and a Re-think The build is now at the stage of completing the final fittings and then assembling the body work to the chassis. However, after some deliberation I have decided that I am not happy with the Monokote chrome trim and will replace it with Chrome paint. This means that I will remove the Monokote strips, carefully mask the body parts, remove the polish/paint from the trim strip area, and then paint. I have not been happy with the Vallejo Chrome in their Metal Colour range – it’s the only one of the Metal Colour range to disappoint. So, I’ve been researching Chrome paints and have decided on Molotow Liquid Chrome. I acquired some of their Paint Pens for testing and like the results but have since discovered that this can also be airbrushed. Rather than pulling a paint pen apart, I have ordered one of their refills. Once that arrives in the next week or so, I will do some final testing with the airbrush before committing to applying this to the model. The only downside of the Molotow is that it takes quite a while to fully cure, before which it is very susceptible to marking from fingerprints etc. Best advice I can find so far is to leave it a few days to a week before handling. Also, it appears that there is no clear coat available that will not dull the mirror like shine of the chrome. Some reviews have said that Alclad Gloss Klear Kote will work, so I’ve ordered some of that to test as well (though I’m not holding my breath for success with this). While it may have been easier to apply this paint at an earlier stage, its fragility means that the later it is applied the better. So, a slight delay while I await delivery of painting supplies and then some further testing. Once that’s done, final assembly will be able to be completed within a day. In the meantime, a very minor update: I have managed to wrestle the tail fin and spare wheels into position. This is such a poorly designed/fitting set of parts that many modelers opt to either omit the tail fin altogether, or to only use one of the two spare wheels. Once again, following Paul Koo’s advice enabled me to achieve a reasonable result. The key is to install the spare wheels before attempting to install the fin. The rod upon which the spare wheels are installed is also slightly too short. This is overcome by adding an extra M3 nut on the outside of the body, leaving a very short section protruding through to the inside to secure the rod in place. This provides just enough length to secure the rod on the inside, and just enough to comfortably install the locking hub on the outside. The fin itself is held in place by three screws – one at the forward end centred between the luggage box covers, and one toward the outer corners at the rear. Attaching this requires installing the forward screw first with just enough threads to hold it in place, then doing the same with one of the rear corners. Then the fun begins. The remaining corner is then bent around the spare wheels with some force to enable it to line up with the screw hole and get that screw started. Once all three screws are started, they can all be nipped up tight. The effect is to actually push the outer spare wheel slightly downward – no wonder it’s so hard to get the fin in place. Even so, you may notice that the fin is not fully seated at the rear corners, but this is probably as close as you might hope to get it without major surgery. The next item to address is the headlight bulbs, reflectors and lenses. The kit provided bulbs are way too long to fit in the reflector without interfering with the lenses. And the lenses themselves are too large in diameter to fit into the reflector housing. The lenses were very carefully sanded down with a bevel edge using a sanding disc in my Proxxon rotary tool (Dremel equivalent) running at quite a slow speed to avoid melting the plastic. At Paul Koo’s advice, I replaced the kit bulbs with some very small bulbs from my local electronics parts store. While this solved the problem of length, they were much smaller than the mounting hole in the back of the reflectors. I solved this by attaching a small piece of 2mm styrene to the back of the reflector, with a hole just big enough for the new bulb assembly. The inside of the styrene was painted with a Molotow Liquid Chrome Pen. The bulbs were then glued in place and the lenses attached using silicon. I forgot to take any photos during the process, but here is the end result. The headlight housing is currently in the paint shop and will be attached in due course. Next up, the windshield components. The windshield is made up of three main “glass” components. The side pieces look deceptively simple, however there is a catch…. The two side pieces are held into a pair of L-shaped metal supports using two screws. The metal supports are subsequently screwed onto the car body. The catch is that the metal support posts are extremely thin, and the holes are not pre-threaded. It would be very easy to destroy these parts. Thanks again to Paul Koo’s advice, these holes were first pre-threaded with a 0-80 tap (a substitute in this instance for an M1.5 tap). The screws are then carefully installed being careful not over-tighten and crack the plastic. The screws are also way too long, so once in place, the excess was very carefully cut off with a cut-off disc in the Proxxon, and the final ends filed with the flat of the cut-off disc. Here’s the end result. Last item for this update is the windscreen wipers. These are composed of a plastic wiper blade that is triangular in cross-section, and a thin metal bracket that forms the arm of the wiper. In the photo below are one completed wiper and one awaiting bending. The two ends on the left of the unformed bracket are bent up at just shy of 90-degress and then there are two small lugs on the blades that fit into these holes. The bracket ends are then bent a little further to lock the blade in place. The other end (on the right in the photo) is then bent up at 90-degrees. These will then be installed with a screw through the windshield into the wiper motors on the inside of the windshield. Once in place, the bracket will then be bent again, folding over on itself and covering the mounting screw. I have not done this final stage yet. The danger in all of this is that these metal brackets are a one-shot affair when it comes to bending. You can bend them only once in any place – if you try to bend them back, or re-bend them, they will snap in half. I’ll be holding my breath and ensuring my tongue is poking out at just the right angle when I do get to this. Now to wait for the Molotow Liquid Chrome to arrive…

-

Thank goodness you’re here Mark - I’ve been waiting for you to arrive and open the bar! I’m over in the corner with Sjors and the popcorn machine.

- 312 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

Nice idea with the transparency overlay Ben. Looking good!

- 889 replies

-

Very nicely done Ryland.

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I just stumbled across this build. Great work so far on a very interesting subject. I’ll be following along from here.

- 53 replies

-

Ripping Planks - what I've learned from others

gjdale replied to glbarlow's topic in Modeling tools and Workshop Equipment

Glenn, Thanks for taking the time to share your learnings and contribute to discussion on this subject. As you say, there are many ways to tackle this task and yours is clearly a valid way. I personally use a jig very similar to the one shown and described by Kurt, and I have also used a method similar to that described by Mark Taylor. All of them are valid. All of them are safe as long as you follow appropriate precautions for your chosen method. Please don’t regret your original post based on a few ill-considered comments. The rest of us appreciate your contribution. -

I’m very interested to see this one come together Kevin, so I’m pulling up a front row seat right next to Sjors and the popcorn. We just need Mark Taylor to arrive now to open the bar!

- 312 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

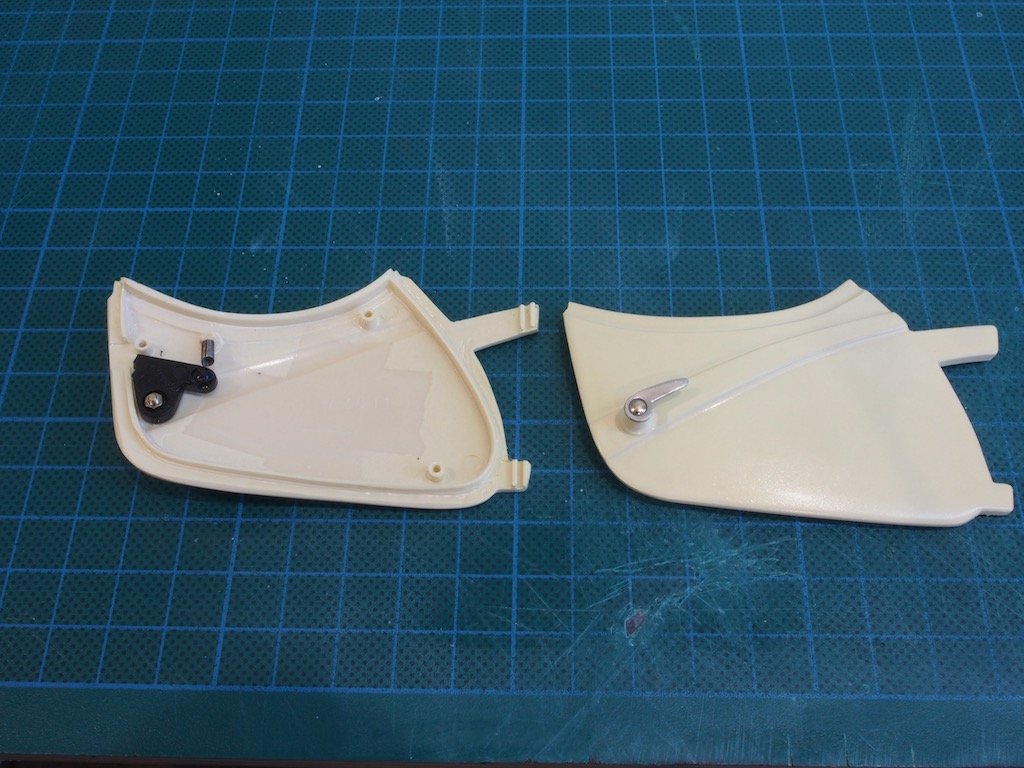

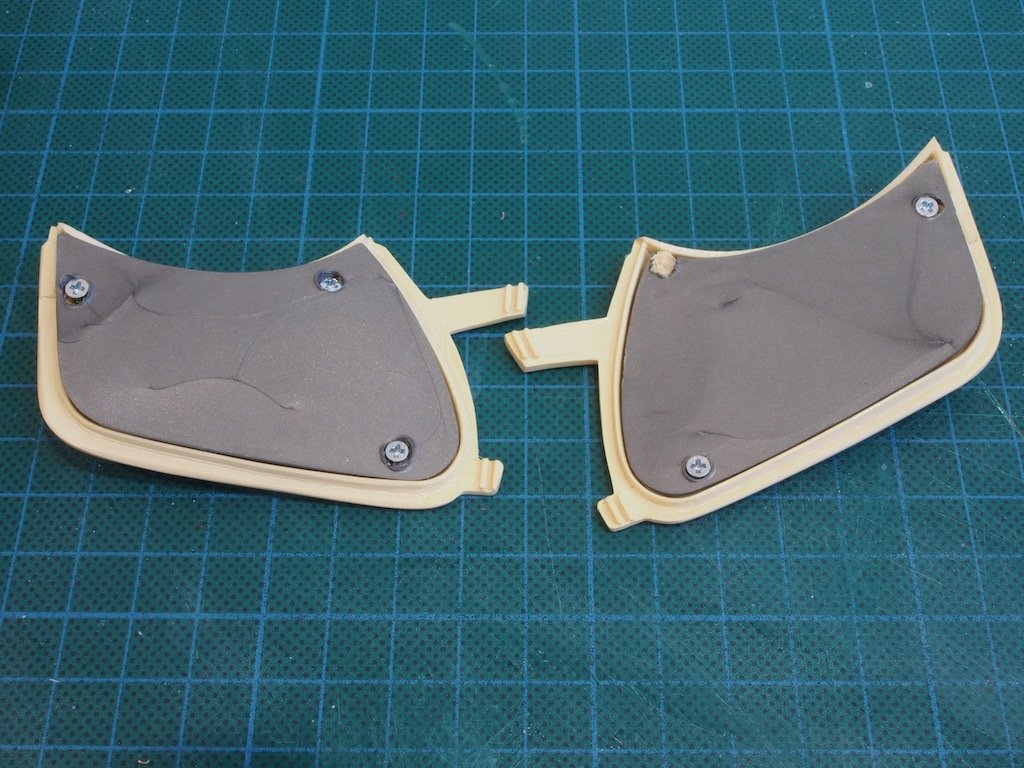

Body Work (continued) The next step was to assemble the hood. At this stage I also added some chrome trim using Monokote Chrome trim. Of the four Hood latches, only the two rear latches are functional, with the forward latches being dummies. So these dummy latches were also attached. Next up was the doors. The doors are supposed to have working latches, but the design is poor, so a modified approach was taken, following Paul Koo’s recommendations. In the photo below you can see the door handle applied on the outside of the door, with the modified latch and spring mechanism attached on the inside of the door. In theory this should still make the door handle spring-loaded, but in practice this still doesn’t work terribly well. The door liners are then added and the next problems dealt with. The kit instructions call for these to be attached with small cheese-head screws. First of all, the holes in the door liners do not align with the screw post in the door, so these have to be adjusted. Secondly, if the cheese head screws are used, these will subsequently protrude as lumps under the leather lining. Thirdly, the screws are too long and if not shortened, will go right through the door. The solution to the second and third problems was to replace these screws with countersink screws that were cut down to an appropriate length. Here are the door liners in place. The final stage for the doors was to apply the leather upholstery. This turned out to be a lot easier than I had anticipated. Following Paul Koo’s advice, all upholstery was glued using Automotive Goop. As a nice additional touch, a separate piece of leather is provided for the map pockets on the doors. The main body then had its upholstery applied. This included seat backs, seat bottoms, dashboard cover, foot-well side panels, and luggage box straps. Monolote chrome trim was also applied, although the photos do not do this justice due to the way the light catches this in the photos. Here is an overview of the main body upholstery. And here are a few extra shots with some close ups showing the stitching detail and the door pockets: The carpet was also applied to the floorboards, though I didn’t take a photo of this. Next up will be the addition of extra fittings prior to installation of the body parts. Stay tuned….

-

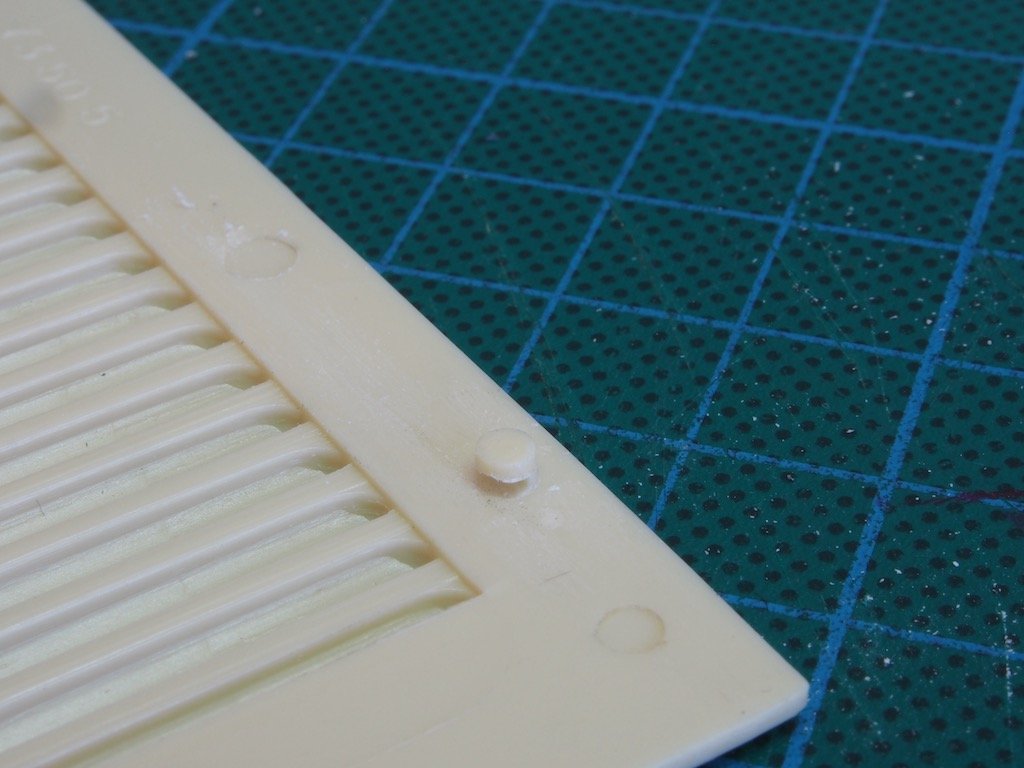

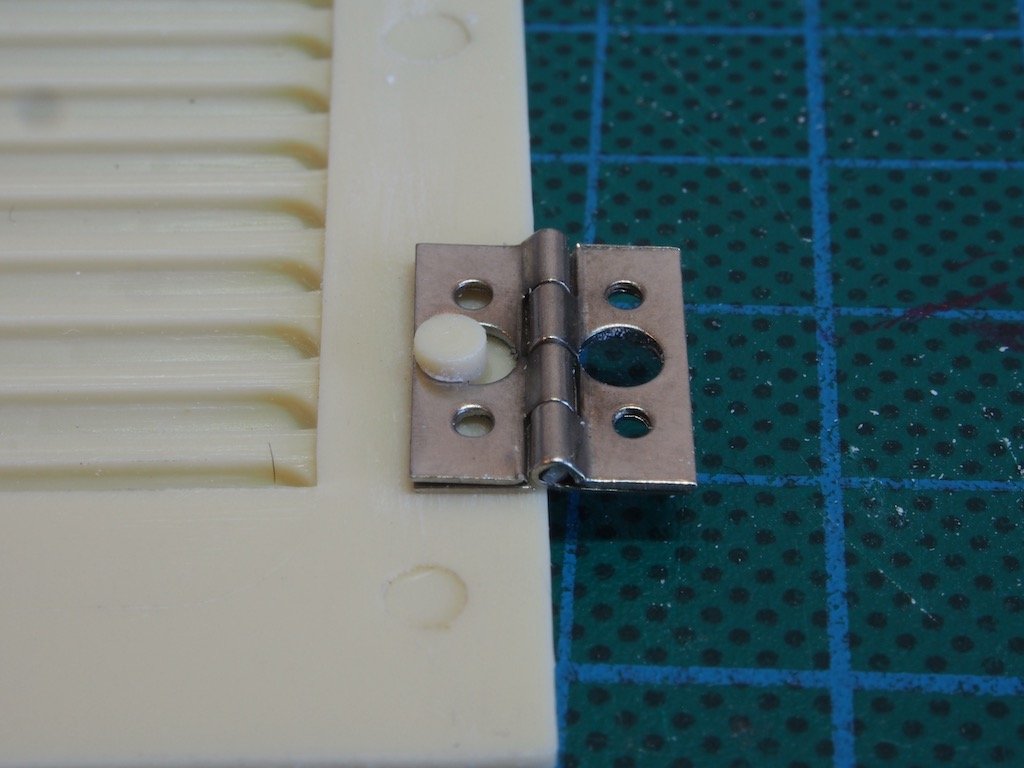

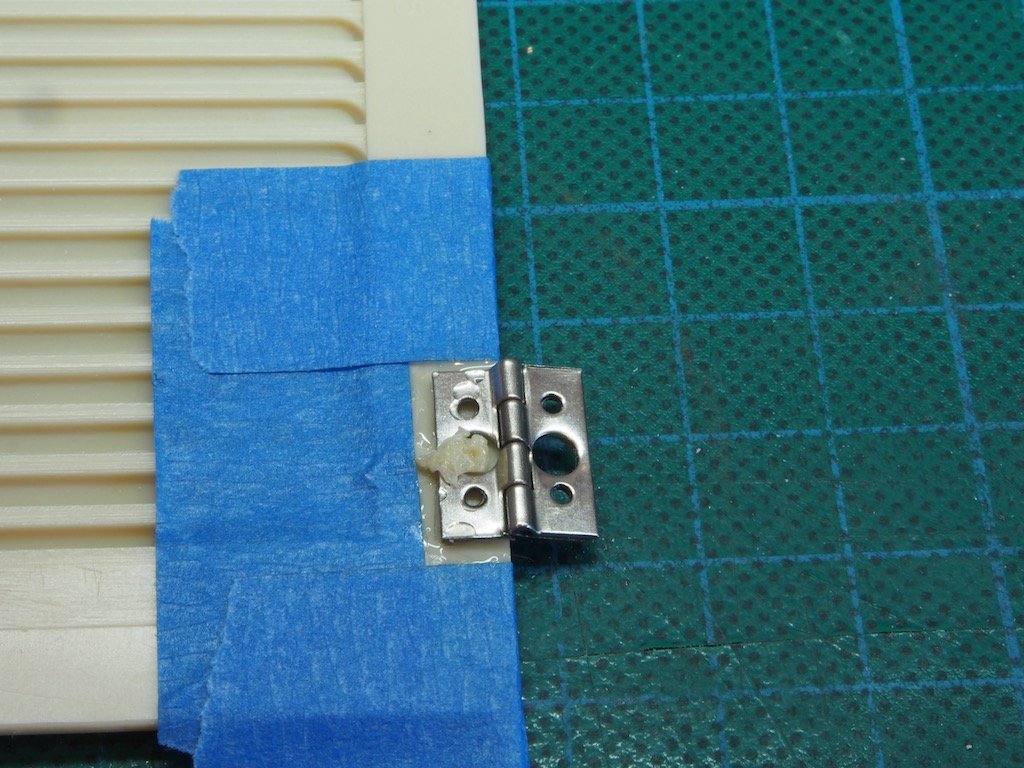

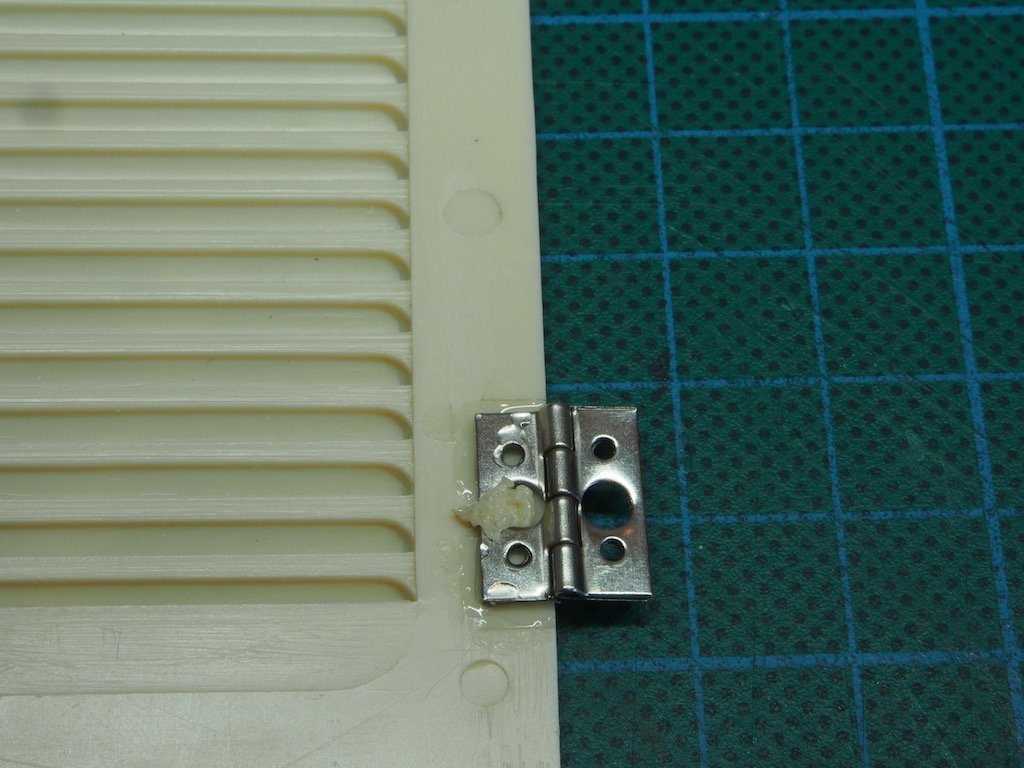

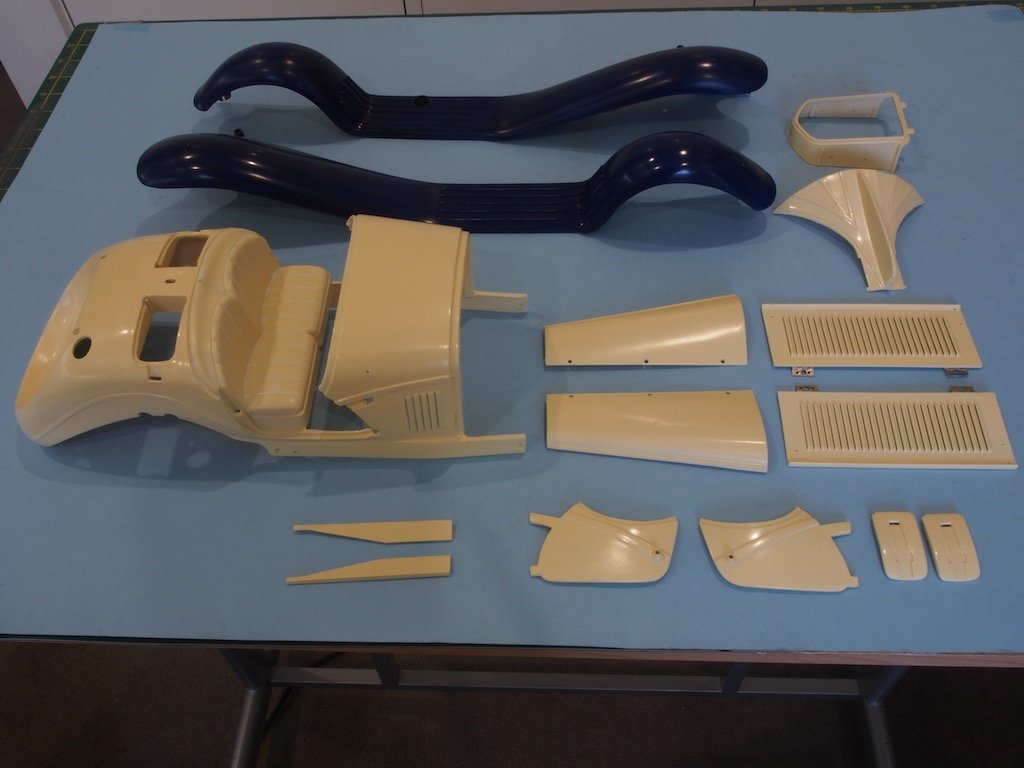

Body Work It's been over a month since my last update, but that doesn't mean that I haven't been working on this model. On the contrary, there is a lot of preparatory work required before installing the body works. This begins with the Hood panels. There are small hinges that attach the side and top Hood panels. The kit parts have locating lugs to position the hinges. A great idea, once again poorly executed. The problem is that these are in the wrong place. The photo below shows a hinge in place on a side panel and illustrates well the problem – the hinge pin is way too low and needs to be moved up. In the next photo you can see where I have removed the small locator pins and then filed a notch into the main locator to allow the hinge to be moved up. The result is shown in the next photo – a properly located hinge. The hinge is then fixed in place by first melting the locator pin and then applying glue around the hinge. The masking tape is simply to contain the glue. And the final result: This process was then repeated with the remaining panel hinges (four in total). Once attached to the side panels, the locating pins on the top panels had to be similarly adjusted both for hinge height and also for fore and aft alignment to ensure the top and side panels were perfectly aligned. A photo of the completed hood is further down in this update. The next job was to make up the four Hood latches. Here are the components for one of these: And the completed Hood latches: Next up was painting the main body parts. This stage seemed to take forever as I experimented with a number of finishes and made a few mistakes along the way. First up, because of the overall size of this model, I took the advice of Paul Budzik (who is a member here and has posted many useful and informative videos on YouTube). That advice was that a regular airbrush was not a good idea for this size of model. I won’t go into the reasons why – you can watch Paul’s videos for that. Instead I had previously purchased a mini HVLP spray gun, again based on Paul’s advice. The spray gun I used is the Iwata LPH-80 with a 0.8mm needle. While at first glance, this spray gun looks to be more complex than an airbrush, it is actually quite easy to set up and use. The catch is that it needs an air volume that is beyond what pretty much all airbrush compressors are capable of, so I had to hook it up to my large (and very noisy) compressor in the garage. The beauty of this gun is that it needs a constant air pressure at the gun (you need a gun gauge for this) of 13psi. Once you have that set, it just a case of adjusting the material (ie paint) flow until you get what you want, and then adjusting the fan pattern similarly. Of course, a change in one means you need to tweak the air pressure to maintain that 13psi, but that is actually really easy to do. My next lesson was about filtering the paint. I had assumed that using a quality primer and paint such as Vallejo would mean that I could just go ahead and spray, with perhaps some thinning, depending on the actual paint. I found that despite good stirring/mixing and thinning, I was still getting clogs and spitting, even with this larger needle. That’s when I had my major light bulb moment (or as I like to say, my Homer Simpson moment – oh, Duh!!!) and decided to filter the paint first. I bought some paint filters from an automotive shop and stripped the actual filter material from them. I then placed this over the mouth of the paint bottle, trapping it in place with the dispenser cap. And just like magic, all my painting problems disappeared……well, almost. Having at last achieved a nice primer coat and colour coat, I had to decide on clear coats. I wanted to stay away from some of the nastier types, so tried several acrylics – none of them particularly satisfactory. I had read online and seen YouTube videos of plastic modellers espousing the virtues of Pledge/Future floor finish as a great clear coat. I was sceptical at first but eventually decided to give this a go. Of course, this product cannot be bought in Australia, so back to online shopping and managed to track some down via eBay. A couple of weeks later that arrived, and I did some trials, finding that the more coats of this that were applied, the shinier the surface became. I found that four coats of this gave quite a nice finish. It sprays beautifully and self levels very well too. My next lesson was that acrylic paints are impossible to polish as one might with enamel paints. The slightest abrasive surface, even with micromesh polishing pads, will quickly strip the clear coat and the colour coats. The best I could manage was to use Novus polishing liquids with a soft cloth. Even then, I could only use the No.2 Fine scratch remover and the No.1 Finishing polish – even the No.3 Coarse scratch remover removed all the paint. So after several weeks of trial and error, and re-dos, and more errors, and more re-dos, I finally had the body parts to a useable state. Here they are, ready to go. Continued next post.....

-

Also "new" member after a long shore leave

gjdale replied to SkerryAmp's topic in New member Introductions

Welcome home Adam, we left the light on for you. -

I’m along for the ride again BE - always interesting to watch your builds and the way you put your own stamp on them.

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.