-

Posts

1,327 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigersteve

-

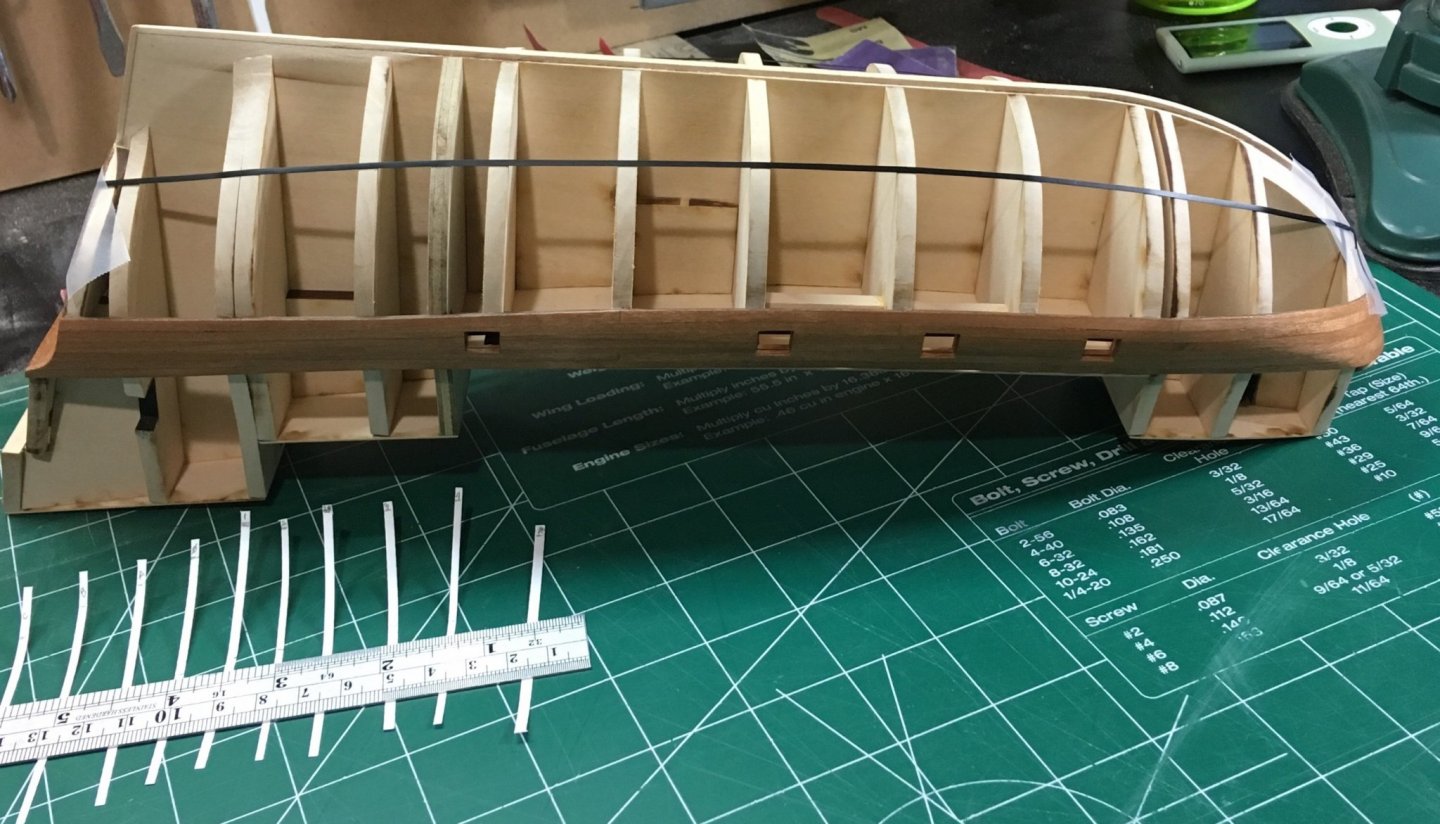

Determining the planking belts. Tick strips were used to determine and mark the halfway point of the remaining area to be planked. This was done from bulkhead D through 4B. Adjustments were made based off these measurements. I could use our experts feedback on the lines of these belts especially at the bow. Steve

-

You should test on scrap wood. Steve

- 66 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

I would use a long free cloth wrapped around your finger and rub your finger between the ribs. Direction doesn’t matter too much on the inside of the hull. Floorboards will cover some of the finish anyway. What stain color did you decide? Steve

- 66 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

@ASAT just trying to add some humor to this. Didn’t mean to offend.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck- Your tutorials are so clear. People are lucky you’ve provided templates for lining off the hull. Next, people will be asking you to mail them completed models. 😆 Steve

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

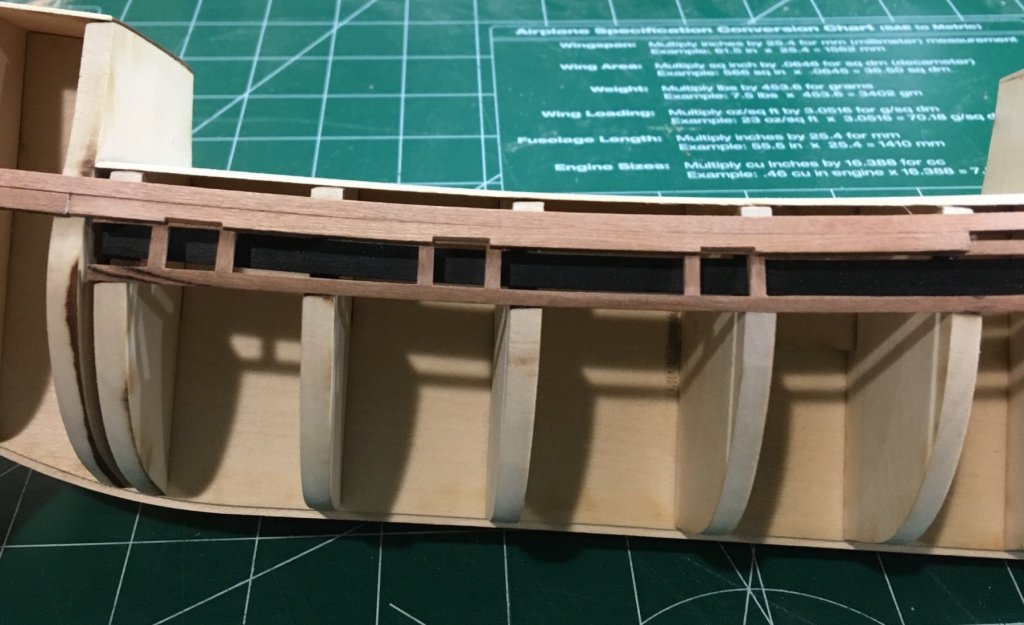

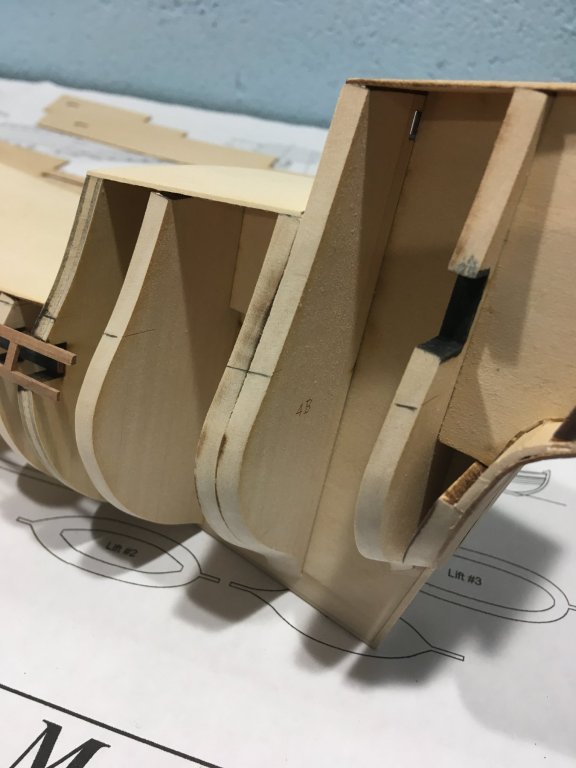

Now that the initial phase of hull planking is almost complete, I thought it would be useful to share the method I’ve been using to plank around this tricky bow. 1. Measure 80% of the 1/8” plank width and mark at the tip of the plank. It’s .1”. I use digital calipers for this. Mark 3” from the edge of the plank and draw a line from this point to mark the taper. I sand up to this line by running the plank across a 220 grit sanding block. 2. Bevel the plank to fit against the previously laid plank on the hull. 3. Soak the plank in hot water for 5-10 minutes. (This is the only time I use water.) 4. Clamp the plank to the hull and heat the plank until it’s dry. Let it cool. 5. Mark the butt joint and sand. Test fit on the hull. 6. When you have a nice fit, mark the edge of the plank to simulate caulking. 7. Apply glue and re-clamp. For the hot water I use a Keurig. I keep a disposable coffee cup in my work area. This works well since the plank lengths at the bow are short. I’ve included a photo of the clamping. Steve

-

People think everything is going to magically sand clean after sloppily planking. Don’t know why. The cleaner it is before you sand, the cleaner it will be after. One piece at a time! Steve

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Requesting feedback for future MSW Group Projects

Tigersteve replied to Chuck's topic in Group Projects on Model Ship World

I like the idea of a stern section. Steve -

Very sharp. Excellent as always. Steve

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

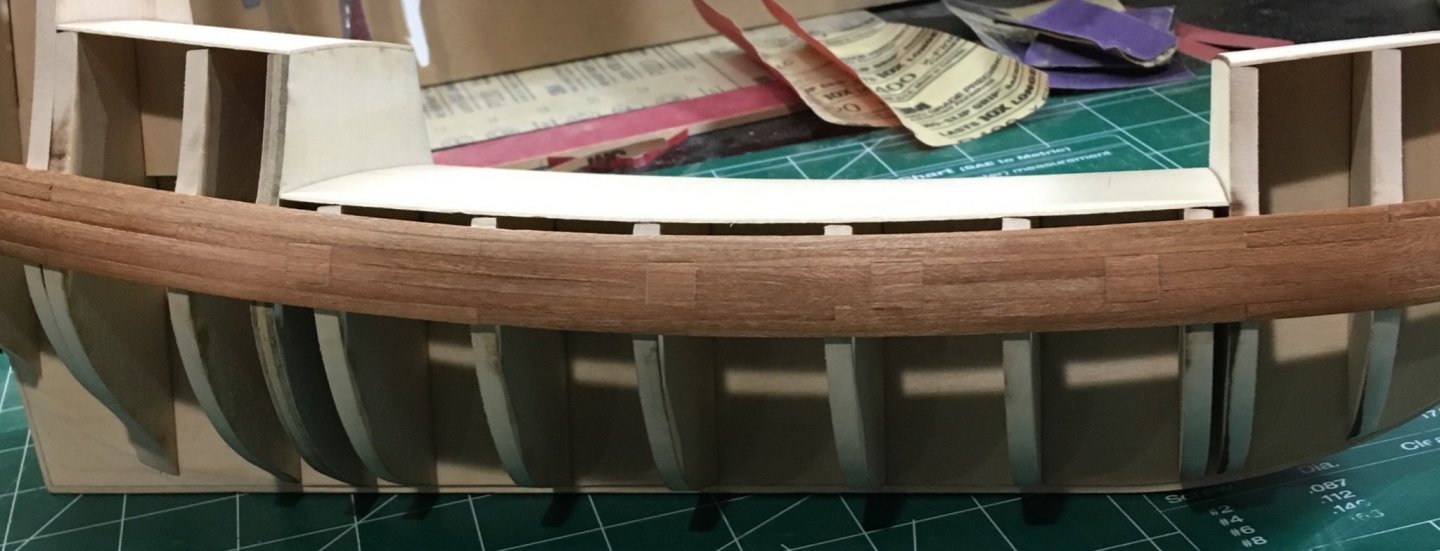

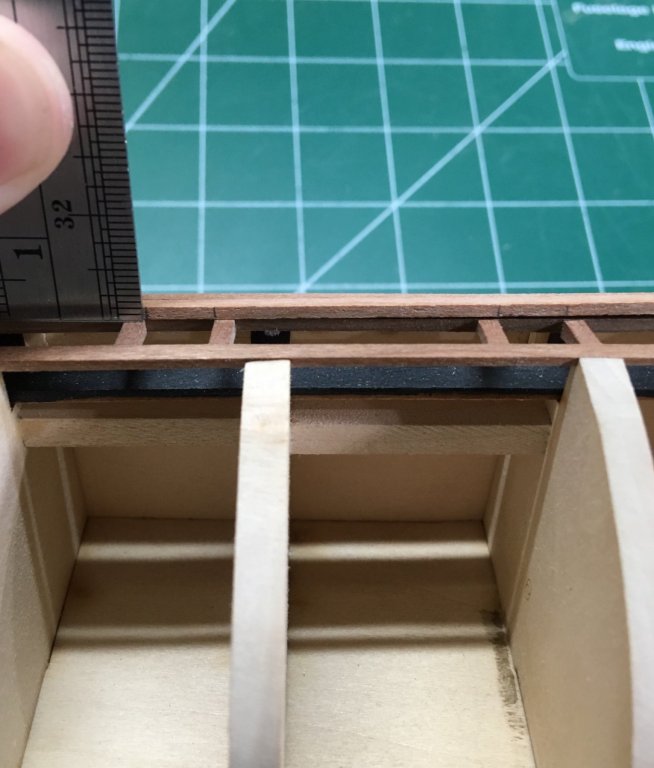

Planking around gun ports- The plank is cut to size and pre-bent with dry heat. Bevel the edge as necessary to get a tight fit. Next, mark the port openings using a straight edge. I like to file the edges and then draw a horizontal reference line representing the top of the opening. Various files are used and the fit of the plank is checked constantly until there is a clean 1/64” reveal. Still working on a more uniform reveal. Steve

-

The last version looks much cleaner and the color contrast with the boxwood is very nice. I’m going to need some moldings for my Confederacy 😜. Steve

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The initial planking is completed starboard. Sanding was done with 220 grit followed by 400 grit. Two coats of Wipe-On-Poly were applied with a 400 grit sanding between coats. 1/16” thick strips were a good design choice for this project. It allows for the needed sanding at the bow, which is tricky to say the least. I planked in scale length planks and left an approx 1/64” rabbet around the gun ports. Steve

-

Here is a company I’ve used for the display case. https://www.casesforcollectibles.com/ Steve

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Figure out a case for sure. It would be a shame.

- 242 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Another masterpiece in the making. Steve

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Some really nice work here. Steve

- 95 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

I marked off the reference lines for the initial planks with the bulwark template. Since I will only be planking one layer, I’m trying to figure out the scale lengths and planking pattern for butt ends. I calculated about 4” planks at this scale. I’m trying to follow Chuck’s planking pattern. It seems that some lengths used were longer than 4”. Are all planks supposed to be 4”? Looking for guidance on scale length planks. Steve

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.