-

Posts

1,327 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigersteve

-

Your hull looks really good. Steve

- 87 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Congrats and nicely done! Steve

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Outstanding! Can’t wait for volume 3. Steve

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I think go with option two, but shape the rear of the panel so it transitions smoothly into the seat back. Steve

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

You are building momentum. Very nice. It’s hard to see how bad the off symmetry is in your photos. I would keep both garboard and the next streak the same shape so you have symmetry. Depends how much this will bother you. If you decide later on to redo it will be more painful. Just a point in reference many of us took forever to complete this project. It’s not about speed at all. Steve

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Looks good. Be careful of your clamping on the bow. The basswood will dent easily. Also, your garboard has too much of an abrupt curve. Just sand/file a bit more for the gentle curve. Before you glue, shape the next strake to see of you have the curve correct. Again, BobF and Erik have done this perfectly. Steve

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you for the compliment. Check out BobF’s log as well as Erik W.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

When you decide to add the transom, you will need to fair it with the hull. You can brace it from the top and even the sides. You can remove the bracing when the planking is done. Depending on how you decide to plank will determine where to place the bracing. Check out some of the logs for how people have done this. Steve

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

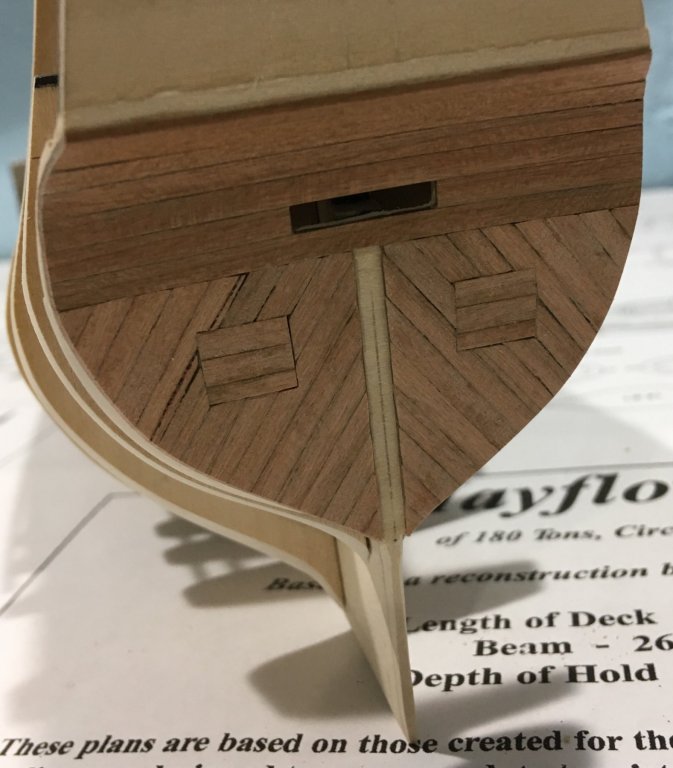

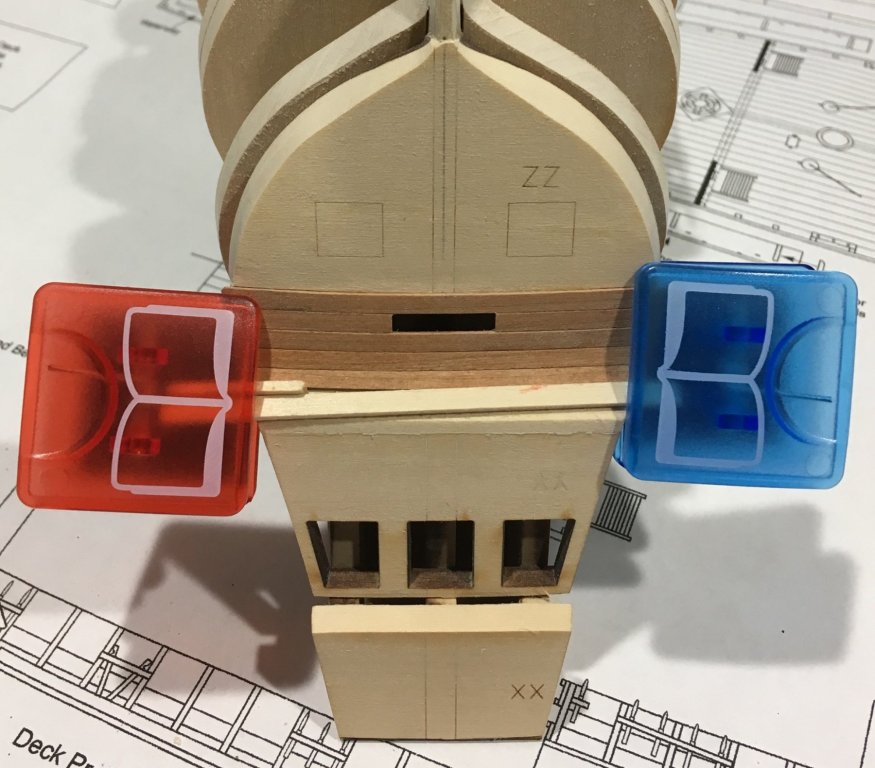

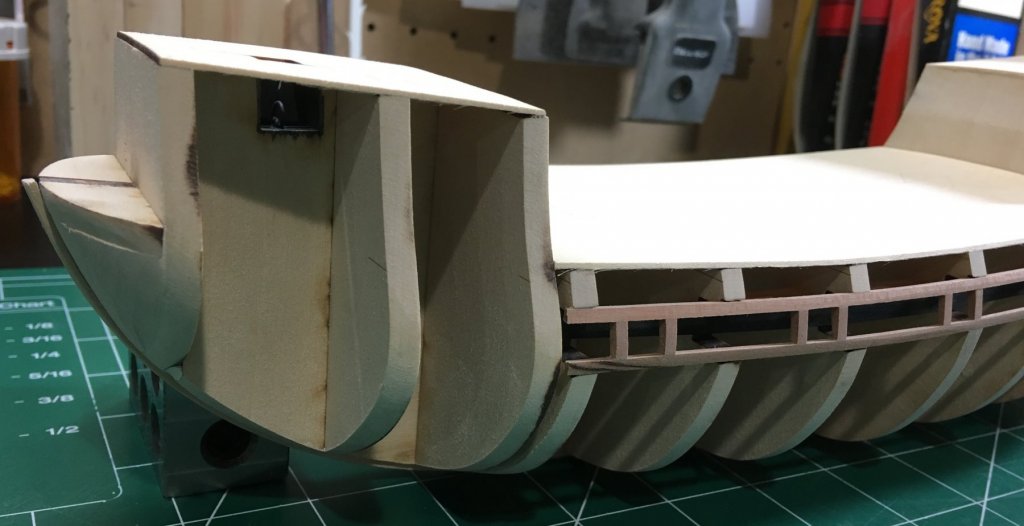

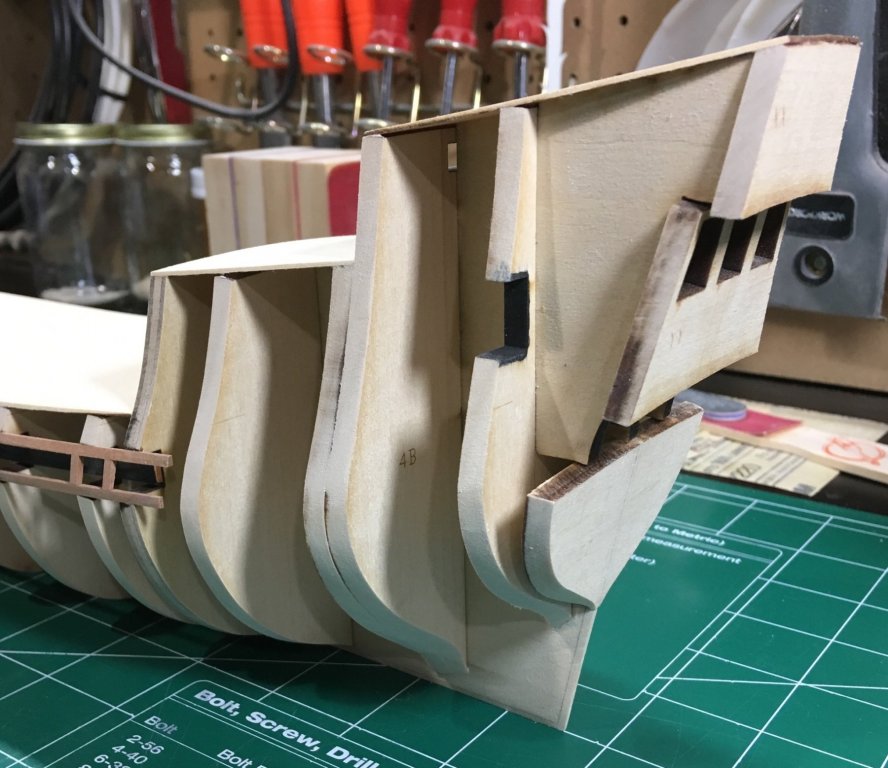

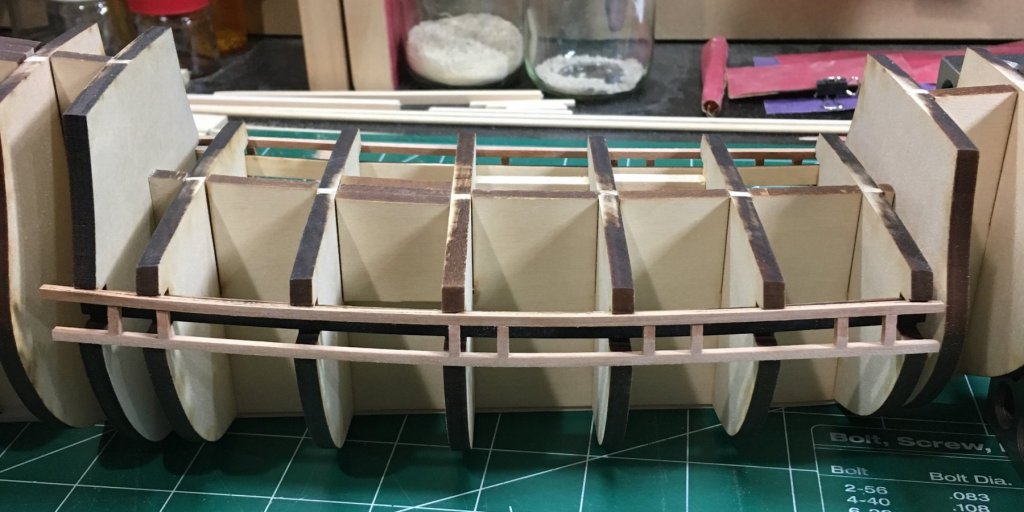

The hull is about 99% fair at this point. Be careful with the fragile gun ports during this process. Filler blocks were added at the bow. This made fairing that area much easier and hopefully will ease the job of planking. The stern needed a lot of sanding to get the batten to lie properly. My concern was keeping the shape of bulkhead ZZ symmetrical. The decks were added and the upper part of the hull was faired again. I included several photos. I hope they are helpful to others. Steve

-

Before you know it you will be on to the next project. What’s next on your project list? Steve

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

It’s a learning process for sure. You have a lot more sanding to do inboard and you should definitely use sandpaper on the basswood. Look up some images of longboats and alternate color schemes for painting. Try something no one has done before. You will feel better about it after you’ve sanded and painted. Steve

- 10 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

I had trouble with this area of the project as well. I used maple for most of the project but for the inboard planking I used basswood. I think I also shaped the wood from a larger piece. That was a difficult curve. See post #116 in my log. Steve

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

Where did you get the new figurehead? Steve

- 550 replies

-

- confederacy

- model shipways

-

(and 1 more)

Tagged with:

-

Gunports are complete. I used a thin strip of wood to mark the port openings. The vertical sections were cut at a 10 degree angle and sanded to fit. A mini 2” chop saw was invaluable for this task. I created a spacer for the gun port openings to make sure they were consistent widths. A photo is attached of the tools used. Fairing the hull is next. Steve

-

Completed top and bottom of the gunport framing. The replacement bulkhead 2b is slightly smaller than the kit’s original so the gunport framing curves inward at that bulkhead. It should be fine after the hull is faired. These bulkheads have notches to accept the framing. Be sure to fit the framing strips deep into those notches. The strips were pre-bent with dry heat and spacers were used when gluing the top of the framing. Steve

-

Yes, the seat template was tricky for me also. Looks good. Steve

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.