-

Posts

1,327 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigersteve

-

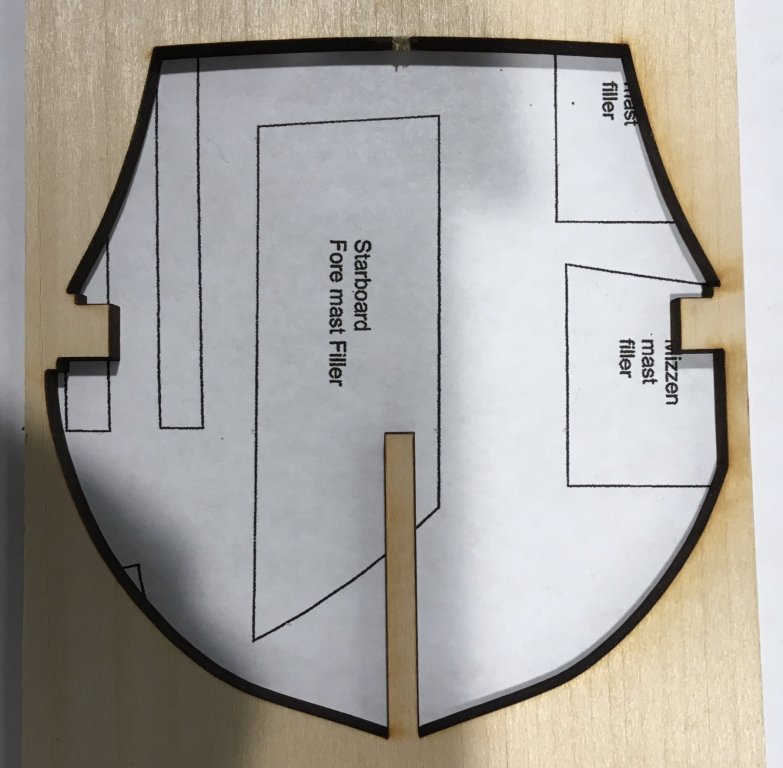

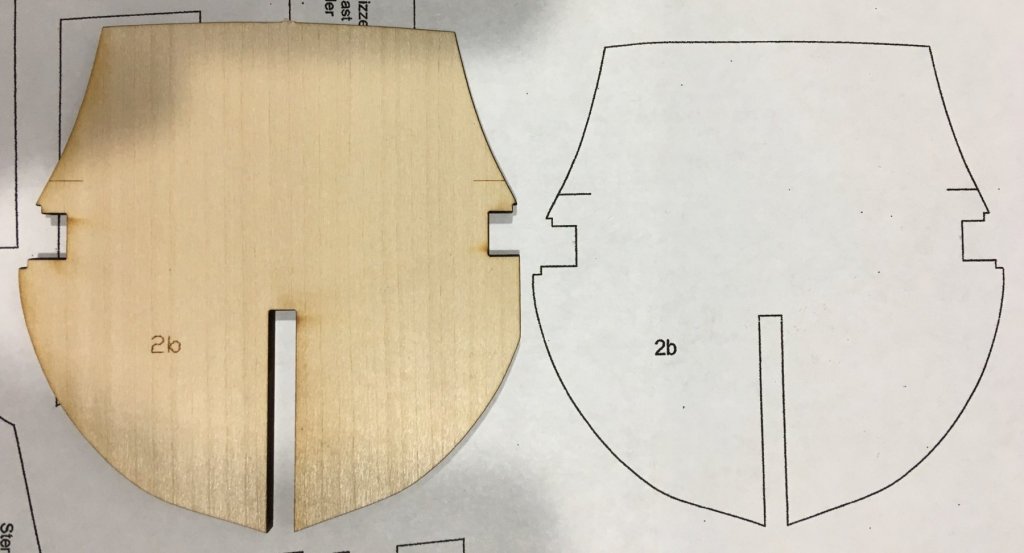

Good morning, gentleman. I’ll attach a photo of the sheet to clarify. Jim, I do not think it was a design mistake on Chuck’s part. It seems like the shape of the bulkhead was altered by Model Expo to fit the sheet. That still makes little sense. Osmosis, I could definitely contact Model Expo, but at this point I will most likely just make the modification myself. Steve

-

As expected there are a couple of discrepancies with Model Shipways’ laser cutting and the plans. Bulkhead 2b is flattened on one side where it should be round. The bulkhead former is not an exact match to plan sheet four. Although, it seems to match on the other plan sheets. Not major issues, but annoying nonetheless. The bulkhead can be adjusted easily enough. I wonder why these discrepancies happen. Steve

-

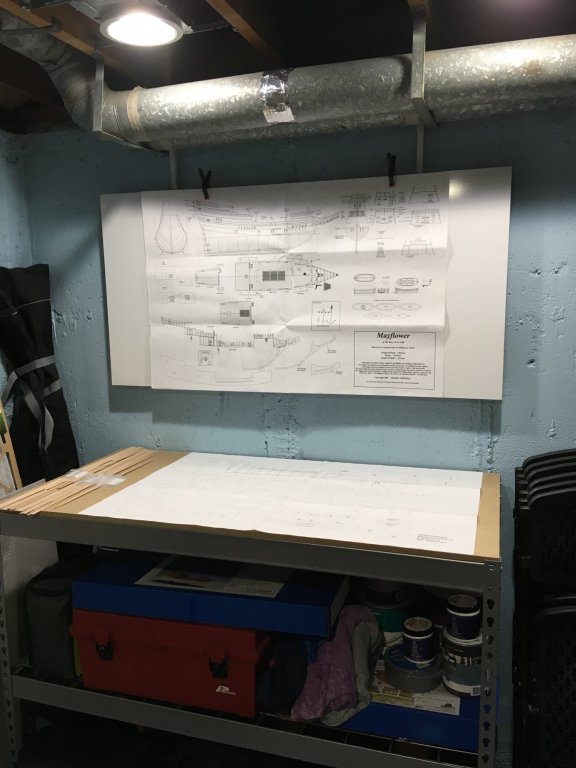

After much planning, trial, and error, I was able to retrofit this dry-erase board to part of my workspace. The board was no more than $10 at Home Depot. Not magnetic, unfortunately. It is mounted with two closet brackets also from HD. Scrap wood was used to space the board from the wall. It holds the Mayflower plans nicely. Steve

-

HMS VICTORY 1765 by albert - 1/48

Tigersteve replied to albert's topic in - Build logs for subjects built 1751 - 1800

Awesome Steve -

Chuck, the model is looking really sharp. Great work. Steve

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Very clear tutorial. Nicely done! Steve

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Looks great! Make the rest now while you have the momentum. Steve

- 109 replies

-

- model shipways

- kate cory

-

(and 1 more)

Tagged with:

-

Congratulations an a fantastic model. Steve

- 1,350 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Disk attachment. The drum attachment will destroy the frames. Steve

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

Would the baseboard in cedar be too soft? Steve

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Good choice. Lots of sanding next. I was able to use my rotary tool for some of the sanding, especially at the bow and stern. You would need to be careful though. I hit this part in several sessions. It’s tedious, but very important. All the remaining work rests on these frames, which need to be very thin. Steve

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

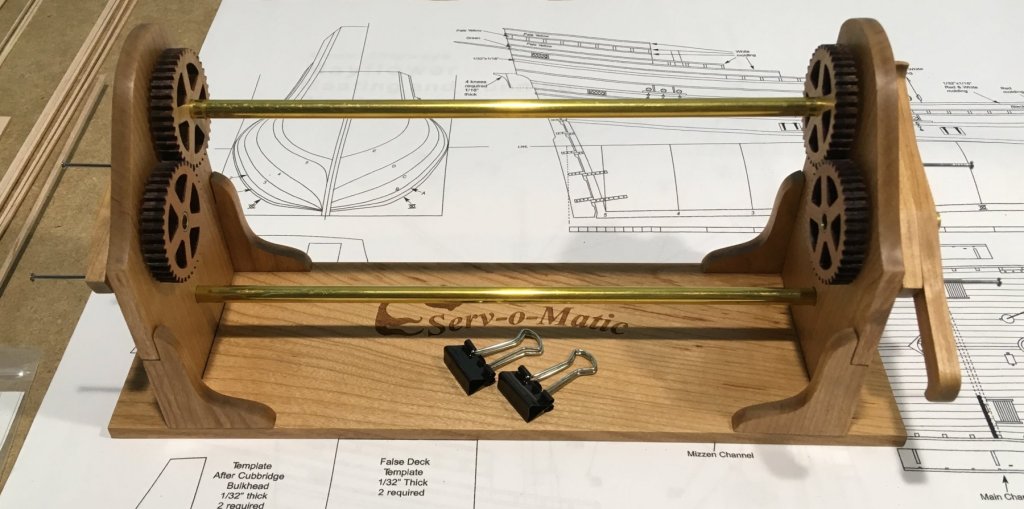

Partial assembly of the machine. The gears are not glued to the brass tubes. I suggest test fitting the gears and rotating them before you glue to make sure they rotate freely. Two of my gears were just a bit off when I glued them and this caused them to not rotate freely. Parts are laser cut precisely. Chuck is mailing me some new ones. Before assembly, a third sanding and coat of Wipe-on-Poly was applied. A very smooth finish was the result. Steve

-

They will barely be seen in my opinion. Steve

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.