-

Posts

349 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Beckmann

-

-

-

-

Mike, that is an increadable example of patience an accuracy. Your Winni will be an extraordinary model, once completed!

Matthias

- FrankWouts and Stuntflyer

-

2

2

-

Wow, that is certainly a big help! You are an expert!

-

Bravo, ein phantastisches Modell!!!

Grüße, Matthias

- mort stoll and Henke

-

2

2

-

What an excellent and beautiful design!! We are lucky to participate in this, thanks Chuck!

Will you leave this black hole for the rudder like it is, or open it later?

-

Thanks everybody for the comments and likes!!

I learned two or three things while doing this:

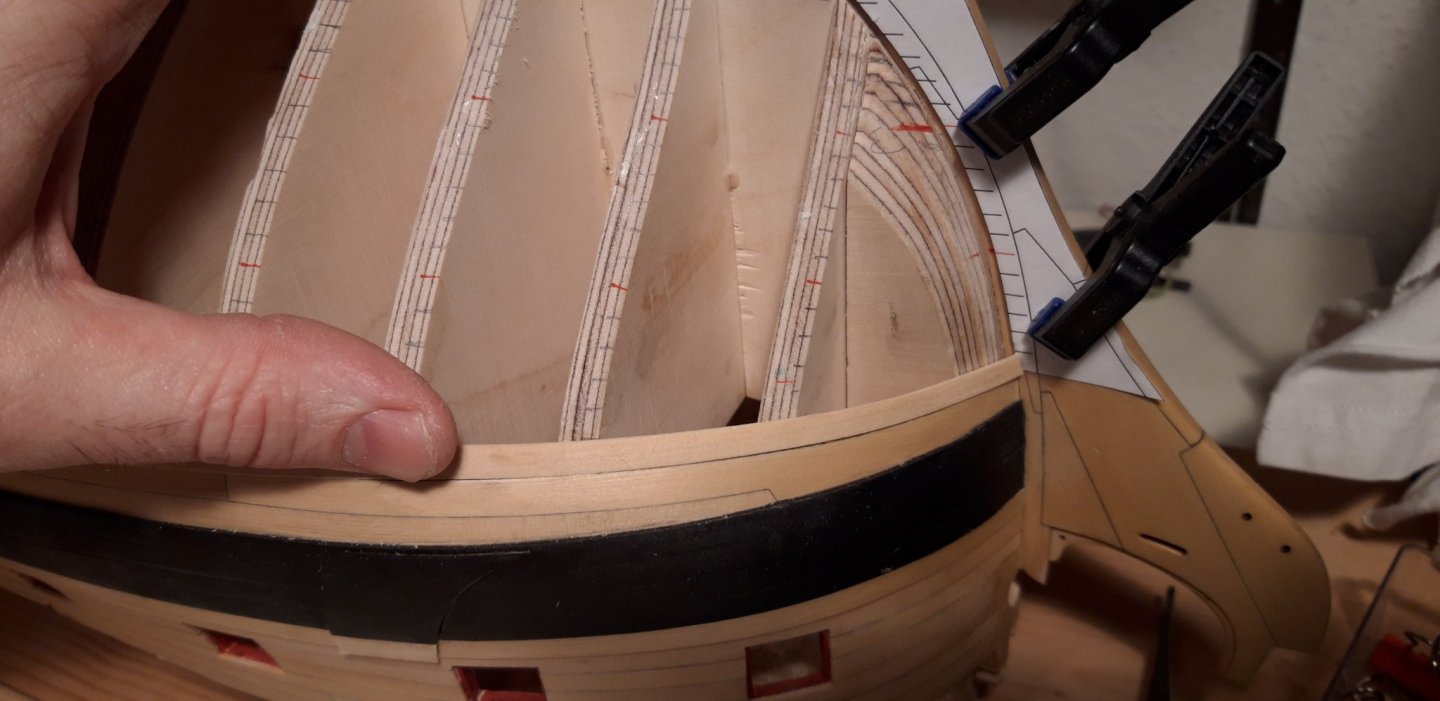

The bulkheads need to be in perfect shape. If not (and mine are not) it can happen, that you get a bump in the surface. And then, if you sand everything, you suddenly see the bulkhead. I had that at two points. I had to change those planks, wich is really not a nice thing to do. The other thing is, that the planks should not be too thin. Better more near to 2mm than 1,6 mm. That makes is all more safe and stable. And the better you bend the planks before glouing, the better they fit. Forcing it in position always makes problems. There is a saying about building houses in Germany: Make the first one for your enemy, the second one for your friend and the third one for yourself. That is probably, what I should do with this Winnie-project!😉

Matthias

- FrankWouts, Jack H, Ryland Craze and 6 others

-

9

9

-

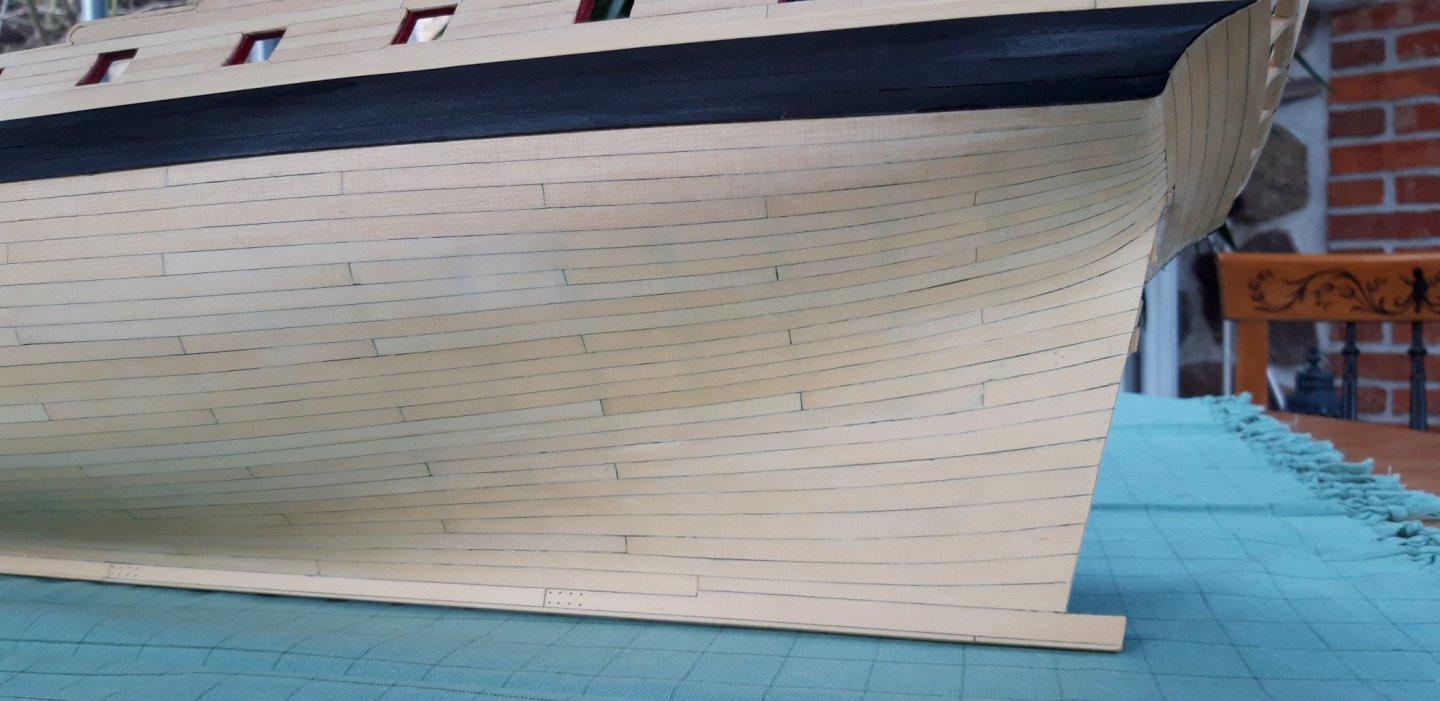

The starboard side is planked two belts. The upper two belts are the next thing to do.

-

-

-

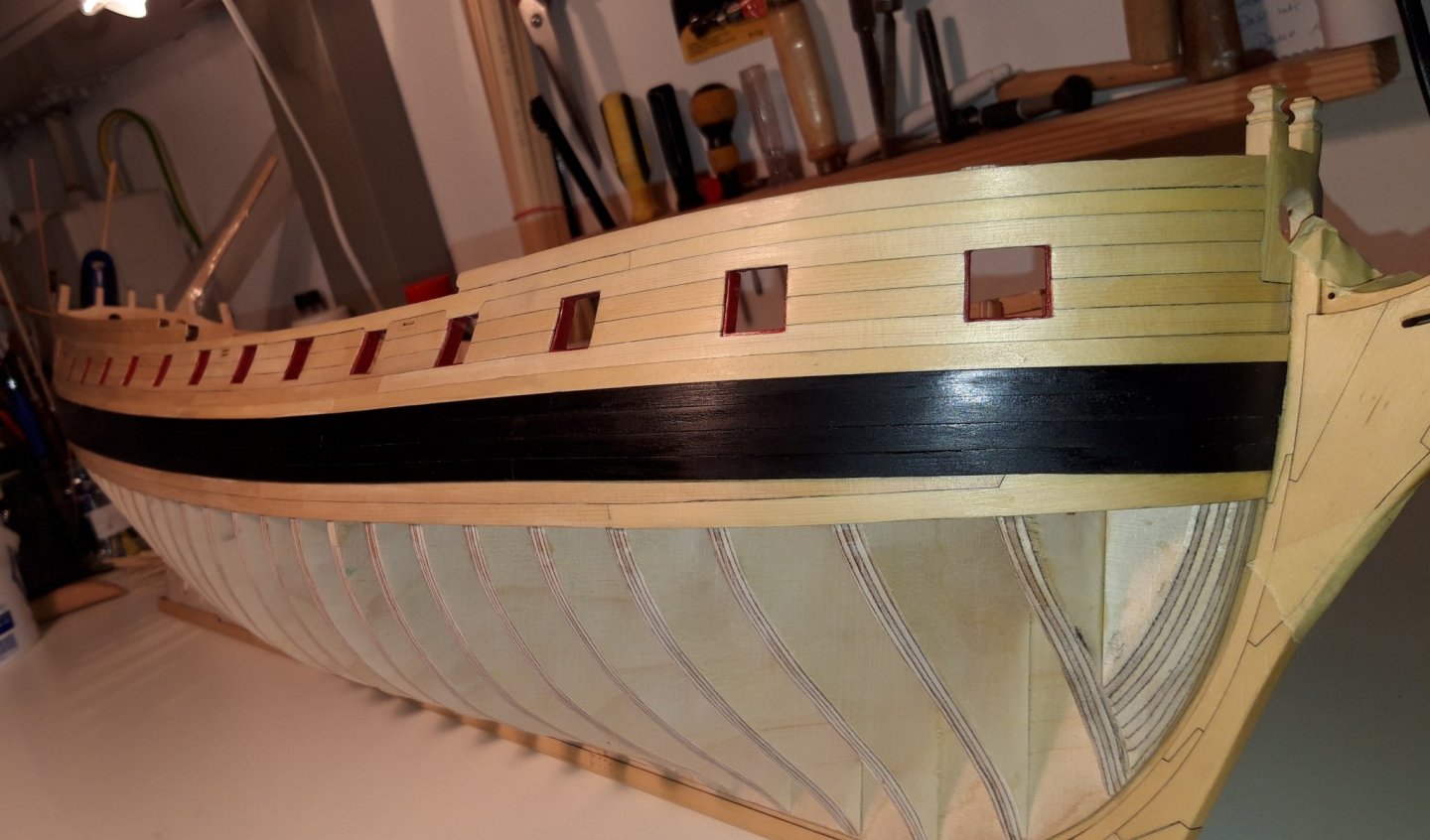

Thank you everybody for the comments, - as I said, these tutorials make it easy to achieve a nice fit of the planks. I switched now to the other side of the hull. Christmas vacations are over now, things will proceed slower from now on.

- JpR62, Jack H and FrankWouts

-

3

3

-

- egkb, rafine, Ryland Craze and 23 others

-

26

26

-

- Matt D, Saburo, CaptMorgan and 10 others

-

13

13

-

Okay I understand, but so far there is no duckboard piece on the model. Or do you mean the channels? They will be black I presume.

-

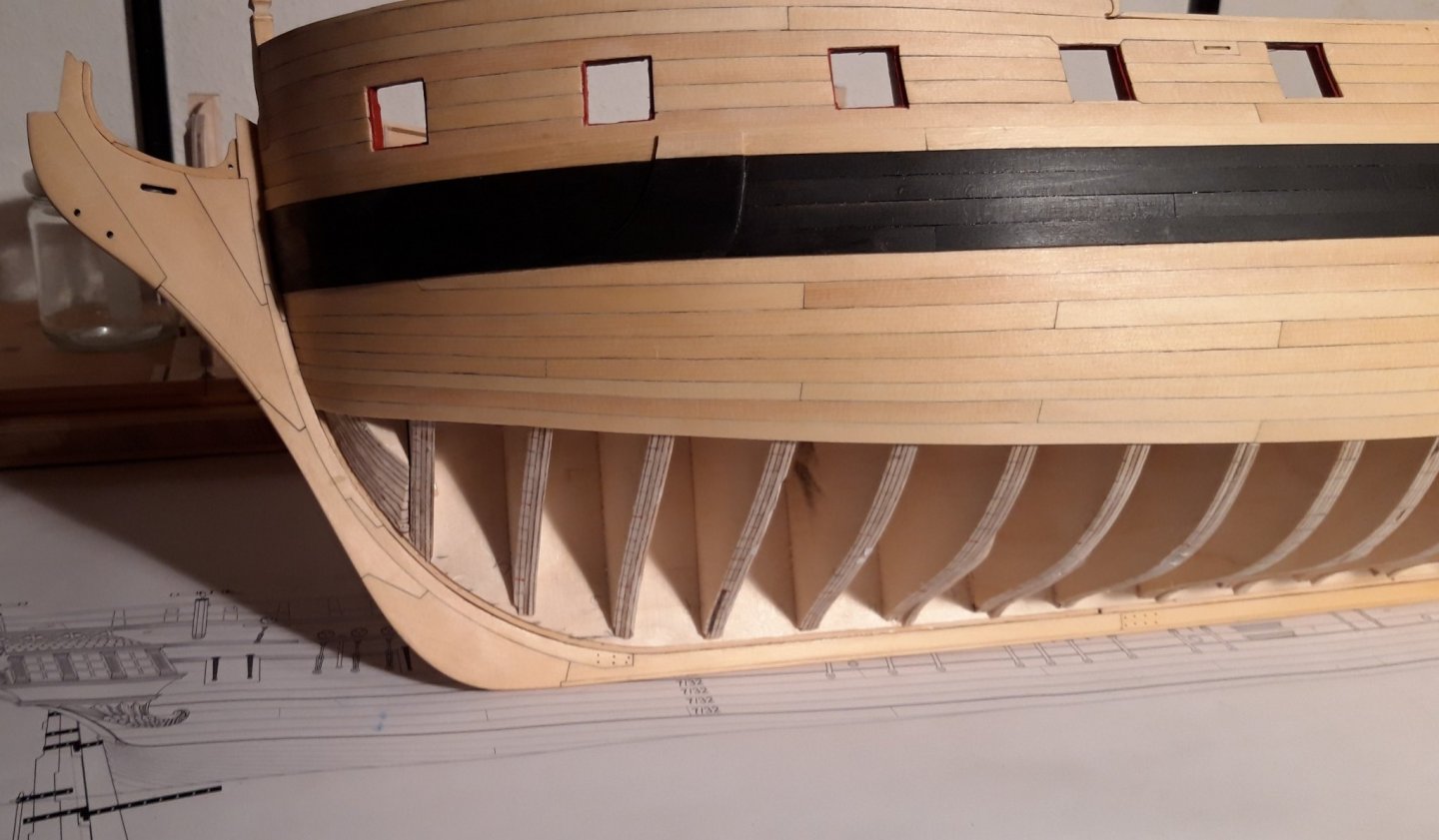

Unfortunately, I have to rip of the 4 rear planks below the wales, because I die not consider that

They go over 9 bulkheads.

They go over 9 bulkheads.

-

Hi Empathry, thank you for your kind comment. ebony is too unflexibel and difficult to bend. What do you mean with "Laufbohle"?

Here is my first attempt with these difficult planks below the wales. It is actually my third attempt, I broke all the others. If I keep going like this, I will soon run out of planks.

I have a question concerning the joints. They jump every second bulkhead from one row of planks to another. And after 4 rows, it goes back to the first bulkhead. Is that right? That produces a regular pattern of joints. And it means, that one plank goes over 8 bulkheads.

- DocBlake, FrankWouts, GrandpaPhil and 6 others

-

9

9

-

- igorcap, Jack H, Ryland Craze and 9 others

-

12

12

-

Hi Chuck,

I know, what you mean. In my case, it is now 7 or 8 weeks, that I started the planking. And there are definitely more than one planks, which I should not have glued in position, because with a little more effort, it could have been better. It is a matter of habit and willpower and Patience. At my work as civil engineer, things are never fast enough. You are actually always behind, trying to not loose connection. So shipmodeling is a bit like a therapy to slow down.

The other thing is, that this model is so much fun. And I think it is a level, which is new for ordinary shipmodelbuilder like me. You just can‘t resist sitting down, doing the next plank. Today for example I spent all morning fairing inbord - and enjoyed it. I will take my time for the planking below the wales.

Matthias

- Rustyj, Chuck, pythagoras and 1 other

-

4

4

-

Thank you Jim. Using mordant always has the potential to completely ruin, what you did so far. Once it is in the wood, you never get it out again. So I am glad, all went well. I wiped some varnish on the surrounding planks, that kept them clean.

Matthias

-

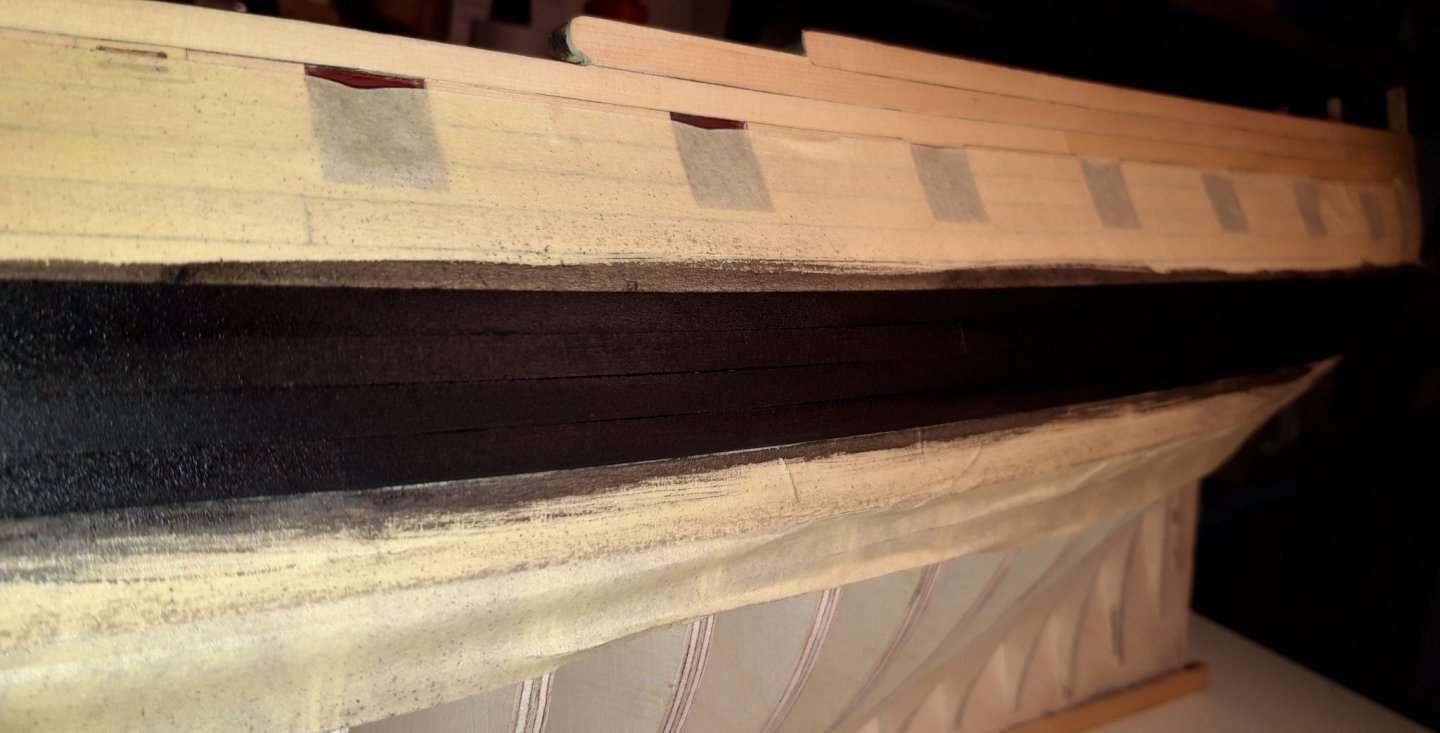

As usual, things didn't quite work as I thought.

I had to do some sanding and following that, some more dying. I would not recommend doing this my way. You have to be extremely careful with the rest of the model. The advantage is, that the planking structure remains very visible. Painting it might cover the seams and joints, so you have one black belt without any visible planks.

In the end it is a matter of taste.

The best thing to do is propably using the black hornbeam, wich JpR62 mentioned above.

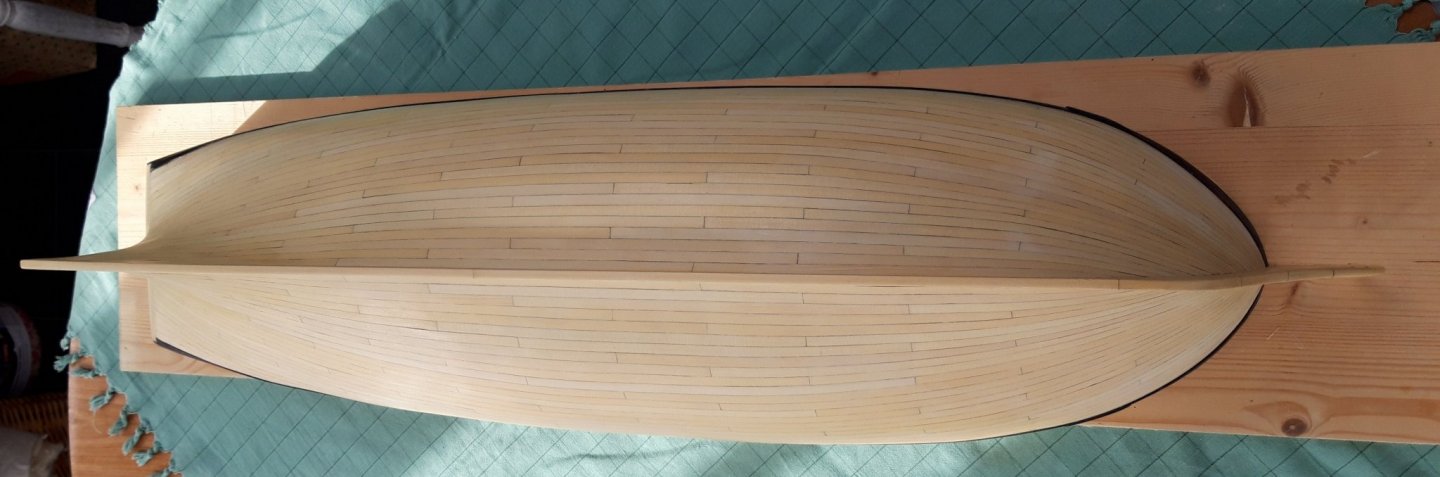

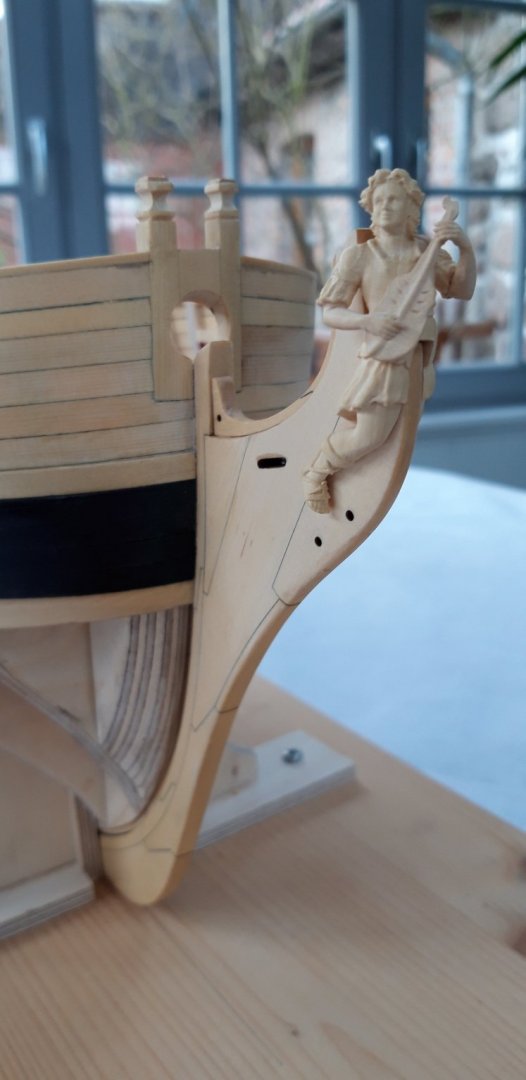

This is the finished starboard side of the model.

Matthias

- Saburo, goetzi73, Edwardkenway and 11 others

-

14

14

-

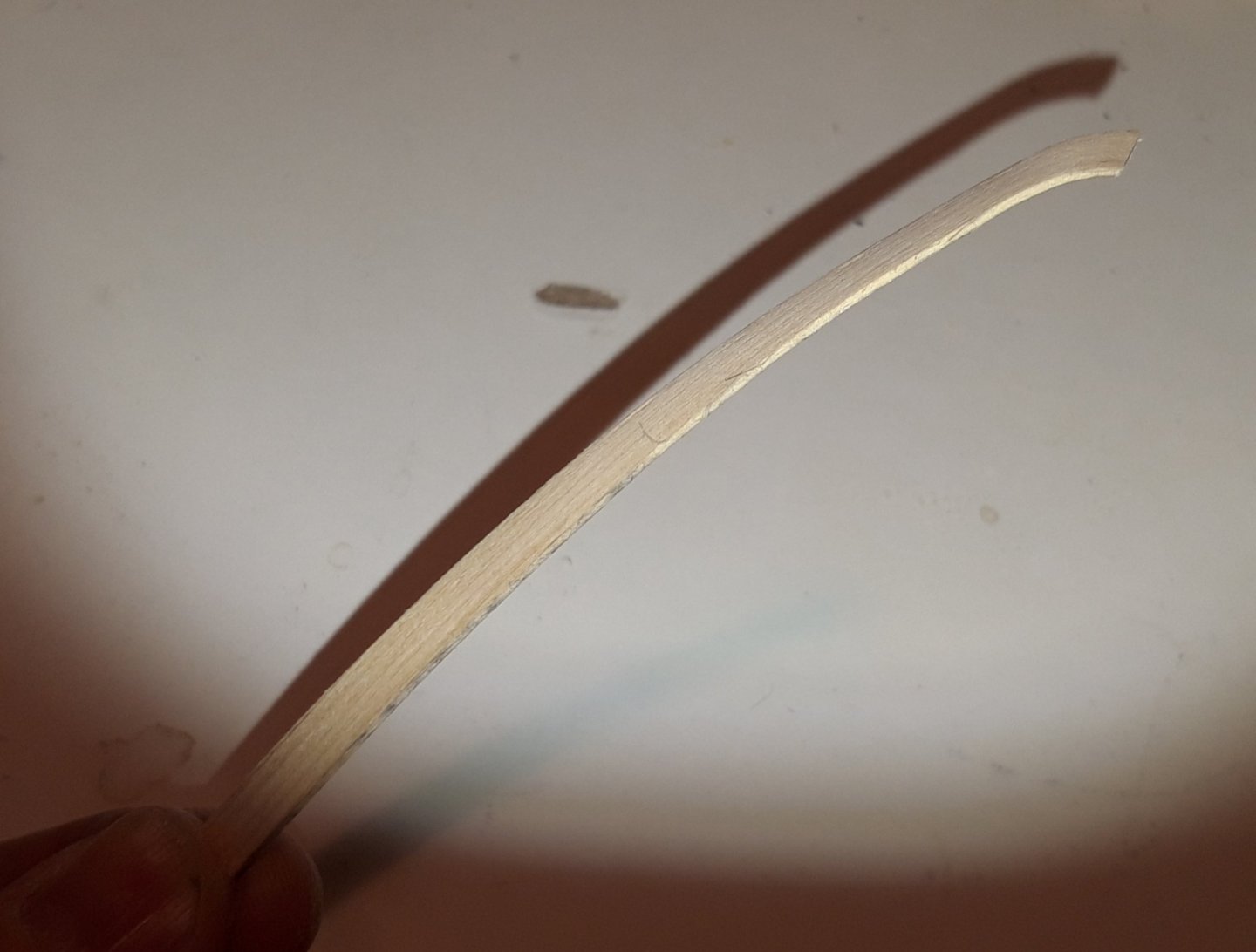

That is, what I did.

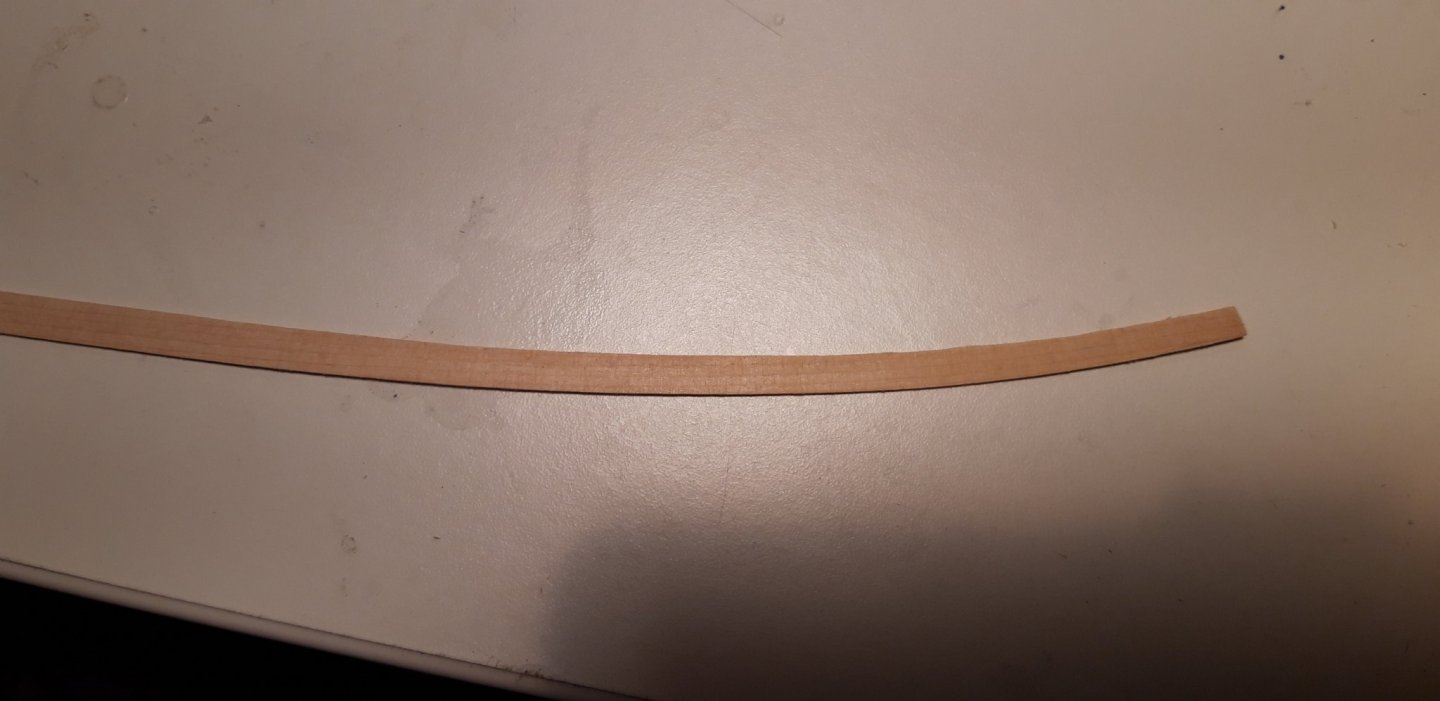

The cedar is so absorbent, that the stain went almost through the entire strip. And You can still enjoy the flexibility of this wood.

- FrankWouts and JpR62

-

2

2

-

- paulsutcliffe, egkb and FrankWouts

-

3

3

-

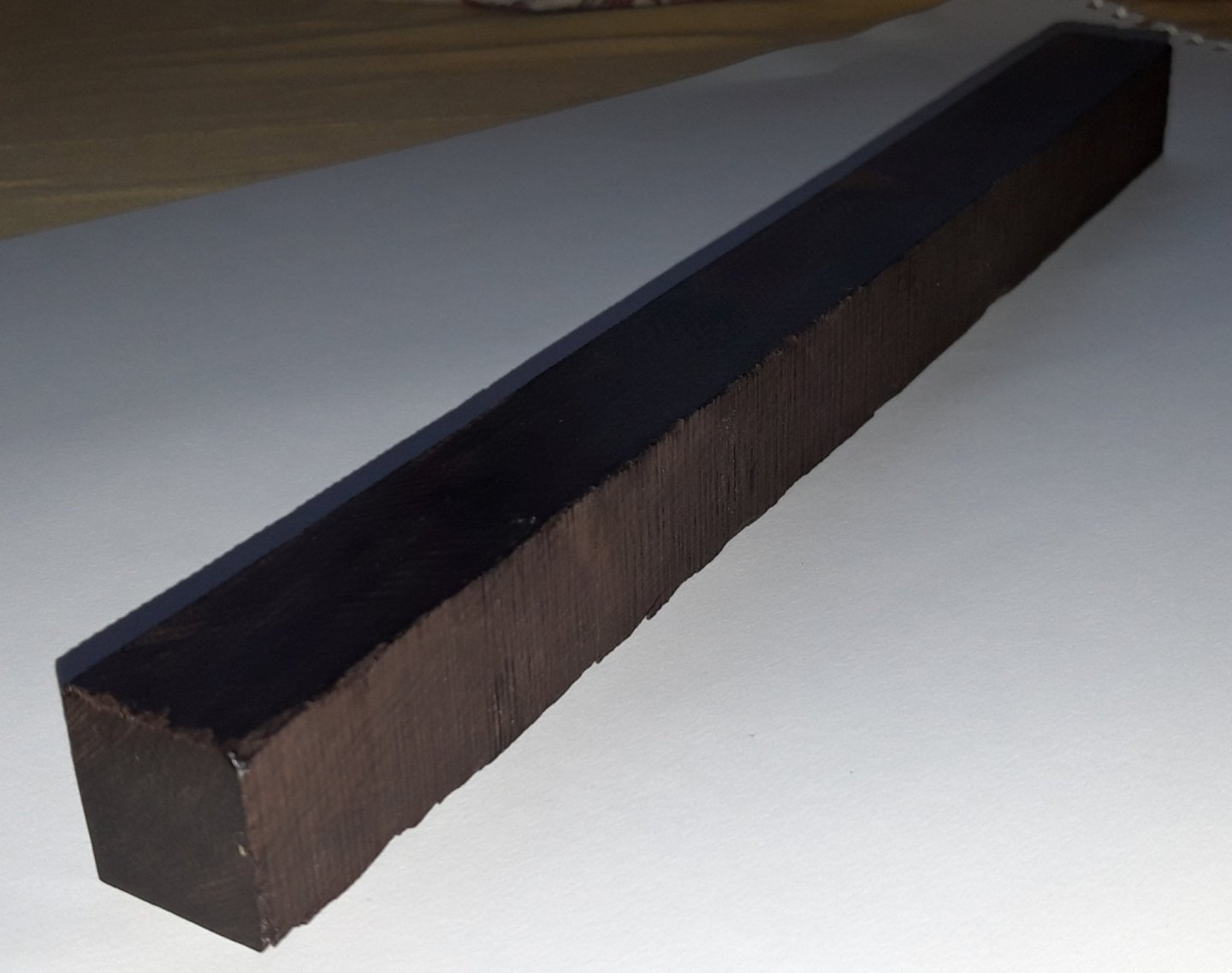

The next thing to do are the black whales. I dyed the strips in advance, so I don't have to paint them. We will see, if that was a good idea or not. The disadvantage is, that you have to glue them very careful into position, because you can not sand the surface later. And no glue on top of the surface. And if you moisten the strips fot bending, you will dissolve the mordant.

But I prefer the look.

- JpR62, rafine, GrandpaPhil and 10 others

-

13

13

-

- Edwardkenway, Saburo, Jack H and 13 others

-

16

16

HMS Winchelsea by Beckmann 1/48

in Member Build logs for the HMS Winchelsea

Posted · Edited by Beckmann

Thanks everybody for the likes and comments. As always I know, it could have been better, but you are right, I am happy, it is done, and I am looking forward to the next chapter wich will be a spectacular one.

Matthias