-

Posts

6,716 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

Tom, welcome to MSW. Glad to have you aboard.

-

Thank you Keith. Here in Michigan during the winter we can count on two hands the number of sunny days we'll get. Winter Blues here is a very real thing.

-

Mark, welcome to MSW. Glad to have you aboard.

-

Phil, you are a machine! I can not believe how quickly you hung the sails and finished the rigging. Congratulations on completing this marvelous ship.

-

Thank you Glen, you're too kind. Dave, thank you. It feels good to be working again on the Tennessee again, a missing part of my life is missing no more. Thank you Brian for the encouragement, it means so much. Dear Tom, i wish this nonsense was mistake free. Maybe someday I'll reach the achievement level of my big brother. Thank you Gary, you and your kind words are inspiration. A huge thank you to all for your comments and likes. It makes the mind numbing task so much easier to bear.

-

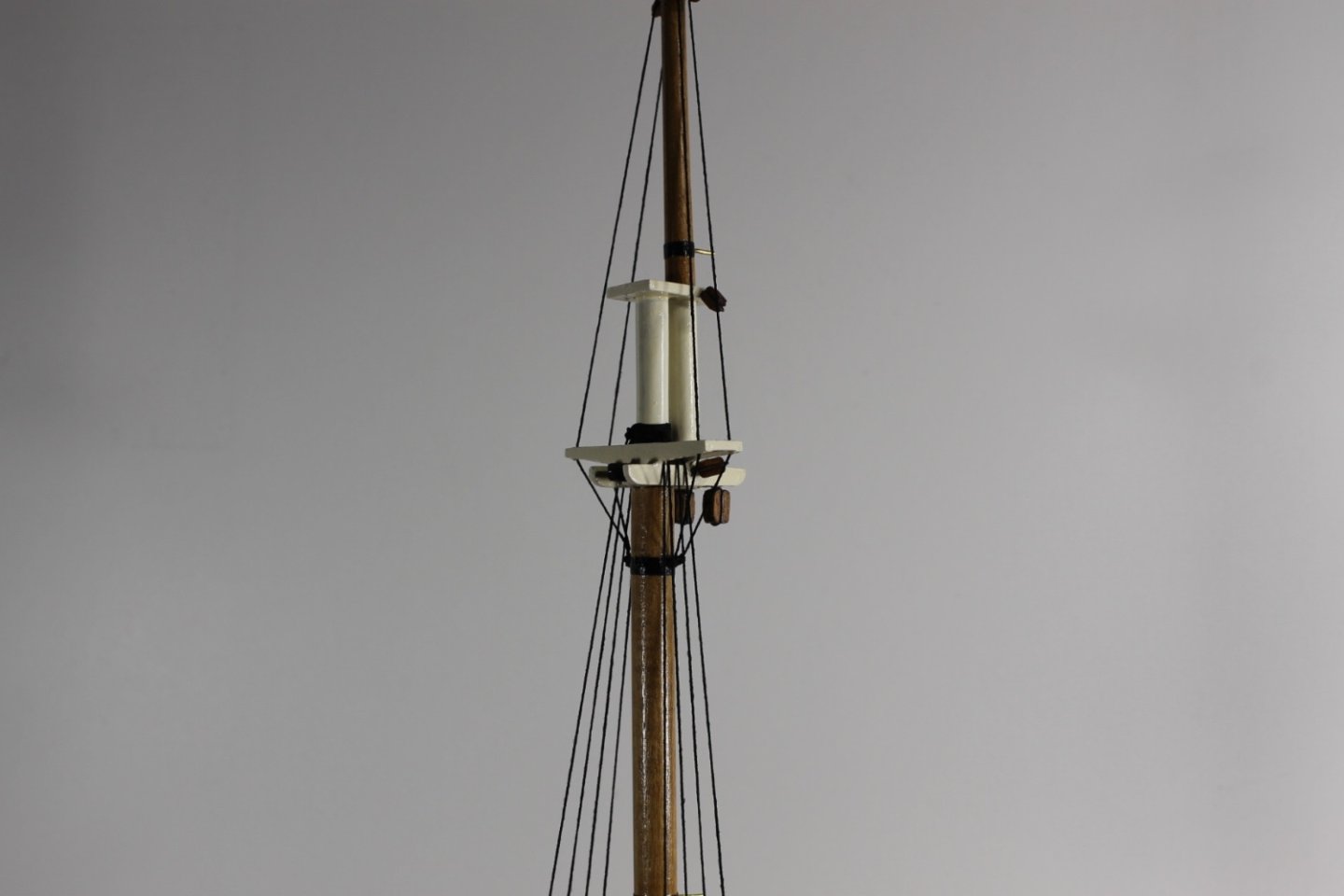

Back in the saddle again. A heart felt "thank you" to all of you for the kind comments, likes, and seasons wishes. It's been a very long time (too long) since I've posted any actual work progress. It's mostly due to the fact that so much of this work is rote and and until recently, during those mindless moments, my mind would drift to things I'd rather not think about but once past Christmas all that seems to have passed. I find myself stealing a couple of hours here and a couple of hours there to go upstairs and work on the Tennessee and I'm enjoying the time I spend working on her. So much so that I've made a New Year's resolution, to finish the Tennessee this year, well, at least the rigging. I've been working on the main mast and all that's needed are the ratlines. Once again I'll be using the weaving method as this works best for me at this scale. A good days work should see that task completed. I'd like to have a sunny day to do the ratlines but sunny days in a Michigan winter are few and far between so it'll probably be a cloudy day but oh well. Again, thank you. Keith

-

Iron Mast Cap Orientations in Steam/Sailing Ships

Keith Black replied to BANYAN's topic in Masting, rigging and sails

Pat, Goober gets it. Victoria's sailing characteristics were set at the dockyard when she was built. The bottle screws were intended to keep the wire rope taunt only but never for rake adjustment. Ships with deadeyes could change mast rake if a captain felt the sailing characteristics of his vessel needed adjustment. Your post #612 in Victoria's build log adds enlightenment to the discussion here. -

I only had one order with Model Dockyard, Nick was an easy bloke to work with. Yeah, I thought the wood effect was spot on.

-

Os, welcome to MSW. Your Grand Banks Dory turned out beautifully done, nice clean tidy work. Glad to have you aboard.

-

Keith, that looks fantastic! That resin ship's boat looks great, Cornwall is such a nice supplier.

-

Iron Mast Cap Orientations in Steam/Sailing Ships

Keith Black replied to BANYAN's topic in Masting, rigging and sails

Pat, I keep coming back to this point and no one is providing me a satisfactory answer. I asked the following question in post #15....."Johny, the Wasa is a perfect example of the issue I'm having trouble with. It appears the rake on the main and mizzen are set at approximately 15 degrees while the fore is set at zero or close to. For the main and mizzen tops and caps to be parallel with the waterline the bow needs to pitch down 15 degrees and that puts the foremast top and cap 15 degrees out from being parallel with the waterline." Plus the rake for each mast could be changed at any time at the captain's discretion regardless of the time period. How were mast constructed so they'd be parallel with the waterline when the set of the rake would possible change at any given time. The photos I have of the Tennessee seem to indicate the mast were raked and the tops are not parallel to the waterline indicating the tops and caps were constructed parallel to one another and 90 degrees to the mast. I'm sorry if this is a case of me being a thick goober. -

Iron Mast Cap Orientations in Steam/Sailing Ships

Keith Black replied to BANYAN's topic in Masting, rigging and sails

Johny, the Wasa is a perfect example of the issue I'm having trouble with. It appears the rake on the main and mizzen are set at approximately 15 degrees while the fore is set at zero or close to. For the main and mizzen tops and caps to be parallel with the waterline the bow needs to pitch down 15 degrees and that puts the foremast top and cap 15 degrees out from being parallel with the waterline. i can't imagine that sailors aloft would have found or been exposed to any more danger working on a top x number of degrees from being parallel with the waterline any more so than working on a pitching top in heavy weather in daylight let alone at night. The guts those men had is beyond my comprehension. I say men, the apprentices were mere lads of 13 to 15 years old. -

Iron Mast Cap Orientations in Steam/Sailing Ships

Keith Black replied to BANYAN's topic in Masting, rigging and sails

Pat, thank you but this has left me confused to say the least. How do you build a ship with the tops and caps parallel to the waterline regardless of the rake? This makes no sense to me. A small degree of rake in the fore and main ( I set the rake on all my mast for the Tennessee at three degrees) wouldn't be noticeable but a heavy rake on the mizzen of seven degrees or more would be noticeable. Setting different rakes for different mast (from what I've read this was a common practice) means not all the mast tops and caps are going to be parallel to the waterline. This makes my ole head wanna explode like a Gallagher watermelon. -

Tom, it looks great, are you pleased with the way Sophie is progressing?

- 346 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Bob, the sails and their shapes look great.

- 179 replies

-

- Second Build

- Pinta

-

(and 2 more)

Tagged with:

-

Gary, I thought it was you that told a story in your Last Dollar build about building a railcar and weathering it? You took it to a show and an old guy dressed you down about the weathering and told you maybe some someday you'd learn how to properly build a model. Something like that or close to it. From the story I thought you built railroad stuff. If this wasn't/isn't your story I deem myself ready for professional help and five o'clock med cups with tiny umbrellas.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.