-

Posts

378 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dowmer

-

What!! No stun’sls!!!.......😫 But they are so characteristic of the clipper..... Just kidding Rob, it’s going to look great. 😁

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Syren Rope Rocket

Dowmer replied to DelF's topic in Rope Making/Ropewalks's Commercial sources for ropewalk machines

Its also to get the fuzz to lay down on line. Anyway, that’s why I use it. It also gives the line a bit of that tarred look if you use a dark colored wax.- 42 replies

-

- ropewalk

- rope rocket

-

(and 1 more)

Tagged with:

-

Syren Rope Rocket

Dowmer replied to DelF's topic in Rope Making/Ropewalks's Commercial sources for ropewalk machines

Yes, wet the line then stretch it. It will help it set. Even real rope was stretched after making it.- 42 replies

-

- ropewalk

- rope rocket

-

(and 1 more)

Tagged with:

-

Rob, When you have time would you detail how you make the paper sails, materials, techniques etc. I’ve seen many different techniques, but your sails look very nice. 😃

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Dont worry, I broke the stem on mine too. Just glue it back. This is a very fragile model. You will find that the basswood in this kit makes it difficult as well. Fuzzy, soft horrible stuff. Other woods are easier to work (sand, carve etc). But basswood will be good for you to learn the ropes.....so to speak.

-

Daforunia, I dont believe the sheer is tapered or the wale plank directly below it. The rest will have to be tapered or spiled to fit the required space. Whenever possible, reference the plans. Chuck is building a larger 1:24 version with a lot more detail. If you have a chance read through it and see a detailed version of what you are building. Lots of great tips to pick up. The 1:48 version you are building can be difficult for a beginner due to the small size and advanced planking required. Just go slow and take your time. Welcome to shipbuilding. A very rewarding but slow and tedious process.

-

Beautiful work Ed. I especially appreciate the arrows you have added to draw our attention through the web of lines. By the way, the natural droop of the chain you refer to is called a "Catenary" curve. Cheers,

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

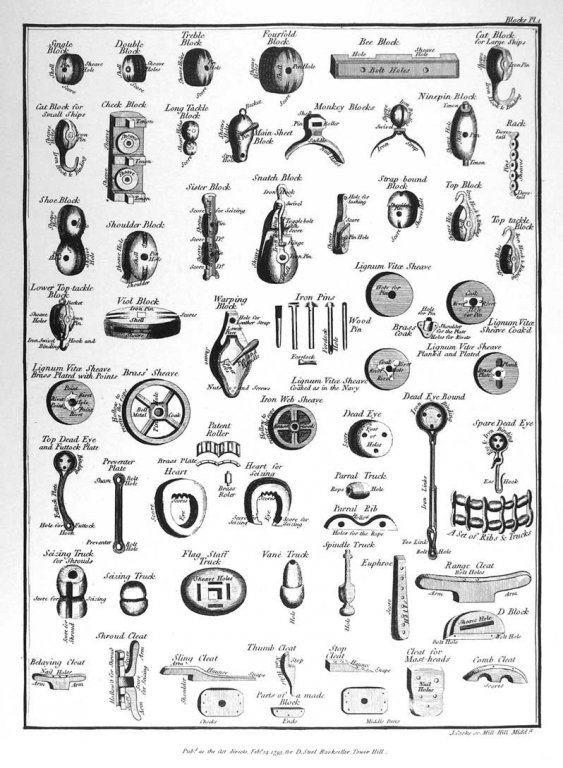

According to Steel, he shows sheaves on each side, so athwart as well as fore and aft. But Ive seen others with only fore and aft etc. So I guess its up to you. You might check Levers "Young Sea Officers Sheet anchor". He might have another picture of one as well. I dont have my book in front of me right now.

-

Bob, oh the horror !!!!!!!!!! 😁 No worries Bob, sometimes you just have to pick your battles.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

In the first movie of Pirates of the Caribbean the crew was holy stoning the deck. Wouldn't that make it lighter? 🤔

-

Delicate work Ed, nice job. What are you going to do about the holes left in the boom from the previous position? I saw a few pictures of a topping lift on an actual working sailing ship "Niagara" like yours set up. I thought you might enjoy the pics. Below was on their facebook page last week. They are currently removing the spanker boom. Here we can see how the crew uses the main yard like a crane to lift the spanker boom before they swing it over the side of the ship. Hope you enjoyed it. Your setup looks pretty close to the placement on the boom with the exception of you have the extra tackles on the pendants.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Oh my goodness Ed, look what I started 😁 I must admit, its facinating stuff and the input from everyone is excellent at the risk of straying from Ed's masterful build. By the way, for what its worth...less than .02 pence if that...........I'd go for the dark brown color for all the reasons stated, but I think Ed was edging that direction anyway.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Thanks Ed for the feedback. Good to know

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Ed, beautilful work. Its progressing nicely. For the deadeye lanyard rigging you have in the channels, is that rigging supposed to be tarred as well like the shrouds? I thought I read that somewhere, that working ships tarred them. That would make the lanyards dark brown or black instead of light natural. Of course this could be a preference too I suppose. I see a lot of ship models like this. Just curious as I see it different ways. Beautiful workmanship 🙂

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I personally like the red one above. But that's just my preference.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Mike, Why not try some Alaskan yellow Cedar?

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

OC, Im in too. So tell me. How do you know the dimensions of the Black Pearl? Its ficticious but are there some kind of plans etc? What are you using for reference?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.