-

Posts

5,935 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks John, appreciate your kind comment. cheers Pat- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi all, again many thanks for looking in and the encouragement. Thanks for your valuable feedback and looking in again Eberhard - I think you are right; that seems the only practical way they may have done it. I'll continue looking for a reference. Thanks Carl, Denis and John, your comments are most appreciated - I have much to learn and improve on yet, especially better control of the files Hi Ed, your many tips and encouragement have been a great help. Yep, those 'races' are milled from a brass plug (inner) and plug receiver (outer). The real life ones were just a thin track on a wood base i believe, but at this scale a little difficult for my abilities just yet. I have been playing around with ideas of how to make the small square bases for the pins (2 x 2 mm) but cannot achieve a consistent product - I think that at this scale I will not use them but will add them to the 1:48 version I do later.- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Looks good Patrick and will look great over a properly prepared hul - you're doing well to resist the temptation mate. Mr. Bond? ... it is more like one of the very modern, luxuriously outfitted yachts one of his arch-nemesis with too much money would have - 007's would be smaller and fitted with more gizmos. cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi again folks, another small update. I have started work on the anchors - Trotman Pattern. The contract for Victoria specified 3 of these, two as Bowers and one as the stream, with the latter a little smaller/lighter. These anchors were assessed by a Committee in 1852 and rated as the strongest/best holding anchors (28% better) yet the Admiralty did not deviate from their "Admiralty pattern". These were an enhanced version of the Port/Hornibal pattern The earlier style of this anchor had the rounded/ovalish shank and the straight iron stock; the bent arm iron stock was not introduced until about 1860. The following photos show the construction of the first anchor from cut raw materials through to completed item. The shank was shaped from a single piece of thick brass then the holes drilled and the slot cut. The flukes were silver soldered to the shank then cleaned up. the stock was made in two parts to enable the ball ends to be turned as they would not fit through the 1mm hole; I don't know how they did this in real life as the is a conical stopper on one side of the stock and a pin on the other - if you look real close you can see I managed to add that detail. The hex head bolt and nut, and the shackle, were some purchased stock from another project, but fit perfectly for this job The anchor was blackened with Birchwood Casey Brass Black (diluted to 25%) The photos are in extreme close up as these are only 21mm long overall and as such show all the early scuffing from my filing before cleanup. The next two should look a little better as my technique improves. cheers Pat- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Looks very good Dave; you've done a grand job on the rigging - the blocks especially look good. cheers Pat

-

ancre Chebece 1750 by Jeronimo - FINISHED

BANYAN replied to Jeronimo's topic in - Build logs for subjects built 1501 - 1750

Stunning carvings and they really enhance your work Karl. cheers Pat -

Needed a knife so I made one

BANYAN replied to Antonio Vasquez's topic in Modeling tools and Workshop Equipment

Hi Antonio, that looks like a good design for modelling purposes. I have putting making a couple off for some time but this may motivate me Did you anneal the metal at all? cheers Pat -

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for looking in and your kind remarks OC. cheers Pat- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

A great tutorial on scale mast making Ed; appreciated. cheers Pat

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

ancre Chebece 1750 by Jeronimo - FINISHED

BANYAN replied to Jeronimo's topic in - Build logs for subjects built 1501 - 1750

Really nice work Karl, I especially like, and am impressed, that you were able to maintain a symmetrical and evenly spaced opening despite the tapering shape. cheers Pat -

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi John, thanks for the kind comments; I hope I can live up to those lofty ideals Eberhard, many thanks again. You have hit the nail on the head. Speaking with my 3D man he said exactly the same, the trick is to print vertically which is the intention. That said, we may also machine a version and do a comparison - appreciate the feedback. cheers Pat- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Great result O.C.; sometimes you have no option but to hold your breath and press on. cheers Pat

- 455 replies

-

- slightly modified

- greyhound

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Appreciate your feedback and recommendations Eberhard, and believe me we have given this some prior thought. The idea of printing the carriage bits is a good one and will probably go that way - should have thought of that myself As to the barrel, we wish to have some of the finer detail captured (cypher, gunlock and sight if possible). Turning will not allow that as easily. We have investigated various printing mediums etc and believe we can get a very good result from Ultra High Frosted Detail resin as can be seen here https://www.shapeways.com/shops/model_monkey?section=1%2F72+Ship+Weapons&s=0 I have had a ship printed (in parts) at 1:350 (HMAS Vampire) in this stuff and the detail is very good; even the gun barrels at that scale. We will not be using the same "home 3D" printer and medium we tried with the funnel but rather taking it to a local professional printer who can do this UFD printing a very reasonable price. I agree the stepping issues are a serious problem with regular 3D printing but this process seems to have nailed that problem if you look at what ModelMonkey is achieving (see his barrels on the above linked page)? Still open to discuss this if you think we are barking up the wrong tree and your valuable experience based suggestions/discussion are most welcomed. cheers Pat- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

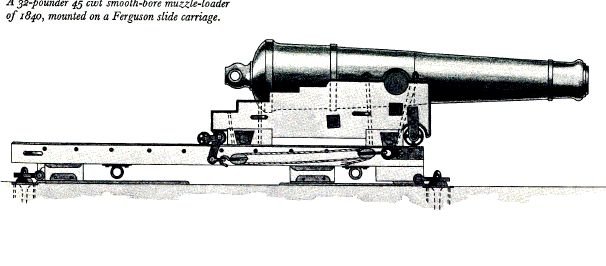

Hi Eberhard, thanks for looking in again. Nope these were machined from a large (and a small) brass ring (plug surround and a brass plug for the smaller). The outer is 26.5mm to the middle of the race, 2 mm high and 2.5mm wide; the inner is about 10.5mm to the middle. The guns will be a real challenge at this scale, especially to show those tiny wheels for excentrics etc. We have already decided to 3D pint in the barrel in UHD as it is a one-off gun. Not worth the while casting it as a coat of paint and it will look the same. The carriage I hope to make up in wood with most of the relevant detail attached. From my research I am fairly confident it is a 'Ferguson' carriage as per the earlier graphic; however the gun is a Blomefield 32pdr 56cwt rather than a Dundas modified Blomefield design (32pdr 42 cwt).- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

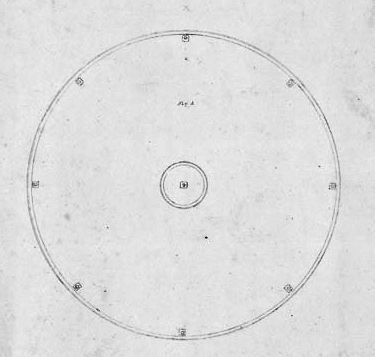

Hi again folks; another small update. i am starting to add some gun details now and have completed milling and lather work for the pivot gun wheel races and the locking pins - the races are simply placed (not glued) to give an idea where they will fit so they are not centred to each other at the moment. The pins were frustrating to make as you can see they are very small - the bottom part is rough as that will be used t glue it into the deck. These pins are used to lock the lower carriage into one of the cardinal or intercardinal points. The idea was the gun pivoted on the rear fold down hinged clamp only with the forward one used to lock it on the bearing. The following photos show progress so far, and the graphic of the gun shows the pin arrangements. cheers Pat- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Nice build concept and great subject matter guys; I'll pull up a chair and watch with interest. Some great history in those V&W Class destroyers. cheers Pat

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

Some good progress OC; coming along very nicely. cheers Pat

- 455 replies

-

- slightly modified

- greyhound

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.