-

Posts

5,962 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Some good progress OC; coming along very nicely. cheers Pat

- 455 replies

-

- slightly modified

- greyhound

-

(and 1 more)

Tagged with:

-

OK that's done it - I need a better (BIGGER) dictionary to find further superlatives - I have run out of ways to compliment your work ED That is craftsmanship at its highest standard. cheers Pat

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

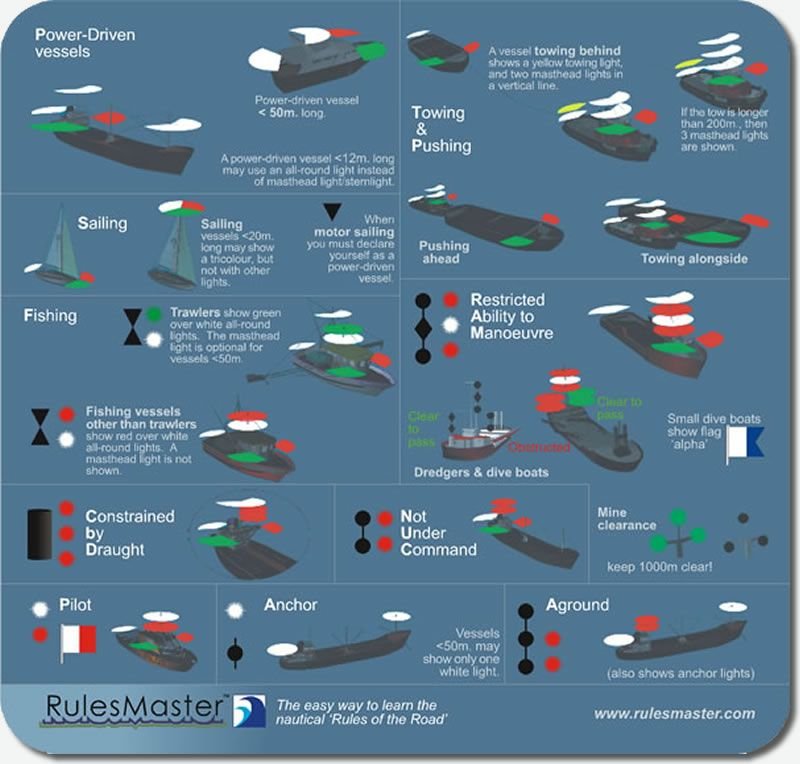

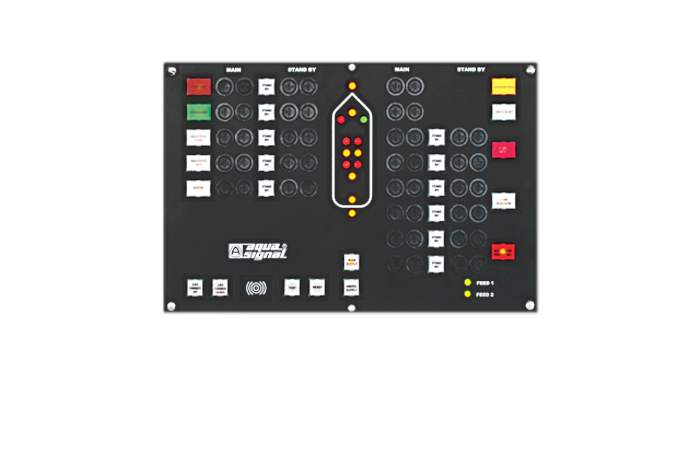

Great looking model Dan; the details are superb. If you look up "the task lighting" section of the "rules of the road" for maritime navigation you will find the appropriate task light colours. The main task lights will need to have catered for - not under command, restricted in ability to maneuver, and perhaps under tow, which mandate combinations of white, yellow and red lights in specific sequences, arcs of visibility and spacing. That may help determine the lighting colours and placement and add some interest? The attached pics provide a summary of some of the task and nav light Rules, and an example light control panel, that while a modern version covers the same types of light requirements for older vessels under the 'rules'. the insignia/logos on the images show from which companies/organisations the graphics originate. I hope this helps you add some life to the lights cheers Pat

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for looking in and kind comments Dave and John - welcome back to the fray to both of you Some further small updates coming very soon. cheers Pat- 1,019 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Looking good Mark; nice to have a laser cutter for accurately fitting parts. cheers Pat

-

Great progress and looking great Patrick. Is it just the angle of the camera or does the flare of the hull (stbd side) at about the two-thirds back mark seem a little wider than for the port side? cheers Pat

-

Looks great Dave; welcome back I hope you had stern words with those slackers in the dockyard cheers Pat

-

Hi Rod, see my response to your PM for some answers, however, a couple of clarifying points for you to ponder. A ship is steered by a helmsman using a compass and is 'conned' on to the course to be steered by the deck officer (Officer of the Watch in RN terms) or the Captain (whomever has the control of the ship). I think it was this way even back then also. The helmsman does not need to see ahead but does need to see the sails (to keep them filled) and have a clear view of the compass - seeing ahead is a bonus So a large binnacle would be okay. The style, design or size of the one used in Endeavour will probably never be known. I went with the larger one (Marquardt) as this being a ship of exploration and, when being refitted, potentially for survey as well, I believe the availability of two compasses a necessity. That does not mean your interpretation is incorrect and may well have been one a possible fit. I only raise my point for consideration. cheers Pat

- 108 replies

-

- endeavour

- caldercraft

-

(and 1 more)

Tagged with:

-

You always achieve such clean crisp joints Chuck; very impressive. Love the wood tones! cheers Pat

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Another warm welcome from downunder Greg; interesting genealogy and one you can be justifiably proud of. cheers Pat

-

Nice work with the case Mike; especially in your recovery of the break. cheers Pat

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Hi Rod, you are making good progress with your build of Endeavour; I'll pull up a seat and follow-along also. As you noted the anchor linings are not well covered in most kits. For mine I dry fitted the anchor to the cathead then traced the arcs the anchor flukes followed as they were catted or lowered in preparation for dropping. that gave me the 'real' arc the lining had to follow. The deck fittings were the most enjoyable for me and you have several good options in the various plans, books and replicas to follow as to how they looked. cheers Pat

- 108 replies

-

- endeavour

- caldercraft

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Many thanks Druxey and Denis; appreciate you both looking in and for the kind words. cheers Pat- 1,019 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Wonderful looking model John; I really like the detailed carvings and extra bits and pieces which make it look very authentic. Better keep your 'helper" away from it cheers Pat

-

Coming along very nicely Dave. cheers Pat

- 742 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for the very kind words and encouragement Russ, Ed, Jason, Carl and Eberhard. Compliments from you guys, noting the exquisite work you do, is very much appreciated. regards Pat- 1,019 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

I have also started on the boiler space skylight and funnel platform. The photo shows progress to date with one hatch and one grating placed, and the funnel dry fitted in-situ. I have also attached two photos showing some of the detail for making the gratings (one on each corner) which are open to the weather to ensure adequate air for the boilers to draw. When shut down, a tarp was drawn over the top. The other photo shows the corner of the skylight taken from one of very few photos of the ship which confirms the grate is open; the metal batten pins can just be made out - I will add these later. To make the grate, I first cut 4 lengths (sized to fit the opening) with my chop saw, I then stack these with a bit of double sided tape between layers then drill the holes with mill using a sensitive drill attachment. I then stain and varnish the wood, thread the blackened brass rod (0.5mm) and use a touch of CA to hold the rod ends in place - the whole assembly is press fitted into the opening. cheers Pat- 1,019 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.