-

Posts

4,669 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by augie

-

US Brig Syren by Gahm - Model Shipways

augie replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Stern looks GREAT! -

I've got to love your strategy.....having fun whilst keeping we ALL know who at bay. I love the sheaves. And looks like we can now both enjoy turning our blocks to dust. On that rope-twirler thingy, do not wear a tie or long sleeves while operating

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

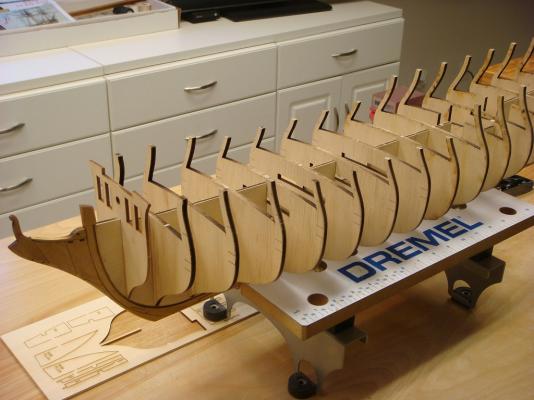

A little progress to report (need to stay ahead of the buffalo herd ). The 16 bulkheads were removed from the laser cut sheets: Note the cutouts on the starboard side of the two near the top center. This will be an opening in the finished hull where the 'framing' will be exposed. The laser cutting on these pieces was quite intense. I lightly sanded them all around but have left some laser char as I find this helps me later during the fairing process. However, the slots on these bulkheads and also the bulkhead former were completely cleaned in order to obtain a secure glue bond. The slots were also just a tad 'tight'. Here, the bulkheads have been dry fit into the former: The last photo shows that the alignment is pretty good for a dry fit: Now we will square and level everything as we permanently glue in the bulkheads. But the fish are calling so we'll be back in a day or so. In the meanwhile ---- STAY THE COURSE

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

I have beige shrouds/rats on my HMS Victory cross section from 1988. They still look great. Not only that, she's never been in a case and the rigging doesn't show the dust!!!! Stay healthy now.

-

That's the spirit!!!!! Stay away from the sawdust and CA for a bit and you'll be at full strength in no time. Now good luck with the tiny bits.

- 384 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

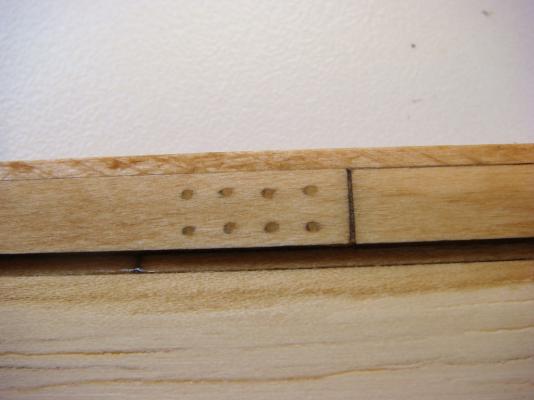

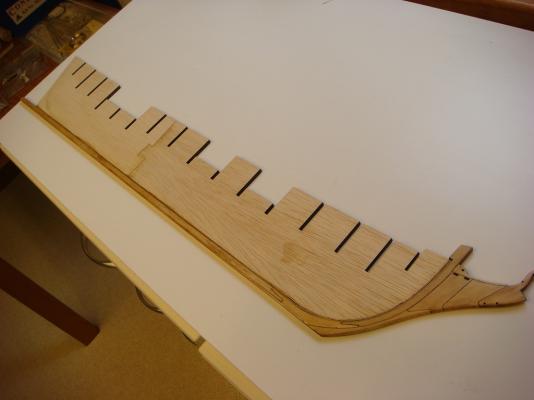

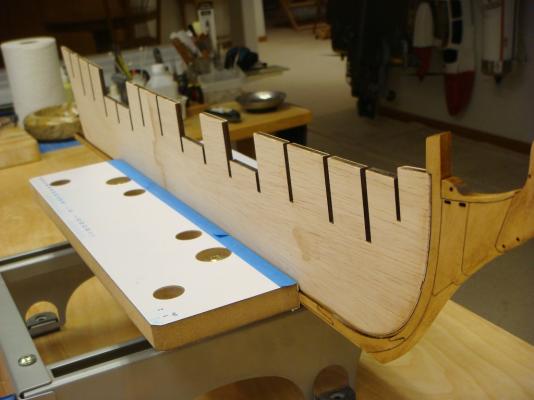

Yes John ---- I noticed. Only thing I can do is work faster (which is the opposite of what I had planned).......and try to outrun the fauna and flora . With that in mind, here's the latest update: CHAPTER ONE is completed. I promised Sjors a picture of the rabbet so here we see it completed now near the stem: I can't label the photo but I think it's easy to see how the laser drawn line on the bulkhead former (the lighter wood) has been slightly tapered down to meet the 1/8 x 1/16 rabbet strip and then the stem sits on that. The result is we have a nice clean, uniform slot which is the rabbet. This extends from stem to stern and shall be where the edge of the garboard plank (as well as the ends of the remaining planks) sit. EASY -- and no carving involved. In addition to the stem and keel now being fitted, here's a detail I like: The keel uses 2 vertical scarph joints along it's length. On the 1:1 ship, these were bolted together. Here, we've simulated those bolts with #70 drilled holes filled with tinted wood putty. This technique is similar to what I will be using for treenailing. Here's a photo of where we currently stand. Note that the false keel has been fitted and that the stem and keels have been stained. Using Minwax products, I first pre-stain then stain using a mixture of 50% 'Natural' and 50% Light Oak. This process will be used numerous times throughout the build. I generally apply several coats of WOP later on. Finally, things wouldn't be complete without introducing my infamous 'one size fits all' keel clamp ---- AKA the Dremel mini work stand. It holds her firmly and straightly in place as we proceed. I know SJORS also uses one but I got mine back when they were $ 9 (US) and I still had hair. Today is our 40th Anniversary so no more building is on the docket. But the next step will be fitting the 16 bulkheads and to say I'm looking forward to that is an understatement. All stay well

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Never minds the ships. You're killing me with the lobster. We can't get them up here in the Rockies as their legs are too short to make the climb

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

I'm just plain confused (as usual). Cleaning paint brushes and the Panama Canal. Well, as long as Sjors is happy, I'm happy!

- 116 replies

-

- finished

- Lackawanna

-

(and 1 more)

Tagged with:

-

YIKES! You've caught me with my proverbial pants down on this one, Mobbsie. I defer to Chuck (as Designer in Chief) to comment. He does the thinkin' -- I just do the buildin'.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Another birthday! Make today a great one, Kevin!

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

As this is a first planking, do what you can filler/sanding wise to even things out. Just use care with the sanding ---it's pretty easy to go right through the planking at the higher spots if you get too 'enthusiastic'.

-

Oh no! Mesa Verde is on Sjors' 'bucket list'. I've been telling him it's in Idaho. Now you reveal that it's 2 miles from here behind the supermarket!

- 116 replies

-

- finished

- Lackawanna

-

(and 1 more)

Tagged with:

-

Sjors --- this is Chuck's way of creating the rabbet....just like on Syren. There will be another plank below that 1/8 x1/16 that I just glued on. Then, when the bulkhead former is tapered toward the keel, it forms a uniform, neat slot which is the rabbet. The garboard plank sits neatly in that rabbet. It's a lot easier to see then to explain so give me a few days and I'll try and post a close up of it. In the meantime, you keep getting better!

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.