-

Posts

16,007 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by popeye the sailor

-

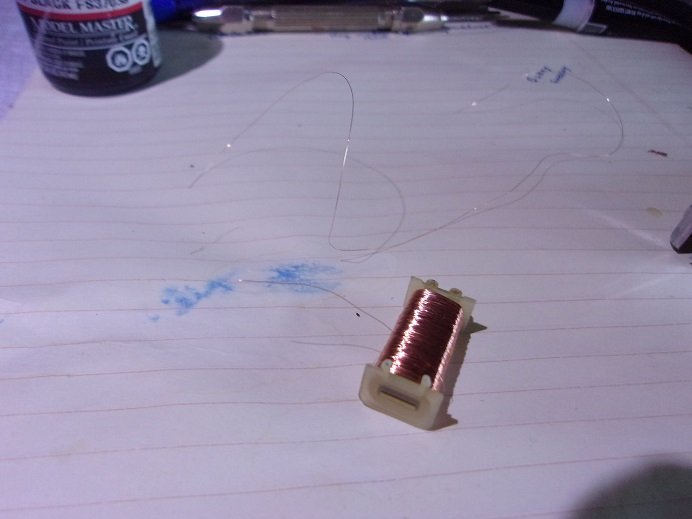

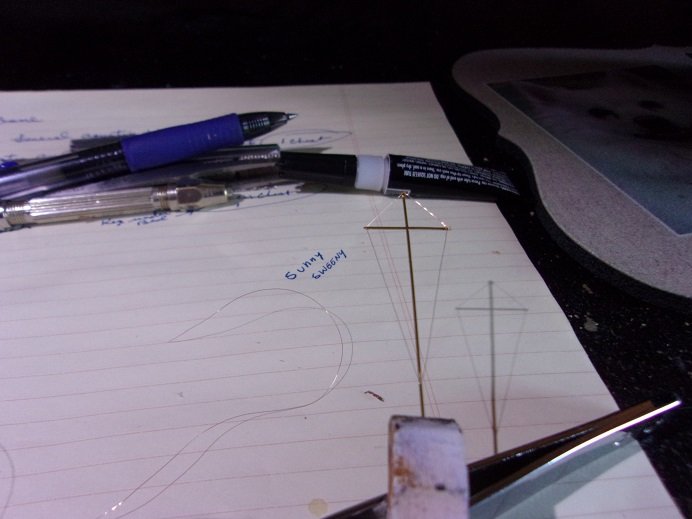

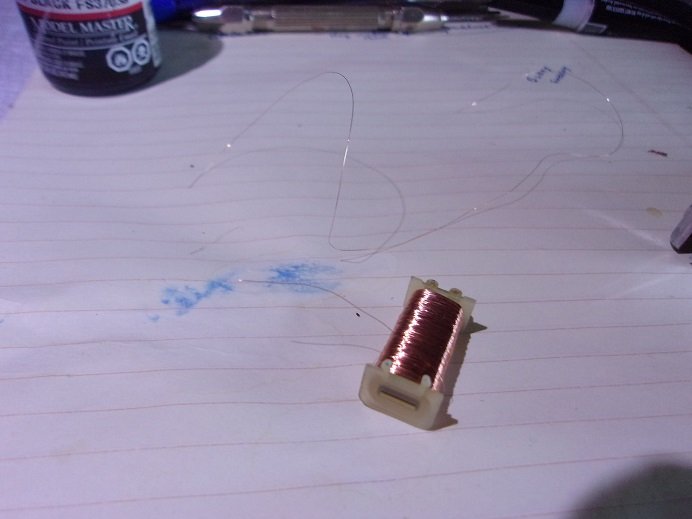

a wee bit further........the antenna was rigged the other day. I got a winding bale of thin wire....thin enough for what I need to do. can't really tell you how thin it is......thickness of dog hair perhaps. but it looks great on the antenna...... I painted it flat black afterwards......I also glued the tiny eye bolts in the dingy.......and that's about what I've done . more soon

-

the Foster's we get must be different........I find it fairly drinkable. I got one of those mini Heineken kegs in the hallway........I had two, but I drank one on Christmas eve. can't drink it at room temp though........that's how I drink my beers.......I put them in in a cool place away from the heaters. the only time I refrigerate, is during the summer. not much for harder stuff now a days.......I have an ample amount of Southern comfort in the cupboard that I bought a few Christmas's ago.........still haven't touched it the Vendetta is on the side table by my desk.......haven't dug back into her yet. almost there

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

she finished off looking superb Mike! so much detail.........hard to imagine that they could have so much. I couldn't see myself going that small......I'd likely make a dog's breakfast out of it .......I tend to go the other way. I have the Shokaku in 1:500, and the Missouri in 1:450, that I got for Christmas....I still have the New Jersey too.....I think that's 1:350. to be honest, I'd love to get started on one, but I have enough going on...the admiral would have me committed! how thin is the EZ line? recently, I rebuilt an old clock that we've had since we got married. I salvaged the windings for the motor....I can't even guess how thin this is....... I'm gonna try this on the Vendetta...there's quite a bit here. you built a great model......I'm in awe .......very steady hands!

- 179 replies

-

- hatsuzakura

- pit road

-

(and 2 more)

Tagged with:

-

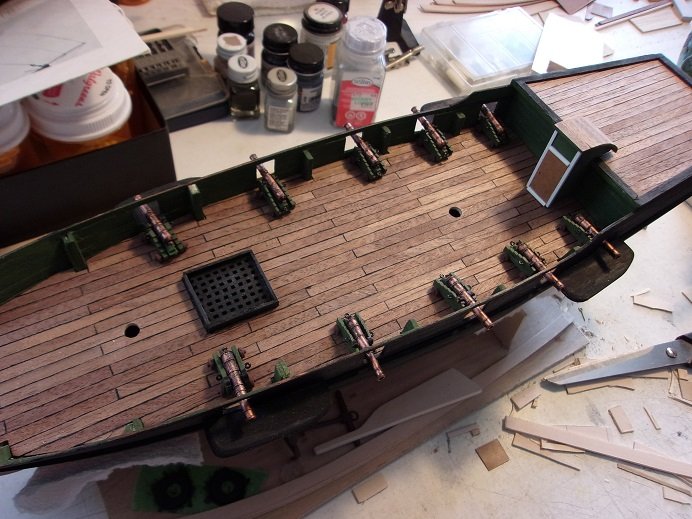

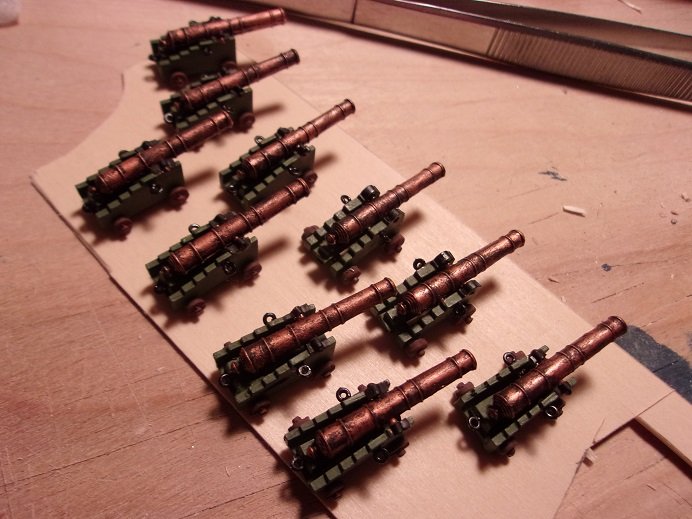

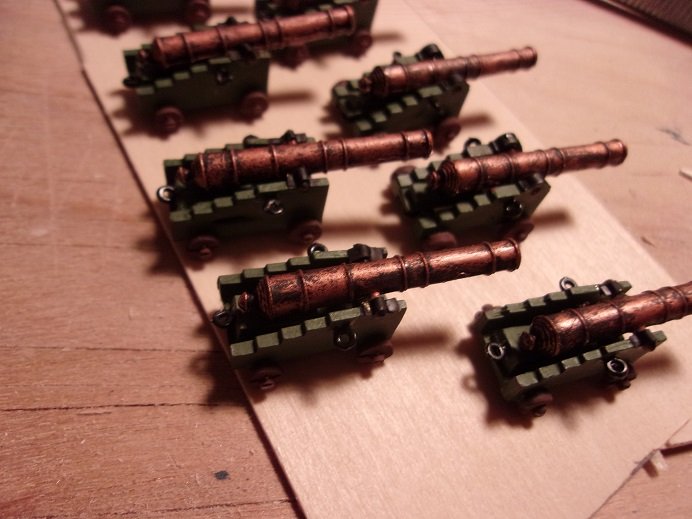

the doctor's appointment turned into breakfast and a trip to the store. then helping the admiral in making lasagna........with sausage {of course}! very good.......I might add not too much done today....I set up the cannons in a dry fit to see how they'd look. since they don't put out any magazines at the doctor's at this time, I brought one of my ship books to glean over while I waited. still no catheads yet...........I'm gonna have to come up with a windlass for this one. I was thinking about a fore deck, but I may kick it to the curb. spent the rest of the day working on the guns for the 'what if'

-

yesterday, I settled in at my desk to flesh out the cannons for the Agillis. two of them are the bow cannons from the United States and the Constitution kits that I have. the rest are from the Constitution kit........I won't need them I made up the caps for the trunions {terminology check} from some sheet brass I have on hand. painted the same color as the inner bulwarks, holes were drilled for the eye bolts and installed. the barrels were painted in flat black, and dry brushed with bronze. when finished, I took them into the spare room, for better light. gotta go........need to take the admiral to her doctor's appointment.

-

toward the end of last week, I got a little bit done........until I realized that I forgot to taper toe top sections of **all** the masts. I settled in doing that for what seemed like the rest of the session.....but then I got sucked into this 'what if...'can I build it' thing {and the rest is history}. what I did get done, was to flesh out the companionway.... ....and then taper the mast tops. they are done and ready for more fittings and yards, which I still need to cut to length.

-

where did you get the ammo belts? they look really good. I checked out the shapeways site...... PT-Boat by Johndrain - Shapeways Shops

-

the guns look great! you really detailed them out nicely the deck layout is getting better and better.......

-

such superb progress on her Kevin.........the sails look awesome, complimented by the fittings and rigging is there to be a bow spirit?

-

the mahogany that is supplied in the kit will cover any boo boo's that show up. now, depending on the quality of your planking, you may be able to side step that process.........sand it down, add filler where needed, and paint. this depends greatly if you plan to do another sponsor, rather than keep her as the Slo-Mo-shun. there are some pretty neat looking race boats out there...as mentioned, I wanted to do one as an M&M boat for the admiral, but she shot me down {drat......}......different configurations too both of these sport somewhat of a mopar air intake......they have a cool look to them. here's one with an exposed engine........ the mahogany look is fairly common though........here's a Ferrari..... this one is a kit........note the direction of the mahogany wood grain. I get a lot of my ideas looking at images, a good place for added detail.

- 55 replies

-

- hydroplane

- Slo-mo-shun IV

-

(and 1 more)

Tagged with:

-

I'm not really sure Kevin.......drills like aluminum, but I'm sure it's a tin alloy. it's likely no different than some of the metal fitting normally found in most kits. all I know is that it doesn't take to solder very well. it does need some general cleaning though......some flash and mold lines. if you like, I can snap a picture of these metal parts, and show you

-

apologies Greg for me being such a sluff are you going to do a larger scale of her?

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

I thought I had downloaded the instructions for her.........realized later that I had printed them. your referring to fig.4........the curvature of the bow does look like the planks need to be tapered, to get the contour of the hull sheer. if your able to create the curvature, as you have started it already, then I don't think I'd worry about it. looks pretty good so far

- 55 replies

-

- hydroplane

- Slo-mo-shun IV

-

(and 1 more)

Tagged with:

-

I can't believe it's been this long already! what a PUTZ I am........ I've been meaning to get back to the Vendetta.......it's carefully stored at the moment. Greg and Carl already have theirs done......I took tomorrow off........I'll see about pull'in her out and assess what I need to do to finish her. I'm a lager kind of guy

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

doing that, the only thing you'll find tedious, will be the pillars. for an easy out, trim the pins off the tops of the pillars. cement them in place so they stand perpendicular and straight. when you add the spar deck, just glue around the edges of the deck....don't worry too much about the pillars {unless you want too}. you won't be doing anything too stressful on deck to matter much it does build into a nice model.

-

I kinda chuckled about the hawse hole........I've built this model already. another person was building it and asked the question about the hawse hole, and I told him the same thing I built mine as the Jolly Rogers, but it can be morphed to be the Le Flore, just like the Capt. Cook kit can be morphed into the Warppen Von Hamberg. there are a few flaws with this kit.....the biggest one is the gun deck not lining up to the gun ports exactly, when the two decks are assembled and fitted into the hull. I think I did a log on her......not the Le Flore, but the assembly is the same. I also have the Flying Dutchman glow in the dark model......not that big of a hoot other than the deck issue though, it is a fun model to build. are those 1:96 scale blocks? I did the same thing you'll like the way it comes out

-

I don't believe I've ever seen that kit by Billings before.....has to be an older kit, likely not laser cut. I've gotten two Nordkap kits in the past......the first one I've built, and the second one I'm building as the Progress, a spin off of the Nordkap and produced around the same time { actually, I think one was a bit older}. older Billings kits did not come with the fittings......they were purchased separately. but chances are, that someone started to build it and gave up........hence the other missing parts. if you have the instructions, I'm sure that there are pictures of the parts panels........you could blow them up and scratch produce your own parts. I do that with the spent parts panels ......I save them {try my damndest not to damage them}. this engine looks very interesting.......can't wait to see what it looks like if you could post a picture of the lugger's box, that would be neat

- 55 replies

-

- hydroplane

- Slo-mo-shun IV

-

(and 1 more)

Tagged with:

-

well......it's accomplished......we had our first dose of the vaccine! I got a little dizzy around supper time, but so far, so good the admiral has been fine. keep at it Jack......you'll get one soon don't know about that CD.......she's still an ugly duckling to me she won't start looking good, till I can finally get some paint on her. with all that's gone on today, all I've really been able to do, is some work on the cannons for the Agilis. thanks for the good word and the likes....more soon good you got it......live long and prosper

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.