-

Posts

1,712 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

I’m fairly certain that model shipways uses the 3m copper tape as well... or some version of it. I’m 100% sold on the tape now after seeing your results with Bellona and having used the pre made tiles in the past. Fantastic work!

-

Thank you Glenn. That was my first go around at Chucks method of planking and dare I say it, but I’m excited to try it again soon. The results are well worth it. Your planking work is very methodical and well planned, it’s setting the bar high.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks awesome Glenn! For a second, after looking at your stellar planking job, I briefly thought about replanking my Winnie. She’s looking really nice, looking forward to seeing more. JJ

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks very nice. I couldn’t notice any error (if you can call it an error) and neither will anyone else. That decking looks great! Well done.

- 475 replies

-

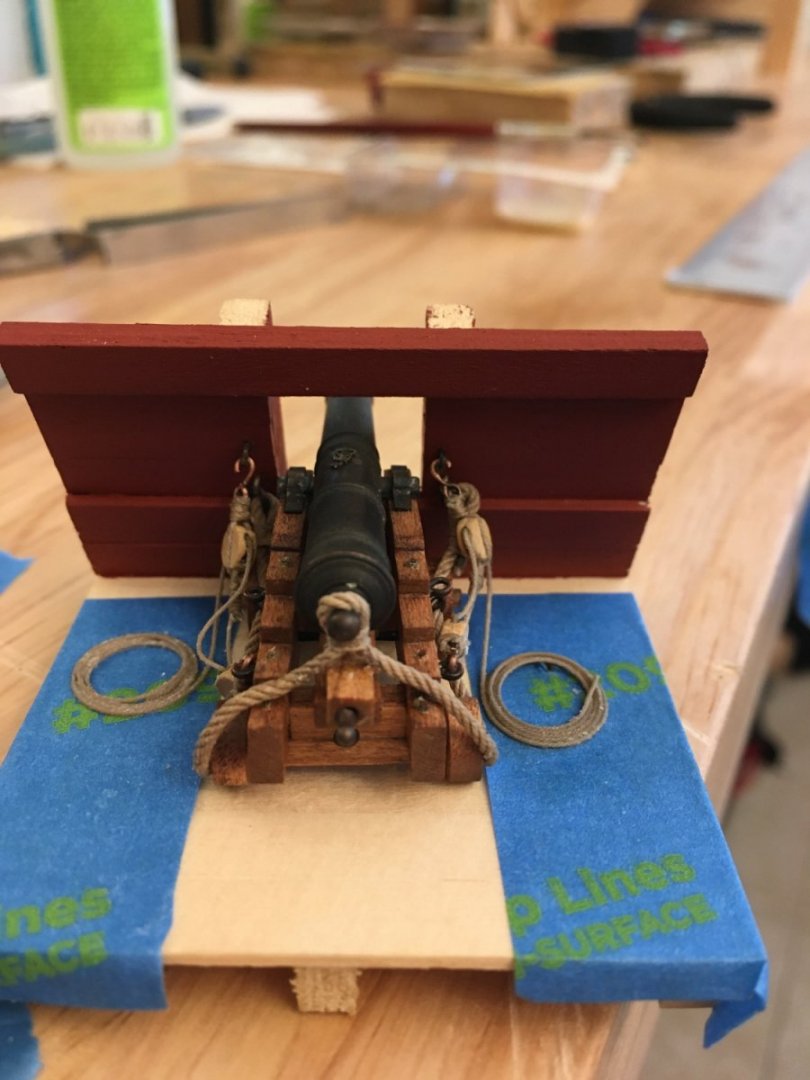

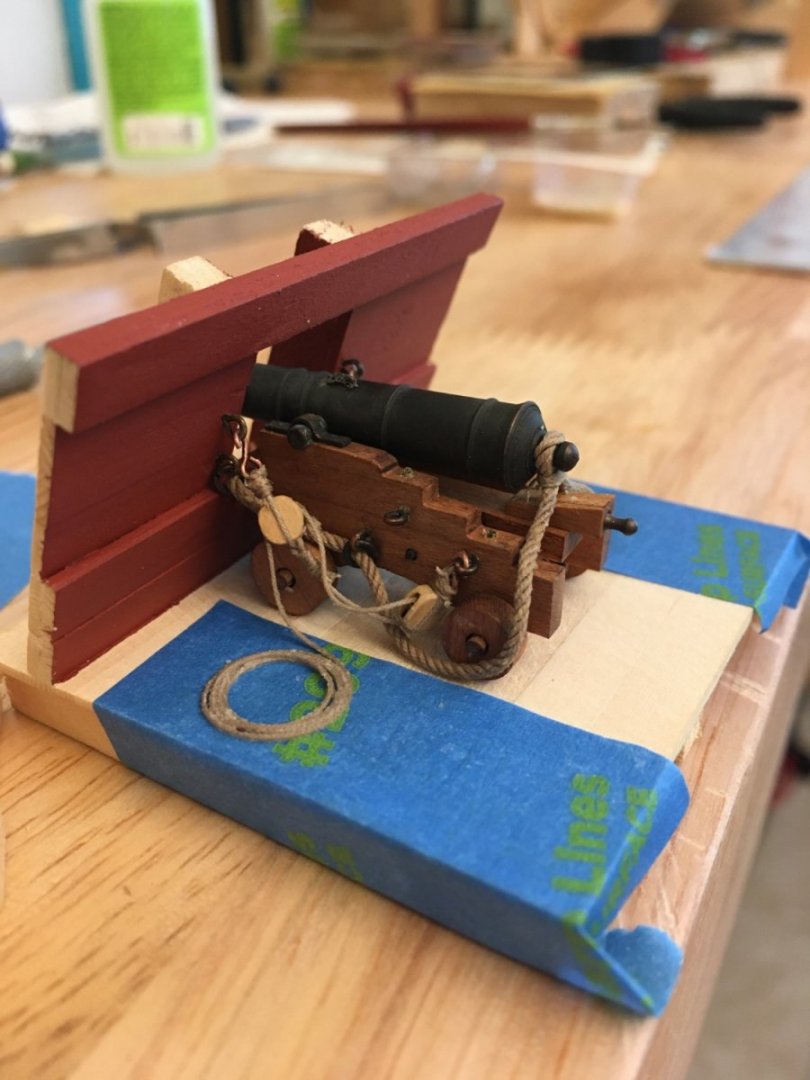

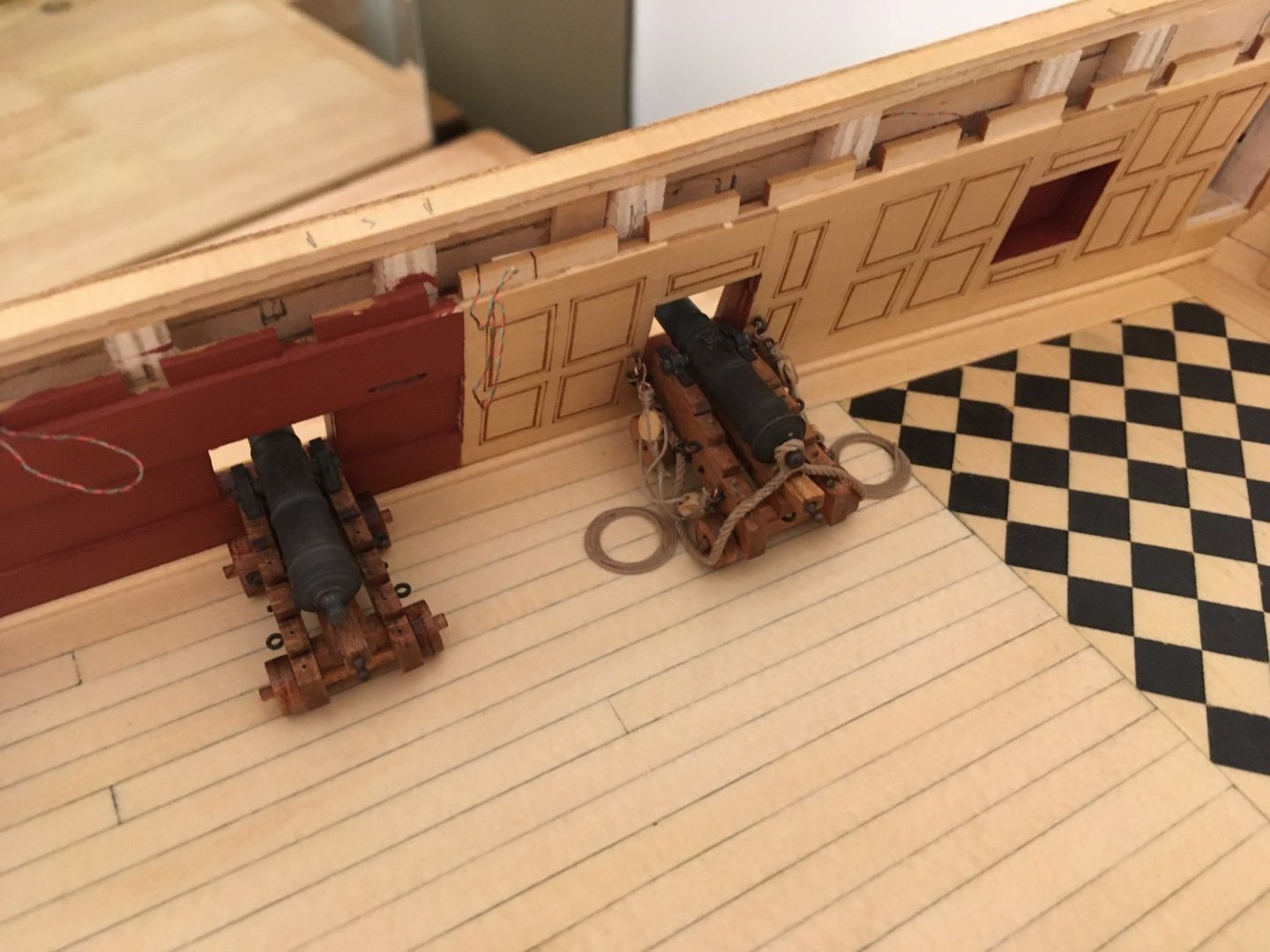

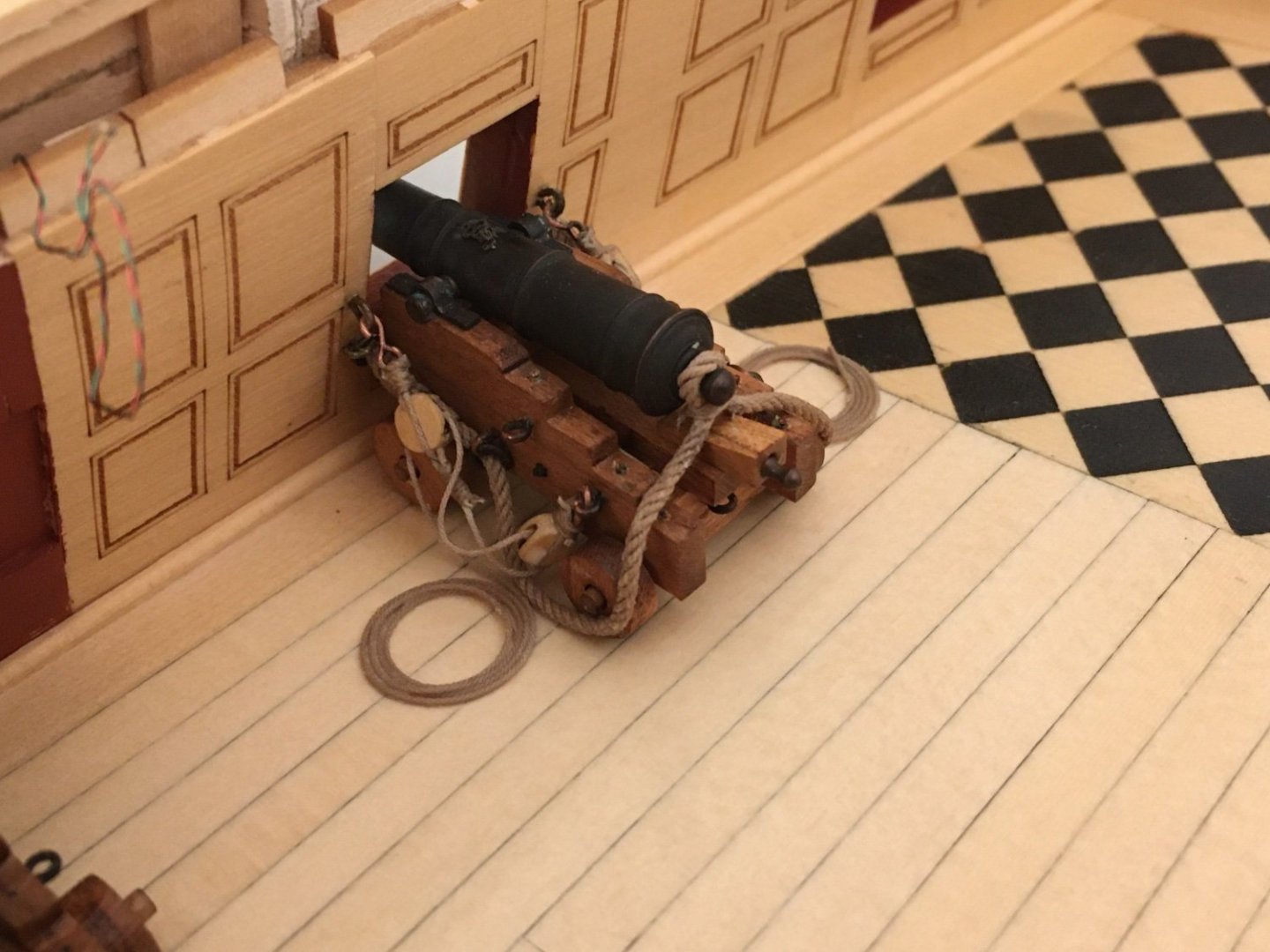

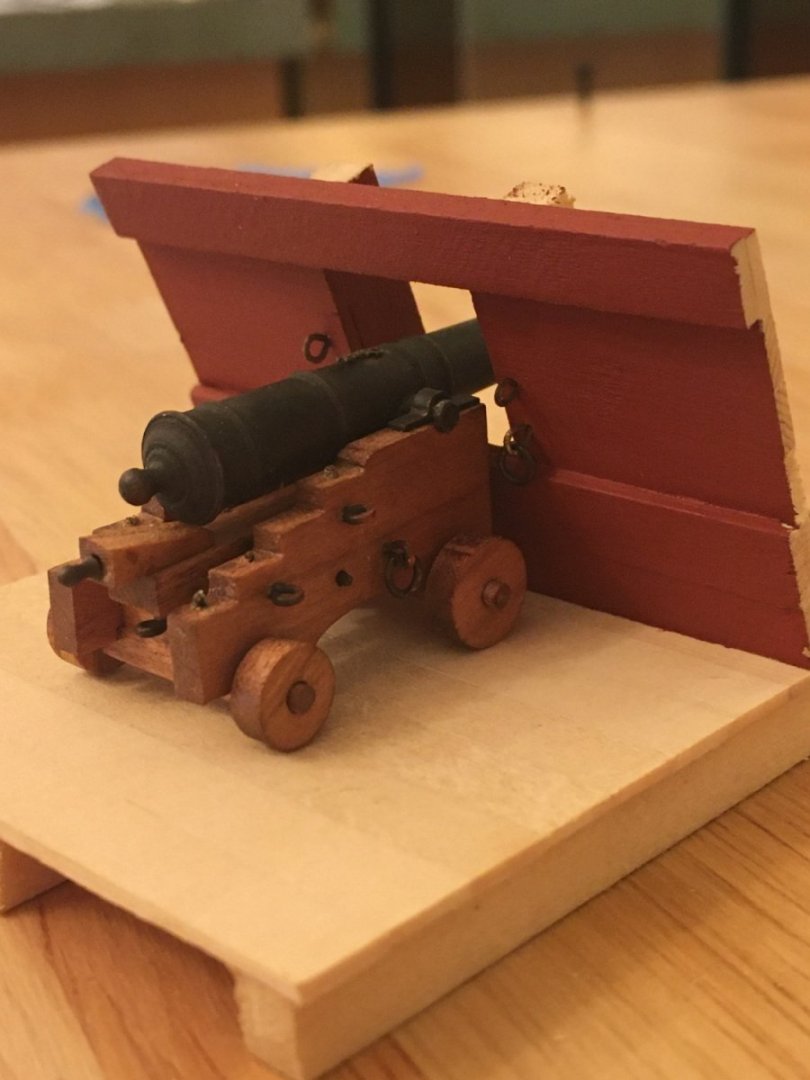

I think Chuck described frapping in an earlier post as a method of securing the lines on museum ships so folks don’t trip over the lines while walking the gun decks. as far as the breech lines being cross looped or seized as I have shown, I’m still unsure, which is fine as I have to wait for a bunch of hooks to show up before I continue with hun work. Fred...where did you come up with your breech configuration? Glenn, you’ll be there before you know it, you’ll succumb to the desire to rig them. Lol!

-

Thanks for the comments and likes guys, I was about to abandon the whole gun rigging process but finally getting one finished the way I wanted it, inspired to me keep going...at the expense of setting back chapter 7 for a very long time. Lol. I’m going to get started on another one soon, hopefully it will get easier. Glenn, I think I understand what you are saying, I’ve seen both examples online. I’ll post a photo of my next one when I start. Would it just be crossed and that’s it? No seizing or smaller line to at all to keep the loop crossed? Would that be standard on a 12pdr? JJ

-

Looks great Ben! Looking forward to seeing your decks complete. JJ

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks great Rusty! What a great shop.. one can only dream.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I really like the balsa idea, I’m going to borrow that from you on my next project. Getting those frames sanded evenly from that angle was a pain!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks awesome! Amazing work, Chuck!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks great Rusty. Wonderful work!

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Your Sphinx is looking really nice Mark! It’s fun watching all these wonderful Sphinx builds come together.

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Beautiful work! Great progress so far!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful work Mike! Good pointers, thank you.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

She will be here for a few more months then back to sea again... for real. I think my Winnie has more sea miles under her keel than the real one did lol! Thanks Matt, it’s reassuring to know others will be participating in the party. I’m Getting started today... I’m going to make a gun rigging jig maybe I’ll have one complete within a week🤞

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.