All Activity

- Past hour

-

Bob Cleek reacted to a post in a topic:

Helping hands vice

Bob Cleek reacted to a post in a topic:

Helping hands vice

-

Ondras71 reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

Ondras71 reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

Ondras71 reacted to a post in a topic:

TRE KRONER 1742 by Beckmann - 3"/8' scale - Transom-Model

Ondras71 reacted to a post in a topic:

TRE KRONER 1742 by Beckmann - 3"/8' scale - Transom-Model

-

Update the upper forecastle portholes are mounted after plating this area, and the Stb waist reling is dry fitted. Also the area for the sprit bumpkin and its fastening eyebolts and stays. Aft deck the template for the breakwater is being estimated for fit. I am eager to get all the hull-related plating complete in order to continue with the painting job and the ELBE 1 name decals. For making the decals I got a great support from another MSW fellow builder. Here credit and thanks go to "Retired Guy", Richard for all his help. That gave me confidence to try and make my own decals instead of using larger sticker letters ( problems with the structured hull surface ) Nils The Railing is from Aronaut- Modellbau in brass and nickel plated. the wooden fastening rail underneath is to get the correct hight the aft breakwater will be mounted in this area. The blank space in the plating ( aft round between the rails ) will tape up the 5mm small sticker-letters for the name "Bürgermeister Oswald" after painting.

- 122 replies

-

- lightship

- Feuerschiff Elbe 1

-

(and 1 more)

Tagged with:

-

Hartron started following HM Armed Cutter Sherbourne 1763 by Isaiah - Vanguard models - 1:64

-

Chapman reacted to a post in a topic:

Soleil Royal by Hubac's Historian - Heller - An Extensive Modification and Partial Scratch-Build

Chapman reacted to a post in a topic:

Soleil Royal by Hubac's Historian - Heller - An Extensive Modification and Partial Scratch-Build

-

tartane reacted to a post in a topic:

Trireme Olympias by Richard Braithwaite

tartane reacted to a post in a topic:

Trireme Olympias by Richard Braithwaite

-

Rik Thistle reacted to a post in a topic:

Westland Sea King HU.5 by chadwijm6 - Airfix - 1/48

Rik Thistle reacted to a post in a topic:

Westland Sea King HU.5 by chadwijm6 - Airfix - 1/48

- Today

-

Richard44 reacted to a post in a topic:

Herzogin Cecilie - Four Masted Barque - 1902

Richard44 reacted to a post in a topic:

Herzogin Cecilie - Four Masted Barque - 1902

-

An accurate build is a good looking build. When it comes to ships, usually accuracy equates to beauty pretty well.

- 4 replies

-

- vanguard models

- 1:64

-

(and 1 more)

Tagged with:

-

Ouch, hope you have a really great outcome without too much pain along the way.

- 95 replies

-

- Cutty Sark

- plastic

-

(and 3 more)

Tagged with:

-

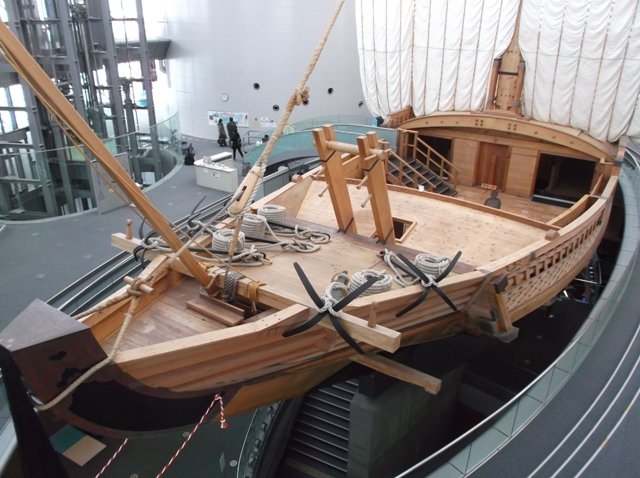

Maybe you can try to find more informations and books related to this floating replica that was made more than 20 years ago in Japan: https://en.wikipedia.org/wiki/Naniwa_Maru I remember I read an article about the technics of construction of this vessel, since they used the same ancient technics to build it.

-

Javelin started following Herzogin Cecilie - Four Masted Barque - 1902

-

Hi Keith, yes there is, not a real pad though. It's simply an area marked on deck. The area is also kept mostly free of piping and the railing on the side can be folded down. Anything sticking out from the deck is also highlighted. Of course there is no helicopter landing officer onboard, but the crew have a bit of training on these things as well.

-

robdurant started following Herzogin Cecilie - Four Masted Barque - 1902

-

A (very) long introduction to my latest project – the repair and completion of a model of the barque ‘Herzogin Cecilie’ for the Australian National Maritime Museum. I will be working on the ‘Duchess’, as she was known, in my time at the museum, while the ‘Meteor’ model will come home, to be worked on when I can. The Story Of The Ship The four masted barque ‘Herzogin Cecilie’ was built in 1902 at Bremerhaven by Rickmers Schiffbau AG as a cadet ship for the prestigious German shipping company Norddeutscher Lloyd. She was built to the very highest standards as she was designed to not only be a cadet ship for Germany’s most prestigious shipping company, but also a floating ambassadress and showpiece for the German Second Empire. She was met with great excitement and media acclaim wherever she went. Her name, Herzogin Cecilie, is from the German – Duchess Cecilie – as she was named for Herzogin (Duchess) Cecilie Auguste Marie of Mecklenburg-Schwerin, who was later to become the fiancée and wife of Crown-Prince Wilhelm of Germany. The ‘Duchess’ as she was affectionately known, engaged in the wheat and later nitrate trades to the Americas prior to World War I sometimes with salt, timber, or coke as the outward cargo. She found herself isolated in the port of Coquimbo, Chile, when war broke out. This put her in a difficult position as she would certainly have been taken as a prize of war if she had attempted to return to Europe from her neutral port. She remained at Coquimbo until June 1920 when she loaded nitrate at Celata Colosa and sailed for home. As soon as the cargo was discharged at Ostend she was handed over to the French Government as part of war reparations. The French didn’t want the ship and decided to sell her. She was finally purchased by the well-known Åland Islands owner Gustaf Erikson on the advice of his most experienced captain – Reuben de Cloux. Thus began the final, and probably most well recorded, era of the ship’s career. Erickson sent her to Australia looking for wheat cargos – cargos that could be loaded slowly and cheaply in the small Gulf ports of South Australia – cargos that could survive the long, slow voyage back to Europe without damage and without losing value. His Master of choice for the ‘Duchess’ was the same Captain de Cloux who had inspected the ship at Ostend, a man who sailed the ship hard (and somewhat expensively as he was prone to carrying canvas too long and losing sails in strong winds). She made twelve voyages to Australia in all, mostly to the South Australian Gulf ports, but also to Melbourne – usually with outward bound cargos of timber. In between her Australian voyages she also made several nitrate voyages to South America. Reuben de Cloux stayed in command of the ‘Duchess’ until the middle of 1929, when he went into retirement as a Ship Master and handed over command to his First Mate, Sven Eriksson, a distant relation of the owner, Gustaf Erikson. Gustaf was evidently not too happy about offering command of the world’s most famous and best loved sailing ship to the inexperienced Sven, however the very tight-knit network of Åland Islands family connections is thought to have forced his hand. During the period when Sven was in command the ‘Duchess’ continued to regularly win the so called ‘grain races’, with the fastest voyages home from Australia, but this may say more about the speed of the other ships involved than the ‘Duchess’ as there are several extant letters from Gustaf Erikson to his Captain reminding him to always take in sail early and not on any account to risk losing sails in strong winds! As the 1930’s advanced, luck began to run out for the ‘Duchess’. In June 1935 her donkey boiler exploded while she was discharging grain in Belfast, killing two of her crew and injuring several other people including the Second Mate. Considerable damage was also caused to the ship’s structure and rigging. Only essential repairs were carried out at Belfast, the remainder being completed in Erikson’s own shipyard in Uusakaupunki, Finland, and the ‘Duchess’ sailed on her final voyage around the world on 29th September, 1935. The bad luck continued as she sailed up the Kattegat on her way to the North Sea. She sailed straight into the stern of the German trawler ‘Rastede’, causing heavy damage to the trawler, which had to be towed into port. The ‘Duchess’ was held entirely responsible for this collision, and it later cost her owner dearly. After the collision, Sven simply continued his voyage to Australia. She sailed from Port Lincoln, in South Australia on 28th January, 1936, arriving at Falmouth, for orders, on 23rd April and on the 24th she sailed for her discharge port of Ipswich on what was to be her final, very brief, voyage. At 0350 on the 25th April, in heavy fog, she struck the Ham Stone in Soar Mill Cove and, leaking badly forward, settled to the bottom with her poop still above water. Several attempts were made to get her off, but it was not until 19th June that she was finally refloated and towed to Starehole Bay near Salcombe, where she was once more allowed to settle on the bottom. On 19th July Sven Eriksson wrote to Gustaf Erikson that several seams had burst and a bulge in the plating was noted on both sides near the mainmast. Her back was broken. The ‘Herzogin Cecilie’, the beautiful ship, was now a total loss! Her rusted remains can still be seen in the sand at Starhole Bay to this day. The Story Of The Model The model of the ‘Duchess’ has a long and complex history. Back in 2007, one of the museum’s model makers, Col Gibson, was asked by two friends if he would be interested in seeing a model of the ‘Duchess’ that was owned by their neighbour. Of course, Col said, “Yes”, and in February 2008, while he was having lunch with his friends, they introduced him to their neighbour, Vera Grainger, and her model of the ‘Duchess’. Vera’s husband Malcolm, the builder of the model, had passed away and Vera expressed an interest in donating the model to our museum however the model couldn’t be accepted into the National Collection unless complete, and thus the “Duchess” model’s long association with the Australian National Maritime Museum and the museum model makers began. Work on the model had commenced in South Africa prior to the Grainger family migrating to Australia in 1978 and had continued here up to the time of Malcolm’s retirement, however after he retired the model languished with the hull and most of the deck fittings completed, and some of the spars completed but quietly resting in a box. Vera expressed an interest in the model going to the National Maritime Museum, and wrote a letter and report to the museum concerning her gift. The model as received by the museum Nothing further happened for about two years, when Col had an unexpected visit to the model makers’ bench by then Senior Curator Dr. Stephen Gapps, who was enquiring about the fate of the model described in Vera’s letter and report. This visit finally resulted in the model being collected from Vera’s home and taken to the home workshop of another of the museum’s model makers, George Bambagiotti, as he had agreed to complete the model. George Bambagiotti holding the stripped down model Malcolm Grainger had commenced the model using plans for the ship as she was originally built, but many major and minor alterations had been made to her structure over the years, even when still under the ownership of Norddeutscher Lloyd. It was finally decided that the model should be altered and completed to show her as she was when she was engaged in the grain trade to Australia, as that was the most relevant period of her life for Australian maritime history, and the way most of the world remembered her. George started cleaning and disassembling the model while Col started on the required research. Researching such a well-known ship sounds easy – there are literally hundreds of photos of her and many books; but the books usually don’t mention alterations to the ship, and almost all the photos are undated, so trying to find out exactly what the ship looked like in early 1936 was no joke. Progress was much slower than anticipated due to many factors, sadly including George’s increasing bouts of ill health, but he was not easily put off. I remember sitting on his bed at a Rehabilitation Hospital together with Col as we tried to work out exactly how various parts of the ship actually looked at the time of her final departure from Port Lincoln. As time started to drag on, Janos Nemeth and I were asked to contribute to the build. Janos, because of his well-known expertise with small carvings, was asked to make a new figurehead for the model, and I was asked to build a new suite of boats. I was also asked to consider rigging the model, with Janos asked to assist with this if needed. The two final blows were the closure of the museum due to Covid in March of 2020 and, far worse for his colleagues and friends, the death of our dear friend George on 27th February, 2020. George’s death was a shock to all his friends at the museum, but most especially to the team working on the ‘Duchess’! While we coped with our grief at the loss of our friend, we also had to consider the future of the model, as the ever-worsening Covid pandemic with its threats of lockdowns made future actions uncertain. We also had to consider relieving Lyn Bambagiotti of the worry of having the model stored in her garage. Fortunately, the museum was able to arrange to have the model moved to the museum prior to everything locking down, but we then lost track of our lovely ‘Duchess’. She had been sitting dreaming on one of the museum store shelves while Col and I wondered what had happened to her until a recent visit to the modelmakers’ desk by one of the museum curators. Not only was the safe ‘Duchess’ in the model store, but the museum wanted the model’s status to be resolved! Things then started moving quicky. Several of the museum’s senior staff became involved, and the project was suddenly moving again. Our beautiful ‘Duchess’ is now on the upper gallery of the museum in her own secure display case and work table, and will be starting to sort our the mess on the model and the mass of possibly relevant bits and pieces that were collected from George’s home starting next Monday. Sorry for it being such a long introduction, but it's been a pretty complex story!! John

-

You had me check. Yep, real McCoy. Made in USA

-

Bob Cleek started following Helping hands vice

-

QuadHands are "finestkind." You'll love them. Nobody should waste their money on those near useless ball-jointed "helping hands" that you have to adjust by tightening wing-nuts. They are really junk. (And, like so many others years ago, I bought one, too! ) One thing to be careful about, though, is to make sure you buy the real QuadHands fixtures. There are "carbon copy" Chinese knockoffs all over the internet, but they aren't the same quality at all. The QuadHands uses high quality alligator clips for one thing. Cheap alligator clips are a dime a dozen, and they don't hold well at all. Don't subsidize intellectual property theft. Buy the real McCoy!

-

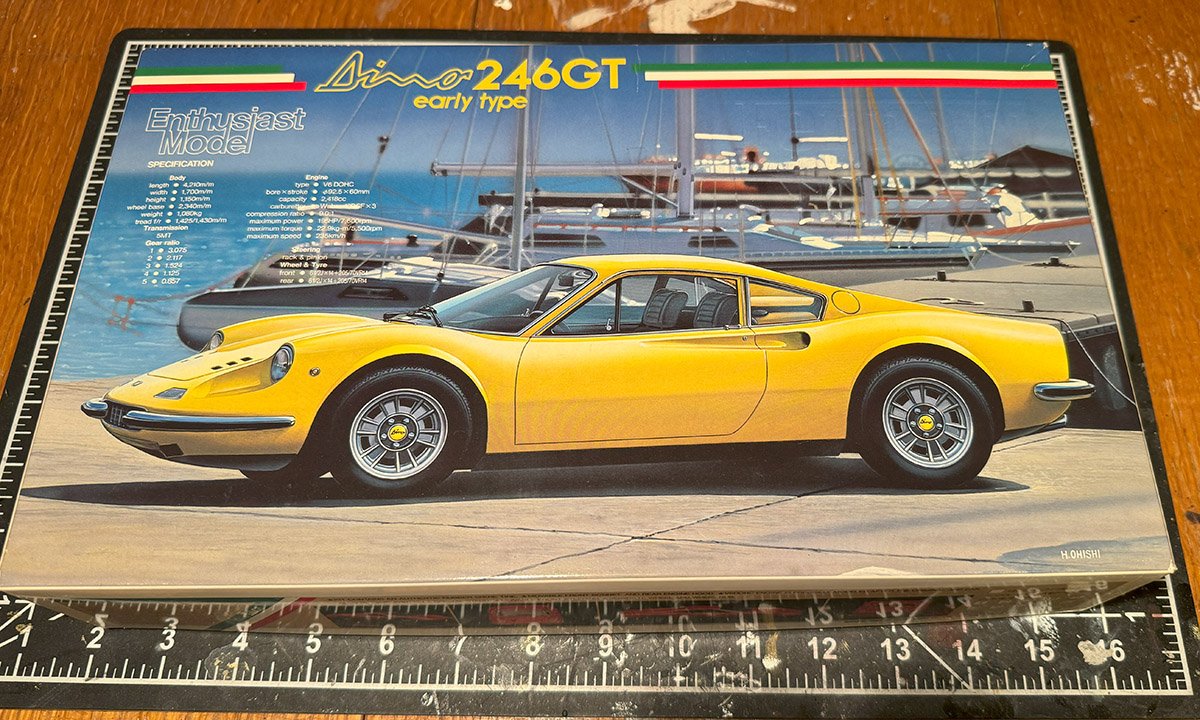

Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

Old Collingwood replied to gsdpic's topic in Non-ship/categorised builds

Seen the main guy on tv buying restoring and selling the real versions - Wayne Carini (Chasing Classic Cars) Looking forward to following this build. OC. -

I gave up on VPN since Disney+ stopped ESPN and took away the NCAA football games of me. Can´t see the point in paying for a service I don´t need or not use anymore. I was using Cyberghost for more than 6 yrs, to watch the NCAA football games of my favorite team. Unfortunately Disney (owner of ESPN) stopped the service last year here in Europe. Therefore I can´t watch any games since then, so there was no need for me anymore to use a VPN host since I don´t use streaming services and especially not foreign streaming services. Micha

-

gsdpic started following Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

-

Pablo Castelo started following Golden Hind(e) by rkwz - AIRFIX - 1:72

-

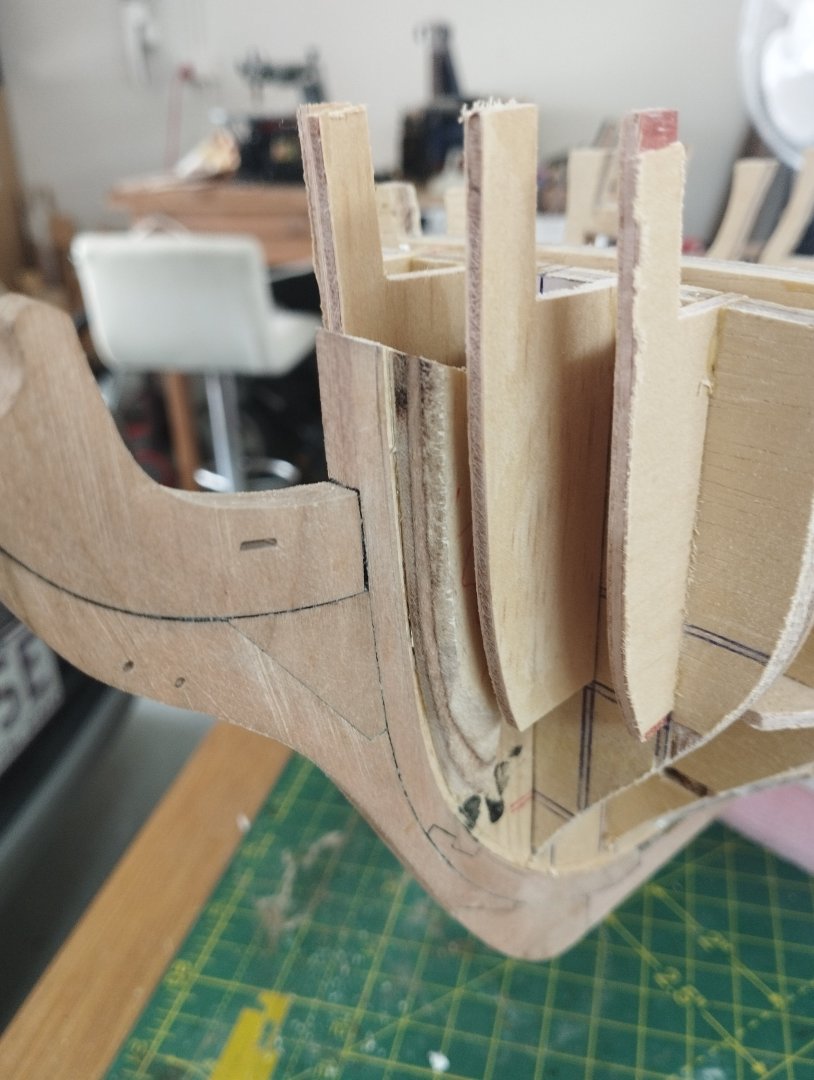

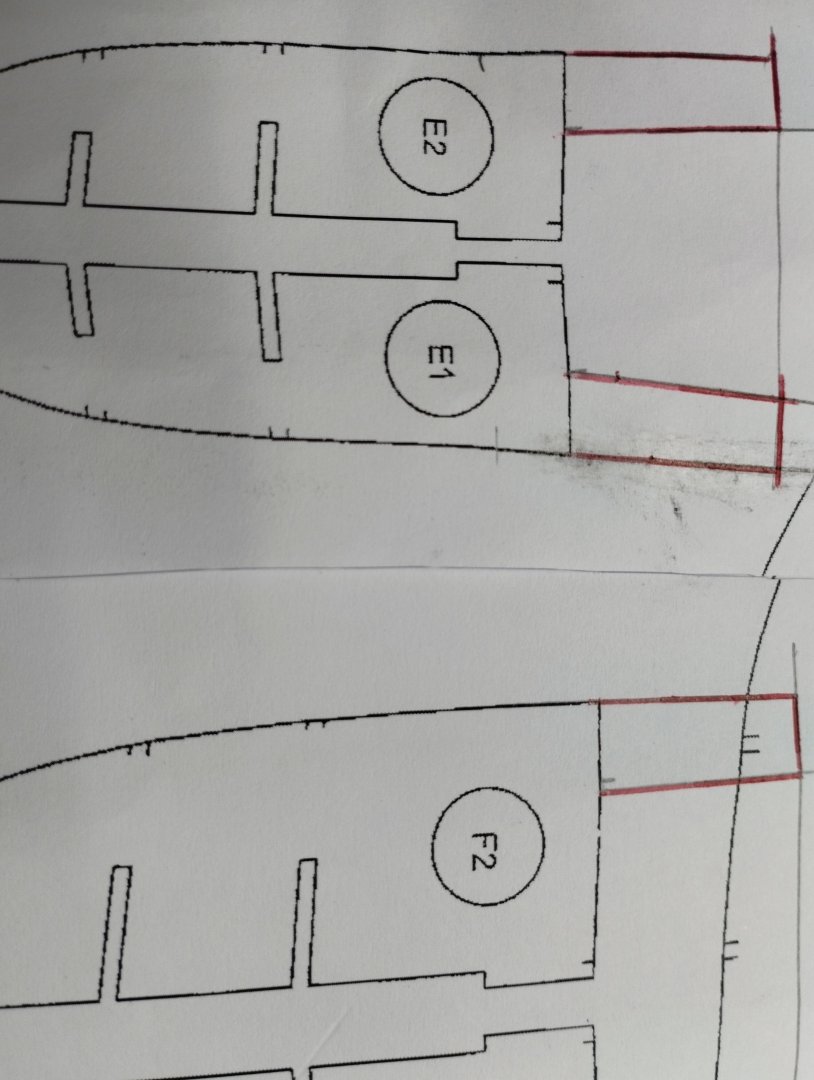

Hi All Thanks for the likes.... Just a quick post setting out the bow area for planking. This isn't the way I've done it in the past but seeing as how I'm experimenting in how I can use a paper model as the basis of a wooden version I've stuck with the way the paper model is done. From left to right shows the process First I extended the formers (red lines) above the deck level with sacrificial tabs to aid in the planking around the bow above the level of the deck Next shows them fitted and I've added some 6mm ply against the spine that follows the curve of the stem post and in line with the rabbet piece i fitted in post #1 Finally I've filled between the formers with Jelutong wood. This sands quite easy but takes nails better than balsa should I need to More functional than pretty Thanks for looking in Mark

-

Belated happy birthday and get well soon. Micha

- 95 replies

-

- Cutty Sark

- plastic

-

(and 3 more)

Tagged with:

-

Isaiah started following Avoiding Chipping while Milling Hardwood

-

Pretty late here but anytime a blade or mill passes out the back of your wood piece there will almost always be tear out. Using masking tape or duct tape at the end of the cut or really anywhere the surface is exposed to the blade. helps quite a bit. Clamping a sacrificial piece of wood on the end also helps.

-

CDW started following Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

-

Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

CDW replied to gsdpic's topic in Non-ship/categorised builds

You are going to love this kit, Gary. I built it long ago when it was offered by Testor's, and could often be found at deep discounts in big box stores such as K-Mart. I don't recall having any fit issues with it at all and it was beautiful when finished. Along with several other built models, I loaned it for display at a local hobby shop. When the owner sold the business, I lost my built models as the new owner claimed it as part of what he purchased. I do have another one in my stash. It came in two versions, one like yours and the other as a spyder with the top removed. -

Inspired by @CDW's Ferrari 288 build and also by the way he immediately starts a new build after finishing the previous one, I present the start of my build log for the Fujimi Ferrari Dino 246gt. I actually also have the 288 in my stash but did not want to be too much of a copycat so I pulled out the 246gt. The Car: In the 1950s, 60s, and 70s, Ferrari had a sub-brand of cars named "Dino", after Enzo Ferrari's son Alfredo "Dino" Ferrari. Initially they produced only race cars for some of the lesser racing series with smaller, less powerful cars and engines. In the mid 1960s they displayed a concept car for a road car in the form of a mid-engined coupe. That concept car was well received and became the Dino 206gt. In those days the model number was derived from the engine size and type. The 206 indicated a 2.0 liter engine with 6 cylinders. Before long, they upgraded the engine to 2.4 liters, and so it became known as the 246gt. In the late 60s, this car competed with the then current Porsche 911 in terms of price and specs. The 246gt was sold from the late 60s into the early 70s, with a few minor modifications along the way. For example, the early cars had the "clapping hands" windshield wipers while later ones have parallel wipers. They also sold a spyder/targa version with a removable roof known as the 246gts. The Kit: The kit I acquired is the original version from 1986, according to scalemates.com. This is from Fujimi's "Enthusiast Model" line of kits, so it is quite detailed, including the engine, chassis, and interior, with over 200 parts. And they were not afraid to make small parts, some are literally pin head size. This early kit had some very attractive box art, as you can see below. You'll also note the "early type", indicating this is one of the early 246gt cars. Fujimi reboxed this kit many times over the years, and in later versions they included parts for both the early and later versions of the car. They also created a "curbside" version of this kit with far fewer parts but no engine detail. This kit includes opening front bonnet, engine cover, and trunk cover, giving at least a little bit more of a view of the details included in the kit. The body parts are molded in white plastic. The engine, chassis and interior parts are all gray plastic. There is a small fret of chrome parts, which I may or may not strip. The wheels are a very nice satin chrome and will be left as is. My Plans: While I like the yellow on the box art, I am more likely to paint it red, with a tan interior. As noted, the kit is already highly detailed but there may be a few more things I can add, such as spark plug wires. At least one bank of three cylinders on the v6 should be visible when opening the engine cover.

-

BruceWayne426 started following USS Constitution by JSGerson - Model Shipways Kit No. MS2040

-

Mufasa: I read the section of your build when you were working with the copper foil tape with great interest. The Mamoli solution of wood chips that are stained a greenish copper color just doesn't look right to me. That part of my build is a ways down the road so I have time to think about the options. Thanks for your response. I am really enjoying your craftsmanship. Bruce

-

That's a good tactic! I might have to try that out myself. 😀

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.