-

Posts

4,541 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Landlubber Mike

-

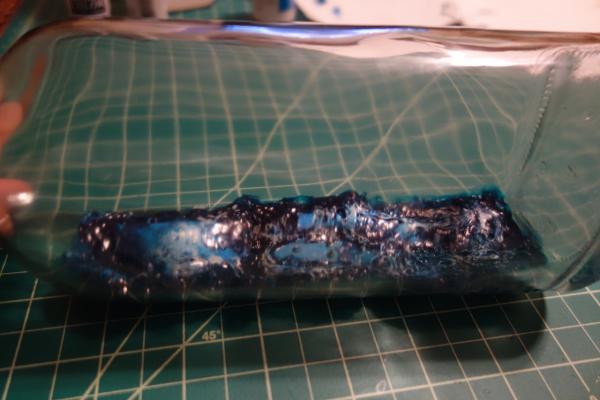

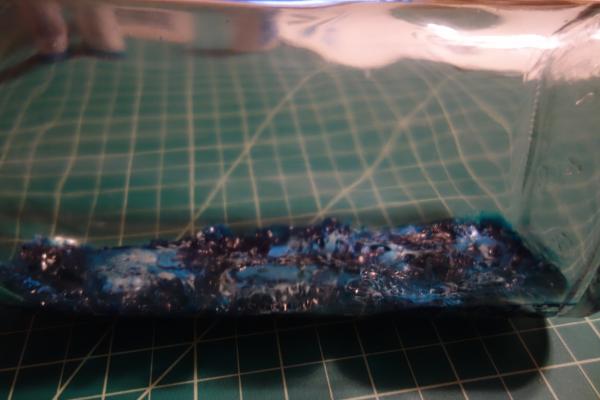

Adding "sea" into the bottle The kit has you glue a small base with four small posts in it into the bottle. If I remember correctly, there was a decorative wood base, plus a brass photo-etch on top. I ended up just using the wood base with the posts glued onto it, and glued it to the center of the bottle while it waited for the sea. My goal was to sit the ship on the base, but build up the sea around it so that it looked like the boat was actually in the water. I had some difficulties as you can see later. This part was the most complicated part of the build. I've seen all different methods and materials. Some use clay which is inserted like a snake and then heated so that it melts and evens out. I've also seen where others have used painter's caulk, which is somehow colored and then inserted the bottle using something similar to the method in which decorative icing is applied to a cake. I decided to go a different way. The clay to me looks pretty fake, and is usually too blue for my tastes. I considered using Realistic Water or something similar, but decided not to (I think it was because to use it right, people usually paint the floor first, and then drop the realistic water on top - that would be almost impossible to do for a ship in a bottle). I eventually came across Vallejo's "Water Effects" - as you can see in the picture below, I picked the Atlantic Blue. The Vallejo Water Effects has the consistency of yogurt. It was a real pain in the *insert body part of choice* to get it into the bottle. I ended up using a small putty knife to drop it into the bottle. The trickiest part was getting it evenly close to the neck of the bottle. Of course, I would accidentally touch the glass and then have to try and get it off - not as easy as it sounds! I also noticed that the stuff forever to dry inside the bottle. The first layer I applied in 2012 was dry. But the stuff I applied in early February of this year was still wet 3 weeks later! I found that it dried when heated. As you can see in the pictures below, the material out of the jar is like a french blue, then when dry, it darkens to a deeper, dark blue. So, I tried it in the oven. At 250, it didn't seem to do the trick. Finally when I got to 325, it changed to dark blue almost immediately. The problem though is that at that temperature, it started bubbling in the bottle, and I ended up with a few "pops" where there was material all over the glass sides. What a pain! It also smells a bit when it is baked, so when I removed the bottle, I sat it next to an exhaust fan while it cooled off. Once done, I used the Vallejo paints in the post above to add some colors and highlights to the water. Used a dry brushing technique starting with the darker colors and going towards the lighter colors. I also bought a foam/snow effects bottle from Vallejo to simulate the white caps, but it was very stark white and I think went on a little thicker for volume. The light green-blue color gave me the effect I wanted, so I stopped there. Again, tricky near the neck of the bottle, and I seemed to always bump the paint brush against the glass.

-

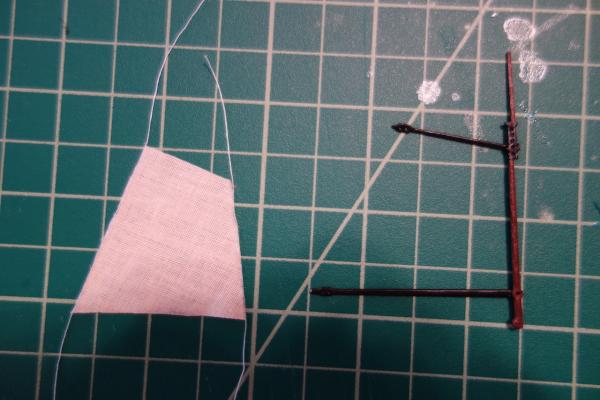

Sails I deviated pretty substantially from the kit on the sails. First, I ended up replacing the kit sails as I didn't like the printed seams, etc. for the sails. I used some very thin fabric that I think came from Model Expo. Probably a bit thick, but it worked ok. Rather than sew the sails on, I used Aleene's fabric glue to glue the lines to the sails as appropriate. The masts and spars are created from photo-etched parts. The parts are very nice, but be careful with the parts, particularly the masts and bowsprit. The brass holds up fairly well, but I accidentally bent the bowsprit a few times and eventually, the part just snapped. It was a real pain to glue back together - I ended up gluing it back on with CA and two thin strips of brass on either side to hold the joint better, but still snapped it another half dozen times. I was really worried that it would snap in the bottle -- and consequently would ruin the bottle as there would be no way to glue it back -- but the modeling gods were with me and it stayed firm. The rigging plan is pretty well diagramed and explained in the kit's instructions. The kit comes with white line, but I decided to use black Gutterman sewing thread for the shrouds.

-

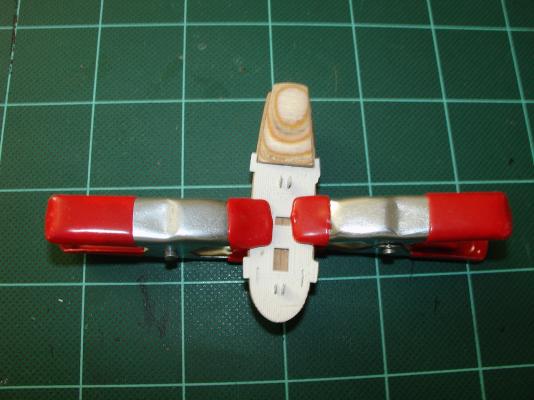

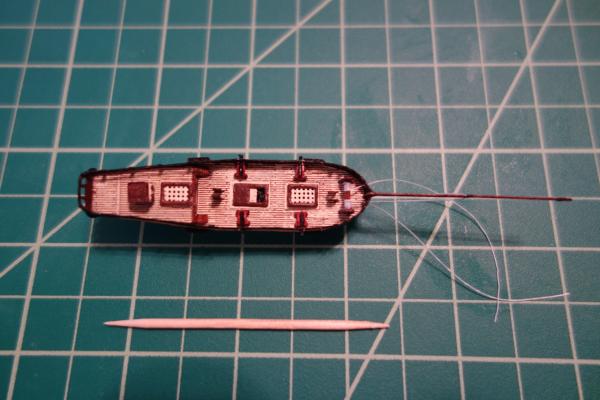

Construction of the Hull The kit is 1:300 scale, which is incredibly small. For scale, here is a picture of the hull compared to an American dime: The hull is constructed by a "bread and butter" technique of layering multiple thin pieces of wood together. The deck, masts, spars, keel, hatches etc. are all photo etched parts. Some of the detail pieces like the anchors, deck house and cannons are cast metal pieces. The cast metal pieces were surprisingly very nice at such small scale. You can see that I decided to paint the ship. I used walnut stain on the wood area, and paints for the rest. Once complete, I used a matt varnish from Vallejo to seal things. I had a really rough time getting the keel around the hull. I actually had to break it into two pieces so that it fitted nice.

-

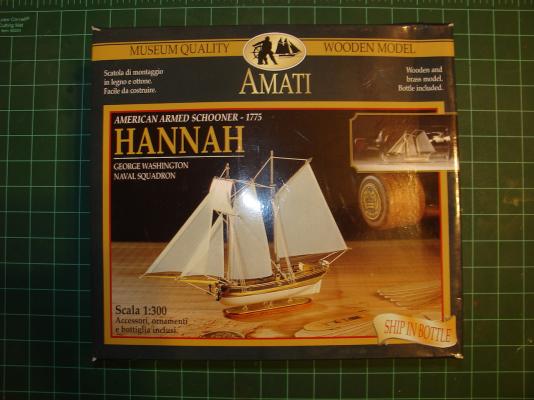

Today I finished my Hannah Ship in a Bottle kit from Amati. I picked it up on a whim off of eBay for $20 a few years ago thinking it might be a fun little project. I spent a few weeks on it during my Badger build in the summer of 2012 to give me a mental break from that model, and then the model sat for the next two and a half years. I picked it up again this year, spending the last month or so finishing it as a break from my Pegasus build. I decided not to do a build log as I went along, as frankly, I was a bit worried that I'd screw up the project and have to scrap it due to my modifications - in particular putting sea in the bottle. So, rather than potentially embarrass myself, I decided that I would post one at the end if things turned out ok. The good news is that it all worked out in the end and so here is a summary log with pictures I took along the way. Introduction The kit is quite nice, with very nice photo etched parts, a nice bottle, and pretty good materials. The instructions are also pretty good. The folks from Amati are incredibly nice as well, as I somehow lost the keel part but they sent a new photo-etched set for free - thank you Amati! As you can see in the picture below, the kit is designed to have the ship sit in the bottle on a stand. I decided that was a bit plain, and made the following modifications: 1. I painted and stained the ship, rather than leave it in brass. 2. I replaced the kit sails, which were dyed to show seams, with plain cloth. I thought the seams, etc. on the kit sails were a bit out of scale and garish for my tastes. 3. I added "sea" to the bottle. Adding the sea really complicated the build, but I think it came out pretty nicely. The next few posts go into the construction process.

-

Hi Max, The FWZP is an amazing kit, isn't it? The plans and cast pieces are nothing short of incredible. I too was surprised at the weight! I'm probably a good 5-10 years away from starting that kit unfortunately, as I have my current Pegasus and Lyme builds going, and also have the Charles Morgan on the shelf as well. I think once I get through those kits, I'll hopefully be ready for the FWZP

-

Hey Carl, not sure if you already got your model into the bottle or finished it. I got my model into the bottle last night and raised the masts. I need a little more time tonight to arrange the sails a little better and she will be done. It was getting late, and I didn't want to make any mistakes from being tired or otherwise rush it. I'll try to post my log tonight, but if I can't get to it, I just wanted to pass along a couple of tidbits. The insertion process is very stressful! First, I couldn't get the rear mast folded down due to the way that I ran the rigging. For some reason, the jib staysail (the inner one) was restricting the mast from fully lowering. I ended up having to cut the line from the top of the main mast, tied that line (on which the jib staysail was) to one of the spars, and ran a separate line from the top of the main mast to the exit hole. So, make sure your masts can be fully folded down. Once that issue was resolved, I tried to figure out a better tool to insert it into the bottle than the string technique the kit calls for. The model is too heavy for the string technique in my experience (or it needs perfect execution to work). I ended up taking a piece of annealed copper wire, bent it to the same configuration as the other metal piece, and then taped it to the handle. When the ship was in the bottle, I cut the tape and pulled out both halves of the tool. The bottle opening is incredibly tight. I filed down the inside bottom edge of the bottle to help push it in. Even then, it required heavier pressure to insert than I was expecting. It was that tight even with the fact that I had sanded off the keel bottom since I added sea to the bottle. Once inside the bottle, I used the insertion tool and other tools to pull the masts up and position the sails. Be careful to do it slowly, and watch for any bent masts, The top of my main mast was bent somehow through the process, which was a little tricky to straighten out. The bottle is pretty narrow inside, making any tool work pretty tricky. The key I think is to make sure the ship is firmly glued to the bottom of the bottle so that you can pull the masts up. Anyway, don't mean to scare you or anything, just wanted to make sure that you were prepared. I'll let you know when I get my log up, but otherwise, let me know if you have any questions.

-

Great work Joe. You and Timmo are married to wise women. My wife stays away from me when I get frustrated during what I explain is a relaxing hobby

- 302 replies

-

- granado

- caldercraft

-

(and 1 more)

Tagged with:

-

Last summer, I ordered one of the Euromodel figureheads from Euromodel for my Lyme build. They were incredibly courteous, and shipped it out the same day before they went on an extended summer holiday. Impeccable service and very nice people. I am really looking forward to building the FWZP in the future (which is sitting on my shelf) in part because of their service - their kits are also beauties themselves too!

-

Looks fantastic Nils. I'm glad you went with full sails - you've convinced me to try full sails on my Pegasus as well.

-

Thanks Hamilton for that link. Carl, I had the same experience with the insertion tool that the guy in the thread above had as well. I'm thinking about other alternatives like blue-tac or something else.

-

Great choices Joe. You'll definitely do a fantastic job on any of those kits for sure. I have the Charles Morgan kit. It's a nice kit with detailed plans, and as John's build shows, it makes for a very nice model. I'm looking forward to building it one day as something different from a war ship. No fiddly cannons to deal with, but seven whaleboats and lots of interesting whaling-related items to build instead. Some of the kit's included pieces are not very well done though - I think you'll find that you'll need to scratch quite a bit, as John shows on his log. Otherwise, I think it's a great kit and it's nice that the ship is available to see up in CT. I'm planning to eventually do mine in full sail, as I think that would really make the model look magnificent if I can pull it off. I think the Niagara would be another beautiful ship to do in full sail too. The nice thing about the Niagara is that you can just buy the plans if you are planning on replacing the kit wood. Constitution is another nice one. My wife thought my Badger at 2' or so in length was big, and raised her eyebrows when I said my current builds are around 3' long. I can only guess the reaction if I told her my next build would be 4' in length Have you taken a look at the Euromodel kits? They are a bit pricier than the other kits you are looking at, but in terms of plans and kit components, they are really nice kits. I managed to get the Friedrich Wilhelm zu Pferde off eBay for a steal, and it's an incredible kit. What I like is that the kit plans give you enough information to add lots of extra details to your build. There are also detailed practicums that are available for free to help one along. I'm saving this kit for last after my other kits to get my skill level up to really do it justice. Looking forward to whatever you decide!

- 302 replies

-

- granado

- caldercraft

-

(and 1 more)

Tagged with:

-

Looking great Joe. You're moving along quickly but with excellent results. You're going to need to start planning your next build soon

- 302 replies

-

- granado

- caldercraft

-

(and 1 more)

Tagged with:

-

Igor, your Atlantic looks fantastic. Very impressive. Carl, I tend to agree with Igor that if I did a ship in a bottle again, I would try scratching it. The Amati kit is nice in that the photo etch pieces are easy to work with, but I think the masts and spars are one area where having custom pieces that are more 3-dimensional without the big holes would make for a nicer model. I thought about replacing them, but figured that I wanted the experience to see how the whole process of inserting the model into the bottle worked first before tinkering with such critical parts.

-

Take a look at my log here beginning at page 15: http://modelshipworld.com/index.php/topic/7267-hms-pegasus-by-landlubber-mike-amativictory-models-scale-164/page-15 What I did was pre-build the hatches, then ran the planking to stop short of the hatches fore and aft, and ran them alongside the hatches athwartships. Then, having built the hatches slightly oversized, I sanded them back carefully to fit the opening in the planking. Once the deck is complete, I will finish the hatches and glue them. That being said, I created custom-sized planks for the deck, making it easier to take this approach. It might be less feasible depending on the proportion of the hatches vis-a-vis the width of the kit planks. For my Badger build, I took the approach of planking the deck, cutting out the holes for the hatches, then gluing the hatches onto the planking. While the approach I took on my Pegasus looks cleaner and is more accurate historically, frankly, once the deck is busy with all the deck items, the difference in the two approaches won't be as apparent.

-

Hi Carl, looks great. I forgot about the flag - I need to add that to my build as well. I've seen people use painters silicone caulk, clay and other similar materials. I think they make a snake of it, put it in the bottle, heat it, and then push a plug into the "sea" to leave a depression for the model. I ended up taking a different route because I didn't have the foresight to build a similar plug early in the build. So instead, I am using "Water Effects" from Vallejo - Atlantic Blue: http://www.vallejo-farben.de/water-stone/page/f10.html I glued the base in the bottle, then using a tiny putty knife with an extended handle, I dropped scoops of the Water Effects into the bottle, which has the consistency more of a thick paint than anything. It was pretty easy to work into waves. The big pain of it was then cleaning up the sides of the bottle where some of the material got on it. The whole process took me hours. I built up the sea around the base, and when it dries, I'm going to dry brush some green on it as well as some white for the spray coming off the boat. I'm not sure how it's all going to come out. Hopefully I built the sea around the base enough that when I seat the model on the stand, it looks like the water is against the boat. What I may do is drop some more right onto the base when I'm about to put the ship in the bottle, but at that point, I really will only have one shot to get the boat in and on the base properly. I found that the Water Effects takes a while to dry inside the bottle. I might use a hair dryer or something to speed things up, as it's still pretty viscous a week after putting it in. I'll let you know how it all goes.

-

Nice progress. I ended up just planking the area under the fore hatch - I don't think you'll see much if any of the rest of the planking, but probably a little laziness on my end as well went into it. Good practice though. Just out of curiosity, what wood are you using for the planking? It looks like walnut, when I think the kit would have you use tanganyika.

-

Looks great Carl. I've been working on my Hannah the last few nights as well, and finally finished the rigging last night. I have to touch up some of the painted areas, but otherwise the ship itself is good to go. I still need to wait for the "sea" in the bottle to dry and harden, at which time I'm hoping to paint some highlights for the water and the foam around the ship. If you don't mind me asking, did you use the cauterize technique to attach the lines? I was really skeptical of the holding power of doing that, so I went with knots and glue. Also, have you tried the insertion tool yet? It's very fiddly. I'm a bit nervous about getting it into the bottle, especially with the sea that I inserted. I'm also wondering how easy it's going to be to get the masts upright and spars straight, and then tie off the two running ends. To say that the bottle opening is tight is a big understatement.

-

Thanks Eamonn, this is an effective technique and your results look great. Did you consider pre-treating the nails with liver of sulphur before installation? Just wondering, as I'm considering adding nail heads to my build but didn't know what the solution would do to the surrounding wood.

- 1,039 replies

-

- ballahoo

- caldercraft

-

(and 2 more)

Tagged with:

-

Tryworks came out really nice Bruce. The color for the bricks looks really good.

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

Looking great Bill. That's going to look amazing in that case! I don't know what I'm more jealous of - your woodshop or the fact that you don't have to do the DC commute any longer

- 335 replies

-

- Constitution

- Mamoli

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.