-

Posts

685 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captain_hook

-

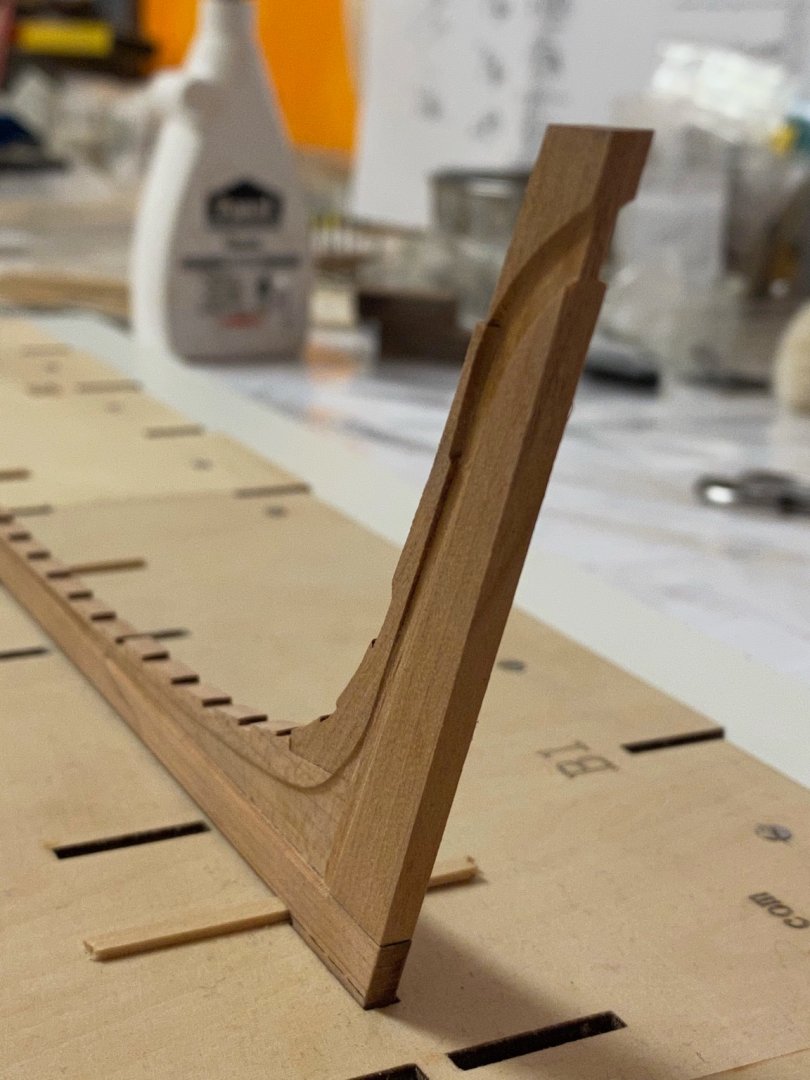

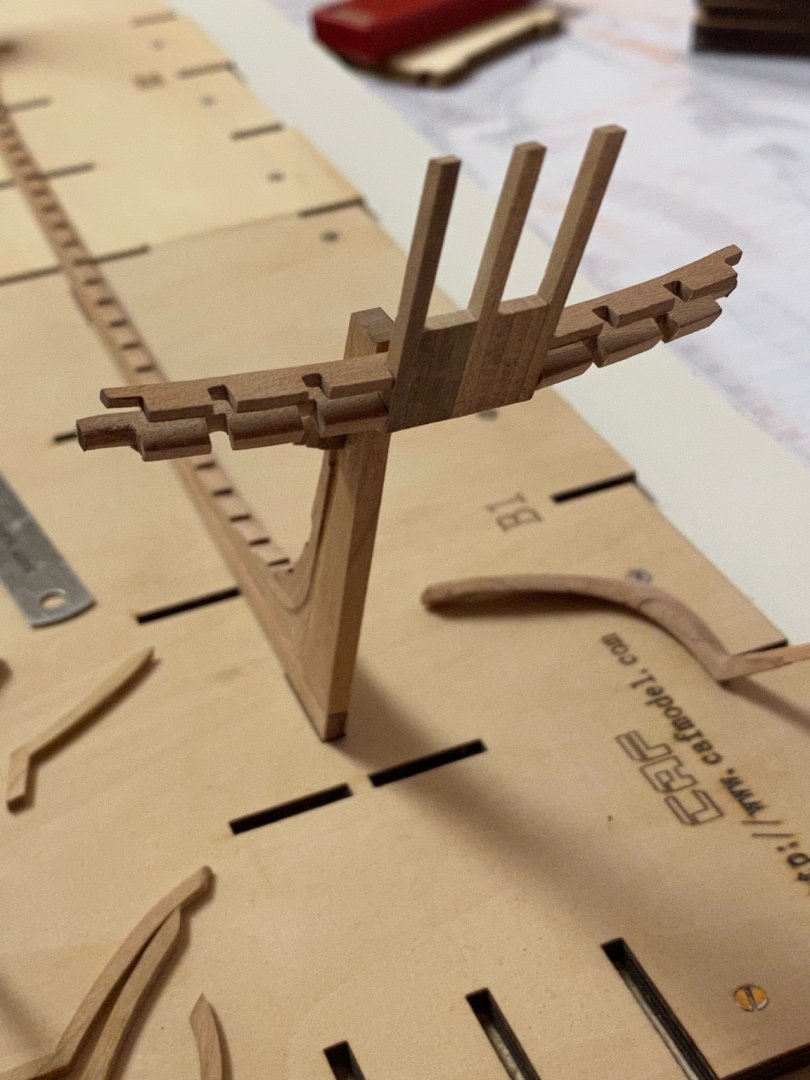

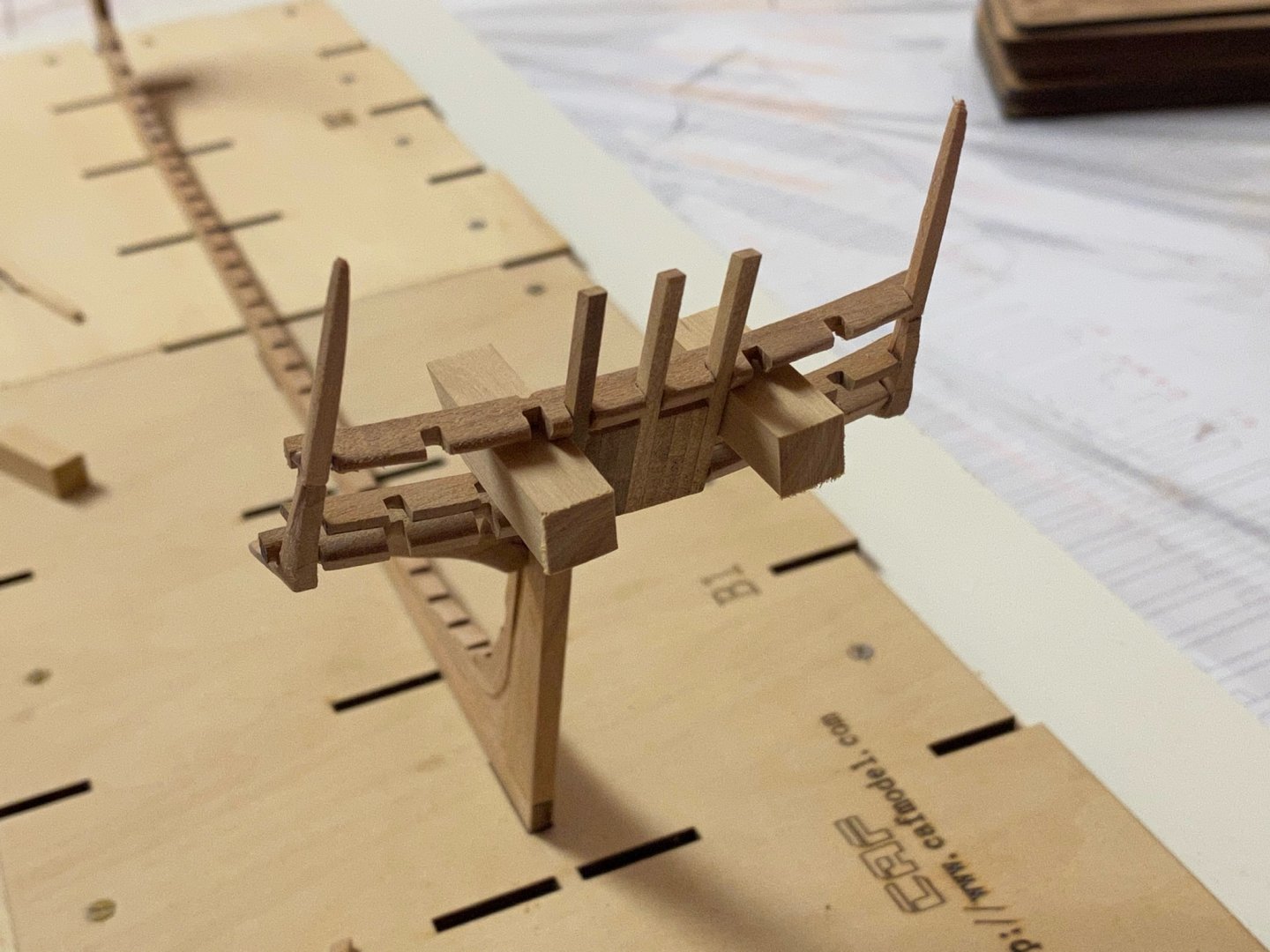

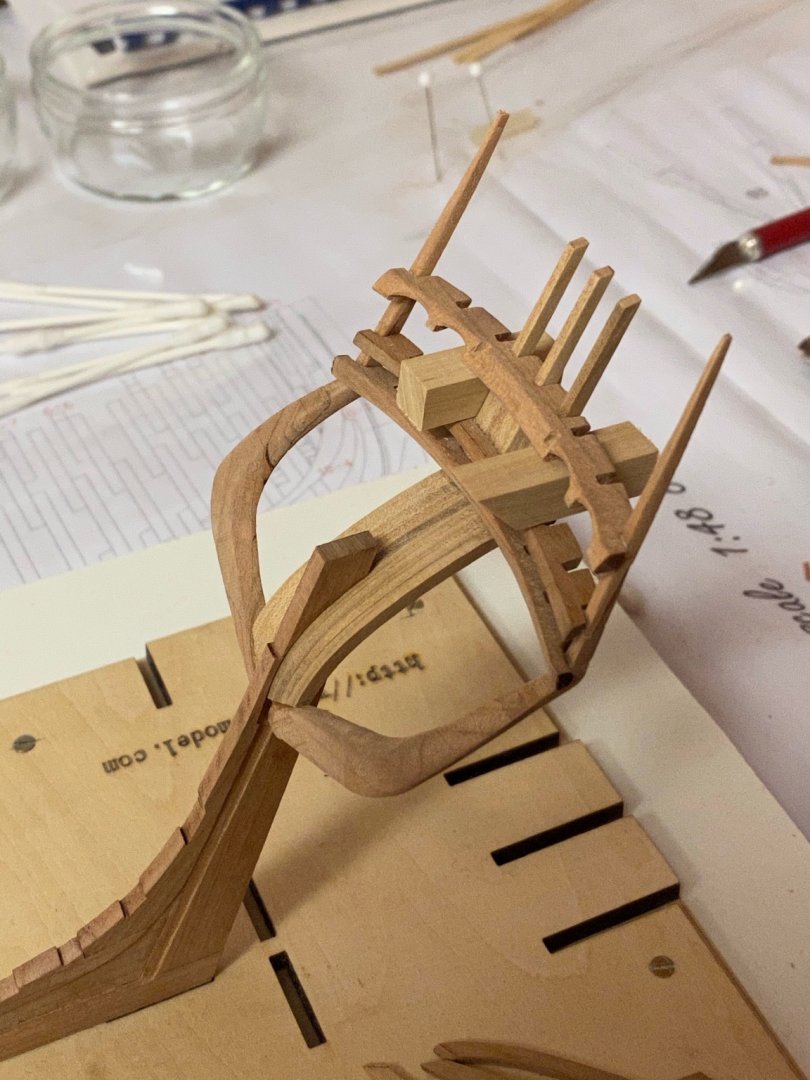

To assemble the stern and counter frames I used the supplied jig parts as reference. I started construction with the 9 middle stern timbers that are glued together to form the center piece. This piece is glued into the notch already milled into the stern post. iAs PoulD has pointed out all frames glued together are much too thick so they require some sanding, These stern frames were the first to be installed and then I used the rear jig parts for reference and installed the center horizontal timber. The lower part was done next. The counter timbers are pre-milled but they still need some post-processing. They come in three separate parts that have to be glued together. After some sanding they were ready to be installed. The last piece to be installed was the one that sits above the windows. I used some wood blocks to equal the height (8 mm) on both sides. Then the rest of the stern timbers were added.

-

After some recovery I am able to continue the.build. Before assembling the counter and stern timbers the parts have to be released from the trays. Although CNC-milled they need some post processing to get rid from the holding bars. I used different needle files and sanding paper to clean them. The stern timber’s are laser cut, so they have to be cleaned too to get rid of all the laser char (again this took most of the time). The sanding has to be done very carefully as some parts might easily break along the grain. Now all parts are ready for installation ... which will be done tomorrow. Stay tuned... and save.

-

A very.beautiful add-on to your already nice Syren!

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Nice perspective photo shots. You can be proud of her.

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Kaiyuan Temple by RichieG - CAF Model - 1/75 - WOOD

captain_hook replied to RichieG's topic in Non-ship/categorised builds

Very nice! Looks more like a 3D-puzzle than a kit. -

Nice job on the planking. The pearwood has such a nice warm colour.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Congratulations, she is a beauty. Nicely done!

- 164 replies

-

- vanguard models

- flirt

-

(and 1 more)

Tagged with:

-

Thank you for your interest and all the likes. Yes, there are a bunch of new kits coming which will bring the hobby to a new level. I‘m going to a endocrine surgery tomorrow, so I will be off modeling for some days but hopefully will continue the build before Christmas. Stay tuned ... and stay safe.

-

Amazing build so far. Looks great! I also like the color variations of the basswood (?) planking, that gives the ship a more realistic touch.

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

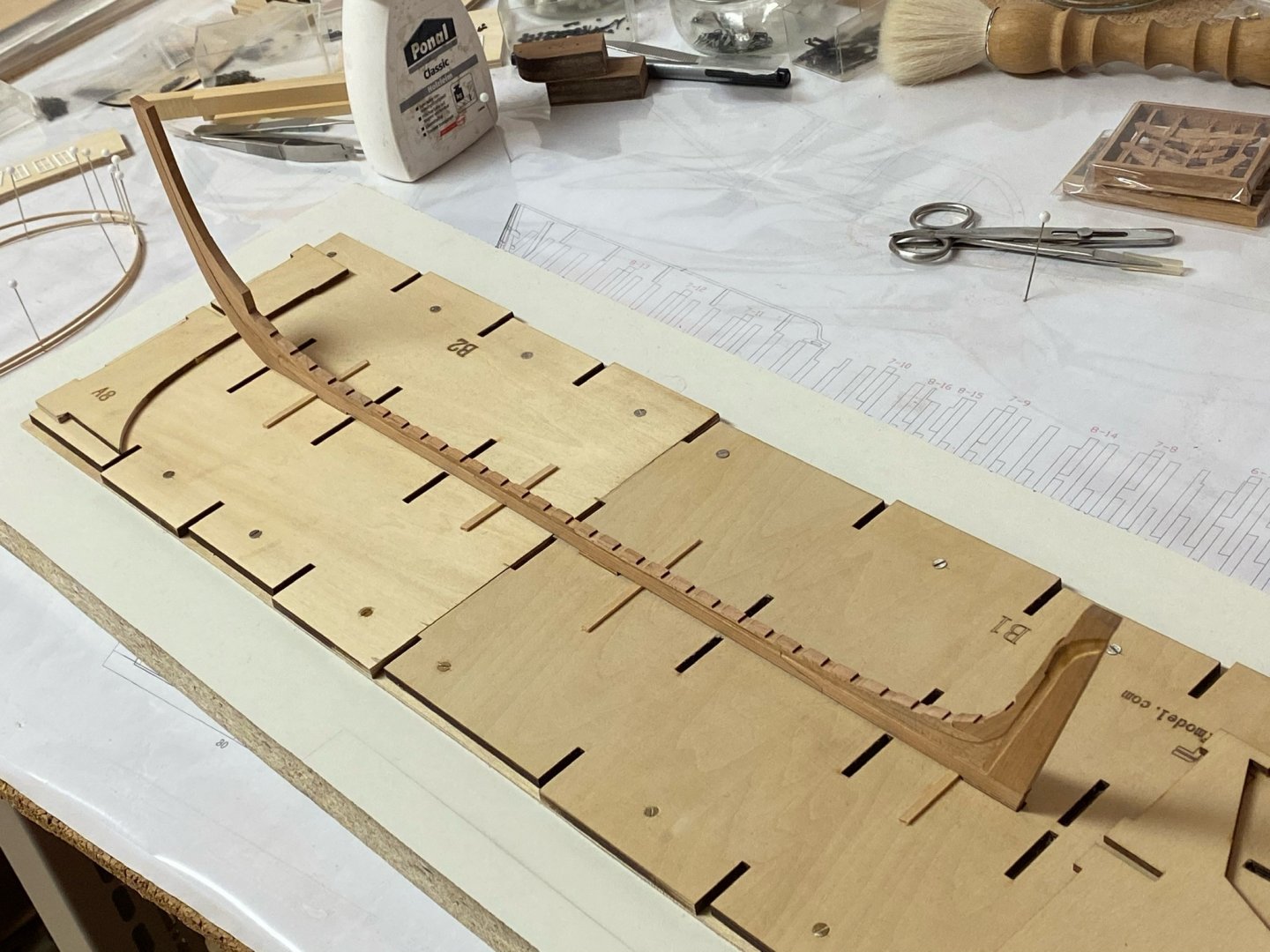

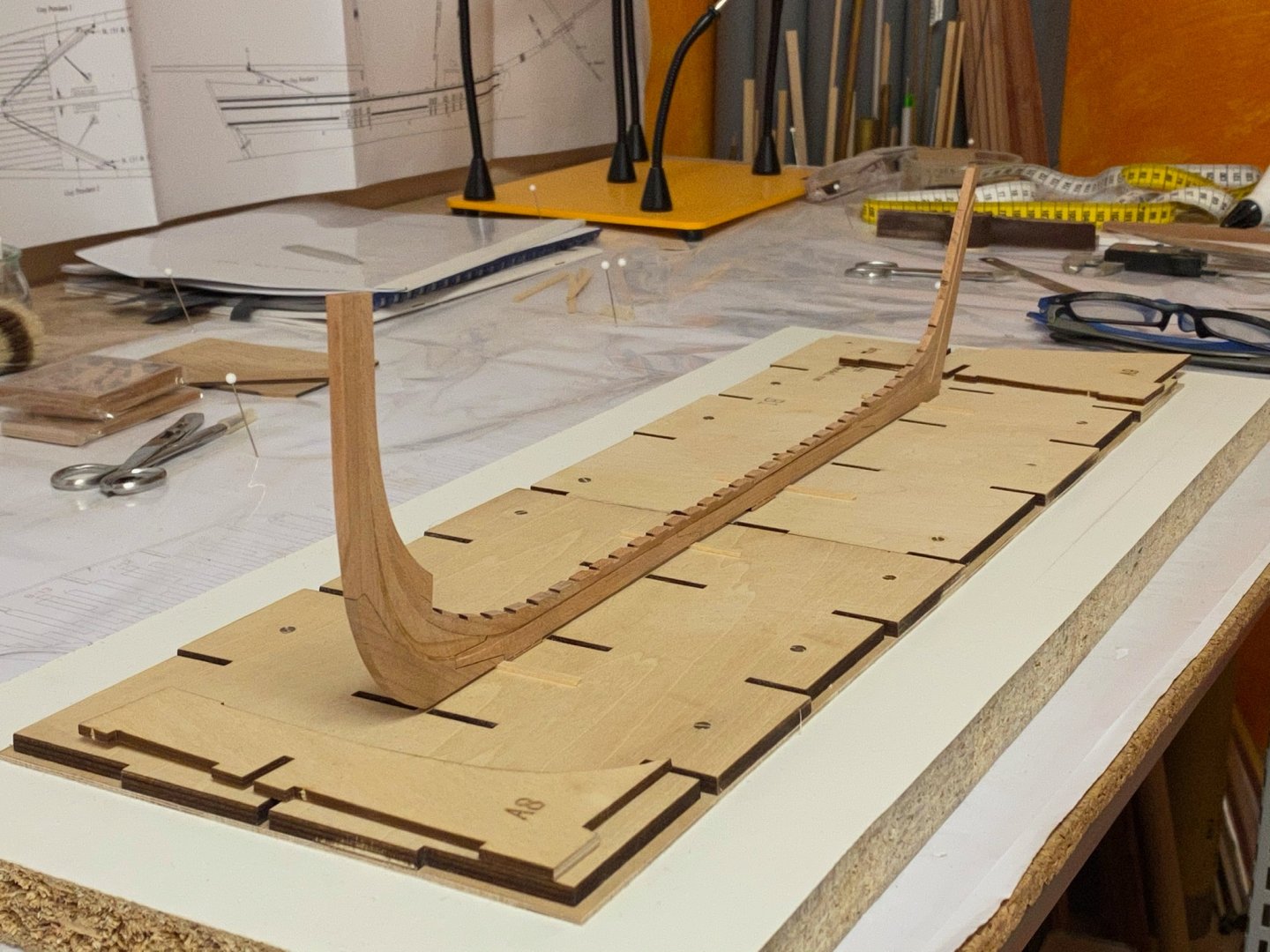

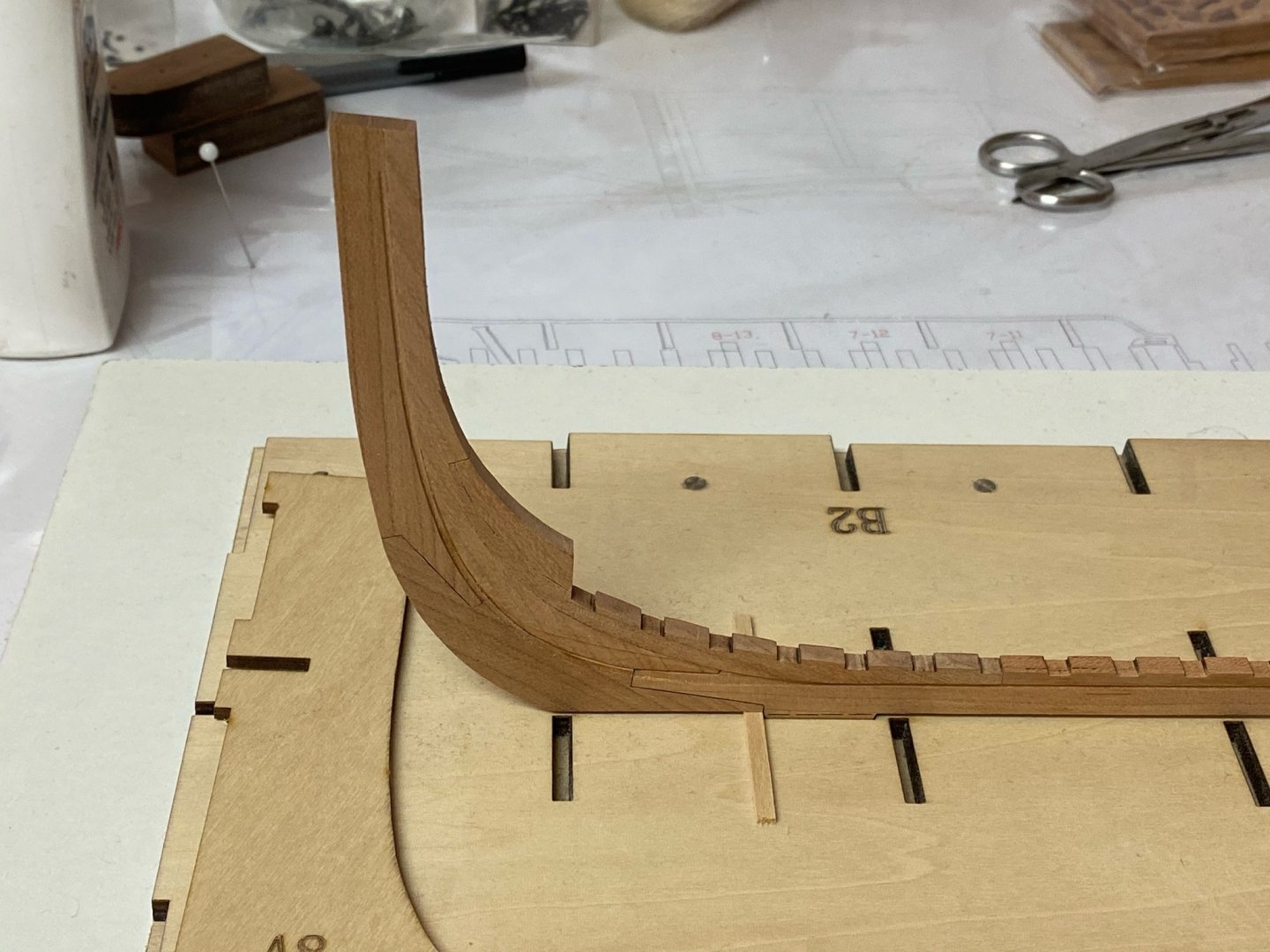

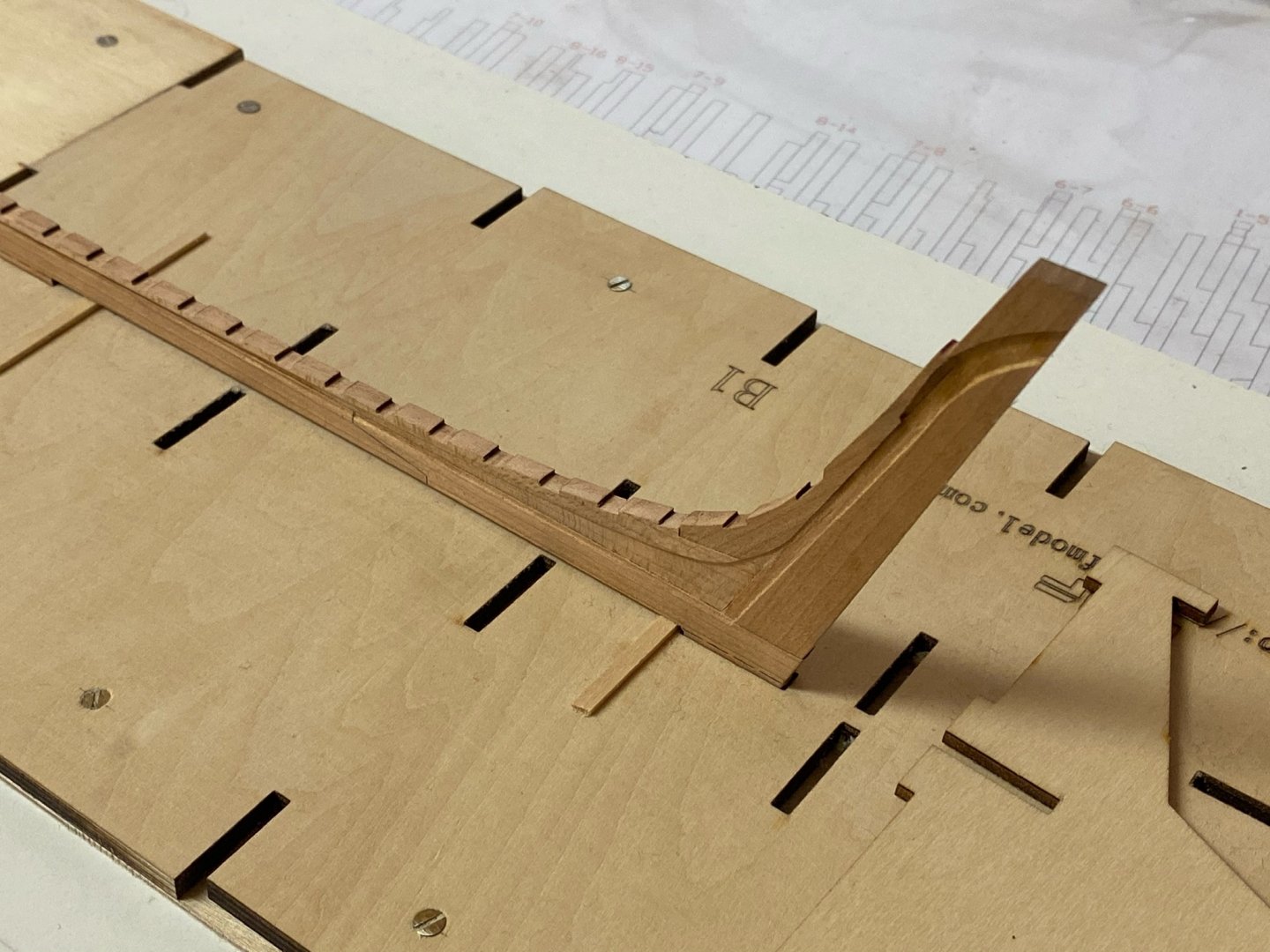

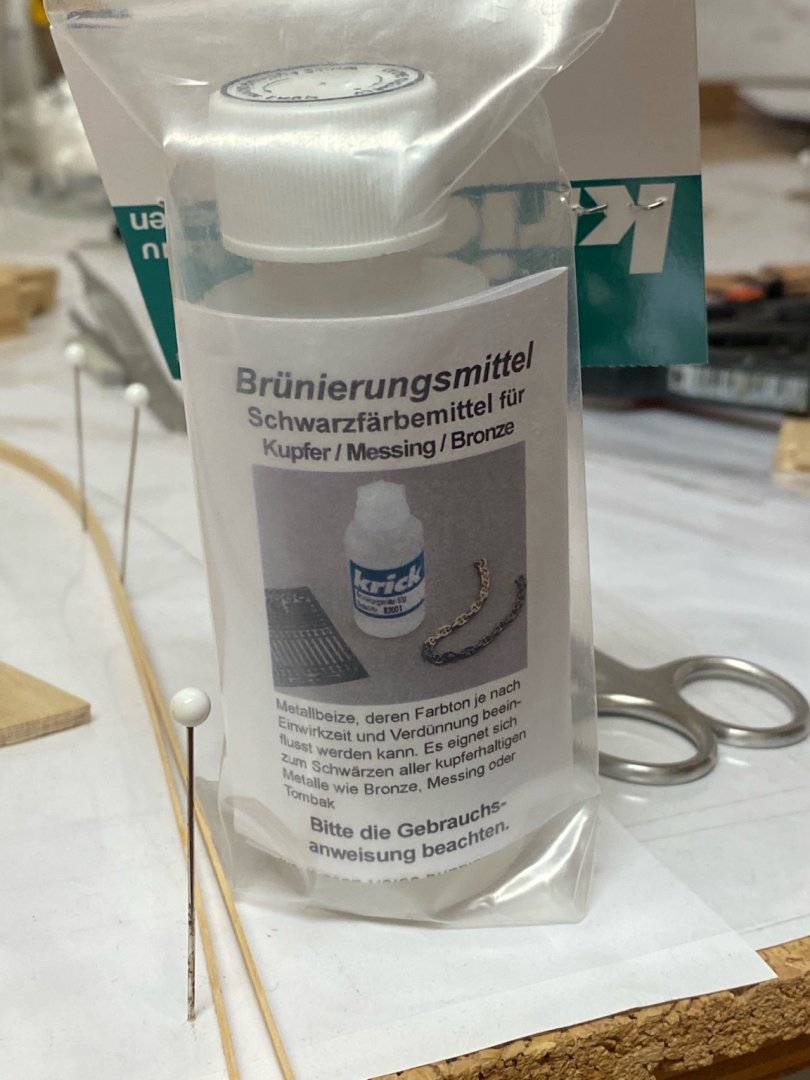

Started to clean the keel parts and dry-fit them on a flat surface. As the laser cuts with an angle, the sides have to be carefully sanded to get them orthogonal to the surface. Will continue tomorrow... @JJT I use a chemical blackening from a German company called Krick. The parts have to be threatened with cleaning petrol first (to remove fat and fingerprints) and then cleaned with distilled water. Then the parts can be threatened with the Krick „Brüniermittel“. It is heat activated (more temperature means faster blackening) and the colour depth is depending on how long you put it into the chemistry. After another cleaning with water the parts are ready to use. Very easy application. Works with copper as well.

-

For comparison: The upper one is the supplied 2-pounder and below a 4-pounder gun barrel which will be used for the Badger - both 1:48 scale. I believe these long low-caliber guns were called ‚falconet‘ - a kind of sharpshooting gun. Not able to penetrate any ship’s hull but able to target crew members.

-

I also started to chemically colour the brass parts. These are brass casting parts that need some post processing. The gun barrels for example are nicely detailed but had to be sanded, drilled and to be bend to shape. Now they are ready for installation (which won‘t be done soon). BTW they seem to be largely oversized for 2-pounders but matches the ones shown in the Le Coureur Manual and plans from Ancre that has arrived meanwhile. Stay tuned...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.