-

Posts

1,327 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigersteve

-

Pandora by marsalv - FINISHED - 1:52

Tigersteve replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

It was a pleasure to follow along. Steve -

Nice progress! Congrats on the finished planking. Steve

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck, is this the method you used for the previous planks? Was there any edgebending earlier? Also, is this method better for a hull like your Confederacy? Steve

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

And so it begins.. glad to see you’ve begun! I think you need to follow Rodger’s advice and remove all the rigging after you photograph everything. (Save all blocks and dead eyes) Don’t worry too much about cleaning the decks to perfection. Remove as much dust as you can with the swabs or whatever gentle techniques you can think of. Remember, you will do some light sanding with fine sandpaper (320 or finer) before you refinish. There are many wood finishes to consider when you reach that point. Some leave more shine than others. I think many will agree the less shine the better. I would advise against using any stain, as that will alter your grandfathers work too much. Minwax Wipe on Poly (satin finish) is used by many to provide a finish that will give you a polished look without too much shine. More on application later. There are many approaches to each project. You’ll figure out the best methods for yourself. I’m sharing how I would approach this if my grandfather left it to me. Steve

-

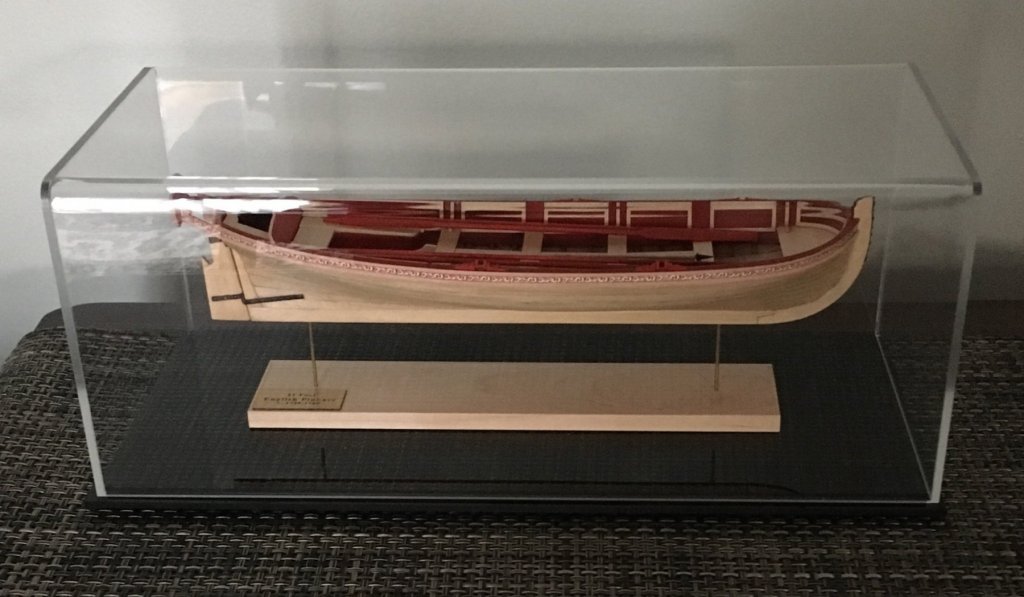

Thanks for the compliments and likes. Mike- I like the black base. It is a glossy finish, but that doesn’t distract from the model. I just wish I had increased the dimensions a bit. I’ll have to get used to it. It’s a bit different design and finish than the case for the longboat. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

One of the best designed and crafted display bases I’ve seen. It compliments the model very well. Beautiful work! I thought your other base was great too. Steve

-

The acrylic display box arrived from https://www.casesforcollectibles.com/ I did not order from the previous company because of high shipping costs. The box arrived well packaged and I am pleased with the quality. However, I did not realize the top surfaces along the width would be rounded. This distorts the view from some angles. The case should probably be about an inch taller and perhaps an inch deeper. This was another tricky photographing session. It’s much more clear in person. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Gondola by AntonyUK

Tigersteve replied to AntonyUK's topic in - Build logs for subjects built 1901 - Present Day

Interesting build. Steve -

Pretty cool, Rob. No slide? Lol Steve

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

QUICK-FIND INDEXES to BUILD LOGS FOR KITS

Tigersteve replied to Dan Vadas's topic in - Index of all kits by brand and subject

Mark one more small craft finished. -

That’s some very nice work all around. Steve

- 48 replies

-

- first build

- bowdoin

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.