-

Posts

5,961 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Glad to hear you had a great trip Glen, even if you put on a couple of extra pounds (sounds so delicious - envious). Looking forward to seeing how you put all those parts together in that bottle; you're making great progress mate. cheers Pat

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

I thought they were the only type of jigs to build John Noice work Steven. cheers Pat

- 110 replies

-

- Paddlewheeler

- Ballarat

-

(and 3 more)

Tagged with:

-

Short answer I think is that it depends on the era and nationality of the vessel. In some ships some of the ratlines started on the leading shroud, but others on the second, and some terminated on different shrouds also, others were staggered in a specific pattern. For English ships, Lees is a good references. For French ships I would suggest Boudriot is a good reference as he is very familiar with French ships. Some research will be necessary to determine what is right for the ship you are modelling for 1577. Some more knowledgeable people here may be able to assist further if you could provide the name/nationality and rate of the vessel. cheers Pat

-

Nice 'bodging' Eberhard, the crew are looking good. Your steady hands have come to the fore with some really well defined fine detail showing. cheers pat

-

18th Century Iron nails

BANYAN replied to tmj's topic in Building, Framing, Planking and plating a ships hull and deck

News to me but an interesting idea/practice. I am researching in the 19th century and have not yet come across this, but I have not really been looking. If I find anything I will get back to you. cheers pat -

Great to hear all is good and see you posting again Michael; I have been missing the Cutter updates. However, life decides our priorities so will wait patiently. cheers Pat

- 2,215 replies

-

That's a lot of detail in a very small space Glen. It's inspiring watching you sort through all of the sequencing issues to get it right. cheers Pat

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

Congratulations again Rob, your excellent model is a very realistic representation of Mackay's majestic vessel. The level of detail make it difficult to discern between the real and the model sometimes. cheers Pat

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

So fighting fire with fire so to speak Glen? Let's hope it never gets to that point. cheers Pat

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

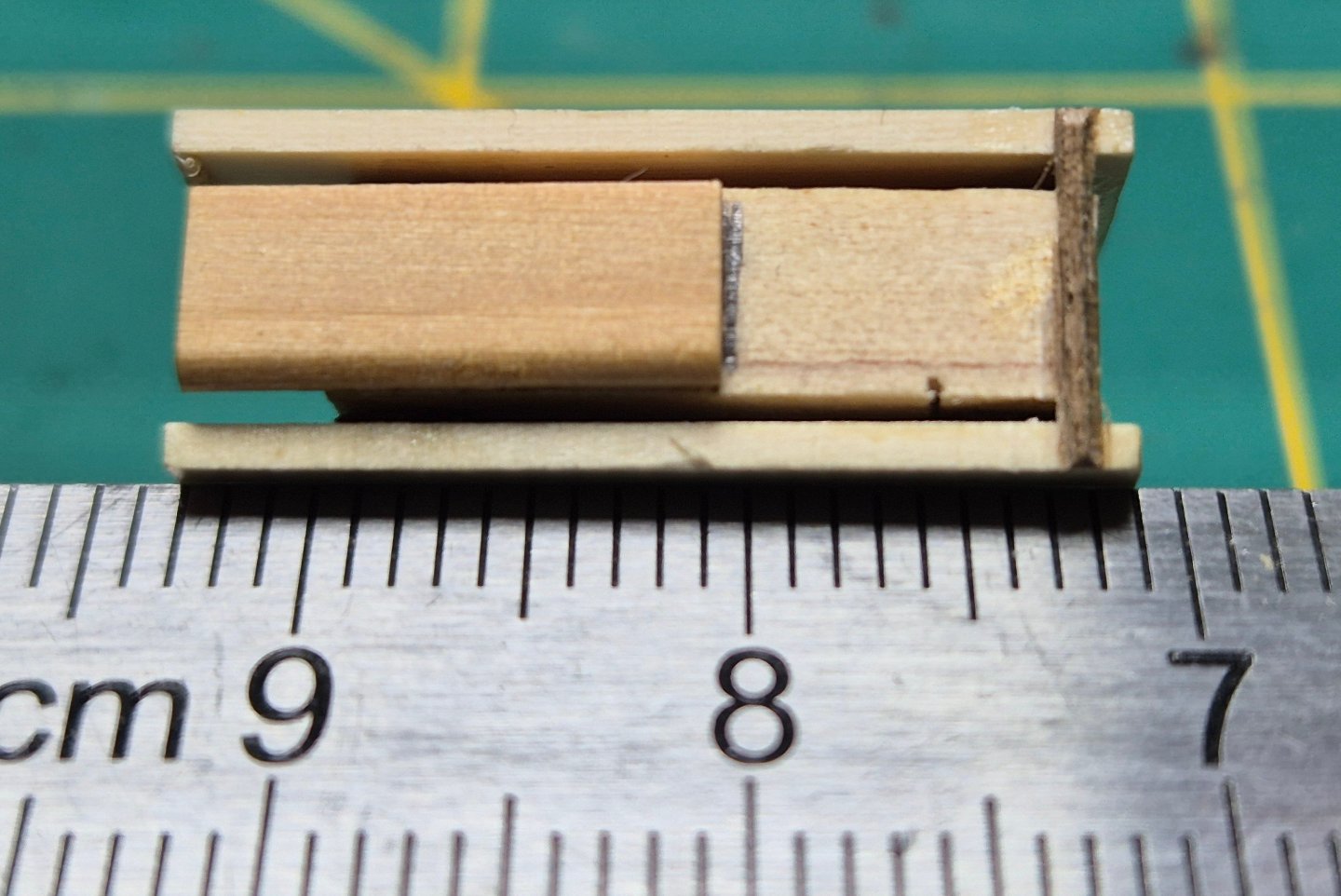

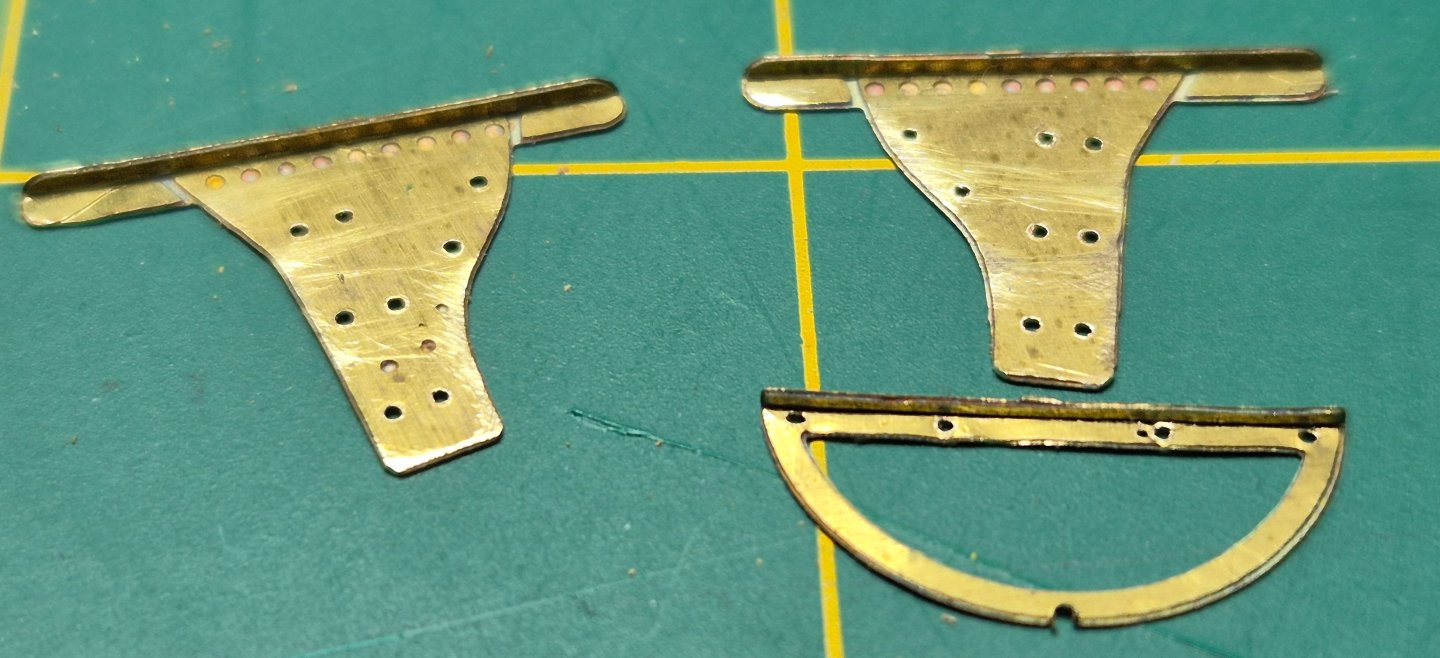

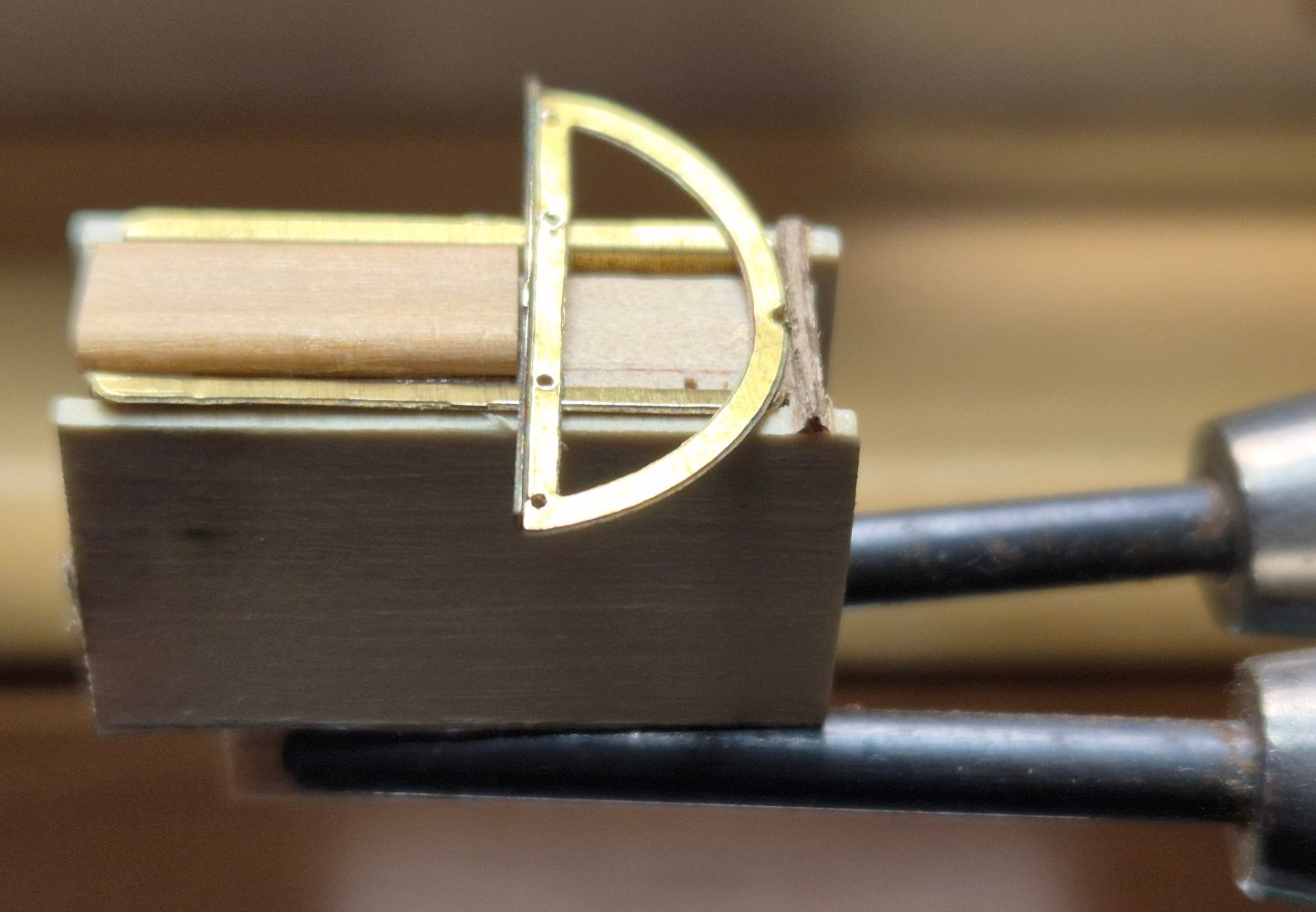

Thanks @wefalck, @Glen McGuire and @Jim Lad, appreciate the feed back. Eberhard, I did have the same idea but using the actual mast. That is pin and glue the cheeks in place first, but with the very small items I was concerned about keeping the tops of the trestletrees parallel and exactly aligned. This jig at least keeps one of these variables (spacing) under control, and with a bit of care should be able to control the parallel aspect. The central spacer is exactly the width of the masthead BUT, there is a tiny bit of 'slop' in the hound/cheek slots, so I may have to seriously reconsider your idea. Glen one of the three key 'bodging' tools - duct tape, 16 gauge fencing wire and a big hammer. I may have to resort to duct tape if all else fails - then again I could get those pesky penguins to hold it in place if Keith will spare a couple - yeah I know 🤐 John, if I hadn't already made the masts that could have been an serious option to consider; thanks for the idea. cheers Pat- 1,018 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

A little more to report. I have been experimenting to determine the best jig to solder these tiny pieces together. The following show a very rough version of what I think I will try. The principle seems OK but the jig needs a little 'finagling' and then to be remade in a denser wood before I dare attempt any soldering. The brass PE parts have had holes drilled to accept the through mast bolts, but as is obvious, they need a lot more clean-up yet I am open to ideas to modify this jig before committing so please have at it. The general idea is create 2 slots held in place at the width of the masthead flats. The rim, which has yet to have the fore part of the rim soldered to it (see much earlier posts on this) then sits on top of them, and, after centering it, will somehow be held in place so that it does not move - I am still trying to sort that bit. The final shot shows how it will be held in my soldering station when I get around to soldering. Then I have to think about how to put on the crosstrees with the iron rod (brass) stays pre-attached to the cross trees and the futtock band... but, that is a problem for 'future Pat' as the saying goes. cheers Pat- 1,018 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

A well dressed (painted) crew you have there Eberhard. You must still have very steady hands to achieve this level (quality) of work. cheers Pat

-

Keith would probably suggest a Penguin sitting on the lip of the funnel steaming its 'hot dog' in the waste steam cheers pat

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

She's coming on splendidly Ian, looking great! Some very neat lashing there, bodes well for your rigging to which I am ;looking forward to seeing. cheers Pat

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

Hi Glen, great progress and a joy to follow along mate. If not too late, what you describe as a 'spine' to the rear of the smoke stack (funnel) is actually a separate pipe with a slightly flared top which was a steam release pipe associated with the safety valve on the boilers. See attached. At your scale though this would be difficult to create (although some brass wire/rod may do the job), and as I said earlier, maybe a little late to change even if you wanted to. cheers Pat

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

Hi Rob, are you hinting this is your last model? cheers Pat

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks for the feedback Glen. I find the way you sort out these 'puzzles' is of great interest to me (being a non-SIB builder). Have fun reading the book, looks interesting. cheers Pat

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

Those images prove the high degree of your excellent research and skills Rob. Hard to tell/find any differences. cheers Pat

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Stunning progress Glen, she is looking great. Hopefully you will be able to maneuver the assembly into position without much of a problem. I am assuming the fore-funnel will not be placed until then? Cheers Pat

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.