-

Posts

5,938 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Great present Dave, you will have plenty of fun with that. cheers Pat

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

That's a heck of a lot of work very nicely done Dave and should make into very nice boats. Thanks for sharing your info and efforts; much appreciated. cheers Pat

-

Hi Dave, that is one model to be very proud of, especially haven taken the plunge into carving - I have yet to take that challenge so I dip my hat to you! I found the clean building table nice for a day or two but had to get on with something, even piece-meal, after a week or so; the club's build (HMCSS Victoria now has pride of place but I have yet to do much Enjoy the break and have a safe and happy festive season. I very much look forward to your "Connie"; ast 1:50 that will be a great scale for you to add detail. cheers Pat

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

That's looking very good Sjors, a really nice model of Aggy; ...... and many thanks for your consideration - two photos for two eyes - let it be known that I am not a one-eyed critic I am also intrigued, what is that clipped/fixed to the main mast (or is it just a perspective thing with the photo and it is not attached? cheers Pat

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Nice job on those flags Dave; they look great. The model looks superb with all its livery. cheers Pat

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

That looks very good Dave, just the right amount of detail. cheers Pat

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Hang in there Denis; it will be worth the frustration of construction in the end and provide some more lovely detail! cheers Pat

-

A bit of dust just adds a great patina Sjors; adds to the intrigue We can wait (but not for too much longer ) cheers Pat

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Crikey Greg, that is something else - great work. All those long hours with fiddly repetitive work are showing their fine results. cheers Pat

-

Gun Port Lids

BANYAN replied to wq3296's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Hi Pete, again you touch on something I have found in researching HMCSS Victoria. Take a look at page 61 of Rudiments of Naval Architecture.... by James Peake (1851). It is a Google Book free to download as a PDF. Unfortunately, only a line drawing of it, with a supporting text description, but may be of interest? Victoria was fitted with Lang's Scuttles (mentioned on the same page) which removed the need for the Illuminator. The description of the illuminator reads: "Illuminator for light when the port lids are down". So basically just a round glass filled opening Lang's scuttles were conical shaped lumps of glass fitted on the end of a threaded rod, which could be wound in and out of a similarly shaped hole in the hull that would allow light in when open or closed. When open, air could come in around the cone (smallest part outboard). In the Victoria, the size was 5" diameter. As to the opening question - on the same page of this reference (valid in 1851) Peake states: "On the upper deck of line-of-battle ships, and main deck of frigates, the ports are in two parts; the lower one hung with hinges on the lower part of it, called a bucklar, and the upper part a half port to put in by hand". This would imply even in the 1850s, gun port lids were being fitted to the open decks of vessels? cheers pat -

Bad luck with those splices John; not enough tucks? Another milestone completed and shee is looking good! Look forward to seeing all those little details appear. cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Great idea and good results. Thanks for sharing. cheers Pat

-

Nice technique with soldering that ring into place Michael. cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Sorry there has not been an update for a little while, I am back at the PC drawing up the plans, and continuing the research. I am going to have to ensure a quality build noting the experience and abilities of the build followers cheers Pat- 1,006 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Wow what a comeback Glenn, I had been missing your updates. Those skylights are stunning. I will be making some for my Victoria project in the coming year and wish I had CNC. I have the mill but I don't think I would use CNC enough to get value-for-money; may need to investigate a little further noting the great results you achieve. You truly are the master of metal; those 'charley nobles' look great, and a neat construction technique. I am learning so much from following your build log; many thanks! cheers Pat

-

A Lorch Micro-Mill that never was ...

BANYAN replied to wefalck's topic in Modeling tools and Workshop Equipment

Now that you have almost completed your prototype, I'll send over my 'Lanco' for you to adapt Very nice work Wefalck; that will be a very useful mini-machine and a fine addition to your wonderful workshop. cheers Pat -

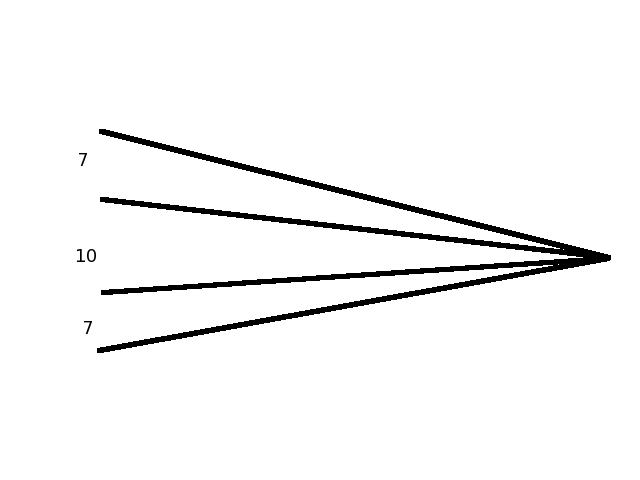

JT here is a rough copy of such a fan someone posted on this site I think (sorry cannot recall who). These are the proportions by which to reduce square stock to get an octagon (the 10 is the meat that remains). Simply place the square stock on the fan so that the edges of the stock meet the outer edges of the '7' fan lines, then mark the wood with the other lines. The lines should be ruled with a straight edge back towards the centre to reflect the angle of taper rquired. For some yards, not direct to the centre but to the point of transition from straight octagonal to taperered round. These then give you the guide lines to which you reduce the square stock with plane, chisel, file or.... Note: the square stock should be reduced to the appropriate thickness before starting, such that the width of the meat [10] ends up wide enough, that after rounding, is the correct diameter of the round - this takes a little calculation. Always better to err on 'bigger' so that you can reduce; harder to add Once you have the round, even in taper, it is relatively easy to maintain it with further sanding. cheers Pat

-

Adapting what we have in accordance with our skills is the key Dave - I see a very nice capstan cheers Pat

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Nice work Michael, those stays especially are looking very good. cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.