-

Posts

8,149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by allanyed

-

Paul, I just now noticed your log and after seeing the latest posts went back to the beginning. Congratulations on all the research you have done and replacing so much of the unrealistic kit parts. Very well done! When you were doing the bottom, did you consider replacing their copper sheathing material with something more realistic like what you show in the McKay close up drawing? Thanks for sharing your build!. Allan

-

Understood, it happens to me every once in a while as well (read that as every five minutes or so)😀 Allan

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

Mark The marks may very well be frame locations on your drawing, but be aware on future builds, they are usually station lines and do not necessarily coincide with the frame locations. In checking a number of framing disposition plans many have the forward EDGE of the floor aligned with the station lines aft of midships. The station lines are in line with the aft edge of the floors that lie forward of midships, never centered. One example where some stations match the edge of the floor and some don't match can be found on the HMS Director, 1784 for which there is a high resolution drawing on the Wiki Commons site https://commons.wikimedia.org/wiki/Category:Ship_plans_of_the_Royal_Museums_Greenwich It follows but may be easier to open and enlarge from the commons site and will be in high res so you can see the location of the frames compared to the station lines which are not the same. Allan

-

Good progress Glenn! One question, are you going to replace the strakes of planking so the butts on adjacent strakes are not on the same frame? There is usually a pattern of the butts that you can see on an expansion drawing. Allan

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

Lyle, What do you mean by splice patterns? I am aware of butt joints, drop strakes, top and butt planking of the wales, etc, but spliced planking is a new one for me. Thanks! Allan

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

Welcome to MSW. It would be a polite thing if you would post an introduction about yourself (including a name besides W) on the new member forum here at MSW. If you post your question with a picture in the appropriate forum such as Ship's Deck Furniture, Guns, boats and other Fittings, (not Nautical History,) someone will probably respond. Allan

-

Hi Rob, I have attached a photo of a contemporary model of Victory circa 1765 at RMG. I assume the kit gives their own design, but note the level of the top of the gratings compared to the coaming and ledges, and the cross pieces in the waist rest on metal saddles as there was no coaming around the waist. While this is not exactly as she appeared overall in 1805, (she still has a white bottom versus copper sheathing) these features are still valid. Probably a relatively easy fix. Allan

- 395 replies

-

Michael, I hope you are correct in that the kit makers start using 3D printed parts for some things. Cannon barrels are perfect examples. I have used a 3D printer for various size cannon barrels lately in black resin and they are fantastic. My only concern is most kit makers will continue to forgo thorough research in preparing the drawings to be sure the barrels or other items are shaped and sized properly for the era of the ship being kitted. Allan

- 371 replies

-

HMS Bounty by AdamA - 1:48

allanyed replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

These look good. They are obviously overly heavy regarding the moulded dimension, as they should be, to allow fairing, but you might want to reduce the moulded dimension a little more before erecting the frames. The fairing can be done either way, but as the top timber moulded dimension is probably in the neighborhood of 4" at the top, maybe get it down to something a little closer before setting them in place. Whatever works best for you is the way to go, but I have done it both ways and find the less fairing needed the more I like it. Continuing to enjoy your log, thanks for sharing. Allan -

scale

allanyed replied to Pirate's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Pirate Why do you think a weathered ship would have larger blocks than a ship that is not showing weathering? Regarding spares, there was a myriad of spare parts (stores) on board, including line, blocks, fasteners, wood, et al. There were gunner's stores, medical stores and carpenter's stores on board to name a few. Consider the damaged parts from an engagement with an enemy vessel. They assumed spares might be required. It would be interesting to find a list of such stores as was specified for each rate by the Admiralty. I did some checking and found a list of stores on board in Richard Endsor's The Master Shipwrights' Secrets that had many items including standing and running rigging materials, but it did not give the sizes or quantity. I hope your research digs up some information as this is an interesting topic. Allan -

scale

allanyed replied to Pirate's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Why do you think that a weathered model uses larger blocks (pullies) than non-weathered models? You wrote above Am I correct that you mean the 18th century (1700s)? Allan -

Welcome to MSW Hans! I suggest you post an introduction about yourself in the new member section and mention your idea there. Please consider finding contemporary plans of a ship to build a 3D model as the above is from a kit from OcCre and their kits are sorely lacking when it comes to accuracy. Michael has done some great work with his kit bashing to improve the model but many things are direct from the kit and pretty much a fantasy by the kit maker rather than resembling anything close to reality. There are plenty of high resolution contemporary plans available on the Wiki Commons site if you take the time to go through them that may be better suited to your project. https://commons.wikimedia.org/wiki/Category:Ship_plans_of_the_Royal_Museums_Greenwich Did you study the forum here on MSW on 3D and CAD articles? https://modelshipworld.com/forum/34-cad-and-3d-modellingdrafting-plans-with-software/ It may give you some ideas and a place to share your project with like minded members. Allan

- 371 replies

-

Was Howard I. Chapelle Controversial

allanyed replied to SaltyNinja's topic in Nautical/Naval History

I only have Chapelle's American Schooners book. have used it extensively and will continue to use it, but it takes forever to find anything once getting to the Notebook of Details half of the book. I realize it is a thrown together compilation of papers/drawings that he and others prepared, so is organized in something of alphabetical order rather than subject. If you want information on rigging for instance you need to look for one chapter on blocks, another page on "main boom iron work", another paragraph on gaff downhauls and the list goes on..... and on. I have a sincere love/hate relationship with this book and would quickly drop the hate part if there was a detailed index for the Notebook section of the book and the segments were organized in a manner in which things can more easily be found. The index that does exist only covers up to page 311 and the Notebook section goes from pages 312 to 683 with no index. Allan -

Your workmanship is superb and your photos give me renewed faith that a quality kit can be produced thanks to Chuck Passaro's efforts. I hope some of the other kit producers learn something by taking note of the materials used and attention to detail that comes with Syren's offerings. Allan

- 112 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

This is an interesting point for me. As the boats were usually stacked one on another depending on the number of boats, rate, etc, Were they actually covered or did they have drain holes that were plugged when set asea? I looked, but so far found nothing on boats ever being covered in the 19th century or earlier.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Was Howard I. Chapelle Controversial

allanyed replied to SaltyNinja's topic in Nautical/Naval History

While I am in agreement with the sentiment, what does this have to do with Howard Chappelle? -

It never dawned on me to make so many things off the ship then install a complete unit. It has to be much easier to assemble ahead of time but getting an exact fit into the hull must be exasperating at times. Templates, templates, templates. Beautiful work!!! Allan

-

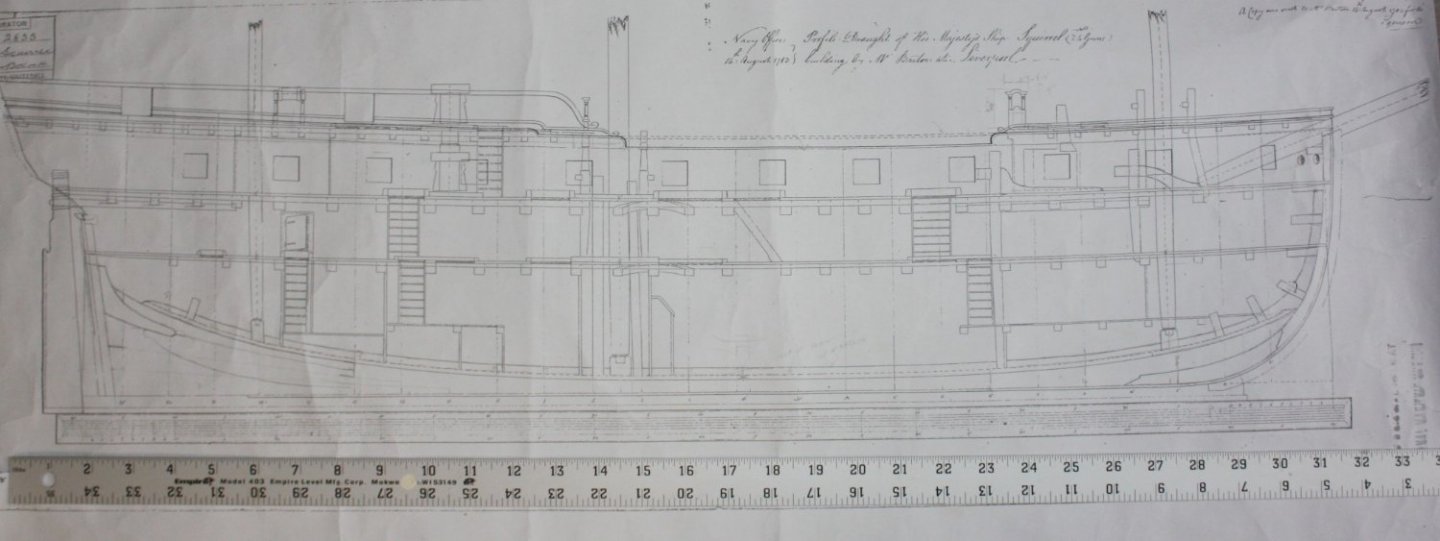

Jud, Suspicious perhaps, but look at the contemporary drawing of a 64 below and the fact that the bitts are a few inches from the stove. If you research other contemporary drawings and you will see this practice was not uncommon. Squirrel 1785 inboard profile below also shows how close the bulkhead is to the stove. Hold a piece of wood or paper a few inches to the side of a hot grill set at 500 or 600 degrees or a fire place and it does not catch fire. (At least it didn't when I tried it) 😀 Allan

-

Hi Gregory, In addition to time periods, Lees refers to various rates for lower masts lengths and diameters, bowsprit, and rigging for the lower yards, top yards and cross jack. Vadas correctly carried this through in his spread sheets based on Lees' ratios (except as many know for 1670-1711 where every figure is wrong as he did not use the proper formula) Allan

-

Hi Bill, Thank you for sharing your build, it is a joy to follow. Couple things about copper sheathing, I really hope you don't mind me butting in. If you feel you must show the fasteners, keep in mind they would be nailed with something like 1/4" nails that had heads about 1/2" diameter spaced about 2 inches apart. This means there would be dents, not raised bumps that are only 0.04" diameter at your scale. Yours look to be about 2 inches in diameter and up against each other. Also, the plates overlap on both vertical and horizontal edges 1.5 inches rather than sit next to each other so the nails on the edges went through both plates at the overlaps. The plates on larger ships were 48X15 but for the cutters, I could not find anything so they may be a little different overall size. Below is a sketch of plating superimposed on your picture. Also note that the plating was about 0.13" thick at most which at your scale would be essentially foil that is 3/1000" thick so can be bent by hand with a simple straight edge. For a really nice history paper on cutters go to https://media.defense.gov/2017/Jul/02/2001772348/-1/-1/0/USRCS1789-1849.PDF Everything from letters from Alexander Hamilton, to crew lists, to pay for each rate. Captains on one list were making $50 a month!! Allan

- 89 replies

-

- bluejacket shipcrafters

- revenue cutter

-

(and 1 more)

Tagged with:

-

Do add it to your B'day list. I reference this book continually when doing any rigging on rated vessels and even more when rigging questions come up here at MSW. Towards the back of the book are a series of ratios for mast and spar sizes and every rope on ships of various sizes from 1625 to 1860. The Danny Vada spread sheets here at MSW can also be used for sizing in this period as they is based on the Lees ratios. The only exception is between 1670 and 1711 where he apparently used the wrong formula so none of the sizes are correct. Allan

-

IF possible JD, I would suggest getting Lees' Masting and Rigging. It covers a lot of years and is explicit in words and drawings for all rates of ship. I don't know about The Art of Rigging, but Rigging Period Ship models is based on one ship, Melampus (36) thus there may be discrepancies with Bounty, a much smaller ship. Allan

-

Gregory, go ahead and open the can. 😀 I think hearts would be more appropriate for the period but Bounty may have had rigging that was anomalous to rated vessels. Allan

-

Super congrats Reece. Looks like you got a great start with the dory model. One little trick to make the handles round, if not tapered, is to drill a hole in a piece of brass, aluminum or steel, cut a couple slots and then chuck it in drill or drill press and run down the handle area. Picture below when I used it to round the axles on gun carriages. Allan

- 9 replies

-

- Model Shipways

- Lowell Grand Banks Dory

-

(and 2 more)

Tagged with:

-

Welcome Dan!! What Mark said above.... in other words forget a galleon or other large ship until you give a try on something smaller and simpler. It will avoid frustration and wasting your money by taking baby steps before running a marathon. Cheers Allan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

_FRAMINGPLANRMG_J3139.thumb.png.499b057f362f0b0b33305b7f1cbf79b1.png)

_Nassau_(1785)_UPPERDECKRMG_J3360.thumb.png.e01dcd4229f669e1d780eec04a08c654.png)