-

Posts

8,149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by allanyed

-

Thanks re: the port lids. This is what I expected, but the reason I asked is that there are port lid stops in the ports. I understand their use when there are lids, but why are they there when there are no lids? This may have been normal but common sense usually prevailed so why not just have the frames and sills as the lining as seen on a number of contemporary models where no lids were used? Looking at photos of models at Preble Hall and RMG, there are a few models with stops in the waist area even though there are no lids, but most do not have stops. With all the exactitude in the RN, this inconsistency surprises me a bit. Thanks again Allan

- 113 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Your model looks REALLY good!! I know it is still only part way through the build, but did Cheerful and/or other similar cutters have any gun port lids? Thanks! Allan

- 113 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welcome to MSW Michael. It would be nice if you would post a little intro about yourself in the new member section. Regarding your question, Caruana gives similar dimensions and is specific that these are circumferences. For breechings he has a table on page 385 in volume II of The History of English Sea Ordnance for various years from 1723 to 1765 as the sizes changed, especially in 1747 so the era is part of the equation as well as the gun size. Allan

-

Hi Jon, It is great to read about the history there in Boothbay. You are fortunate to be in an area loaded with maritime history. Allan

-

Super warm welcome Shaun. I have not had a chance to visit SA for many years but I have fond memories of the folks I met in Capetown, Durban and East London back in the day. Know that you have over 40,000 new friends here. Allan

-

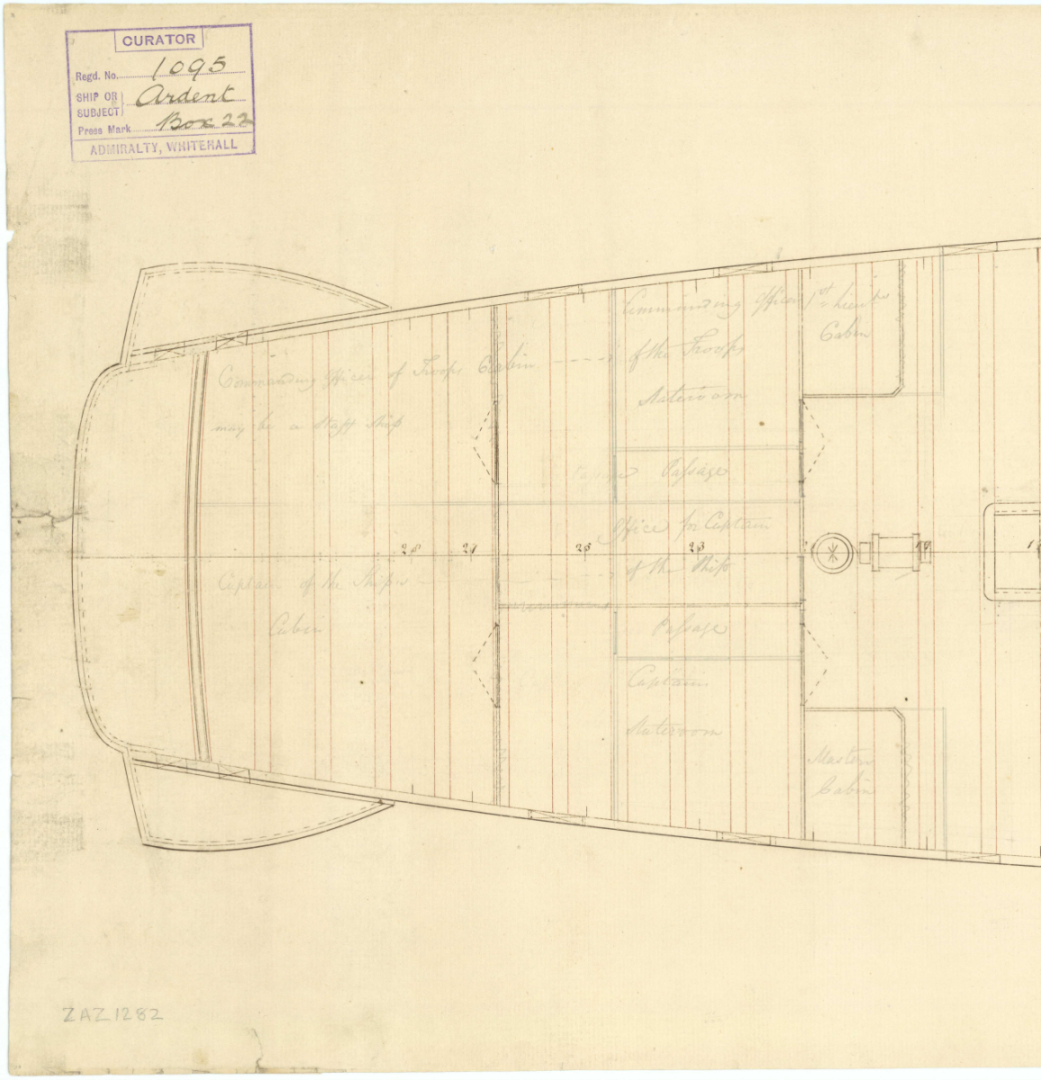

As with so many things with these ships a lot depends on the ship and the era and possibly nationality. Looking at the Ardent (64) 1764 plans below there are no gun ports in the Captain's cabin, but two in the Captain's stateroom starboard side. I would guess the same layout would be appropriate for Indefatigable before she was cut down to a frigate in 1794. Looking at the QD drawing of Indefatigable 1794 at the RMG Collections site, when she was razeed the layout changed and there were two gun ports in the Captain's cabin, one port, one starboard. (www.rmg.co.uk/collections/objects/rmgc-object-82166). Allan

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

There are several closeup photos of contemporary models showing anchor mounting details in Lees', Masting and Rigging just after page 181 as well as drawings on page 129. Can't post these as it is copyrighted work. There are some good photos on the RMG site as well. Allan

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Polishing and Varnishing

allanyed replied to Sparky2041's topic in Painting, finishing and weathering products and techniques

Welcome to MSW Sparky2041 It would be very kind if you would please post a little intro in the new member section. What ship/year/etc is your model? Many models we see are shined but keep in mind before the advent of fiberglass and gelcoat, a high shine finish was not all that common. (Polished teak may be an exception) Look at photos of contemporary models. A muted finish seems to be the norm. Sandpaper down to perhaps 400 or 600 grit seems to be sufficient for most modelers. After thoroughly cleaning up any saw dust, an eggshell or matte finish using a spray or brush should do the trick. 3 or 4 coats of a properly applied spray usually looks best not having the worry of brush strokes. Just my two cents. In the end put on a finish that YOU like. Allan -

Love the build, love the sails, all around a great job! Thanks for the build log. Allan

- 104 replies

-

- Bluejacket Shipcrafters

- smuggler

-

(and 1 more)

Tagged with:

-

Welcome aboard! 20 years young-- Enjoy these years! I envy you having this forum at your age and in the beginning of what I hope will be a lifelong hobby for you. Do read EVERYTHING you can here at MSW. It will save you some aggravation and guide you on which kits will help improve your skills. Allan

-

Tiziano, I would like to thank you and your family for our fantastic day in Livorno together. With my little bit of Italian, your little bit of English, our combined little bit of French we had great conversations! Of course as your daughter Erica speaks fluent English, she helped on the difficult parts. 😄 You topped my day by asking me to sign your copy of the Euryalus book and I sincerely thank you for that honor. It was a day I will always remember. Allan

-

As impressive as your model is, the fact that your first post on this was 8 1/2 years ago and you have stayed with it is just as impressive. Kudos!! Allan

- 708 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

BR I am not too sure that you can tint paper consistently. Have you studied David Antscherl's booklet from Seawatch books and the You tube videos by Tom Lauria on making paper sails as suggested above? Allan

-

I use a scroll saw for cutting futtocks of the ship's frames but for 1.48 ship's boat frames, which are about 0.032" - 0.80mm at the top even using castello boxwood, they break very easily before I can finish the sawing, Do you use a power saw to cut the pieces or a coping saw, or a knife, or some other tools? Grazie mille Michele. Allan

-

Absolutely lovely build Tim I particularly liked seeing the use of Lego blocks. I have a handful that my grandkids gave to me quite a few years ago and use them quite often. Just curious, but is your screen name based on the military acronym? Allan

- 145 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Deck planking plans

allanyed replied to KingDavid's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Gregory, In addition, the top and butt planking was sometimes oak whereas the balance of planking was sometimes a different species. This was not uncommon as it is stronger than straight strakes. As you point out I would not be surprised if anchor stock patterns were sometimes used in place of top and butt as well. I believe this is described in some detail in Goodwin's The Construction and Fitting of the English Man of War, but I have no access to my copy for a few days, (maybe longer if hurricane Ian hits us before we get back home 😢) Perhaps another member with a copy of Goodwin's book or other reliable source can shed more light on this. Allan -

Deck planking plans

allanyed replied to KingDavid's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Dlowder Are you referring to the curved beams at the area of the masts that are fayed to the full cross beam adjacent to it? Other than that I cannot think of anything that is a half beam. See contemporary example of Dorsetshire below and please let me know if you are referring to something else. There are many more on the RMG site including Victory upper deck that are similar https://www.rmg.co.uk/collections/objects/rmgc-object-79917 Thanks! Allan -

Tiziano, It comes to the smallest things at times that make the difference and you are giving everyone a great set of lessons in doing this. Pre-drilling the holes wherever possible makes it much easier to drill them where they should be. I will be paying more attention to this in the future. Allan

-

Mine is OK now. I have no idea what that was about. Allan

- 135 replies

-

- Occre

- Santisima Trinidad

-

(and 2 more)

Tagged with:

-

Can't get much closer than that Chris. 😀 What material are the balls? Number 8 shot is smaller but may be hard to find these days although that is what we used when dove hunting back in the day. Great to see your attention to detail in even the small things at Vanguard. Allan

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

B.E. These are way past just a click on the like/thumbs up button. Your boats are some of the best shown here at MSW. Thanks for sharing these in detail. Allan

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Polaris by JDillon - OcCre

allanyed replied to JDillon's topic in - Kit build logs for subjects built from 1801 - 1850

Go to the RMG Collections site for some excellent photos of similar contemporary models. https://www.rmg.co.uk/collections/objects/search/Coastal schooner models Click on each one for multiple views. Not sure any will help, but may give you some ideas for your own version. Allan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

_RMG_J3114.png.ff013ab08b5828d99c1fdf16d253970b.png)