-

Posts

1,543 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mike Y

-

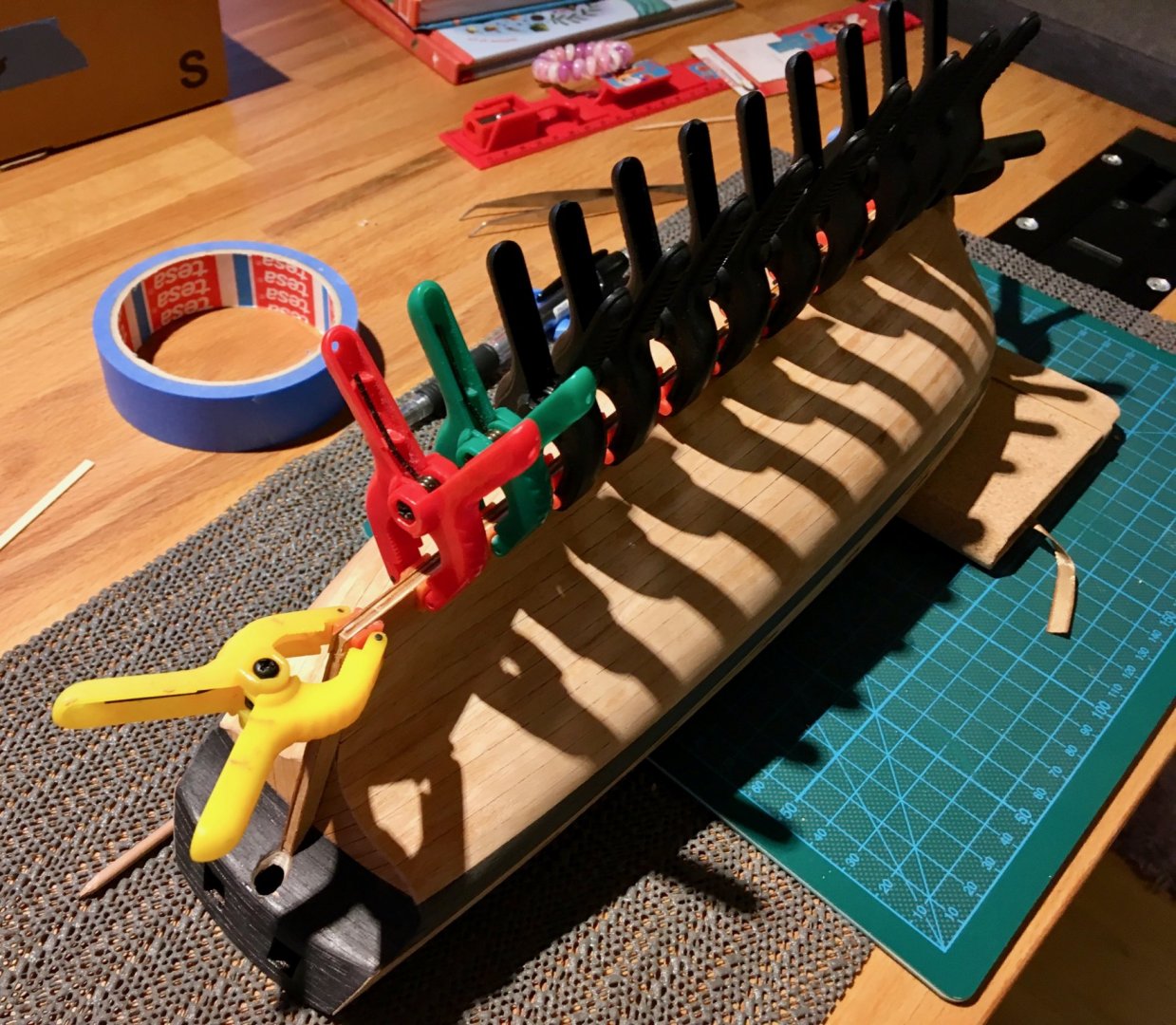

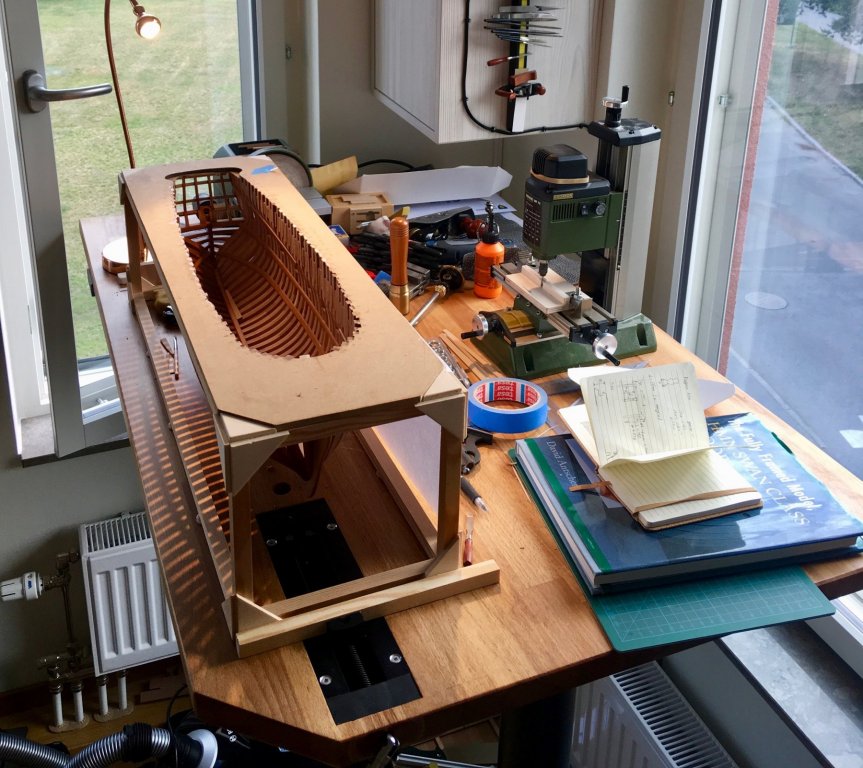

Thanks a lot for your comments! It is becoming increasingly difficult to clamp. Soon it would be a time to try the CA+PVA trick (using CA spots to fix the plank, while the PVA wood glue is setting). And some magic tricks that a Hahn jig allows you to do I love it more and more, it is so easy to position the hull on an angle when planking, avoiding glue drips and just generally orienting things the way you need. The key is to have a vice that can hold an entire jig.

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Thanks Carl, Mark, Pontus and Grant! Grant, Daria is stretching her time between school, friends and various hobbies - she got into dances, bead bracelet weaving (with really tiny beads that are too small for adult fingers), and now nursing her little sister Emelie. We are still working on her model few times per month, more like our own little thing. Soon she is planning to get a pet rabbit, so her time would be even more limited. It is a good problem to have I'll sort out my model on my own, somehow. Even a few sessions per month is better than nothing. Everybody should have a getaway!

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Construction progress is not so fast, for a good reason - we got a second daughter a month ago (yay!). Everything goes well so far, we are a lucky parents and Daria (the youngest) helps us a lot. But, as expected, there is little time for anything... Though I still sneak a plank every now and then, so it is moving with a pace faster than zero, one streak per week on average! Each plank takes from 1hr (for a simple straight planks midship) to 2-3hrs (curved ones with difficult shapes). Sometimes a plank goes to waste, so overall it is not a fast process. It is a nice to get a bit of your own time and work on a model, even late at night. Makes for a good photos Back to the build progress. Got quite comfortable with heat bending, pretty low error rate. But I still feel that the plank made this way is more brittle than the one shaped with steam. Luckily it is not a big issue. Since I did a bad job in fairing, there are some low spots that are fixed by adding a filler underneath the plank: Or chiseling away the high spots: Slow but steady, I passed the equator - 7 streaks done (plus limber streak), 6 remaining! Nothing is sanded yet, and considering bad fairing I expect to spend a lot of time scraping and sanding to make the planks look smooth and fair. There are a lot of glue traces, they would be cleaned up after treenailing. I'm glad I started with internal planking - it is a good training exercise, that would be barely visible on a finished model, hidden under all decks and cabins. Hope to get enough skill to do a better job on external planking Consider this a practice piece.

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

variable height desks

Mike Y replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

Checked IDÅSEN in IKEA. It is actually very good from technical point of view - hard to shake it even when on maximum height, very stable. It is flipped upside down comparing to BEKANT - wide parts of the telescopic legs are in the bottom, narrow ones are on top: Nice design of the control buttons - instead of pressing a button you pull a small lever up or down, very intuitive. I like it! There are two problems though: 1) They do not sell frame only, you buy it with a table top which is too weak for our purposes, it is an office table. So you need to buy a solid table top, making it more expensive. With BEKANT you can buy a frame and put any top on it, a bit cheaper. 2) Leg design, the look a bit ugly for my taste, and I will hit them with my feet all the time... Comparing to a flat design of BEKANT: -

... still hoping that Glenn is doing well and will have an opportunity to come back to MSW some day soon

-

Hi Lawrence, Thanks! I am happy to report that the build is progressing, few planks per week, but slowly getting there. The camera is just a phone, iphone SE to be specific. No extra lenses. It is not always focusing ideally on the right part of the model, but I just make a series of photos from different angles and then pick the ones that are focused on the right places. My wife's iphone 8 is making even better photos, but I am too lazy to borrow it when needed A "proper" camera requires much more fiddling with white balance and such, and can do wonders in hands of people who knows how to use it (see Gaetan), but for a simple build photos any decent phone should be good enough.

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

ancre La Belle 1684 by Nenseth - 1:36 scale

Mike Y replied to Nenseth's topic in - Build logs for subjects built 1501 - 1750

Neat! Very nice shape Please keep them coming! -

ancre La Belle 1684 by Oliver1973 - 1/36

Mike Y replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

Very interesting build, I am learning from your methods and jigs! -

Yes, just bending a cold plank around the former would not work (tried it a few times) - the contact area is very small, so the plank can't get hot enough. So first I heat up the future bending area by using this aluminium former like a clothing iron, sliding it back and forth. Probably a clothing iron is even better, but I did not want to fiddle around with two hot tools at the same time. Only once the plank is hot - it can be hooked to the former and bent. Jorge, very nice solution! It is interesting that there are so many contraptions for the same job, and everybody have different preferences

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Interesting idea with these curved blocks! Need to invest some time into making those as well... I guess they should give a better result then just eyeballing it and using flexible sanding pads to achieve a smooth curve. Have you considered making them from something softer, like a cork block? I made a few shapes with cork when fairing the hull, it is just the right softness level for fairing and it would not scratch the rest of the model if you bump it accidentally.

-

Practiced more today, and so far for edge bending a small clothing iron works better, takes just 15-20sec to heat up that boxwood strip (5mm wide, 1.6mm thick) to give it a slight edge curve. It is not powerful enough to overheat the wood, while a soldering iron is too aggressive. For the other dimension I had a good result with this soldering iron attachment - press it into the wood for 15-30sec, then when the area is hot enough - hook it and bend it slowly. The iron that is shipped with it is probably not powerful enough to make this big chunk of aluminum too hot, so no problems with wood burning and overheating. I do not have enough experience with heat bending really, just a few evenings and a dozen of planks bent in various directions. Thanks Chuck for promoting this method! It works so far, adding one plank per evening, trying not to miss any days The second inner planking strake is done. But I would still use my old preferred method for thick planks (like deck clamps or wales) - dunking them into a boiling (!) kettle for 30-60sec, then carefully bending by hand and just clamping onto a model overnight, with a slight over-bend. Works like a charm, allows for complex shapes with multi-directional bends, the only problem is a long drying period, can't just glue it right away. No steam box needed, but need to be sneaky so nobody sees you bathing wood pieces in a kitchen kettle, otherwise one would have an awkward explanation to do. My daughter knows though, but she keeps that secret

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Thanks for the advices! It is nice to be back, spending a bit of time per plank every evening. Easier than trying to dedicate a long modelling session. Mark, I was trying to avoid soaking, because a soaked plank need to dry for some time, otherwise it will shrink and there would be a gap. The whole point was to be able to bend and glue the plank right away. Maybe it would become dry enough in the area that is heated, maybe not, but it would still be wet in the non-heated area. So I'll just practice more to find that sweet spot where wood bends, but haven't dried enough to be brittle.

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

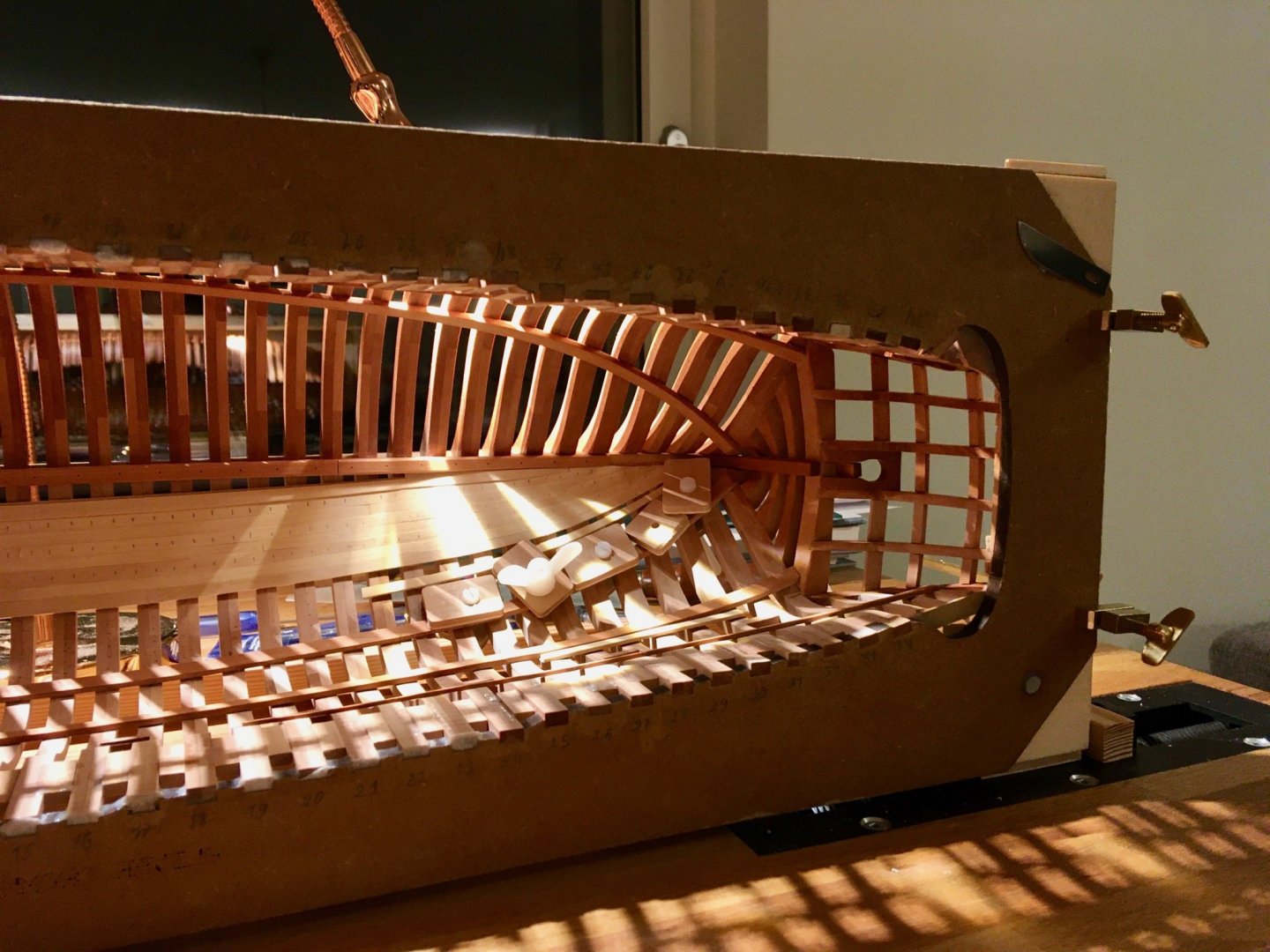

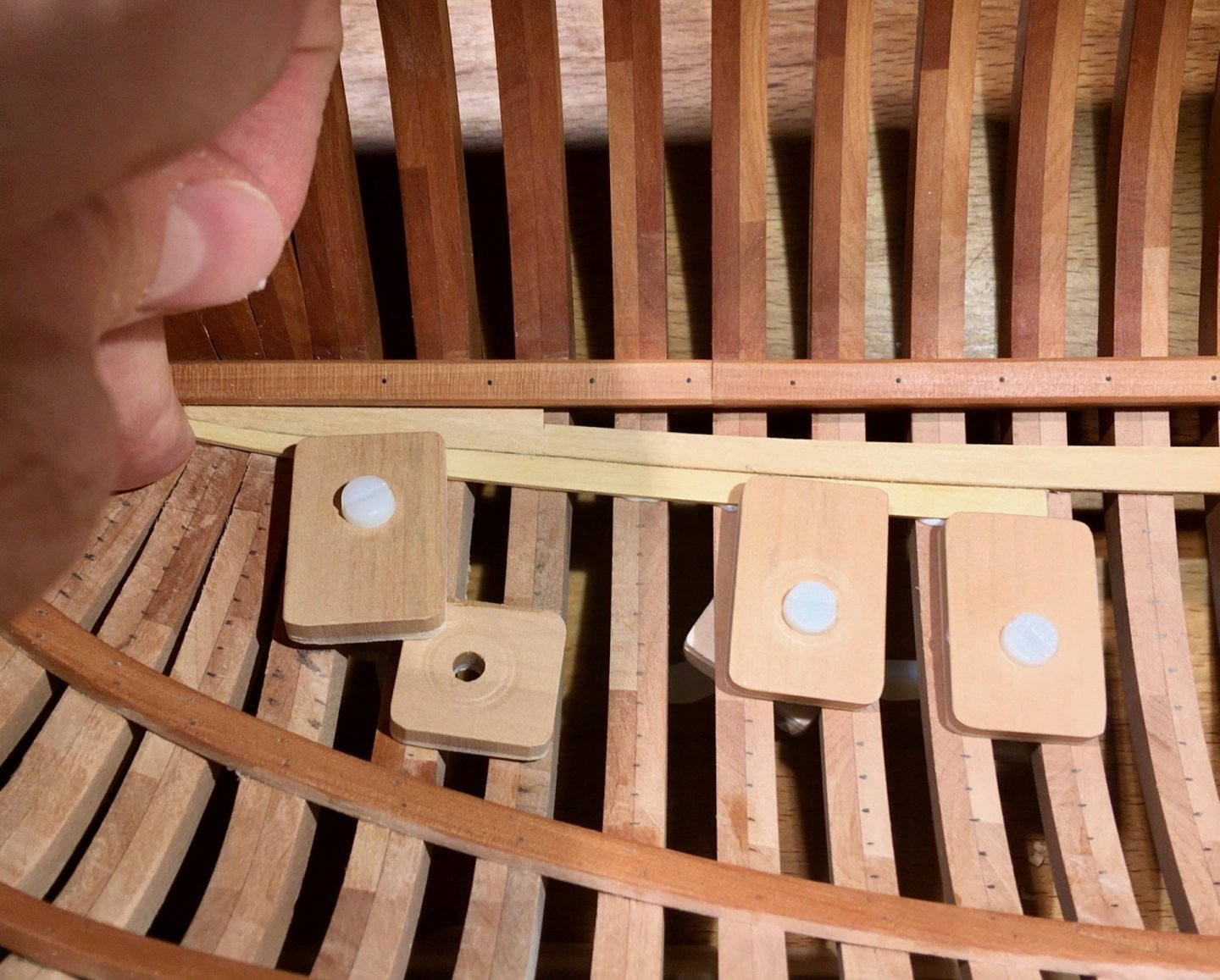

Thanks a lot for the comments! They are inspiring Had a bit of a block before continuing the inner planking. Started improving my build jig by adding some magnets to it. Very simple and very convenient, now I can attach tiny plane/chisel/scraper right to it, and nothing will fall off. Just stick magnets to your work surfaces, they are cool! Decided to try dry heat bending (thanks, Chuck!), ordered a tiny iron and a soldering iron with some special tips (really nice way to bend a circle!). It takes some practice... Who knew that you can overheat the wood by heating it for too long? Had a number of planks cracked because of that: A lot of mistakes were made:I need some margin, because it was not easy to control the location of a bend. Will practice more. Unfortunately you can't practice on scraps, results really vary depending on a wood type, width and thickness. I had two identical boxwood planks, one 5mm, another closer to 4.2mm width - the narrower one bends so much easier! But I like the method, no clamping and no need to wait for the next morning. Hopefully I will master that skill and will be able to prepare a bunch of planks during one modelling session. Finally I realised that I do not need an extreme side bend, just a little bit goes a long way. The first bent and shaped plank is in place, made out of a straight strip. So nice to find a method that works! Now I can continue with the rest of the planks. The glue-up was a bit awkward though, since there was no way to clamp the front tip. Luckily it mostly stayed in place because of the pre-bending, so keeping it with a finger worked just fine.

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

No words... I hope your spark will come back to you soon enough, and something else (Belle Poule?) will bring a joy back! Too young and green to really feel your situation, but desperately trying to add a tiny bit to that massive community support. Hope to see you onboard again, soon!

-

Daria is back after the summer, yay! The modelling sessions were rare, but enjoyable nevertheless. We learned how to taper flat surfaces: Fine fitting is easier now, she can do it alone: My clamps were quite handy when laminating the stem, it is tapered so you can't just clamp it between two pieces of glass, and veneer bends with moisture. First time using marking knife for precise trimming of veneer pieces so they fit each other: And her favourite photo: Also learned how to use a chisel in gentle pairing motions. Keeping a consistent angle is hard! And a few last pieces were done completely without me, she did everything from masking to fitting and gluing: But clamping a long piece with a masking tape is more fun if you do it together Hope we'll finish the stem soon!

-

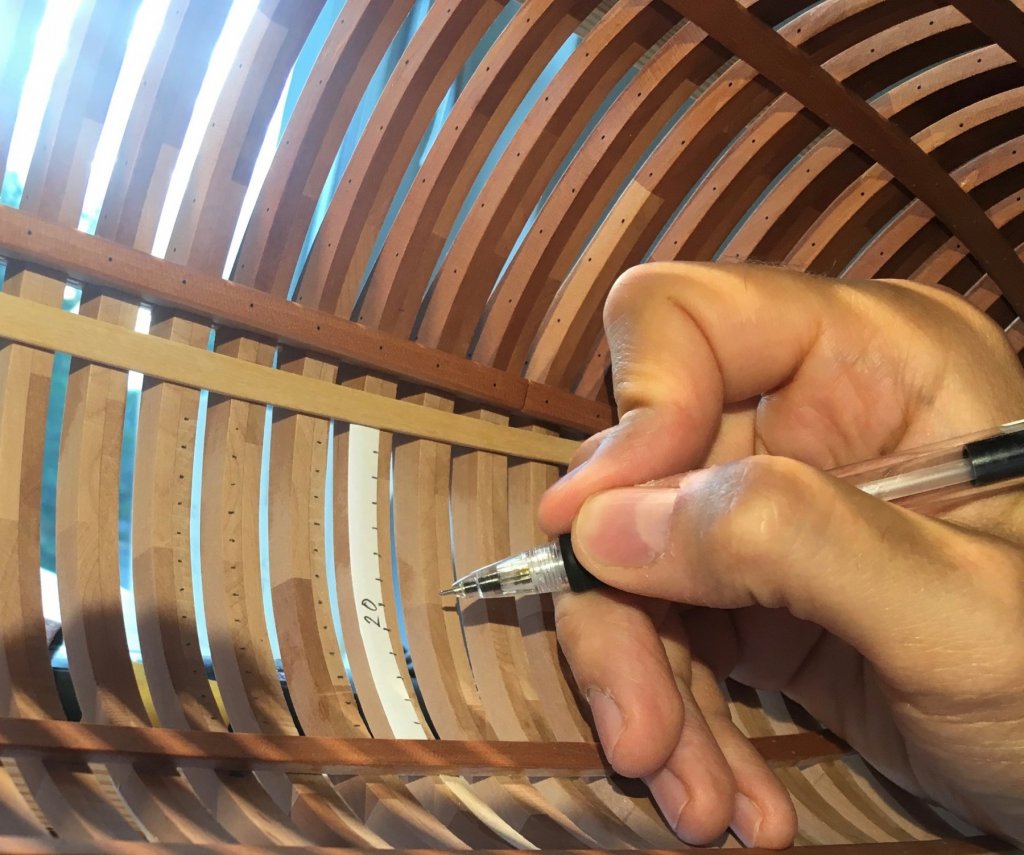

Before installing any more planks, started drawing the reference lines using tick strips. I should have done that before installing the limber strake, but I really wanted to cut some wood to resume modelling.. I am still happy with my flexible jig, that allows working with model in any direction. Very handy for such jobs, allows resting the hand instead of using it suspended. Now it's time to face some sloppiness that I made when fairing the hull. The exposed side got a lot of love, while the other side had a lot of areas that are not properly faired. "Not a big deal, I will plank this anyway", said stupid me a few years ago... Some areas are easy to fix (just adding a thin strip to bridge the gap): But some are bad, and are located in tricky areas. So I spent a few hours with tiny chisels and riffler files to level cant frames. Luckily no need for a nice finish, since planks will hide all the dents. But it is a very delicate task to avoid scratching everything around. Some masking tape and care is necessary. Note to self, and hopefully somebody will avoid the same mistake: spend extra time fairing everything, especially tight areas. Use a strip of wood to check the smooth run, your eye will deceive you. Any hour saved on fairing phase means you borrow that time and will spend 5x fairing it in situ. Damaging something while doing it. So now everything is lined up, but the close-ups around the stern are brutal Most of it will get hidden though. I assumed equal plank width when lining up, but of course they will have different thickness. It is good to have guide marks anyway! So now it's time to start planking, and hopefully avoid too many redos. Really worried about sloppy fairing biting me down the road, will see. Will try to counter it with creative sanding. In worst case scenario - will use a full set of carlings & ledges when making the deck, so nobody will see the mistakes

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

variable height desks

Mike Y replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

As a user of an adjustable table with the motor, I adjust it all the time... Different operations require different distance, and instead of bending to the table - I can just adjust the table a bit. Also working while standing is more convenient sometimes. I have the IKEA electric table, model name BEKANT. Works great, with very little wobble (heavy table top helps as well). The least wobbly of all the desks I tried. Note that they sell it with or without table top, so you can buy the base itself, and mount some thicker table top, more suitable for modelling other than office work. IKEA have some hardwood tops that are pretty cheap as well. But I would not dare using a hammer / mullet on that table, since that might damage the mechanisms inside the telescopic legs. The hand-cranked desk they have (model name SKARSTA) is built much cheaper and lighter, it is less stable and have a considerable wobble. I see that they have released a new line - IDÅSEN. A bit more expensive, only one size, different construction. Haven't tried it yet, just spotted on the website. I have it for probably 5 years. Once some electrics broke, it simply stopped working. IKEA mailed me a few replacement parts and then delivered a new table, no questions asked.. Not sure if they have the same level of service in US though. After that replacement, it worked with no issues. I guess some early versions had their faults (I bought it the same year it was released), but hope they fixed them now. Here is the final setup I ended up with. The combination of an inset vise + pegs allows me to quickly fix the model and work on it without holding. Note that the table is lifted to some sort of mid position here. Making fine continuous adjustments is very neat, I would not recommend to have a table that you can only adjust rarely to some fixed positions. -

Here is the video from the wreck, it is really surprisingly intact:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.