-

Posts

13,371 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

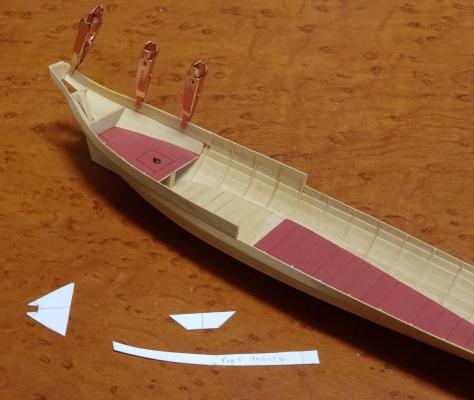

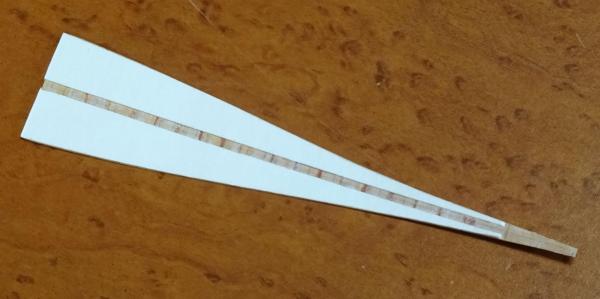

The inner bulwark sheathing proved interesting. It took several pattern pieces to figure out the developed shapes of the planks. The first photo shows one plank being wet-bent into position. The card pattern for this is in the foreground, as well as patterns for the steersman's bench. The second photo shows both inner sides complete and the vertical portion of the steersman's bench in position. The top of this has been made and painted. The same strategy as for the other horizontal surfaces was used to build it. The paint is in the process of drying and I'll install the top tomorrow. There are several possible items I could now tackle, but I think that the risers (horizontal planks that support the ends of the thwarts) should be next.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Mechanical Solar System by jim_smits - Eaglemoss

druxey replied to jim_smits's topic in Non-ship/categorised builds

Just found this thread - your project is sooo cool! I guess that the company don't export to N. America, or I'd be tempted. I remember seeing orreries in museums when I was young, and being fascinated. All the best with moving and your upcoming nuptials, Jim. -

Congratulations on a fine model, Vaddoc. Very nice indeed.

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

Hopefully the end of your nomadic period, Dan? Nice looking main mast partners. See you when you return.

- 268 replies

-

Well, a start has been made on the inner sheathing of the bulwark. The compound curves involved make this an interesting exercise!

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

The simplest and most foolproof 'water' would be plain glass, as it's the least distracting and avoids a huge learning curve. Perhaps others may have other opinions. If you wish to try for realistic water, perhaps consult some of the model railway fraternity: they are very good at landscaping.

-

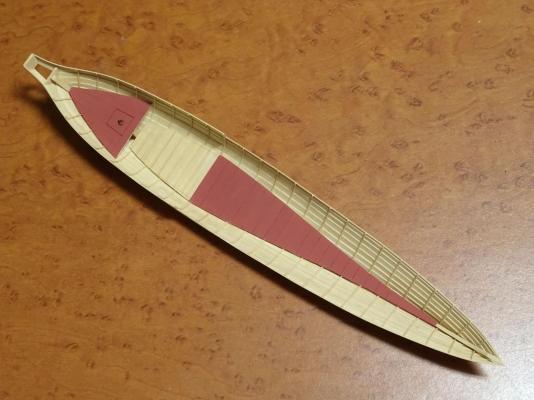

Again, thank you for the kind compliments. 'Precision' is merely taking sufficient time and care, plus accurate marking out. These come from experience; you know, the 10,000 hour thing. The aft platform has been made, painted and installed. The next challenge is covering the compound curved surface above this platform up to the height of the topside.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

If I'm visualizing your description correctly, the display idea sounds very good. Do you have a sketch or rendering of this presentation for us to see?

-

HMS Naiad 1797 by albert - FINISHED - 1/48

druxey replied to albert's topic in - Build logs for subjects built 1751 - 1800

That's an interesting mix of wood and iron standards! Beautiful work, as usual, Albert. -

Thanks for everyone's continued interest. More pattern making is required to define the shape of the aft deck. I've modified the design of Prince Frederick's barge to suit this vessel. On this deck, furthest aft, will be a raised area for the steersman, but that cannot be defined yet. The aft deck with its scuttle needs to be made and installed first, as well as a thin panelled lining on the inner sides of the bulwarks.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Thanks, Siggi, for your helpful contribution.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

That second photograph (https://blog.firedra...015/01/7531.jpg) should answer your own question, Siggi. Thanks for the link: that particular image hadn't turned up for me when I searched.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

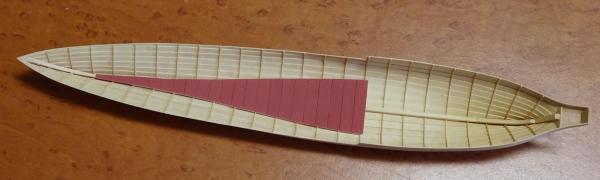

Time for a small update. The cabin floor was made in the same way as that for the forward section of the footwaling. In this case the wood was left 'bright' and the joints slightly enhanced using pencil lead. The finish was dilute sanding sealer. The footwaling aft of the cabin will be installed at a higher level, with a small scuttle for access. Some pattern-making will first be required, though.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Somehow I missed the last few months' updates, so just caught up with you. Lovely work there on such a small scale, Clare!

-

I'm sure that there would have been battens of some sort to support the footwaling plank ends in the actual boat, Carl and Joel. As these would be hidden (as are the floor/futtock joints), I omitted them. Thanks, everyone, for your continued interest and likes.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

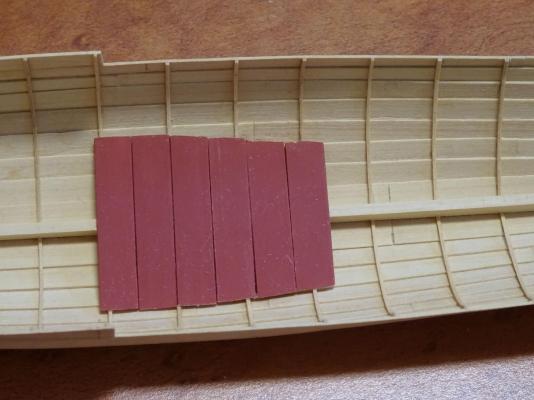

The footwaling is now complete, after making a false start. I initially tried cutting and bevelling each board to length in situ. The result, as you can see, was not pretty. Having thought things through, I then made a card template which was used to actually attach the boards to. When complete, I channelled out the card so that the boards would sit at the correct height on the keelson, then glued the assembly in. This gave a much improved result.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

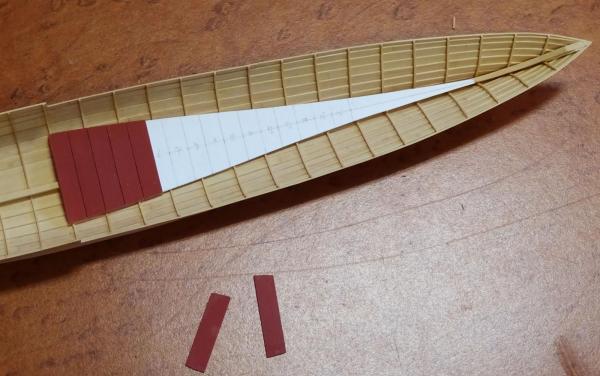

Time for a progress photo. It shows a 'stand-in' footwaling piece positioned so that the first pre-painted board is correctly placed. The pre-painted strips, 10" wide and ⅝" thick are also shown in this photo.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

No worries, Paul. I hope you continue to recover. Thank you for your interest and contributing to this thread.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Thanks, Gerhard. I've already seen all those images. The Greenwich Hospital barge is not as elaborate - thank goodness!

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Frégate d'18 par Sané , la Cornélie

druxey replied to JohnE's topic in CAD and 3D Modelling/Drafting Plans with Software

Odd that the rake of the stern in that Justice draught is so elegantly raked, but the headwork looks like a turned-up nose!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.