-

Posts

26,270 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

Frégate d'18 par Sané , la Cornélie

mtaylor replied to JohnE's topic in CAD and 3D Modelling/Drafting Plans with Software

I don't envy that computer swap, John. I've been giving it some thought on mine as it's getting a bit cranky occasionally. The local shop and I think it's the hard drive. They'll swap out the drive with an SSD, image the old disk and put it on the new for a lot less aggrevation than a new computer. I guess upgrading the power supply wouldn't have solved your problems? -

I'm not sure "Wow" adequately describes this... not enough "wow" in it.

- 1,083 replies

-

The skylights are interesting.. I can see the need for light but there were more than few battles where the Confederacy held the bluffs overlooking the river and could fire down on anything on the river. Seems these ships were armored well on the sides but not so much on the top which contributed to casualties and losses on the part of the Union.

-

That's in interesting bit of research, Steven. The shields hang on the side of the ship, right? Would something like sculpy clay work?

-

This is good news Jan. For years the Billings Kit was the "official" model of the Museum and the most update as far as the research from the ship itself.

-

Mike, Maybe one of these: http://www.modelexpo-online.com/search.asp?SKW=cat1_PM%20cat2_I0 There's just some planking, painting, and a wee bit of rigging.

-

I've done the Billing's kit although it was the one offered about 15 years ago. Replace the plastic grates with wood and locate some planking for the dieck. The plastic figures aren't bad and paint up well. The nice thing is that with some careful warming, the ones that need to be bent to fit the galleries can easily be worked to fit the curves. There's more than one log here on this kit and here's one that finished.... he do a lot of bashing to bring it up to the latest research by the Museum.. http://modelshipworld.com/index.php/topic/1815-wasan-1628-by-nazgul-billing-boats-vasa-175-finished/

-

Ken, I recall reading somewhere... (one of Frolick's posts on one of the old Constitution topics maybe?) ah... found some... The original figurehead was lost on the first voyage. The Jackson figurehead was added in 1830. http://modelshipworld.com/index.php/topic/8550-researching-a-constitution-build/?p=254255 http://modelshipworld.com/index.php/topic/3272-the-two-possible-sterns-of-the-frigate-essex/?p=93243 http://modelshipworld.com/index.php/topic/10406-old-ironsides-is-getting-a-makeover/?p=321003 I hope this helps.

-

Alan has a good eye as he's the only one who caught that about the looms.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

E.J. I think we all do that when planking and spiling. That is, until we've done enough ships that we can be confident that we're doing it right... but I think only a few get to that point. There's so many skills needed for these things (model ships) it's tough to be a master of all of them

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

My condolences on your father's death, Max. Losing a parent is never easy. Take care of yourself and what you need to do.

-

Maury, I found some Williamsburg Dry Artist Pigment "Lamp Black" at a local art store. Not Micheal's but one that specializes in paints, canvases, etc. They do have a website: www.williamsburgoils.com Phone: 607-847-8843 It works well using Elmer's Wood Glue per Ed's instructions on mixing.

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

That is great to hear that it worked, Jack. I've wondered about that method and now that I've seen it, I'm impressed.

- 170 replies

-

- gokstad

- dusek ship kits

-

(and 1 more)

Tagged with:

-

Gerhard, Check with a hobby shop that does RC aircraft and get some canopy glue. It won't affect the plastic "glass" like CA does.

-

Denis is right... just go slow and easy. You might reassure yourself by checking every few frames with a batten just feel comfortable with the process. So far, she's looking good.

-

Thanks for the likes and comments... Indeed, this will be fiddly. However, I do see the need for several jigs... I've got one done for bending the decorative trim and am working on a sanding jig. If you look carefully, there's a slight curve to the window line and the trim pieces above and below..... And then I need a small jig to get everything uniform. Thank heavens for basswood and a scrap box which gives me cheap jig material. I just noticed this.... the plans show 3 X 3 rows of glazing on all the windows. The Hahn model only has two vertical rows on the forward window. Hmmm.... what did he know or find out while building this ship? Pat, I'm not sure if this bravery or just being over-confident. It's going to be fiddly to say the least. Carl, the rebuild was by the French before she was caught... This bit is going to either make or break me, I think. I've asked to Admiral about what size knitting needles would be good for a starter project. So am I, Steve... I'm wihging it here. You might just be right, Gerhard. Although the head has similar issues as far as complexity.... Paul, That's part of what I had to get a feel for. From hull to the outside of the gallery is about 3 to 3 1/2 feet. The deck the officer/captain would stand on is actually in the drop so that has to be hollowed out some or it will block the doorway... I'm being picky... I may end up doing that, just because, Denis. I'll have to see how horrible it looks from the outside looking in also. Although with the liquid glazing, everything will be blurry anyway so it just boils down to which is correct for the period.

-

After seeing the picture, I'd be leaning towards tossed.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

You're doing some nice work on stern, Maury. I would think that laminating up rising wood and deadwood like you did would prevent bending/warping. Thats a good way to make that area, In my opinion. A lot less fiddly than chiseling.

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

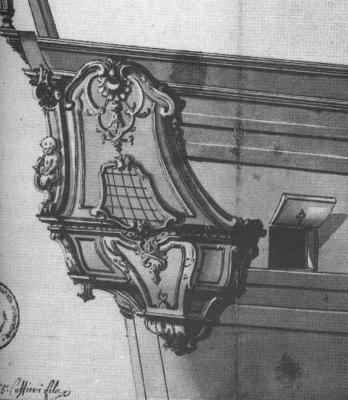

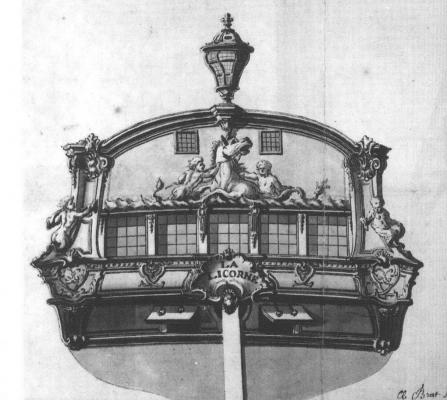

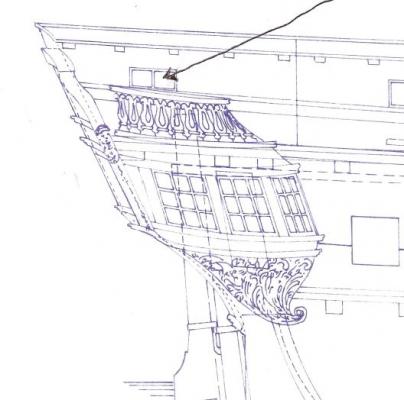

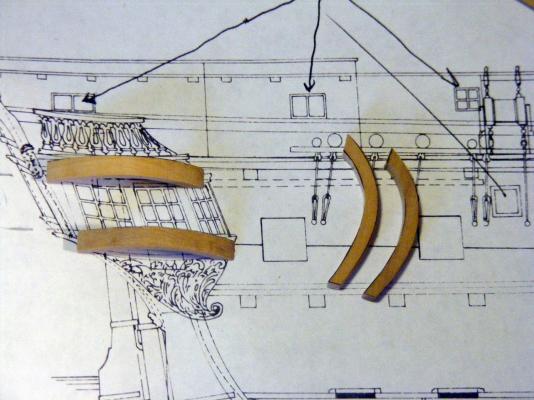

After much thought, reading, Googling, staring at the ship, fiddling with paper and cardboard, I'm starting the galleries. First, here's the drawings of the Licorne as built in 1755 with the same style galleries as Renommee and others of that era. Ornate and distinctively French. After the rebuild, the wales changed to more like Belle Poule and other frigates of that era. There is one problem though, the galleries are NOT like anything I've able to find. I trust the NMM drawings as the lines, etc. were taken off after she was captured. The big "whoa" moment is that the galleries extend beyond the transom taffrail. Newer ships fell under the edict of galleries, when viewed from the stern were to be "hidden" by the transom taffrail. See drawings... these are from the Hahn plans but match the NMM plans. There are no plan views (top down) that show the galleries shape. What I ended up doing was using cardboard, paper, cellophane tape, blue tape, lots of invectives, and finally some rationalization. Hahn built them as semi circles and I think he's pretty spot on. The mockup was pretty much destroyed fit the bits and pieces into the scanner for converting to parts drawings. So, sorry there's no pictures. It wasn't very pretty to look at but it filled the need. Here's the first parts I've cut. Basically the upper matches the bottom as to size but with some reshaping as to the outside for the trim strip. If you'll look carefully, they are not a true semi-circle. When I viewed the mockups from the side and the rear, this curve is the only one that matched the views and this didn't match the other ship plans I looked at. Part of the reason, I believe, is that Licorne's stern is a bit narrower than the normal of the time and the sweep of the top rail has more arc than other French frigates I looked at. I'm starting to fit them now. I'm starting with the bottom piece on one side and then make the other side a mirror image. One other note.... On the old style galleries, only the center pane of the window (or of the center window for larger ships) was glazed. I'm in a quanadry about glazing all the panes in all the windows and all the models of frigates of that period that I've seen haven't had glazing. Even Frolich's... just black or blue paint in the panes. Hmm... my decision at this moment is to glaze the center window entirely and deadlight the other two. However, that's open to discussion.

-

I think the answer to the question about all that rigging for hauling boats, cargo, provisions, guns, etc. is "depends". Not a solid answer but there's variables such as type of ship, country of ship, and even the Captain and the Master have input. I've seen some where the line is left run through the blocks and then both ends are coiled and belayed. The free hanging block has a hook and is set to an eyebolt. Others, just pull the lines and blocks and not worry about it. The pendents are usually fixed. I suspect they were coiled on the stay or yard they were attached to. But again, I've seen where they ran a line through, put a stopper knot and belay the bitter end. If you can, look for James Lee's book on Masting and Rigging of the English Man of War. It's very thorough.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.