-

Posts

26,270 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

It's good to see that you get to make a bit of sawdust, Walter. You're off with a good start...

-

Pat, Faking it will work. I've set up the parrels and trucks off ship such that there ends up a single line coming off each end of the parrels much like a necklace. I then wrap and tie the parrels to the yard. I hope that makes sense. If not I'll try to find a picture or make a quick drawing.

-

Brig USS Enterprise 1799 info gathering

mtaylor replied to CharlieZardoz's topic in Nautical/Naval History

Then they should scan it so they have the drawing for when that one falls apart. Engineering departments do that all the time for that very reason. -

Pat, If it's not too late, pin the yard to the mast. It'll give you some stability and hold the mast in position.

-

Brig USS Enterprise 1799 info gathering

mtaylor replied to CharlieZardoz's topic in Nautical/Naval History

Oh... a copy... that changes everything then. -

Brig USS Enterprise 1799 info gathering

mtaylor replied to CharlieZardoz's topic in Nautical/Naval History

Alex, I don't think your wrong... but there might be other stipulations on the plans or with whoever gave them the plans. Perhaps the issue is that they're worried that someone will take the plans and turn around and sell them like certain pirate sites do? Might be worth a short email explaining that they're for personal use... Then again, some museums are really protective which limits their usefulness as a research resource from a distance. -

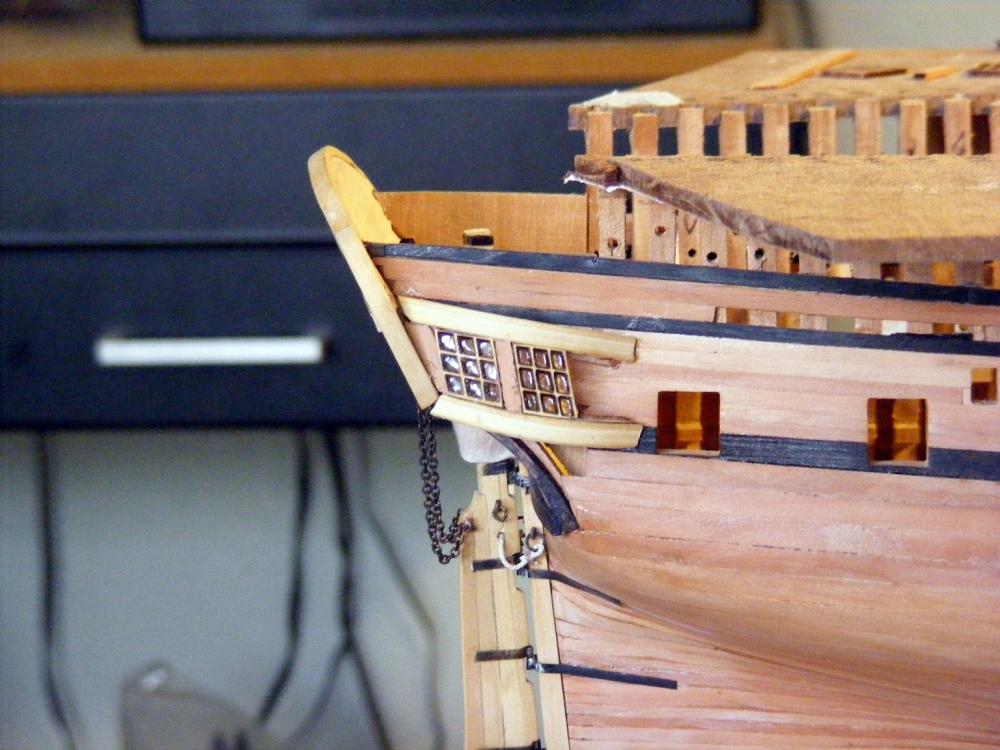

Thanks for the comments and "likes". It's mostly just fiddly work in Corel Draw. No programming as such, David. Which makes me very happy. Well, all has not been quiet here in the shipyard. making progress. On the down side, it is slow, slightly maddening work to translate a 2D drawing into a 3D part.... Luckily, when the first side is done, the second side should go a lot faster. I've got two of the three windows glazed and in place. The third is currently somewhere in the workshop with the glazing drying (I'm using liquid glaze). I've probably cut and re-worked, and re-cut 20 or wo windows to get to this point and I find them very fiddly indeed. I've started working on the gallery roof(s) and drop(s) for both sides but have nothing to show in photos yet. So here's the two windows in place. Feel free to speak up if something is awry while I can still get access to the part. The slight (ahem) misfit at the bottom of the taffrail where the lower molding meets will be hidden by carvings. I've started those also....

-

Amen to the manta, Greg. I was thinking the same thing about cross-sections, etc. It reminded me of Jeronimo's Bon Homme Richard done in 3 sections.

- 889 replies

-

On the actual ship plans (and not all kit plans have them) there's the lines drawings. If you'll go here and look at Russell Barnes article on interpreting line drawnigs, you'll see them. What Ben is doing is using those type of drawings. The waterlines on the body plan give references (not actual waterlines as we think about it) to height above the keel. Then he's using the warterlines drawing to get the shape of the hull for beveling. I think that with most kits, most builders just fair the bulkheads using a batten strip and don't go to this trouble.

-

Can i live without a BYRNES TABLE SAW

mtaylor replied to shihawk's topic in Modeling tools and Workshop Equipment

Al, Have a look here: http://www.hobbymillusa.com/byrnes-saw-operation.php Jeff has guidlines for teeth count for different thicknesses of wood. -

I too, know next to nothing about sailing these but what you're showing seems reasonable and less complicated than what the plan called for.

- 64 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

It's still amazing work you're doing, Greg. Wood kits require a lot of bashing also along with all the poor fit of parts, etc. I'm not sure what it is about ship kits. It might be the markets. Kids seem to be interested in the RC cars and there's the trains and planes. The hobby shops I've been to seldom carry a good selection of kits. But, if you ask, they have the catalogs will order. I think it's the Internet.. a bigger selection, cheaper and faster to buy online.

-

Bill, Would there even have been room inside for the gun crew to work any guns in those ports?

- 382 replies

-

- sovereign of the seas

- carving

-

(and 1 more)

Tagged with:

-

Looking great, Mick. I like that cutting jig for the ports.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Your buddy could be right. The photos do look like the real thing. Wonderful work, Neal.

-

It's a pity that the Admirals are spoilsports. That is impressive and a feast for the eyes, Dave.

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Stunning work, Nils. Using steel cable is something we don't see often but it looks great.

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Can i live without a BYRNES TABLE SAW

mtaylor replied to shihawk's topic in Modeling tools and Workshop Equipment

Al, Are you using the right blade? Can you post a picture? -

Sorry to hear that the time has come to pack it all up, Rusty. We'll just have to wait for things to be moved and the turmoil that moving entails to be settled.

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

mtaylor replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

I like the methodical approach you're taking, Nenad. It's paying off with the pieces you're making.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Wefalck, Sherline recommends that this "upgrade" only be done on machines that are well run-in and also to monitor the bearing temperature. When it gets warm, shut it down. As for longevity.. good question. I did a mod my (non-Sherline) and so far, so good. But then, I'm not running it very long at any given time, either.

-

Planking questions

mtaylor replied to tarmes's topic in Building, Framing, Planking and plating a ships hull and deck

Tim, I'll answer the best I can... #5 works well for kit wood as there's no extra for spiling. You'll also probably need to use stealers and drop planks. If you apply heat and soaking, bending the wood is pretty easy and will fit quite well. For kit, most, if they spile, just spile the 2nd (outer most) layer. The first layer isn't seen so many (myself included) use filler to get a smooth form for planking. I can't answer why #4 isn't used. Or maybe it is and has not been identified as the method used. Planking, like many other things, is one of those things that you'll have to try yourself. Spiling is the "real" technique, the rest are simulations. But use the one you feel comfortable with and gives the appearance that you like. I found spliing not to be that difficult when I stepped into scratch building but then again, I made sure to have a pile of wood handy to allow for waste. If I didn't, I would have used a different method. -

Planking questions

mtaylor replied to tarmes's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Tim, Method 4 or 5 will give you a nice appearing hull. Do consider using that of #5 to prevent things going wildly out control due to tolerance buildup, .. or not. Spiling is the way the old ships were done, however. For a double planked hull, you can spile the first layer but it will be hidden by the second. If you look at the planking tutorials at the top of this section, you'll get some good ideas. Also, in the article database here: http://modelshipworldforum.com/ship-modeling-articles-and-downloads.php In the planking section is a good article "Simple Hull Planking for Beginners" which might be very useful. Good luck.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.