-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

MDF is hard, I used a sawblade that I wax down with beeswax every 10 or 15 strokes. Also, the dust is toxic so cut outside, or wear a mask and run a vacuum while cutting. A scroll saw works well but it does eat the blades, even waxed if you're cutting a lot. As I recall, I went through 2 blades on my build board. The problem isn't the wood fibers but the glue binding the fibers together. If you can, check the store where you get your wood and see if they have a small piece of scrap you test with.

-

To spile or not to spile...

mtaylor replied to fish's topic in Building, Framing, Planking and plating a ships hull and deck

On spiling.. if you line off the hull per the tutorials at bow, the planks will need a taper. If it gets too 'thin' on the taper, a drop plank will be needed. At the stern, if the needed planks get too wide, stealer time. The tutorials are a big help and about the only difference is the method in laying out the runs of the planks. On plank width... shoot for a plank length around 28-32 feet or so... It's going to vary from place to place depending on what was available at time. Width could be 6" to 12" wide... again, depending on what was available. Crackers... microwaving works but you'd best move it to the workshop as the planks cool down fast, in my experience. I've been using the curling iron method which works for me. I'm trying the Chuck heat gun method but so far, I don't have the hang of it. -

To spile or not to spile...

mtaylor replied to fish's topic in Building, Framing, Planking and plating a ships hull and deck

You can taper to a fine point, but that's just not realistic. In the real world, you would need at least one nail/trunnel/whatever there to hold the end down. The usual rule of thumb (rules are made to be broken...) is to not taper more than half the plank width... but see about rules made to be broken. -

Buying an Expensive Kit and throwing most of it away

mtaylor replied to pirozzi's topic in Wood ship model kits

Keith is right...laser cutting is the wood equivalent of a cutting torch. -

To spile or not to spile...

mtaylor replied to fish's topic in Building, Framing, Planking and plating a ships hull and deck

Druxey, In my "scrap" and "misc" piles, I have pieces that I soaked and bent with a curling iron set to "MAX". The pieces are still bent after several years. I did do some steambending way back on my Constellation but the parts on the ship and I'm not finding any scrap... so that's inconclusive. -

Then that's the way you should build them. Everyone builds differently and for different reasons. Go for it. Open a build log and we will follow. Edit: I forgot about this one... http://modelshipworld.com/index.php/topic/10558-sponge-diving-boat-trechandiri-tirhandil-by-mhmtyrl-mehmet/ Lots of character.

-

I've used a 50-50 mix of water and wood glue to harden basswood. About all I can say is that it works. It might take paint, but I doubt it will take stain.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Jim, Looking good. There's a topic here that might help: http://modelshipworld.com/index.php/topic/11214-how-to-make-best-use-of-your-milling-machine-tips-and-techniques/ Posts 35 & 44 These will let you do what you're doing to any length of wood. Before mills.... oh my... custom scrapers to do that. A PITA, but it works.

-

Cutty Sark by NenadM

mtaylor replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

A beautiful throne fit her presence, sir. Well done. And a great story about the hand... or glove as it turned out.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Wow.. seeing mass destruction is never a pretty sight but I'm confident the reconstruction will be excellent. Bold move, Dave... very bold.

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

No Richard, you're not wrong. What I showed is actually the "reverse" of the way the draftsman would do it from what I've read. In that case, they take the measurement of the ports from the keel. Hawse holes are a different critter. What does Chuck have to say about the hawse pipes in the instructions? As I recall, that tutorial/practicum is pretty comprehensive.

-

The Japanese modelers do build in wood. Here's the homepage of "The Rope"... Japan's biggest ship model club: http://www.theropetokyo.org/english/activities/ Here's one set from an MSW member who visited: http://modelshipworld.com/index.php/topic/1710-38th-the-rope-exhibition-tokyo-japan/

-

Buying an Expensive Kit and throwing most of it away

mtaylor replied to pirozzi's topic in Wood ship model kits

Uh.. what rules? The rules as such... build what you want, the way you want. As for "looking stupid"... I don't think so. The reason for this site is to learn from each other and that works in spades. We all make mistakes but that doesn't make us stupid. There's another purpose of this site... the build logs, the questions and answers. They all do more for sorting things than any "official review" could ever do. There's several manufacturers do read and post here and listen to what's being said. -

Have a look at Riverboat's builds... Matt.S.S. There's others, but those two off the top of my head for kits. Kees in the scratch area. I know there's others who weather their ships. It's a part of the hobby. And I agree with Slog.... This is MSW. We're not stuffed shirts who only build models "one way..the true way'' as some places seem to prescribe.

-

Brig Eagle by robnbill - 1:48

mtaylor replied to robnbill's topic in - Build logs for subjects built 1801 - 1850

Nice work, Bill. I like the way you did those sheaves and catheads as well as everything else. -

Buying an Expensive Kit and throwing most of it away

mtaylor replied to pirozzi's topic in Wood ship model kits

Janos, It would appear that Chuck is doing this. The Lumberyard offers "timbering kits' where you buy the plans and select your wood. So far, those and maybe Bob Hunt of whom I nothing of his current operation but he did in the past, have been the only ones doing this. What I got into in my previous build was heavy kit bash... It just pointed me to scratchbuilding since the kit was heavily modified. It's really a pity that the kit makers don't consider this or offer this. Or maybe offer something like plans, metal parts... and the modeler supplies his/her own wood. -

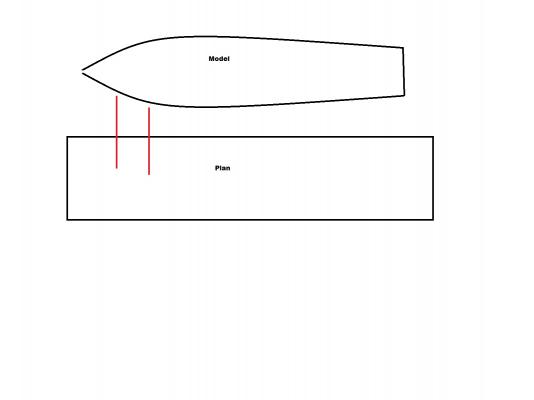

Ron, If you have a top view, use that for marking off things. If not, it's a bit more complicated. Reference my crude drawing.... Set the ship up on the workbench or table. Lay the plan down in front of it and line up the bow and aft. Then it's a simple matter of running line (red lines) using a ruler/t-square/triangle such that you can transfer the ports, etc. to the side of the ship. It seems more complex than it is but once you set it up, it should become clear.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.