-

Posts

5,613 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by James H

-

-

That really is a very pretty little model.

- mtaylor, Canute, greenstone and 2 others

-

5

5

-

42 minutes ago, d'brat said:

And the instruction manual(s) will probably be as long. Absolutely amazing.

That is a certainty!

The manual for Sphinx is 152 pages with about 1000 photos and 27500 words. Over 900 construction stages. I think Indy will easily top that with another 50+ pages. It remains to be seen yet, but there are no corners being cut whatsoever.

- Glenn-UK, BenD, paul carruthers and 13 others

-

16

16

-

Continued.

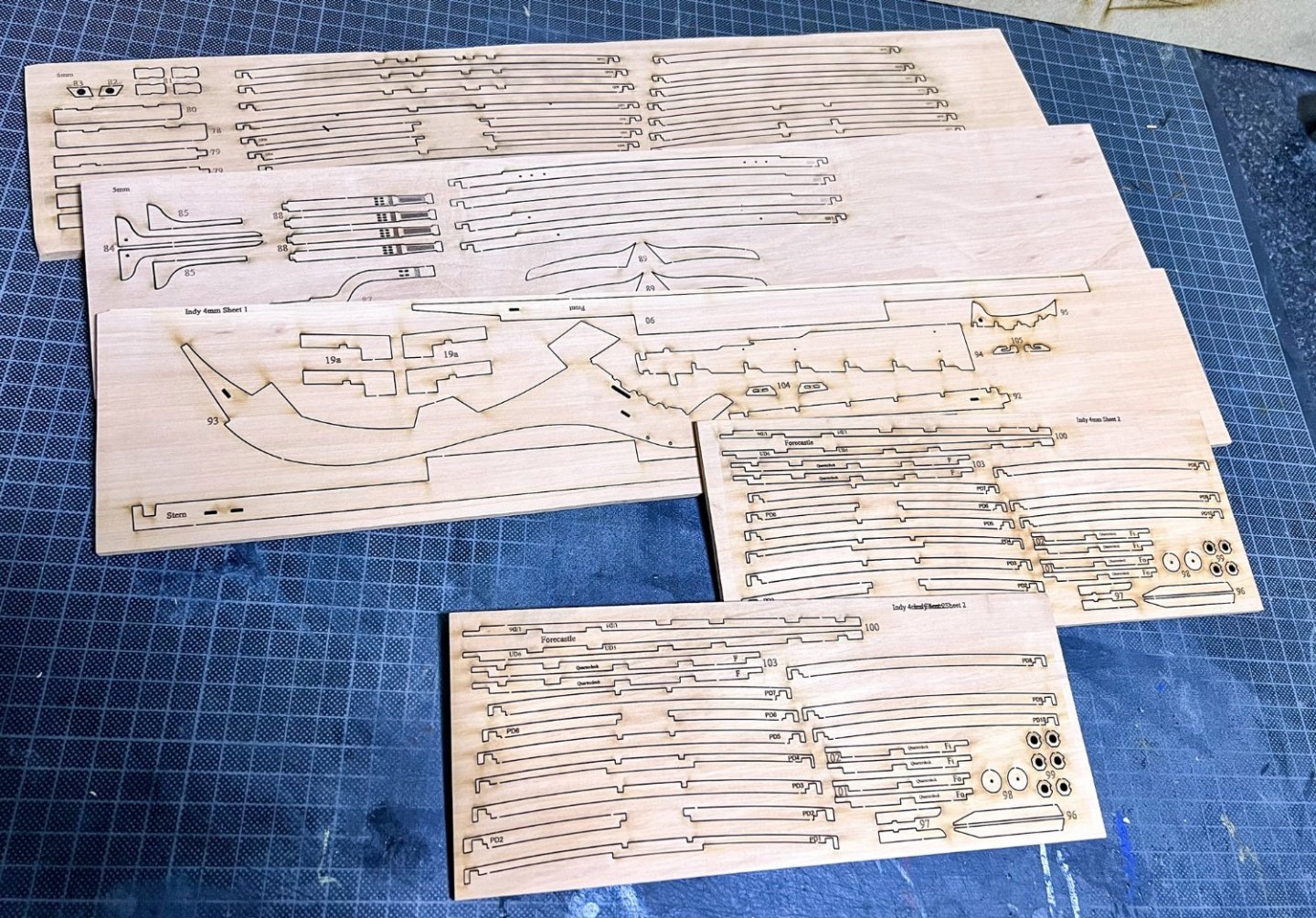

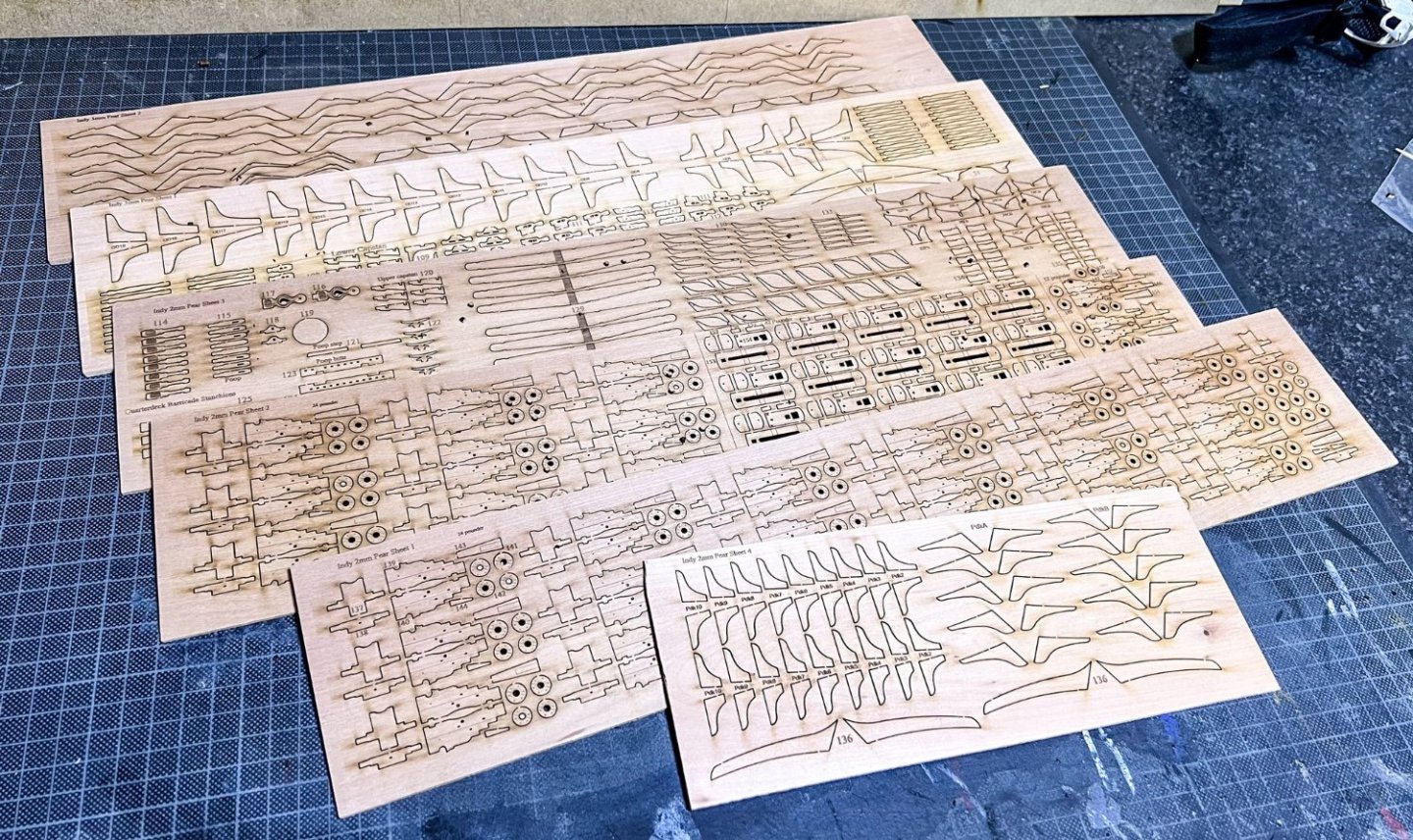

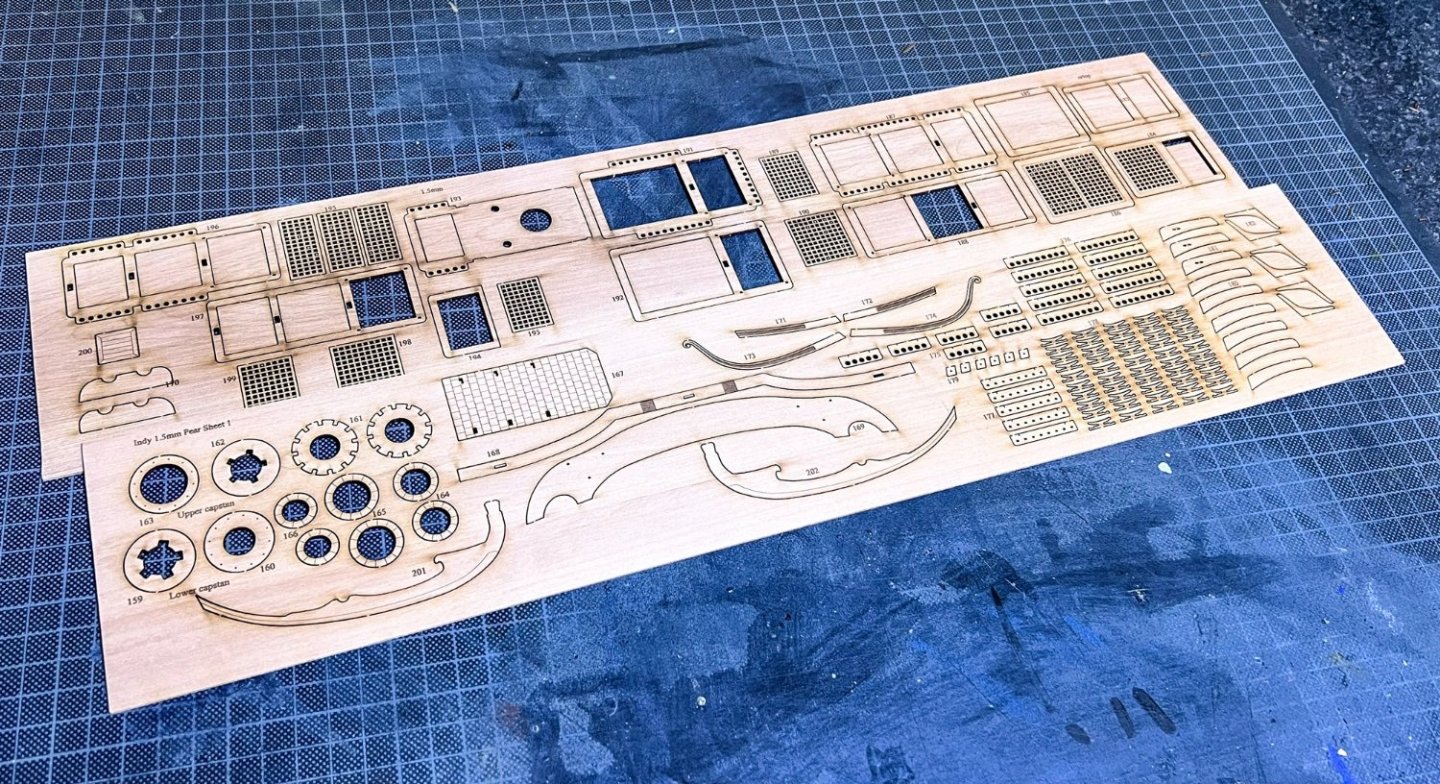

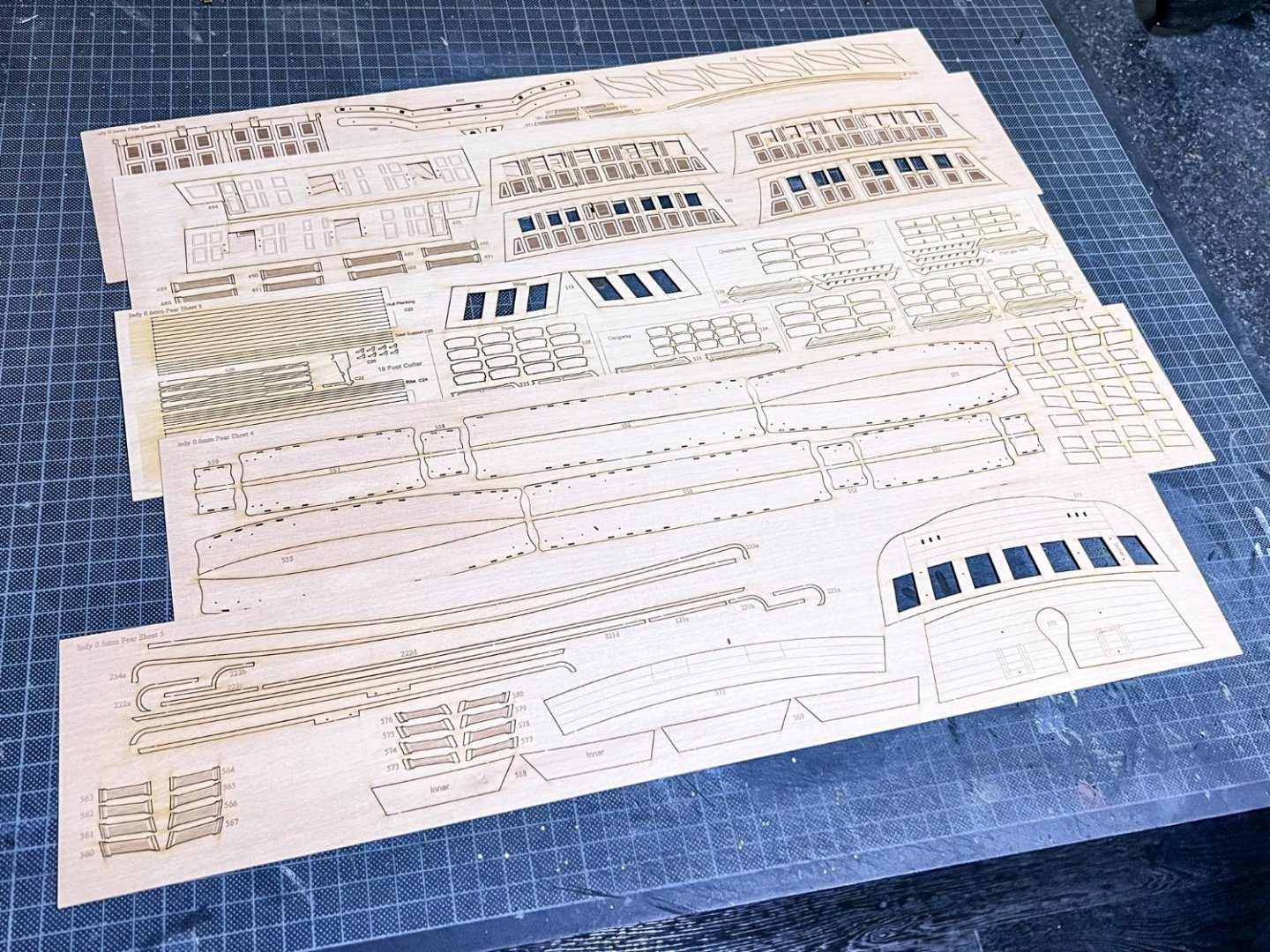

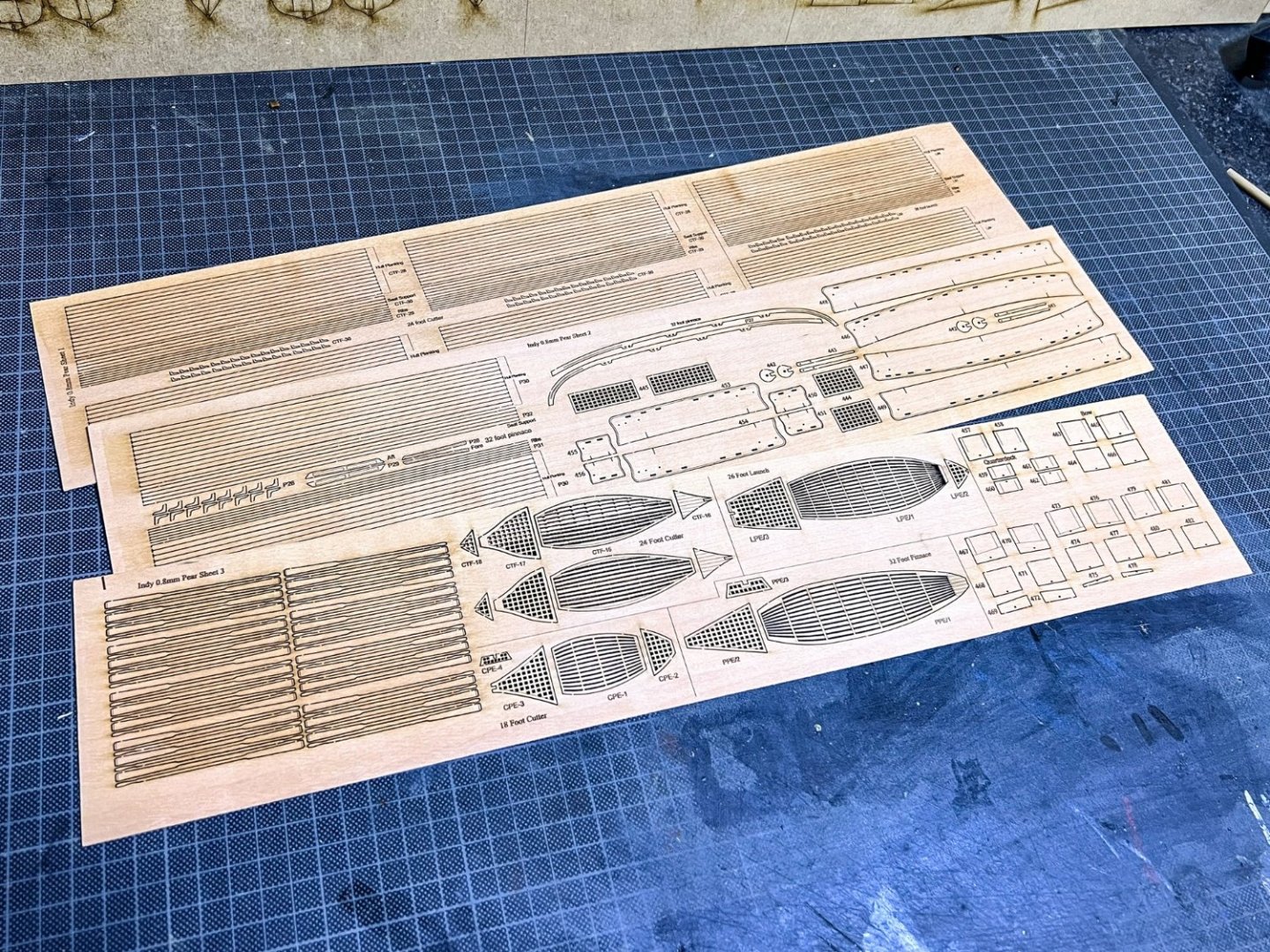

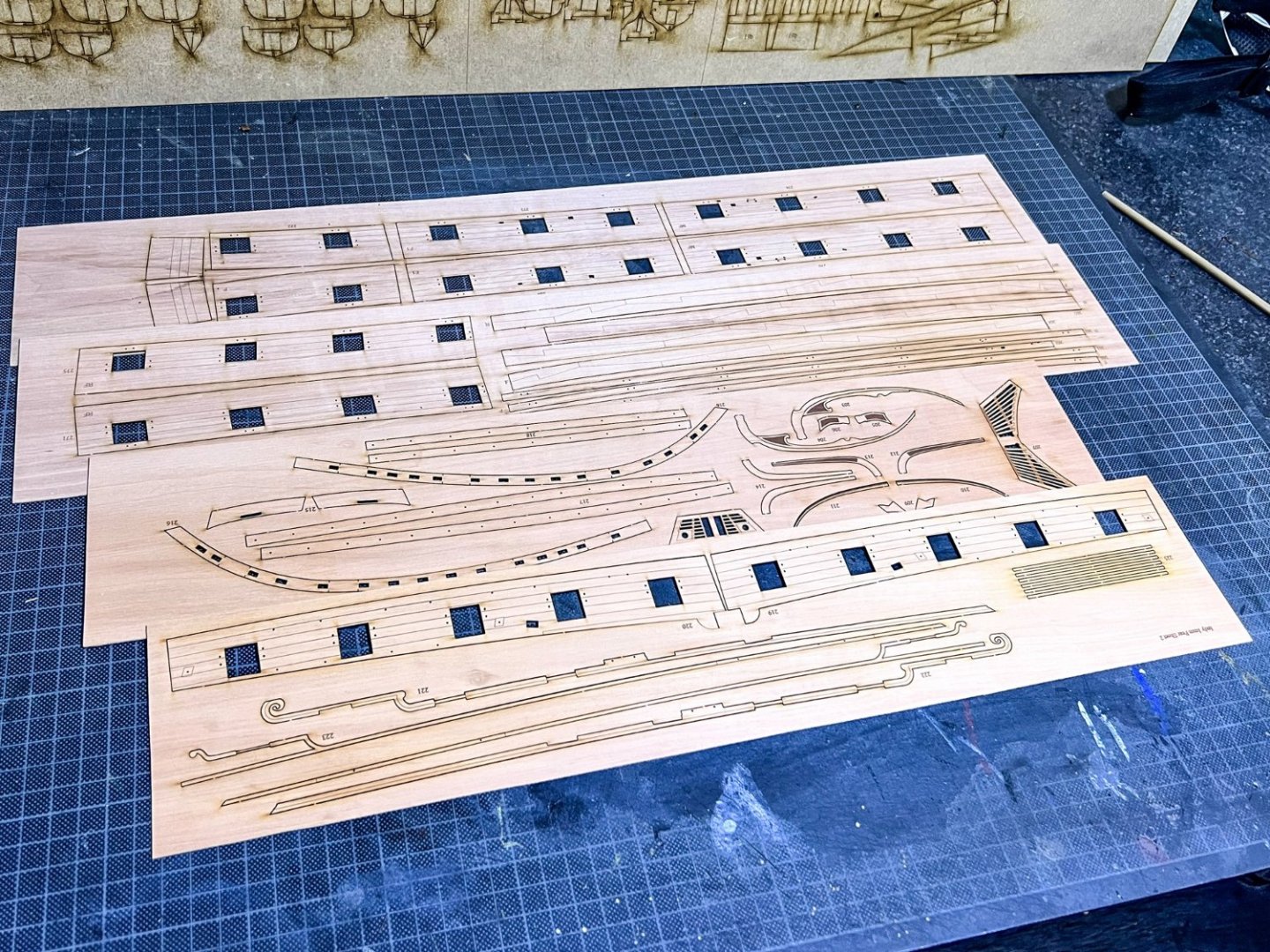

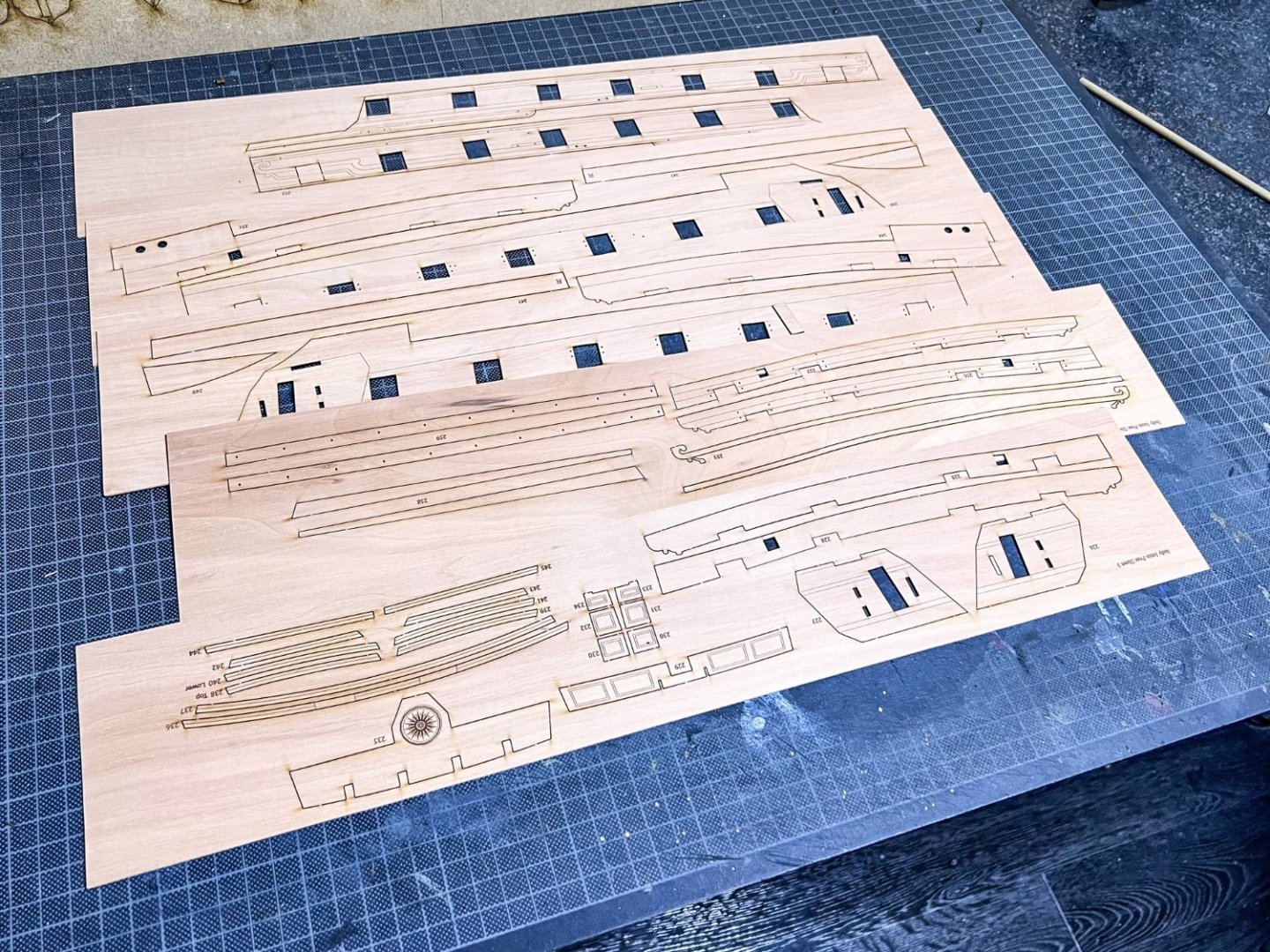

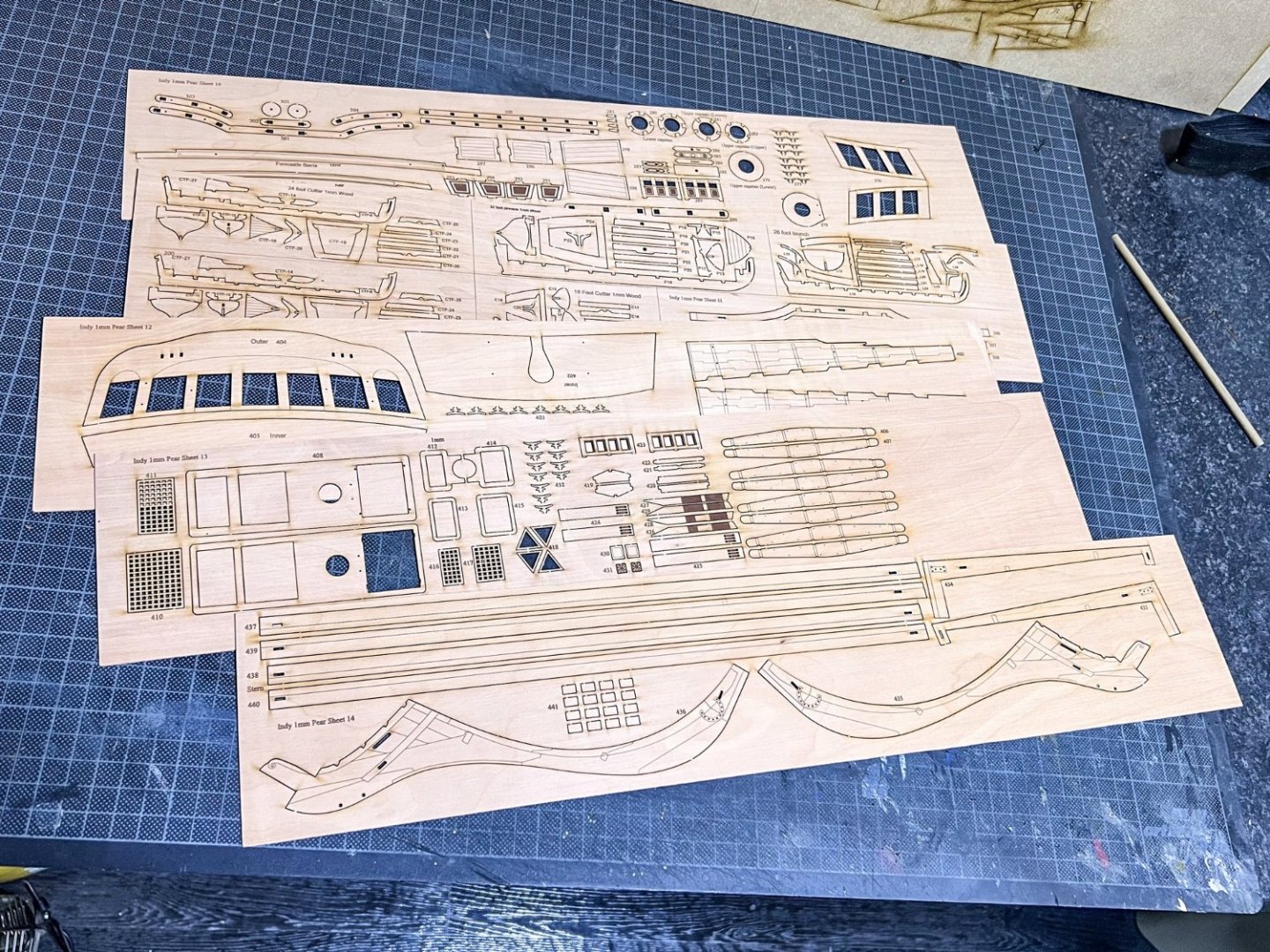

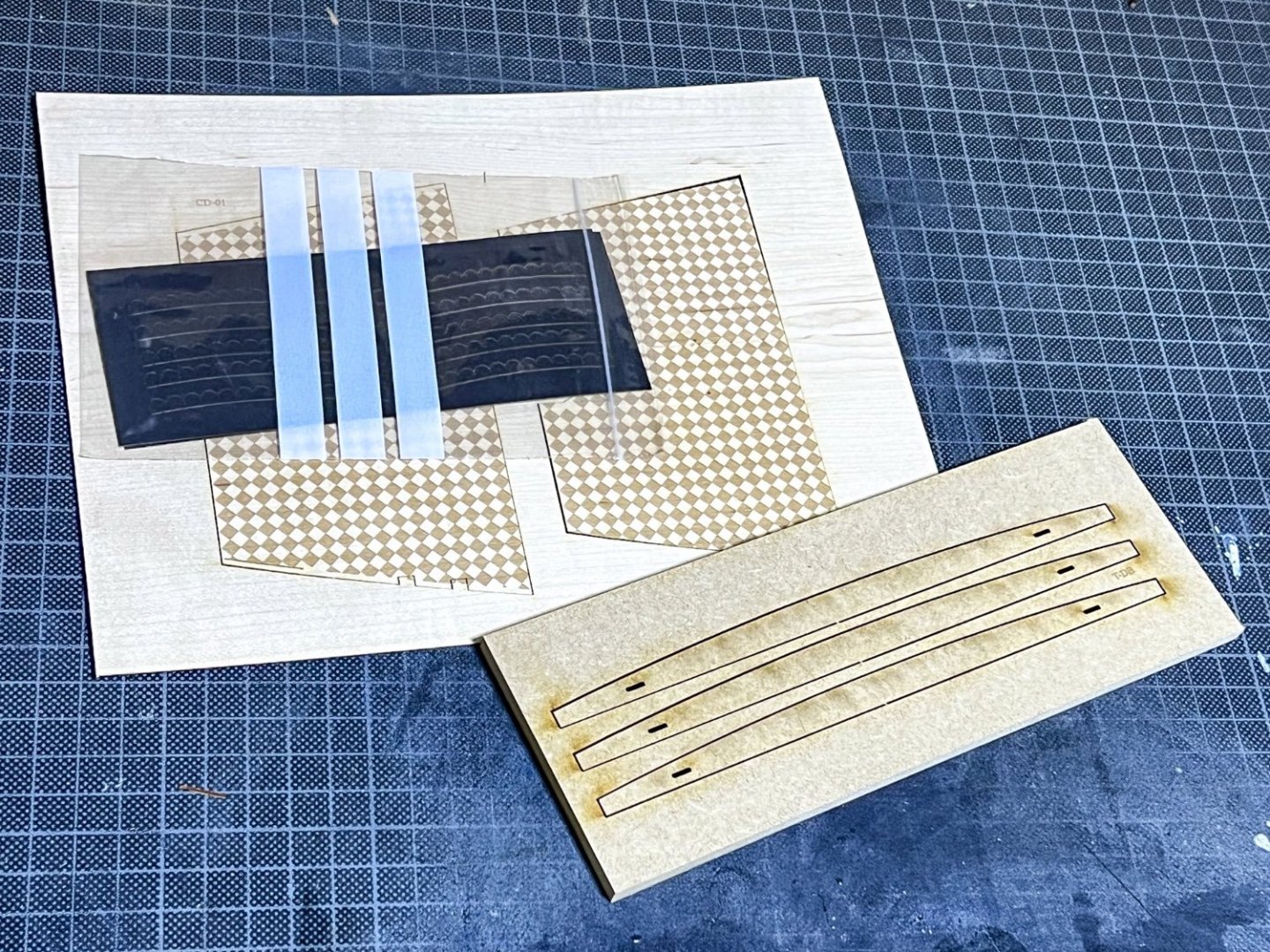

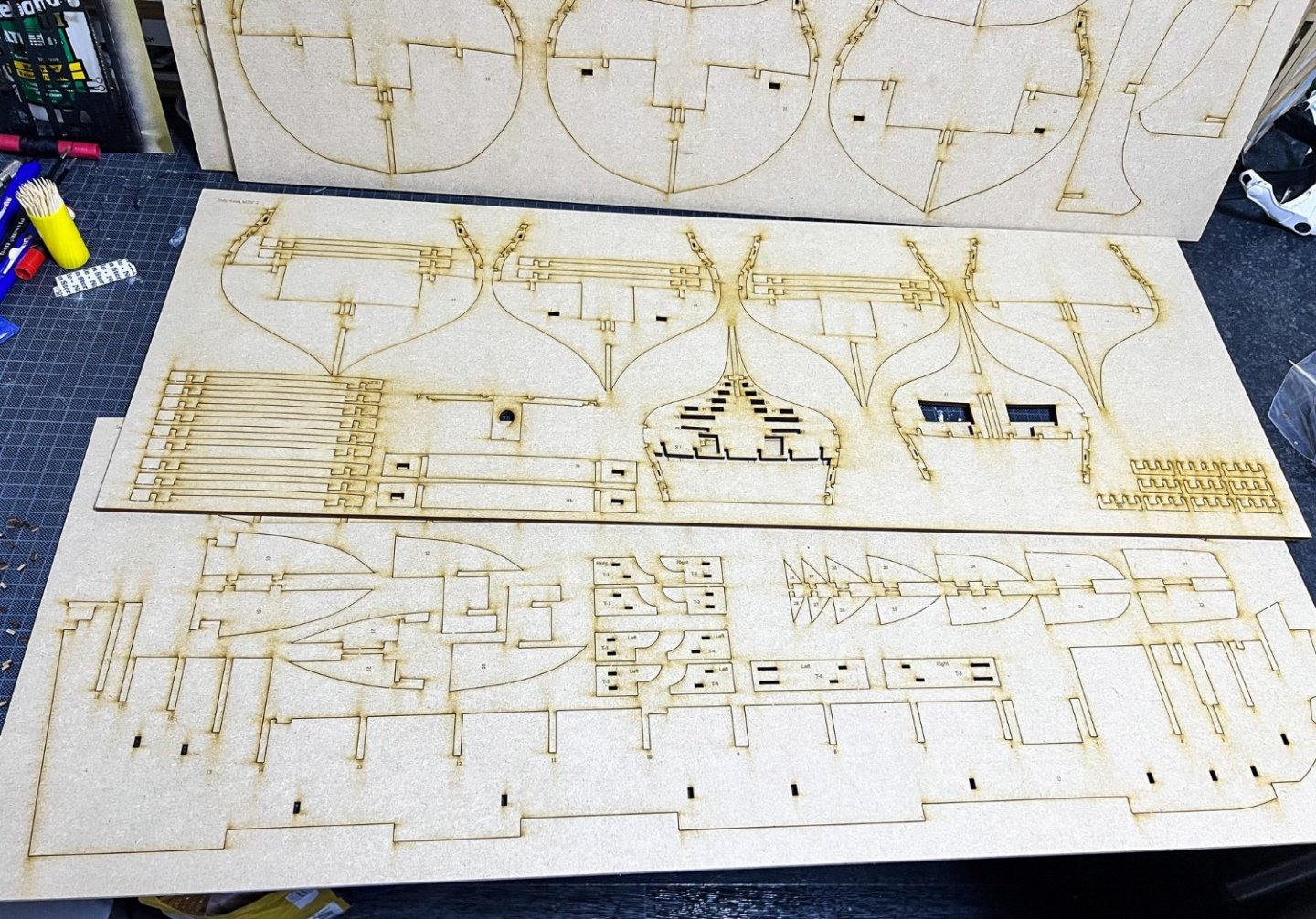

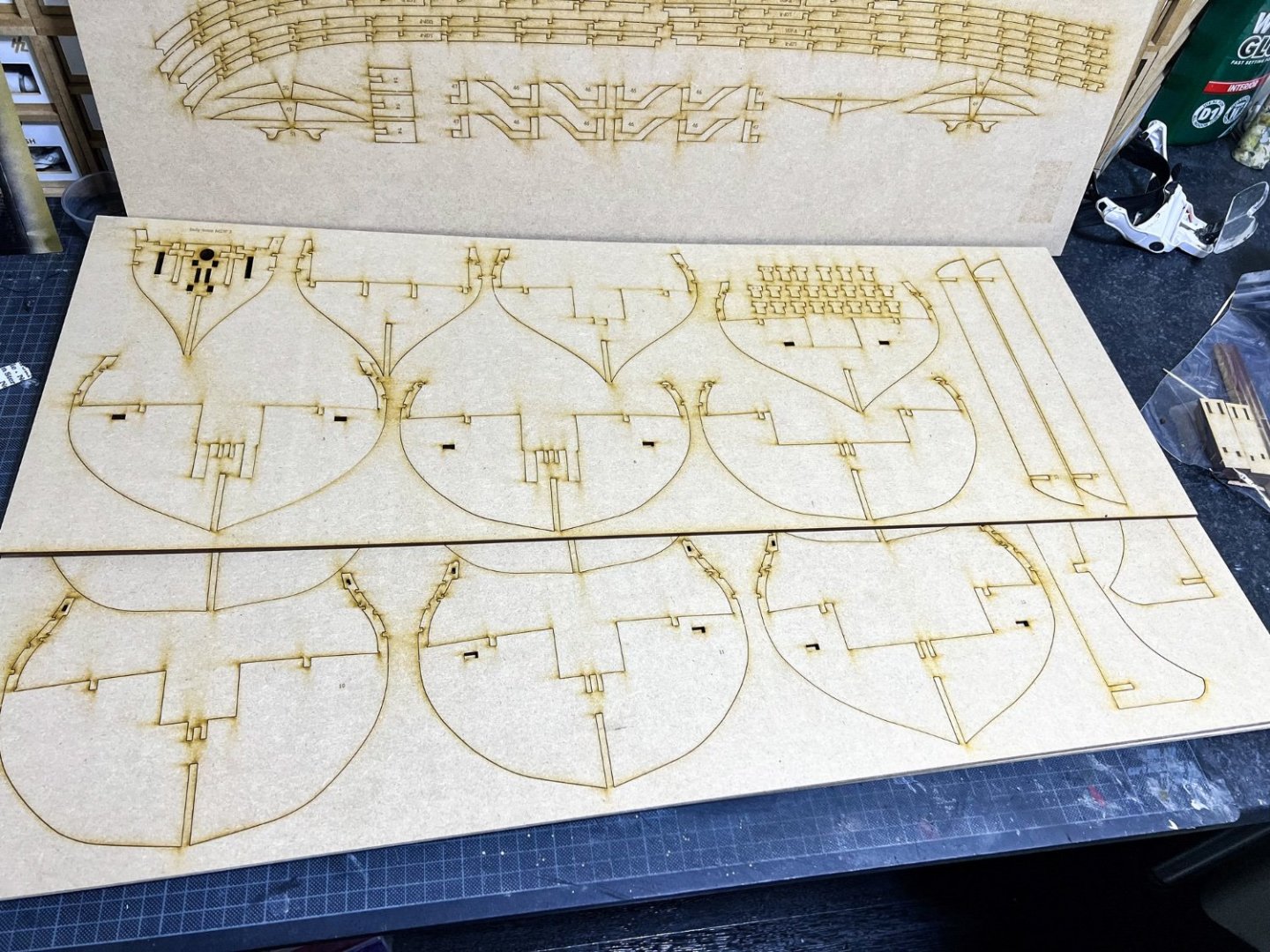

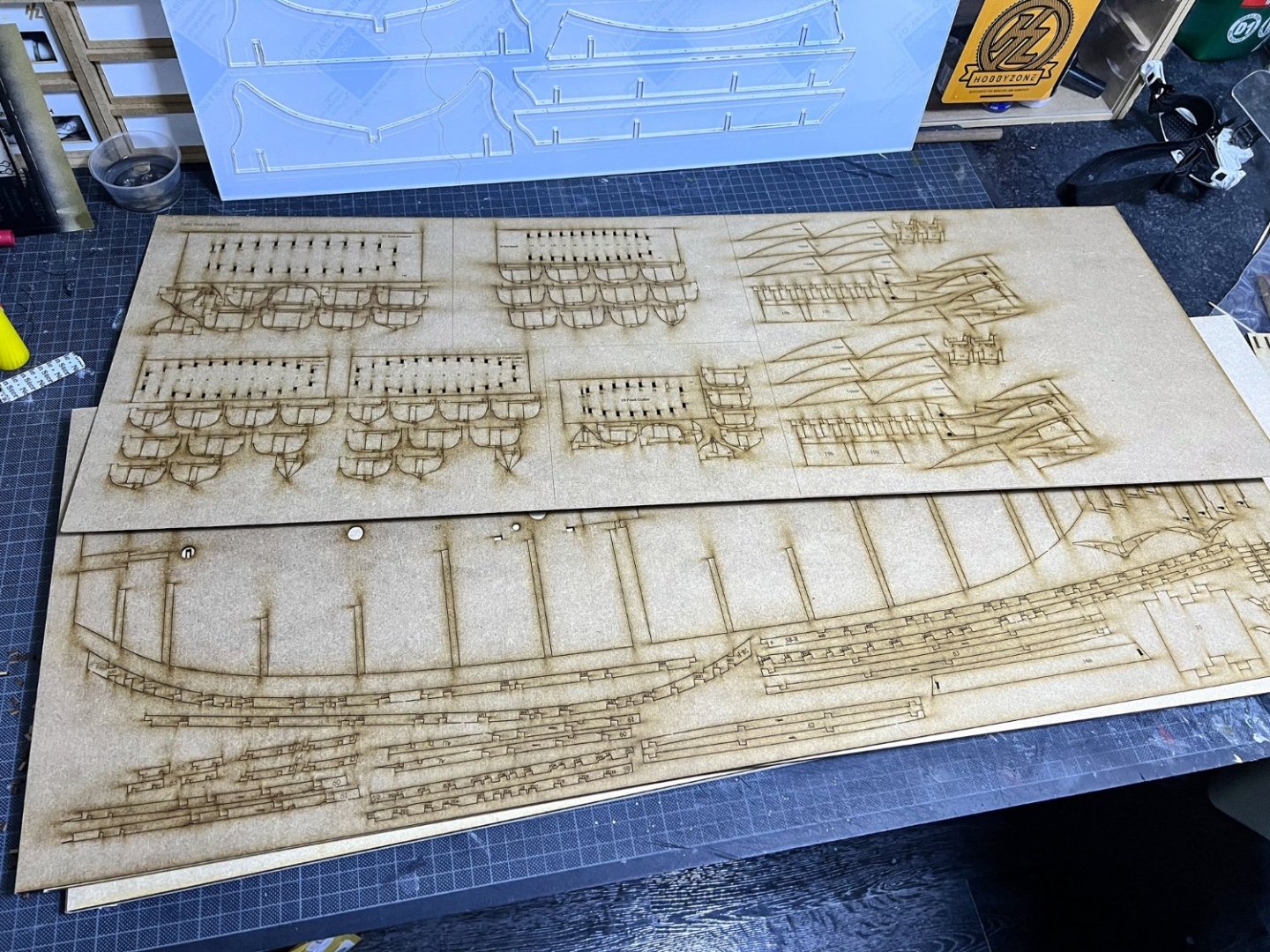

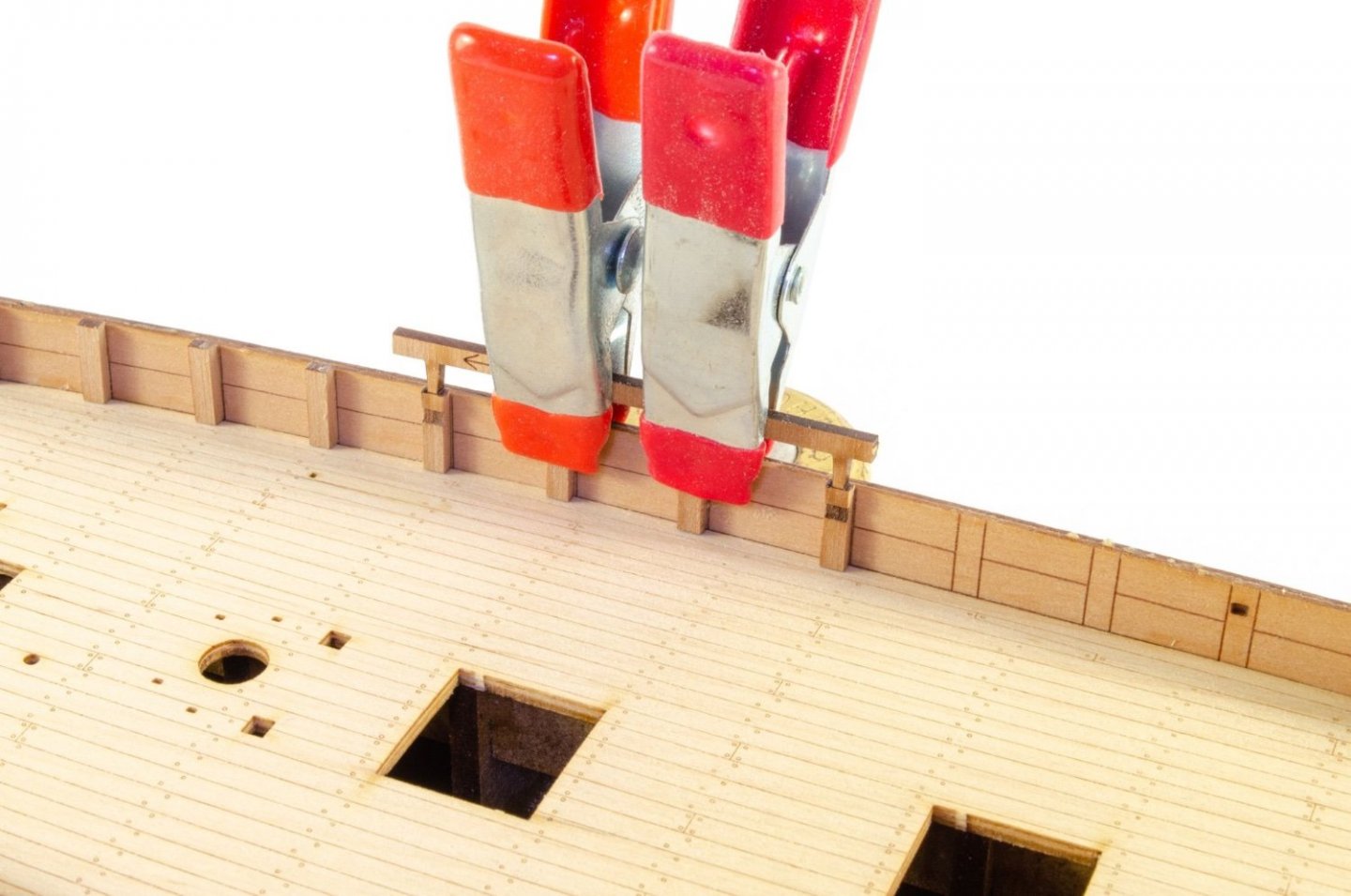

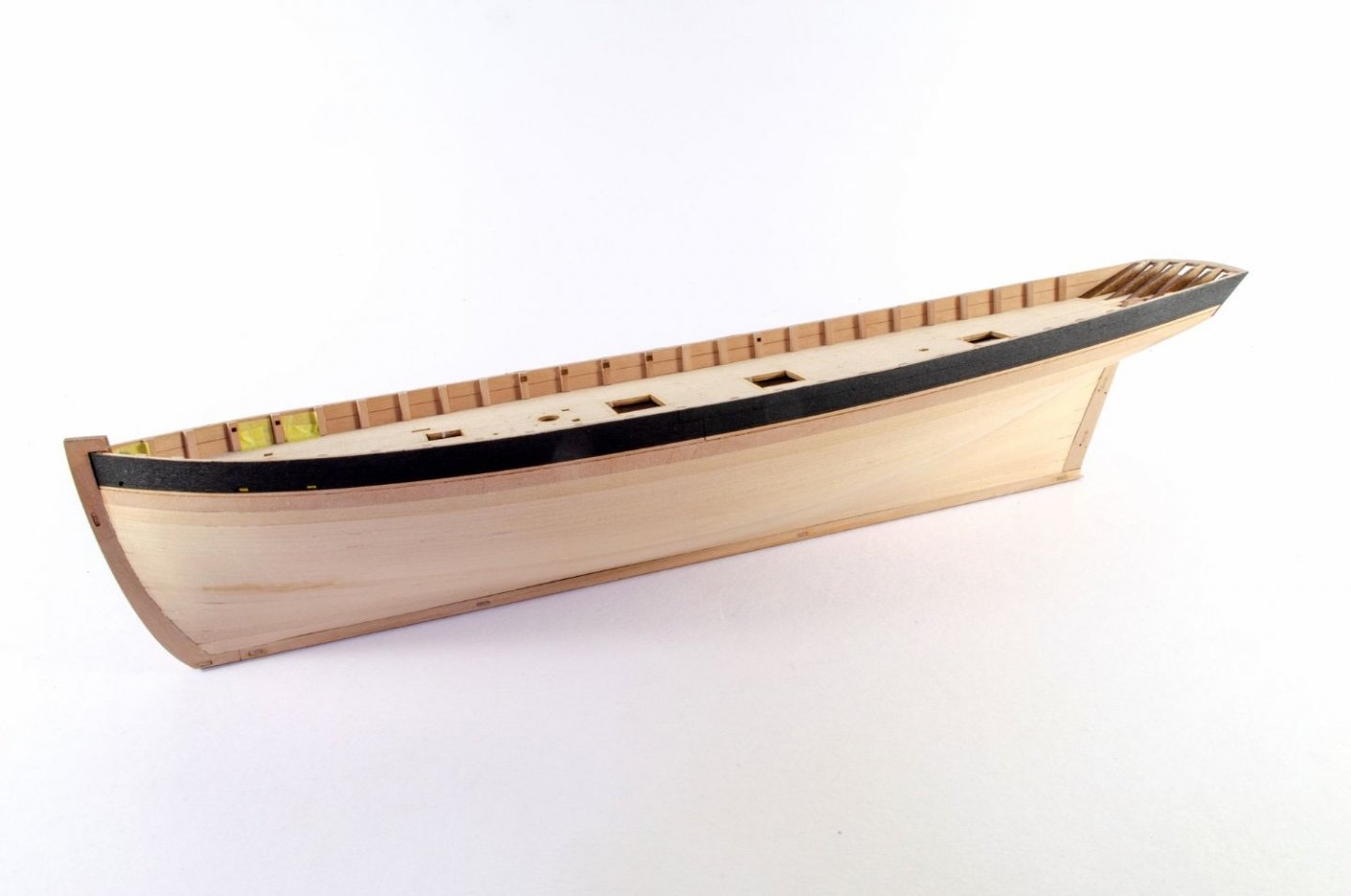

I've grouped most of these photos into thickness of sheet, and there are a lot of various thicknesses with multiple sheets for them. You can see the tabbed gun carts here too. Those tabs are on the forward 'bulkhead', closest to the inner bulwarks.

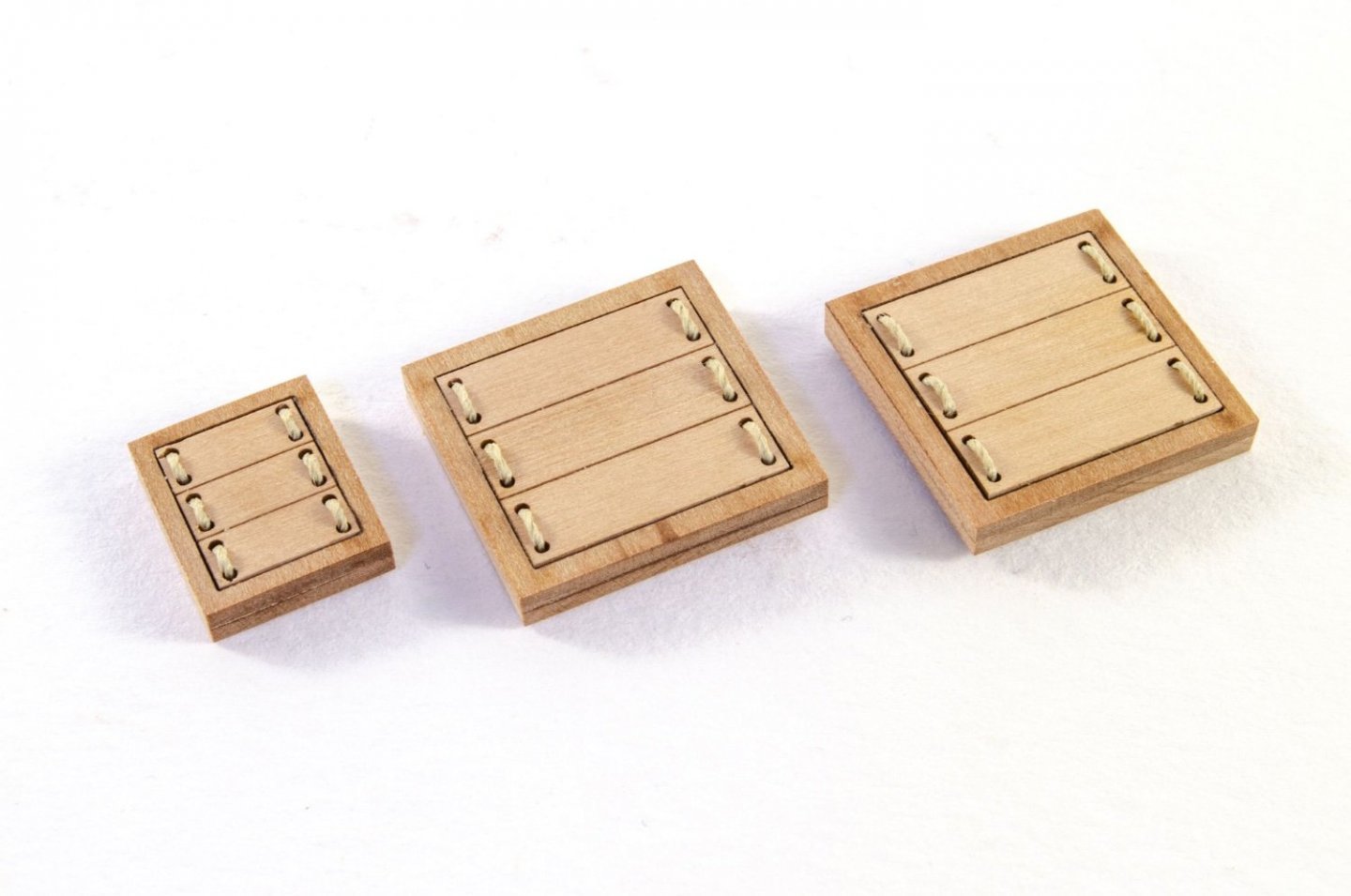

You're going to have to make FIVE ship's boats for this one!

Inner bulwarks are split into three sections to cover the entire length. There will also be doorways from the cabin into the quarter galleries.

3D printed stuff, like belfry, anchors etc. and I do see some copper tape there too.

3D printed stuff, like belfry, anchors etc. and I do see some copper tape there too.

Quirks of prototyping. Various cabin floor sections.

LOTS of strip too.

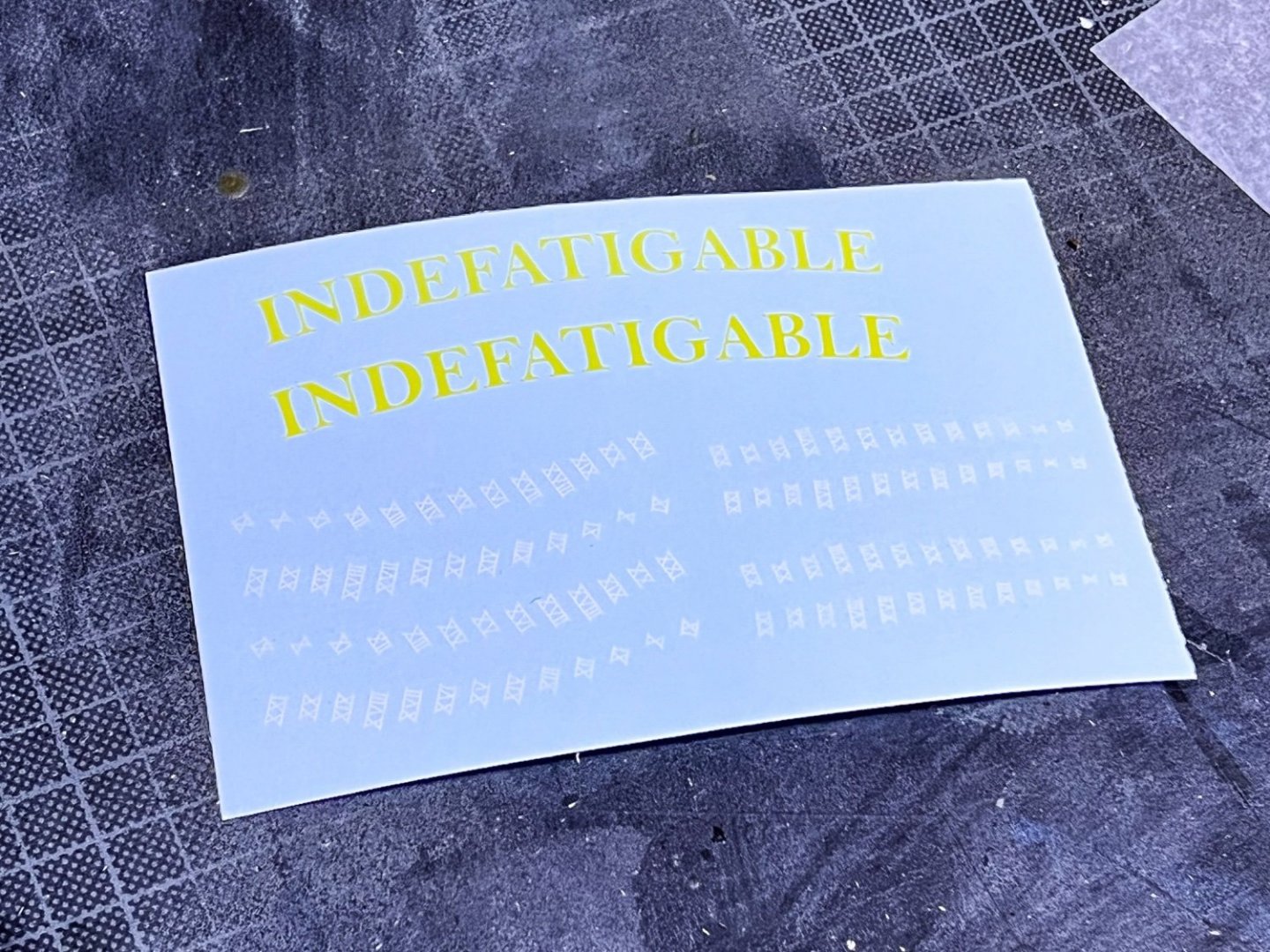

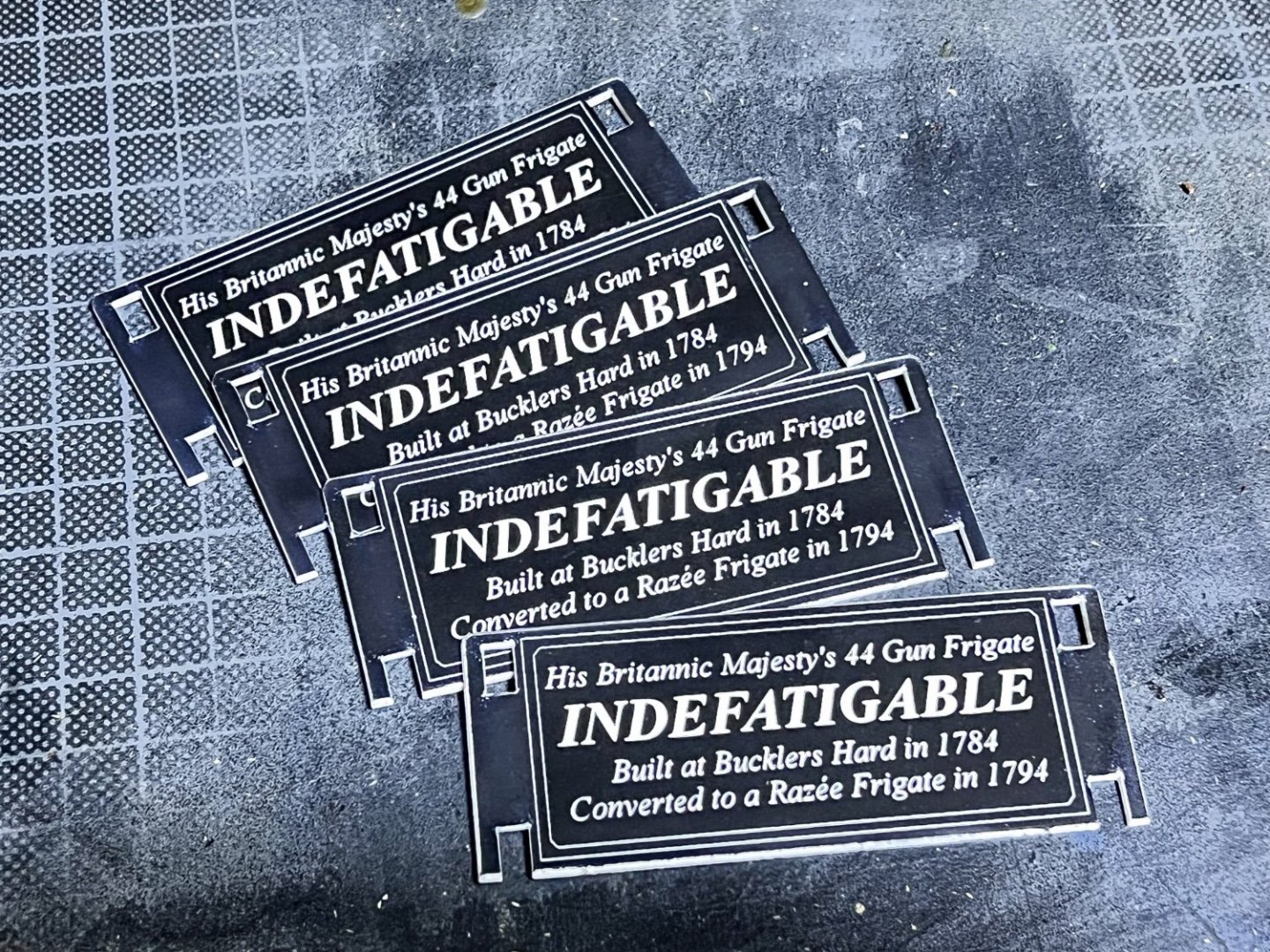

Decals for name and depth markings. Also, there is no white edge on that text. It's merely the light catching the ink edging! I have checked.

-

Time for a quick update. This will be the last one before work starts very shortly.

I'm making this update over TWO posts due to number of pics. These are just camera photos and won't represent anything you see in the manual.

Indy turned up with UPS this morning, and the box is large and heavy. In fact, the box isn't large enough yet as the masting, rigging, manual and plans also need to be included, as well as PE etc. The box was packed out as it was. This one took up two seats on my sofa.

Take a look through and you'll notice some little things here and there. One of those is that the main gun deck carriages are tabbed so they slot into the deck and can't be knocked free later in the build. This is only an optional feature as the modeller can, if they wish, plank over the tab slots and remove the tab from the carriage. That would be up to the individual but this is a perfectly good solution that will be invisible when implemented. If also means the guns will be perfectly spaced too and the barrels therefore evenly protrude from the hull. Those barrels will also be fitted after the hull is painted, so attaching them later won't dislodge a gun cart.

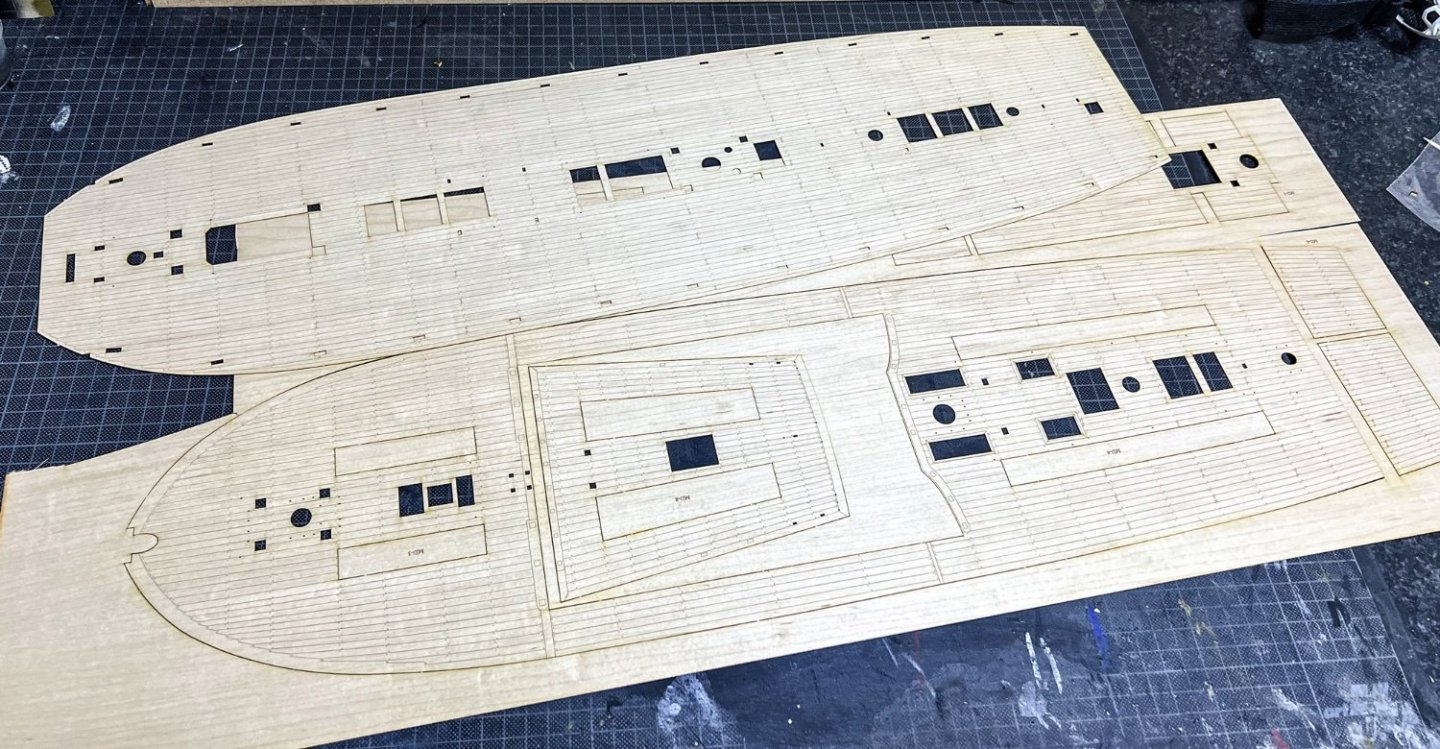

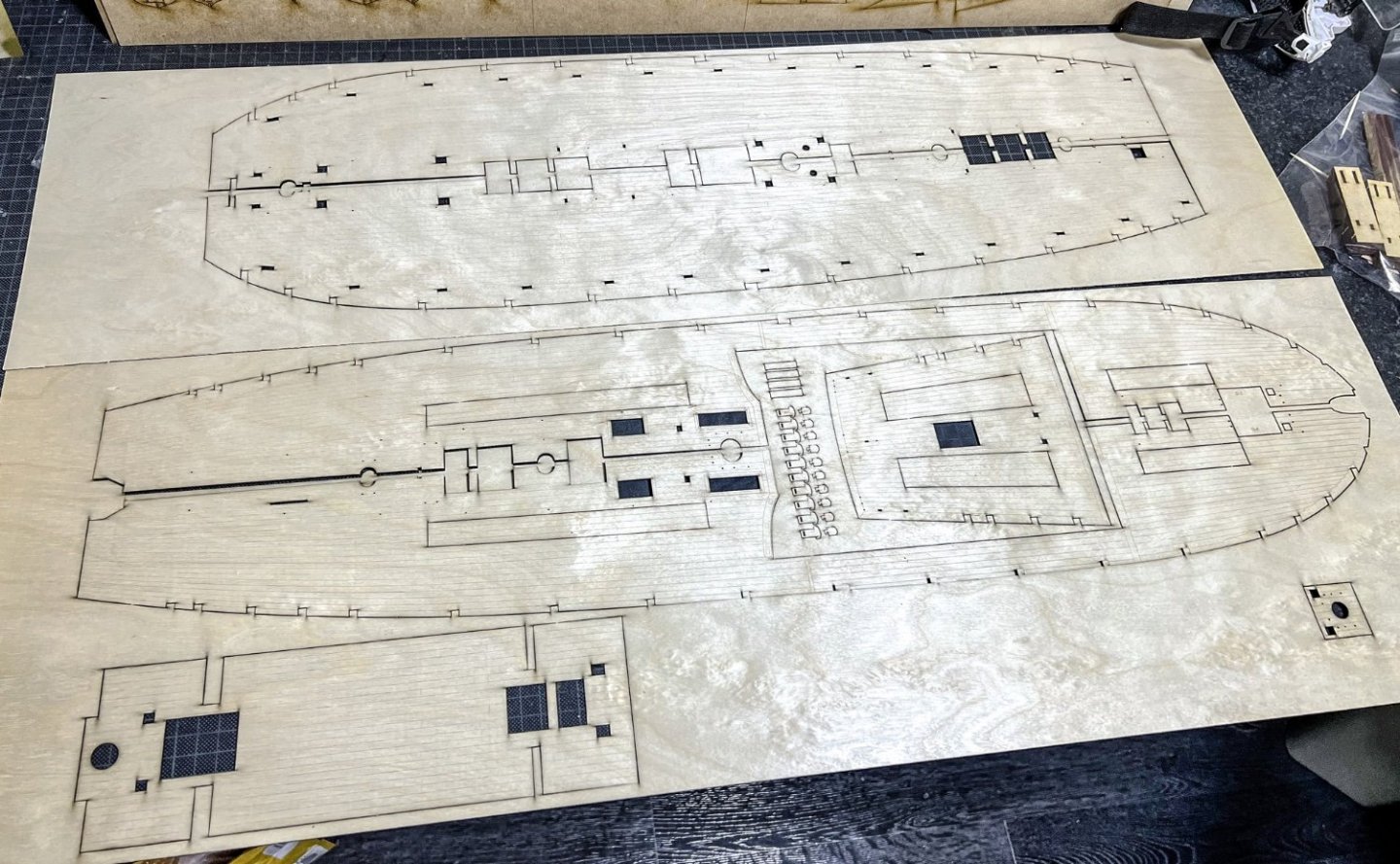

This is the engraved maple deck which won't be included as standard, unlike the other kits. This kit will have traditional planks for the deck, but it is quite likely that this option will be provided on release. If that happens, then the gun carriage location slots aren't likely to be there, and you'll simply open them up if you want use that kit feature. Oh, these parts are BIG!! My cutting mat is in 1cm squares, as a guide.

Not fantastically clear here, but the ply sub decks are engraved with planks. This isn't the finish. It's designed to give you a template onto which to lay the kit planks. That will save the modeller having to mark up stuff themselves.

-

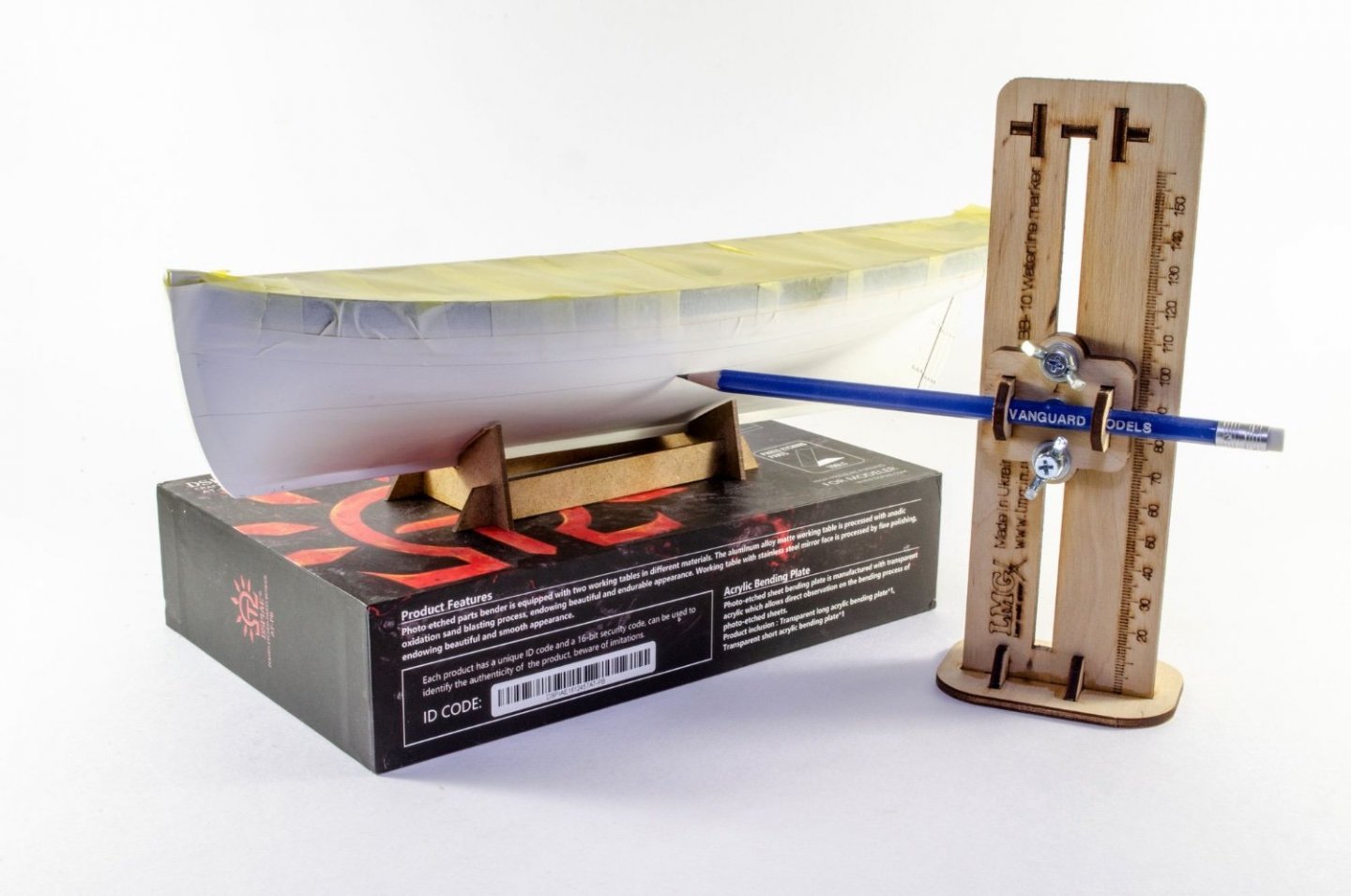

I don't really use much in the way of tools for what I do.

To build VM prototype kits, I use:

- Scalpel knife

- sanding block and sandpaper

- tweezers

- steel rule

- clamps - 2inch and 4inch

- nail pusher

- pin vice with selection of drills

- long nose pliers

- needle files

- waterline marker

I do have a plank nipper for occasional stuff, but really use it. They are cheap enough though.

Most of what you see there is very basic and quite inexpensive.

-

49 minutes ago, allanyed said:

....and does it explain about the foremost shrouds being served for their entire length to protect them from chafing?

lol! I really don't think that's the remit of any kit! I've certainly never, ever seen that from any manufacturer.

-

1 hour ago, Sluicemaster said:

Thank you ccoyle. Both of your suggestions were great. Just one more question. To add a new post to my build log do I just click on the button "reply to this topic?" I searched high and low for a button that might say "update log" or something to that effect. Again, thank you!

Just click the 'Reply to this topic' you see in this screenshot in the same way you replied to this topic you created.

That applies throughout the site.

-

-

Member banned.

Previously registered under different name and banned for supporting piracy.

- mtdoramike and mtaylor

-

1

1

-

1

1

-

Member banned.

Previously registered under different name and banned for supporting piracy.

- mtdoramike, mtaylor, Ryland Craze and 1 other

-

2

2

-

2

2

-

Eugen, that looks superb and beautifully clean work.

When do you think this one will be finished?

- greenstone, BobG, mtaylor and 2 others

-

5

5

-

-

Just sand and fill, sand and fill. Most of this is under paint anyway and if you're unhappy with anything above paint areas, you can always extend the scheme a little.

That's not looking too bad at all. Use your fingers to feel for imperfections, then sand as you feel anything.

- chris watton, Glomar, Craigie65 and 1 other

-

4

4

-

I'm pleased that I did my bit with the instructions build and that it's easy enough to follow.

God help me when I have to do the pics for Indefatigable! 😂

- Andyrew, chris watton and AJohnson

-

2

2

-

1

1

-

Don't forget, PayPal also lets you spread purchases too. Depending on region, stuff can be spread between 3 and 5 months too.

Indy will be very reasonable in cost, especially over the time it will take to do this kit justice.

- thibaultron, BobG, AJohnson and 7 others

-

10

10

-

I know cost is relative, but if we take a look at something very pertinent, then we get a better idea:

Caldercraft 1:64 HMS Agamemnon. A kit that uses the legacy POB methods, with dummy barrels for the lower gun deck, nothing in the way of laser-cut/engraved parts. Many generic fittings and also the gun port positions are determined with a paper template, with the exception of quarterdeck ports that are cut into the inner bulwarks. Finishing and detail timber is generally walnut with Tanganyika for decks. Aggy also doesn't have a lower gun deck at all. The main gun deck is complete, but stops fore of a ply bulkhead so doesn't extend to stern cabin areas as they don't exist in kit. In all, Agamemnon is an amazing kit, and we've seen some fantastic builds of her.

What does she currently retail for? £935 direct from Caldercraft. This is a kit that's now 22-23 years old.Vanguard Models 1:64 HMS Indefatigable.

- A kit that uses new design techniques with gun ports built into the hull framing.

- Stern cabin with internal engraved details (chequered floor, panelling etc), accessible quarter galleries with seats of ease. Stern cabin windows can be posed open or closed.

- Complete main gun deck with option to plug the gun carts into position so they don't come adrift accidentally.

- No generic parts. All guns on kit are designed to be the exact ones, printed in matt black resin, complete with George III emblems.

- Other 3D print parts include a proper scale belfry, Brodie Stove (in 4 parts), anchors, carronades/wheels, and also some rudder parts.

- 10 thicknesses of laser cut sheets.

- Planking will be in pear, and not walnut. There really is a price premium for going with the much better pear. Less brittle, less fibrous, finer grain and more realistic in colour. Deck planks will be either Red Alder or maple, depending on supply situation at time.

- To assist with painting, main gun barrels will be positioned after hull painting, and carronades are designed to retract into the hull until the externals are painted, then they can be pulled out into position!

- Detailed bulkhead screens for cabin.

- Deck beam positions are also to scale and in scale position, and do not relate to the MDF bulkhead positions.

- As with other VM designs, a rabbet is built into the keel, allowing easier plank positioning.

- Multi-layer channels to simulate the edging of the real thing.

- Engraved ply sub decks to assist with planking.

- Five mini kits for each of the ship's boats.

- Laser cut acrylic window panes.

- Laser cut and engraved acrylic stand with two-colour nameplate.

- Large and heavy full colour assembly manual detailing every aspect of construction and providing tips.

Of course, Aggy is a 64-gun, but is around the same size, more or less to the razée Indefatigable. Indy just loses the razed areas, but it actually longer than Aggy due to the flying jibboom.

Price? Tentatively around £1000.

A whole 23yrs after Caldercraft's kit was released.

-

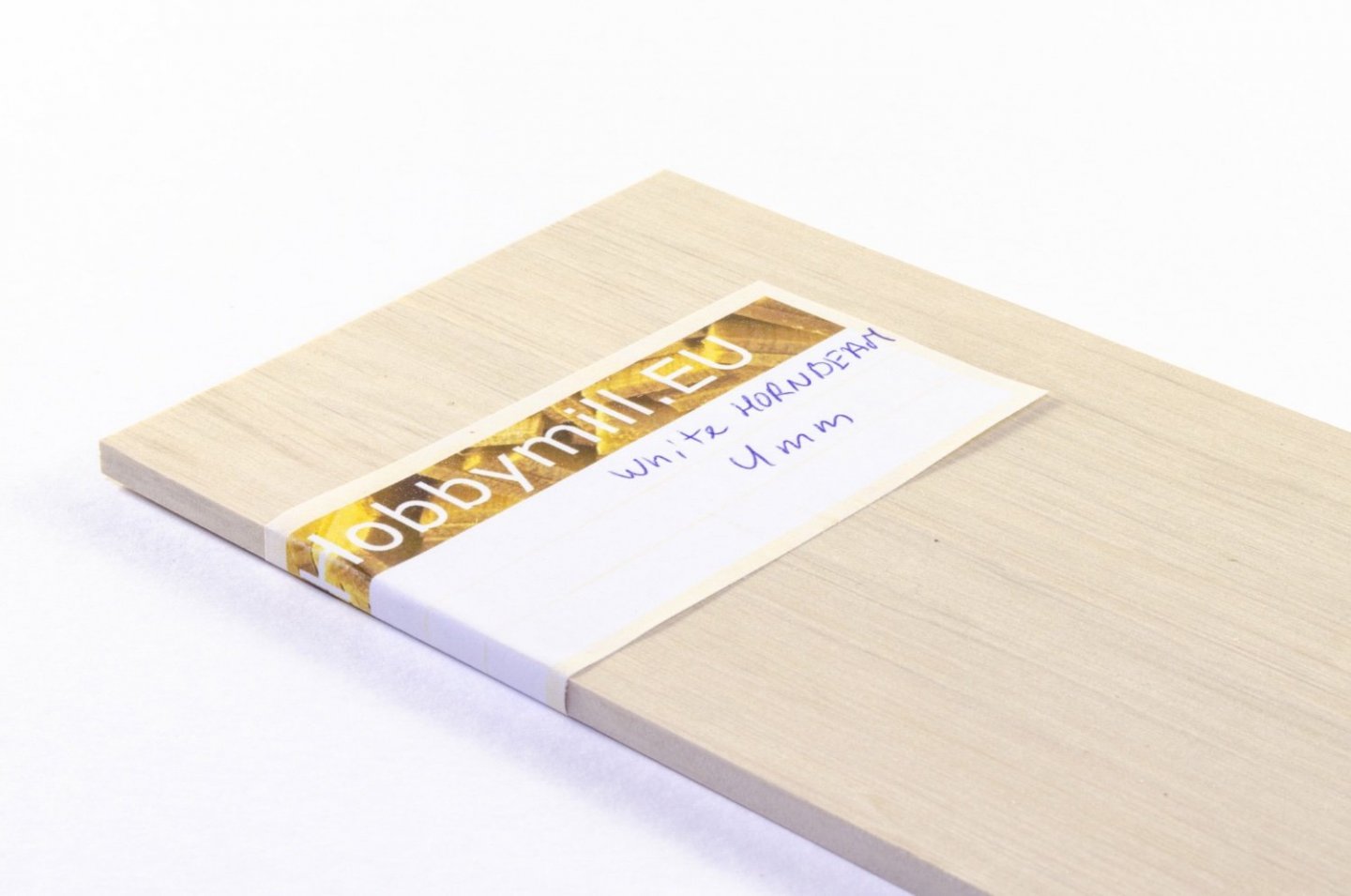

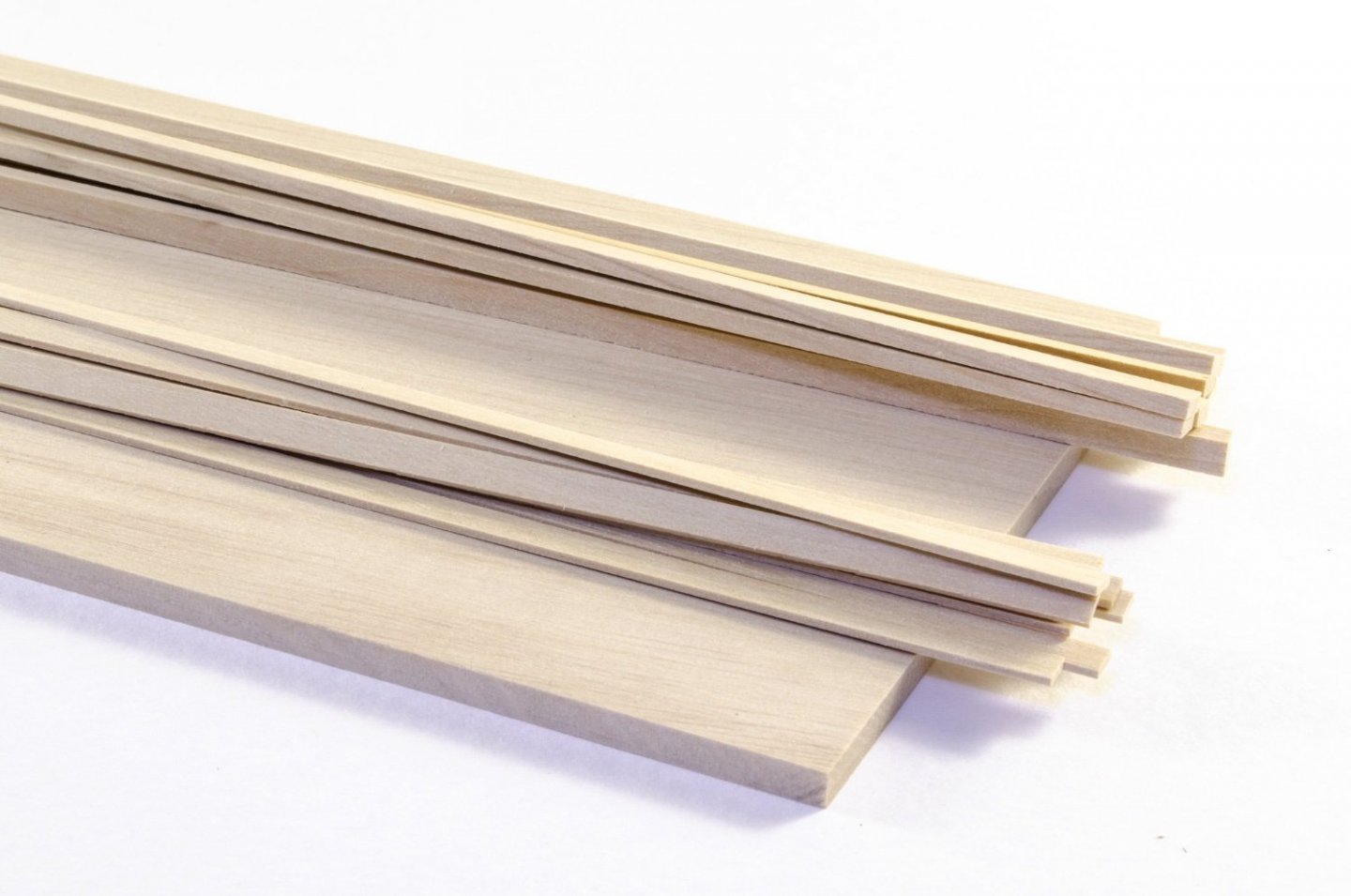

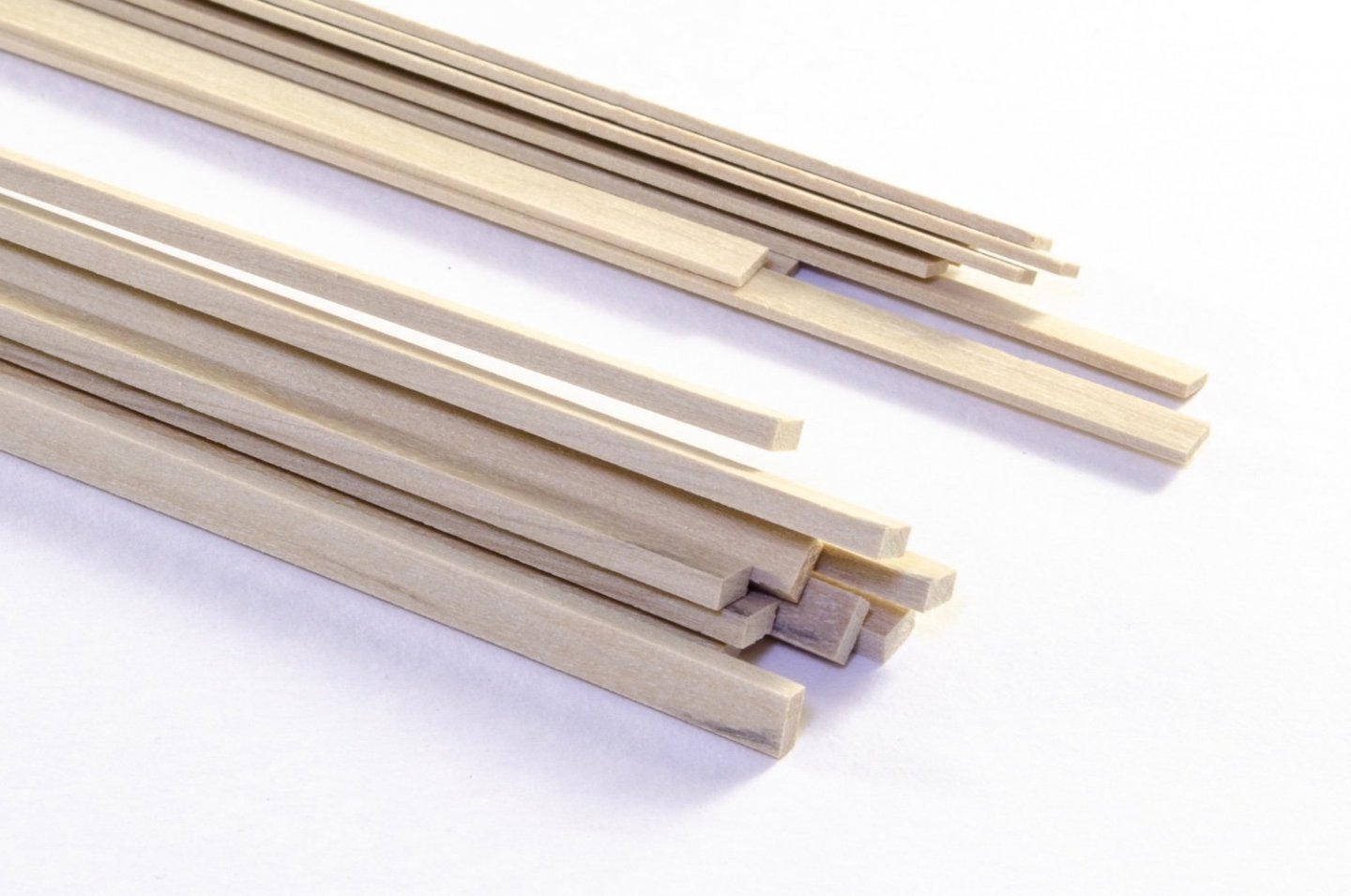

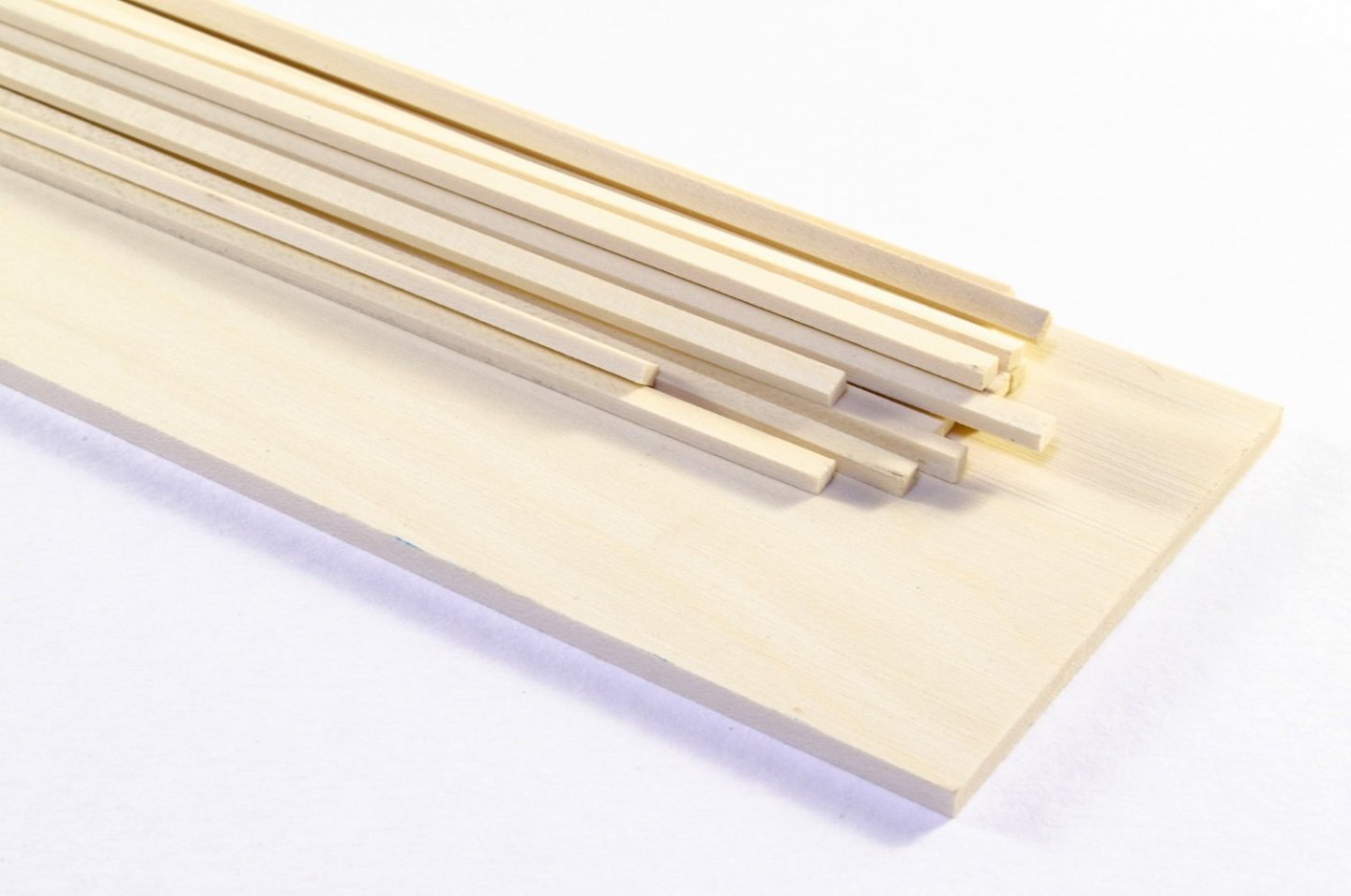

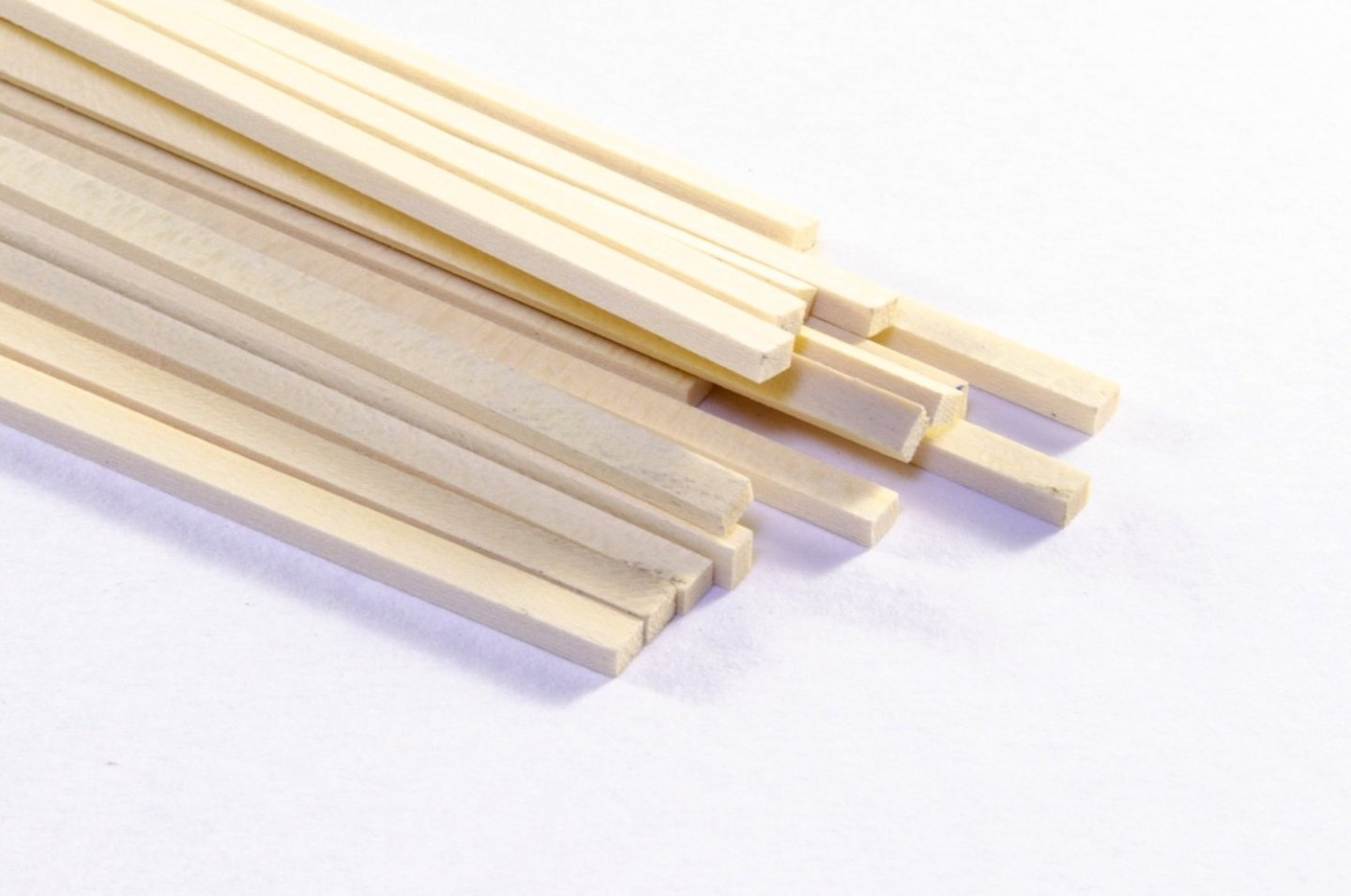

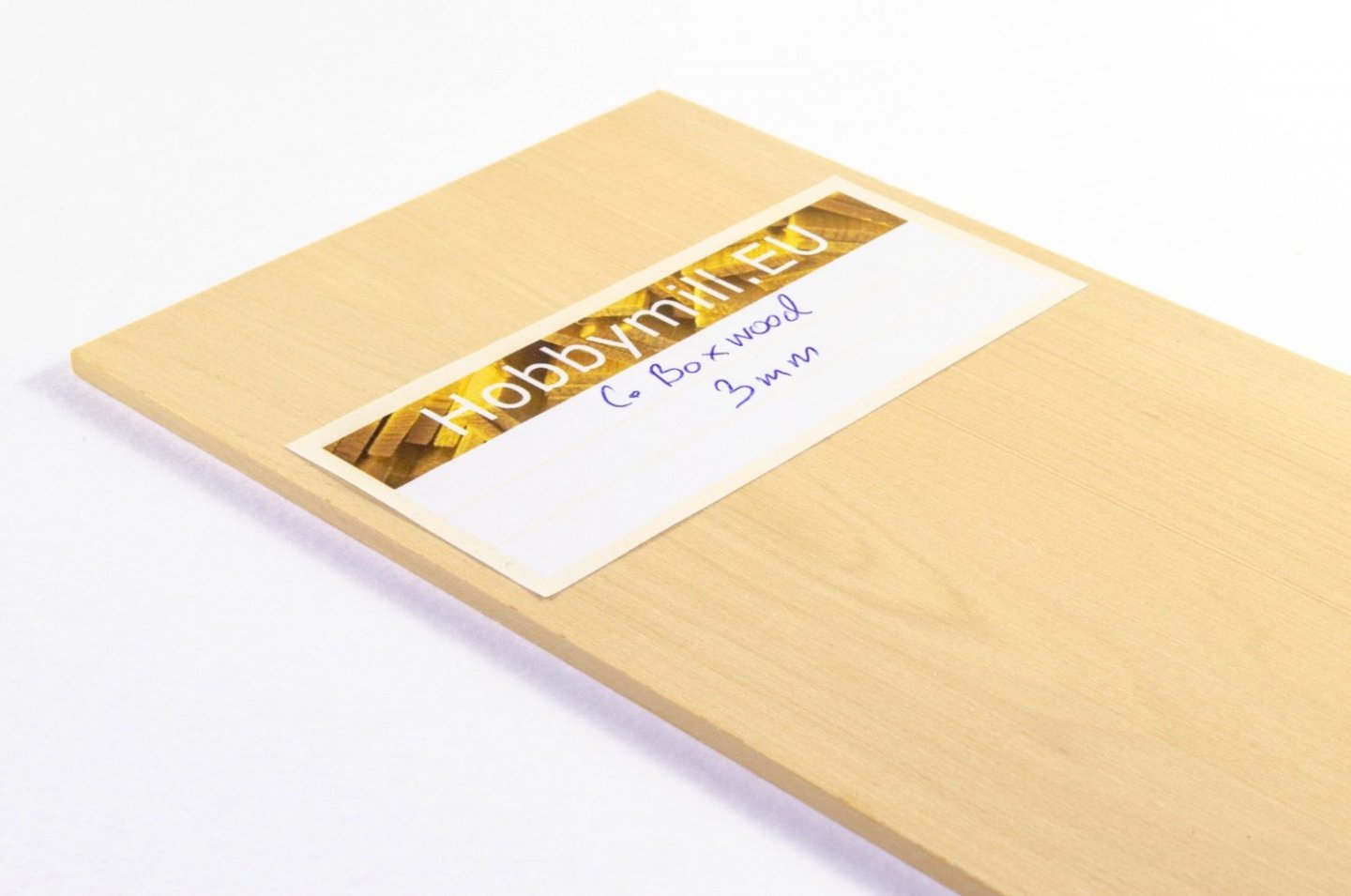

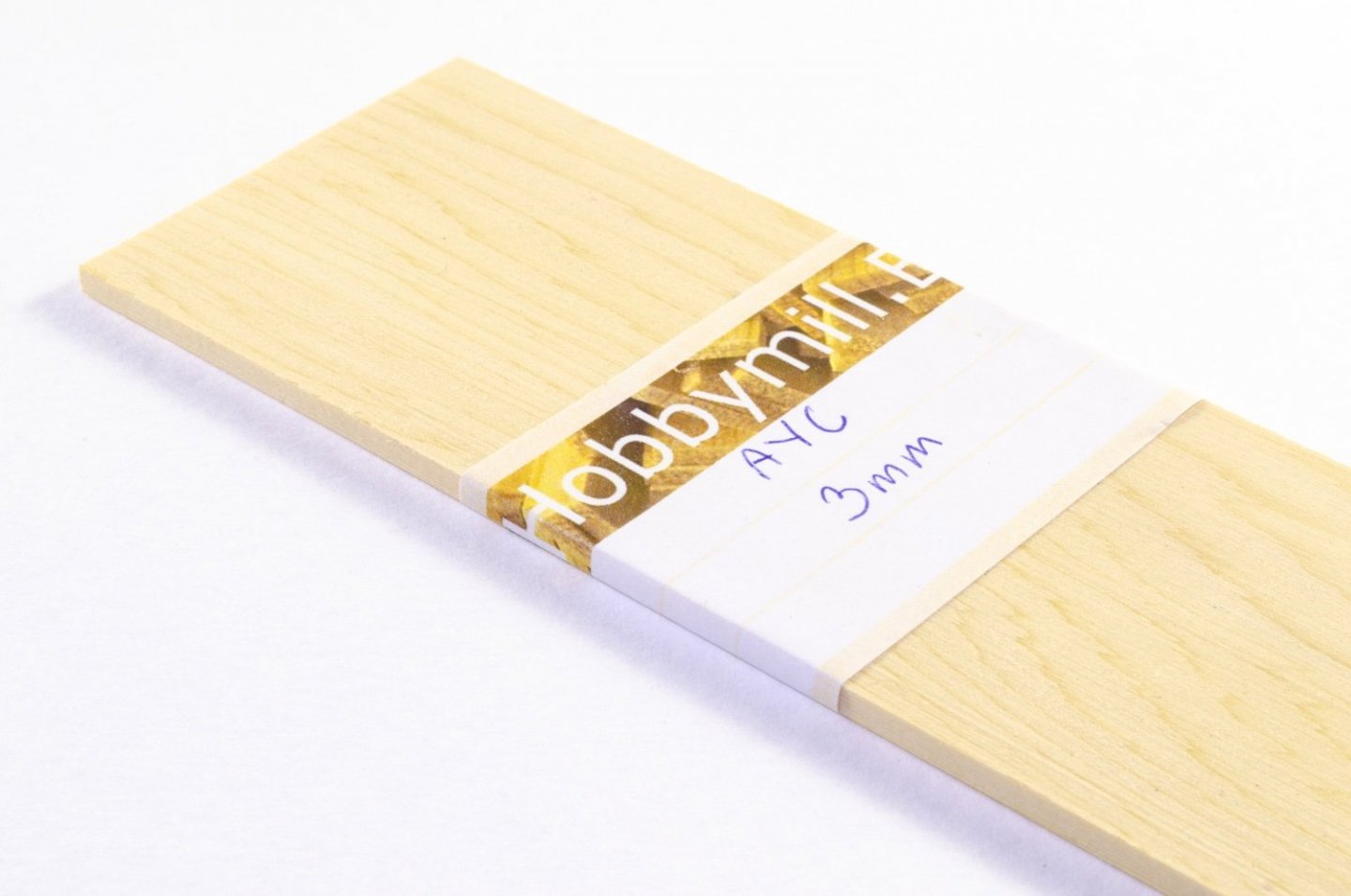

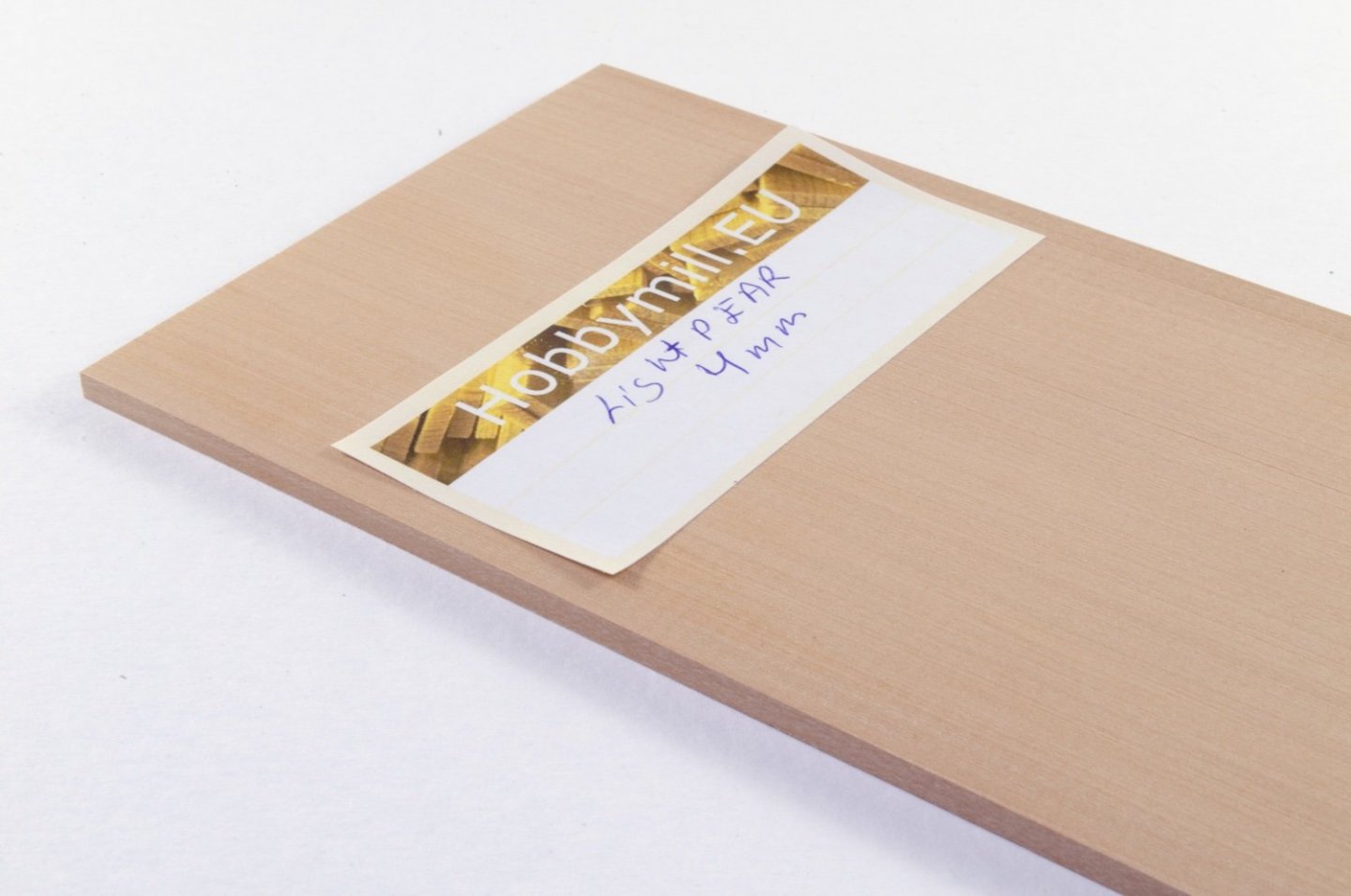

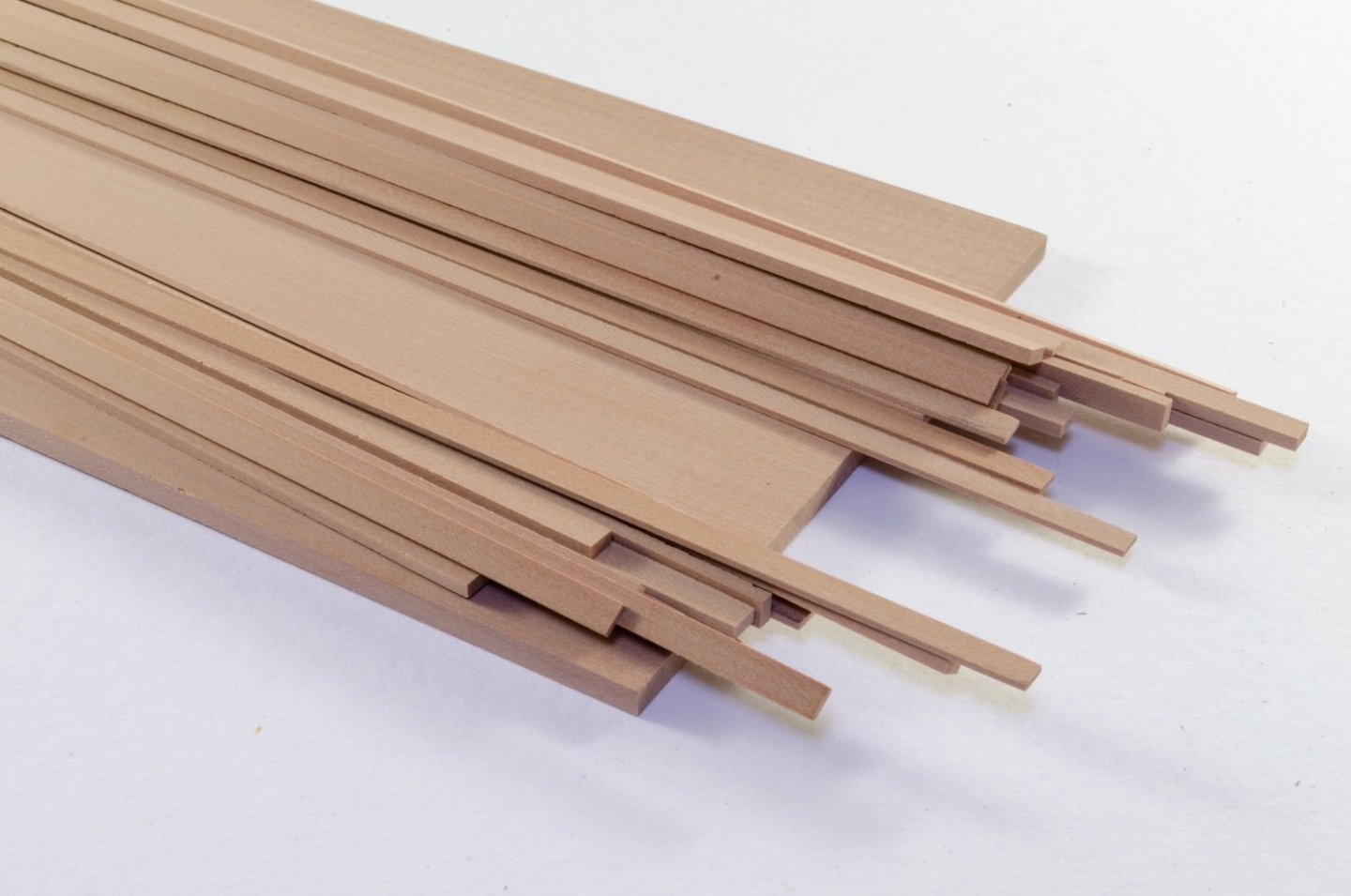

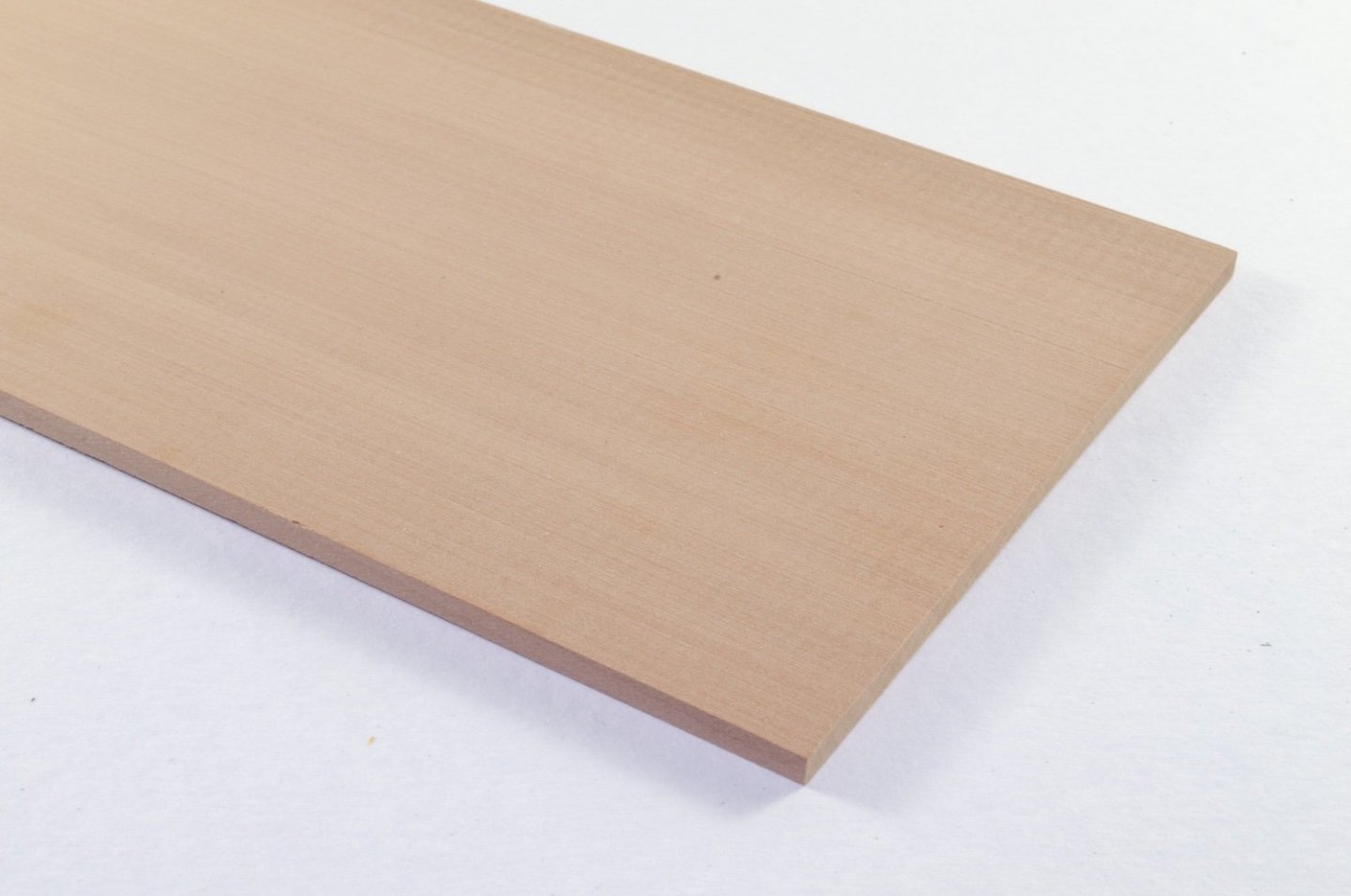

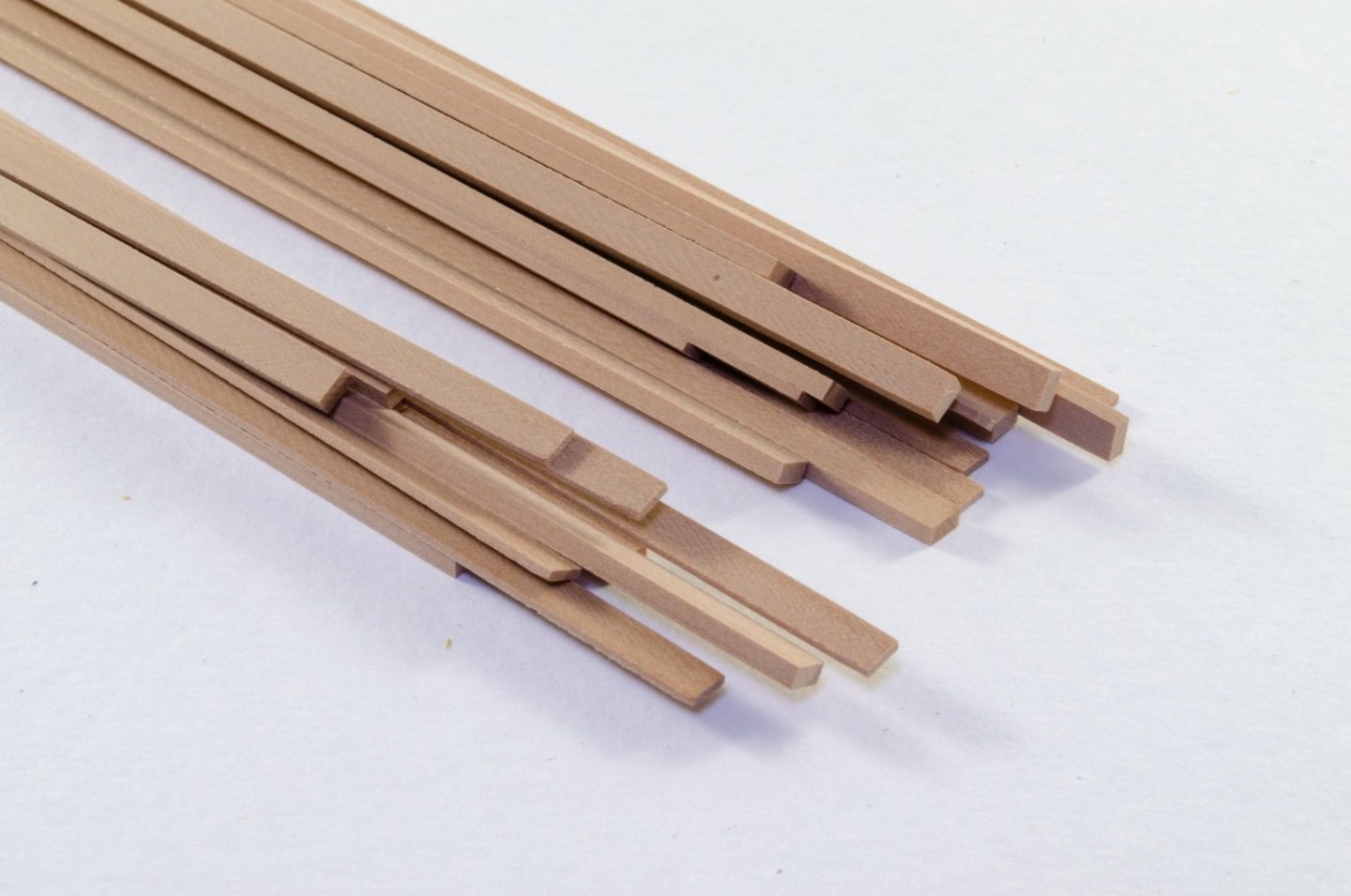

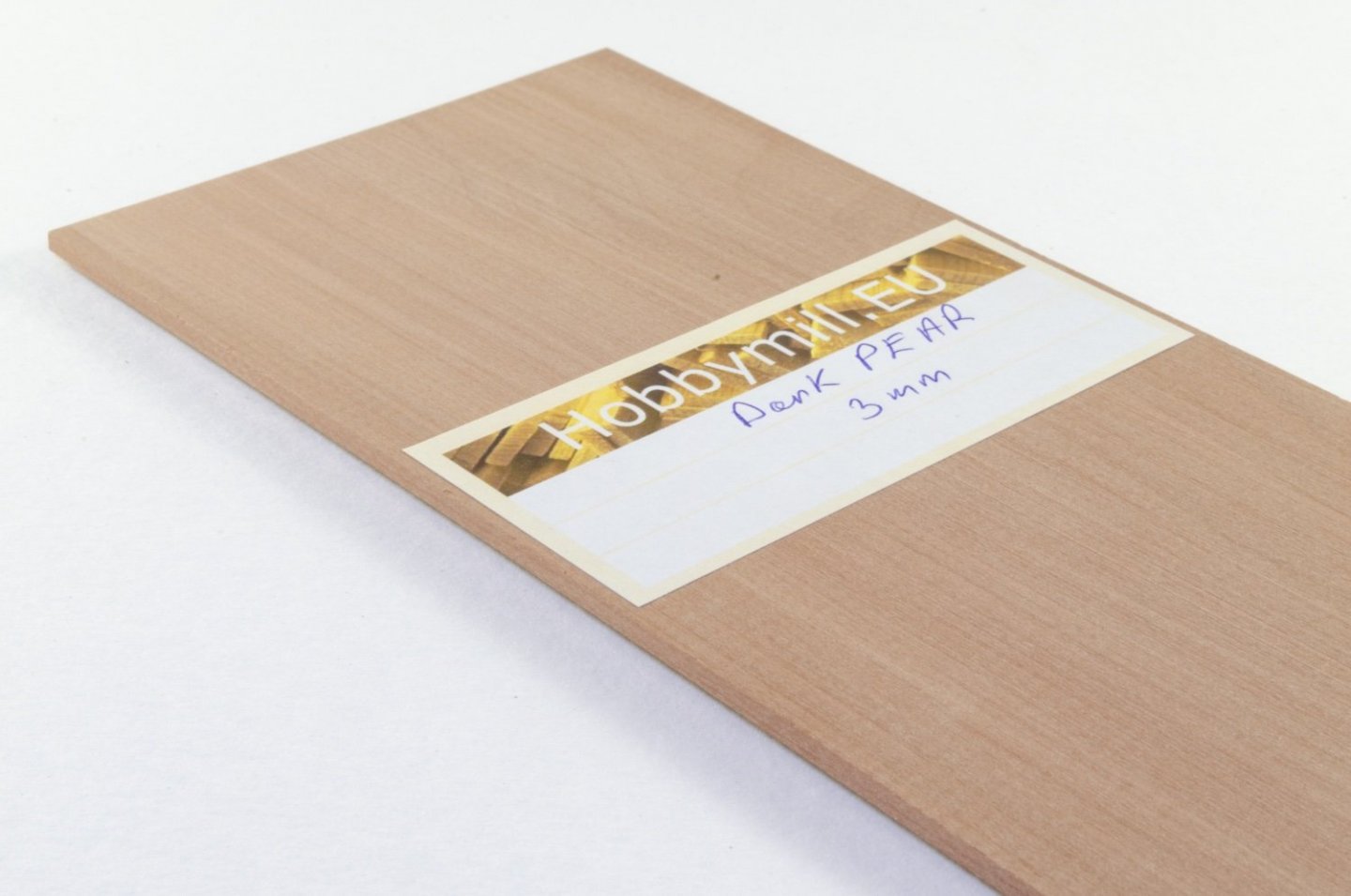

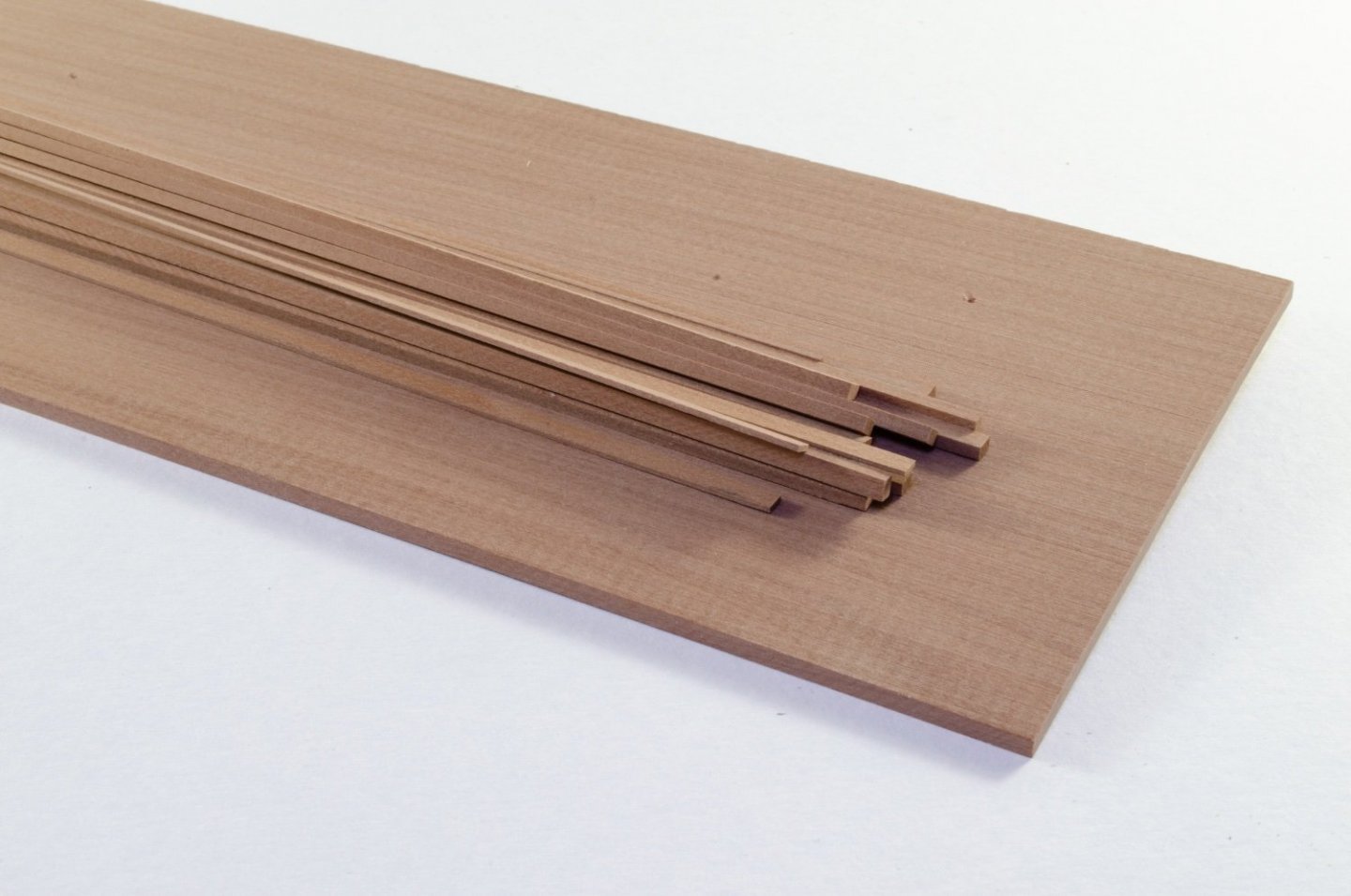

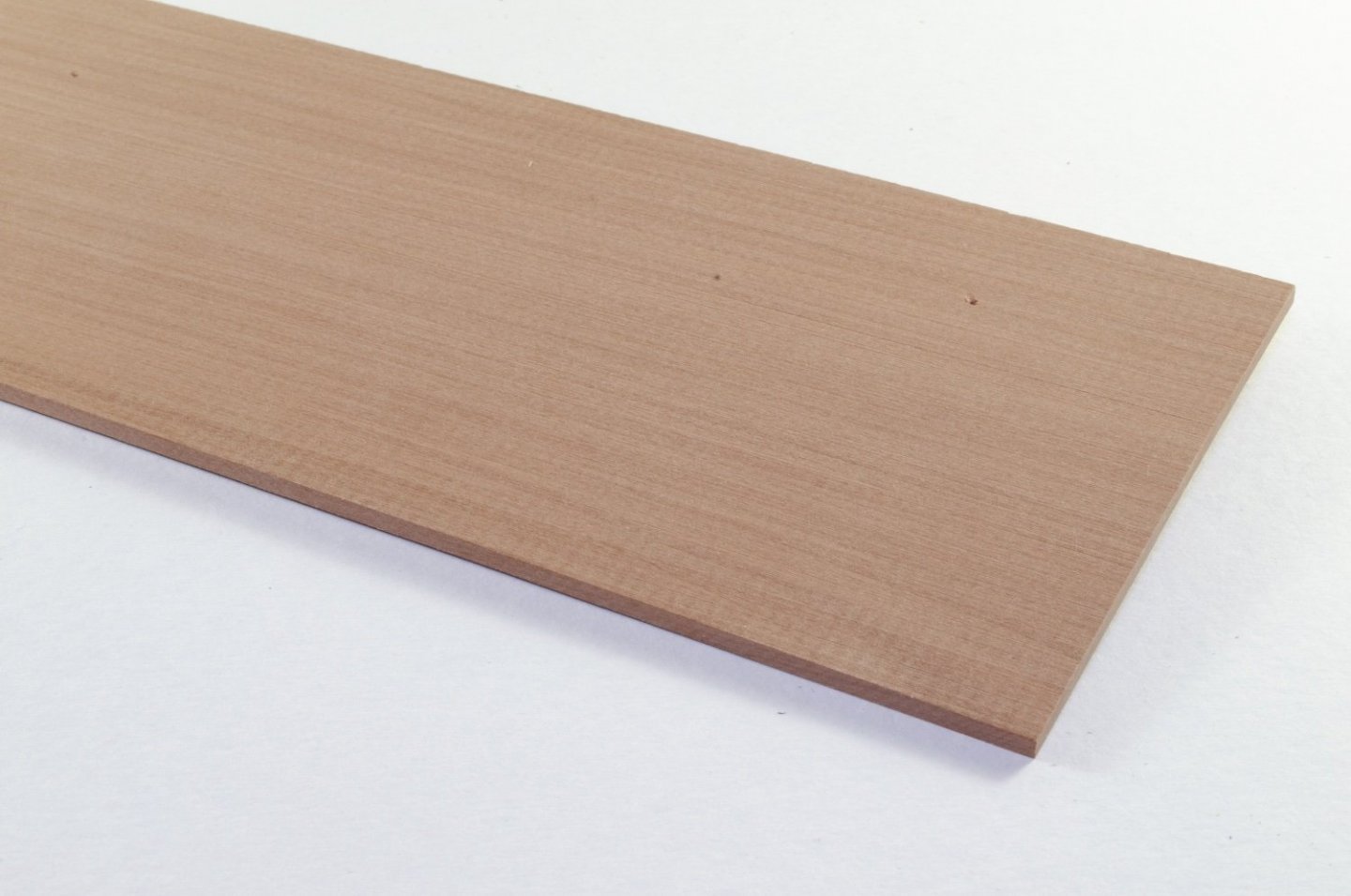

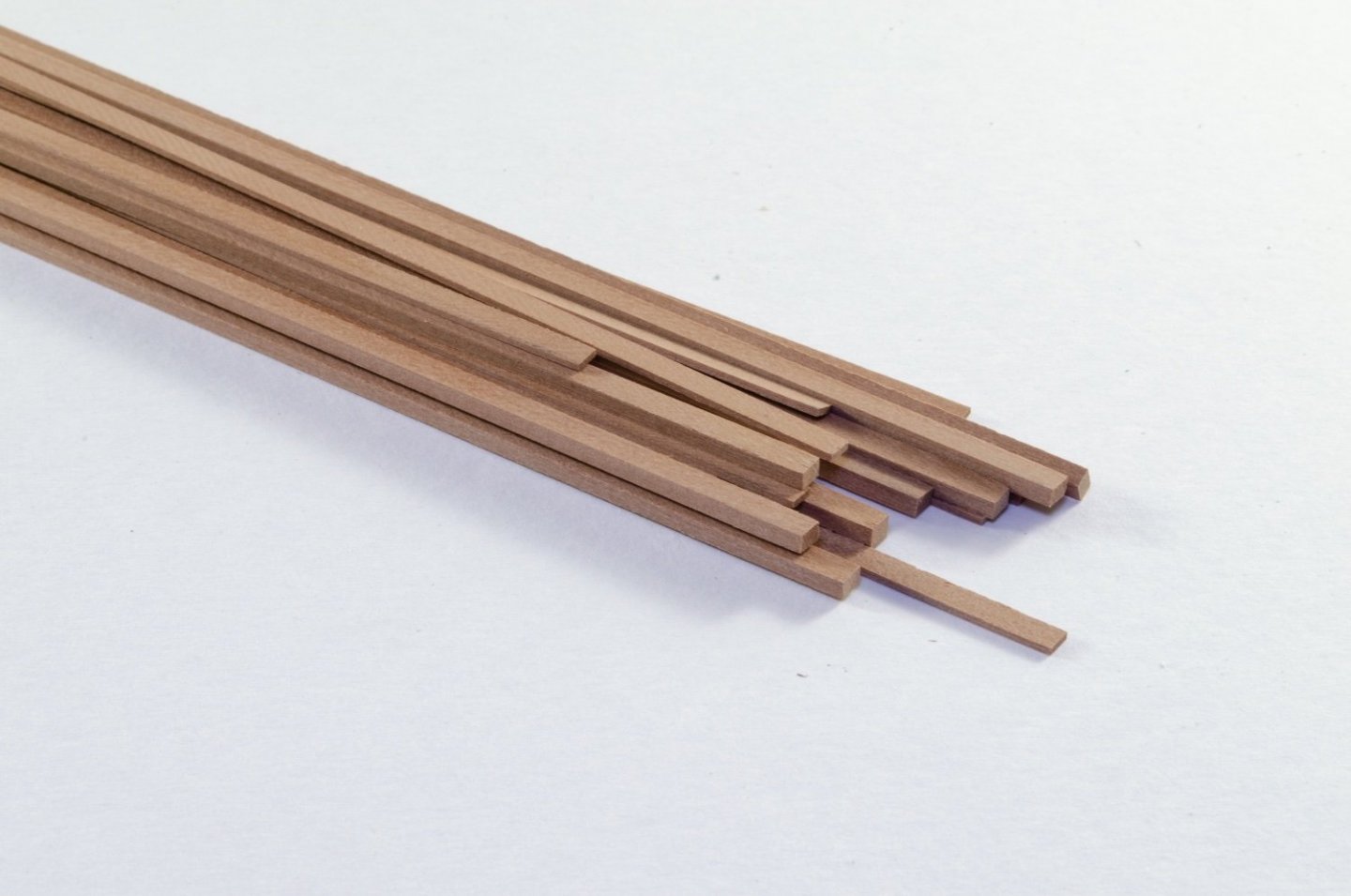

Timber - Various sheet and strip

HobbyMill.EUsee website for sheet and strip price

HobbyMill.EU are an Estonian-based company (Tallinn), operated by a guy with a very real passion for what he does, and both my communications with him and the timber samples sent, clearly show that. The material he saws and processes is sourced from quality EU-based suppliers. Timber as a natural product, can contain colour variation, imperfections etc. and because of any small flaw that may be present on the strip, for example, I'm told that where this happens, a small number of extra strips is usually added so the customer gets exactly what they need in usable material.

The same also goes for width. If you order a sheet that's 100mm wide, the chances are it will be slightly more than that, depending on the size of billet that it's being cut from. If there's 20mm (for example) width to produce 100mm wide sheet from then you will get the 120mm so as not to waste any material.

Another note goes for the sides of the sheets being parallel. I have to say that mine are pretty darn good, but you may get a little variation. It really doesn't matter as long as the grain is true and the edges are nice and straight, and they are indeed that on my samples....which are taken from the general production in order to create a true reflection of material quality.

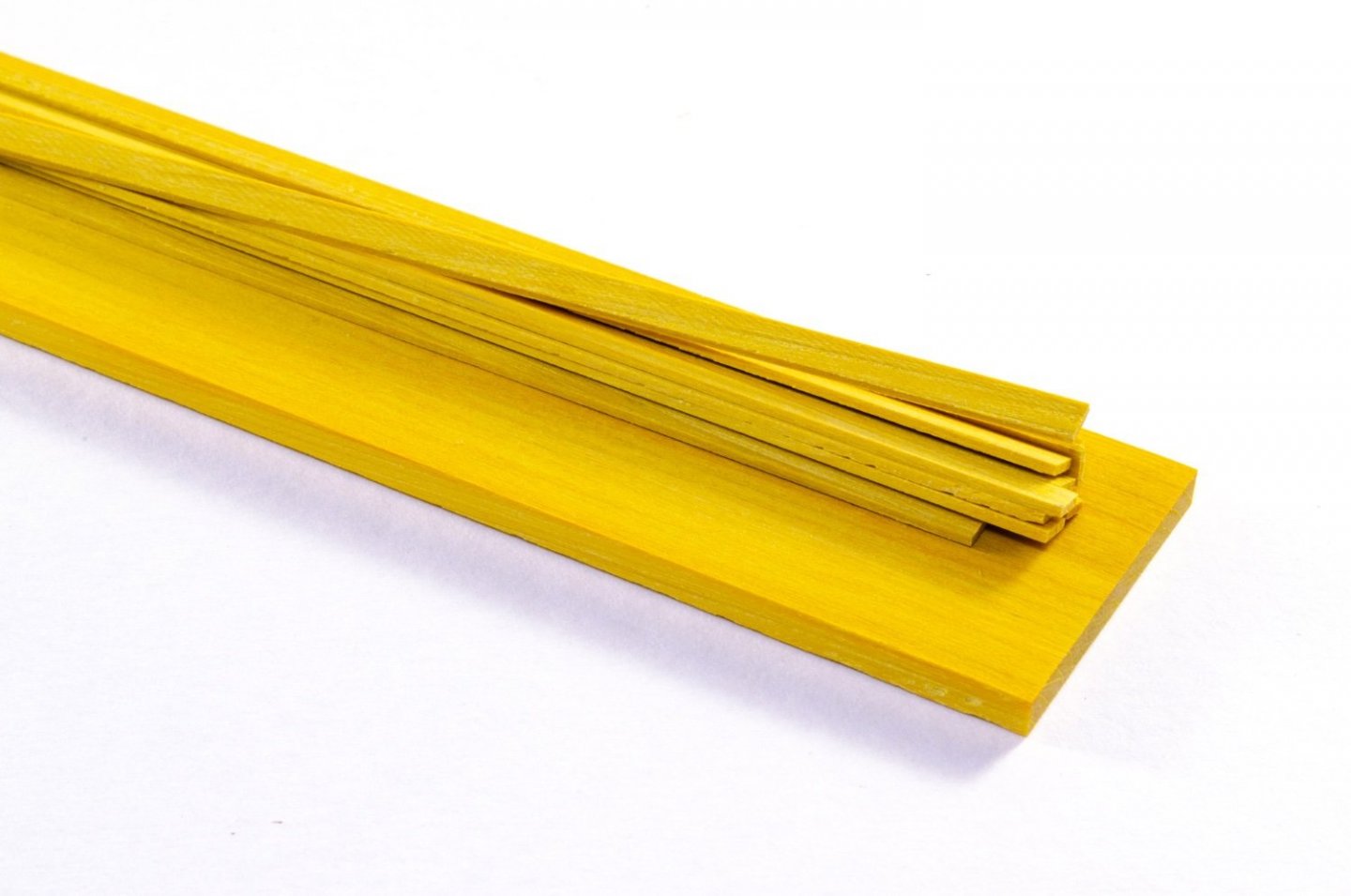

All edges are nice and sharp and the ends are clean. There are some very faint machine marks in places, but I only really notice those on my photography and not really on the actual product, apart from the coloured hornbeam. In order to cut the timber, HobbyMill are using Byrnes tools etc.

The timbers sent to me for this article are:

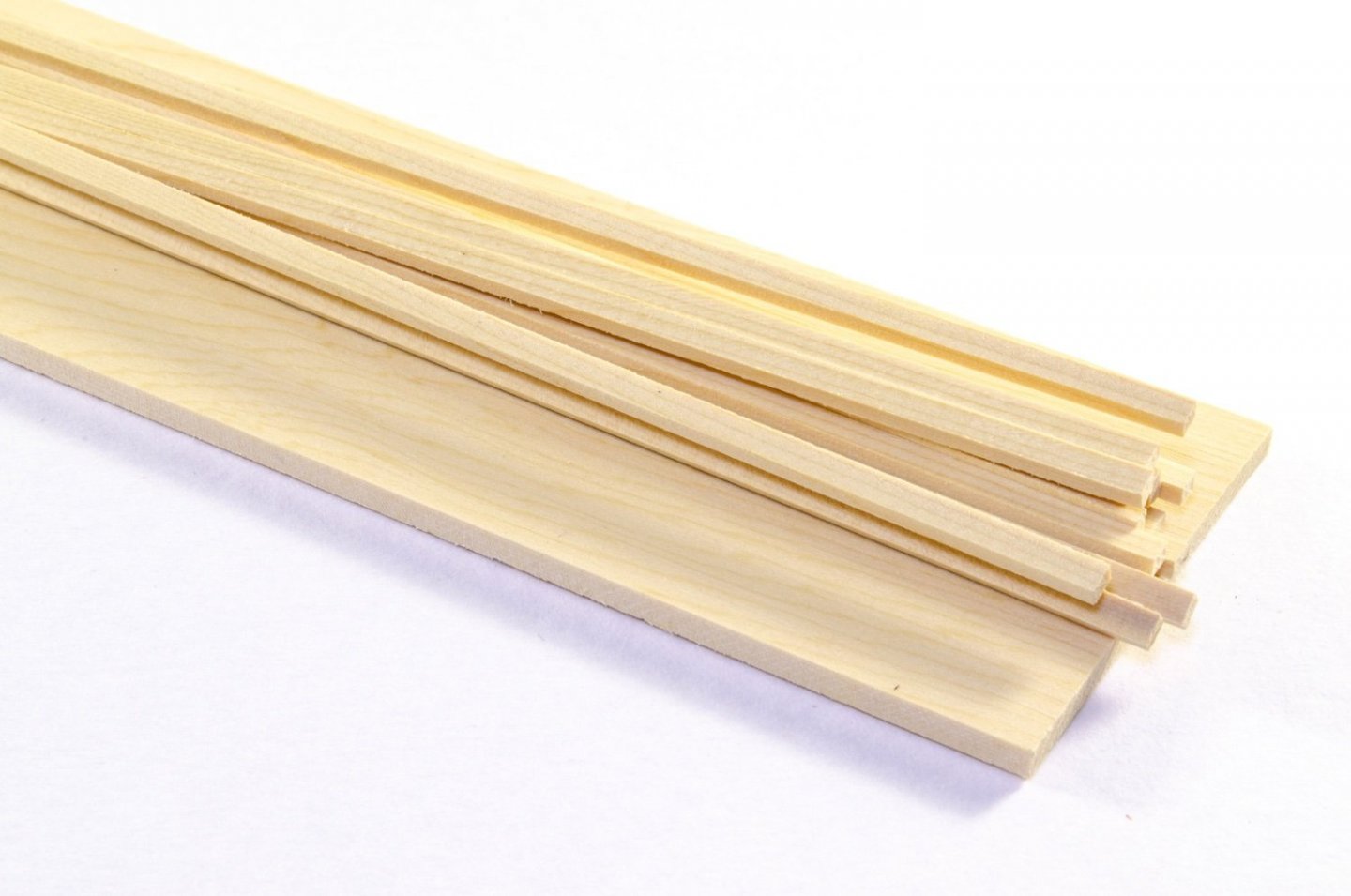

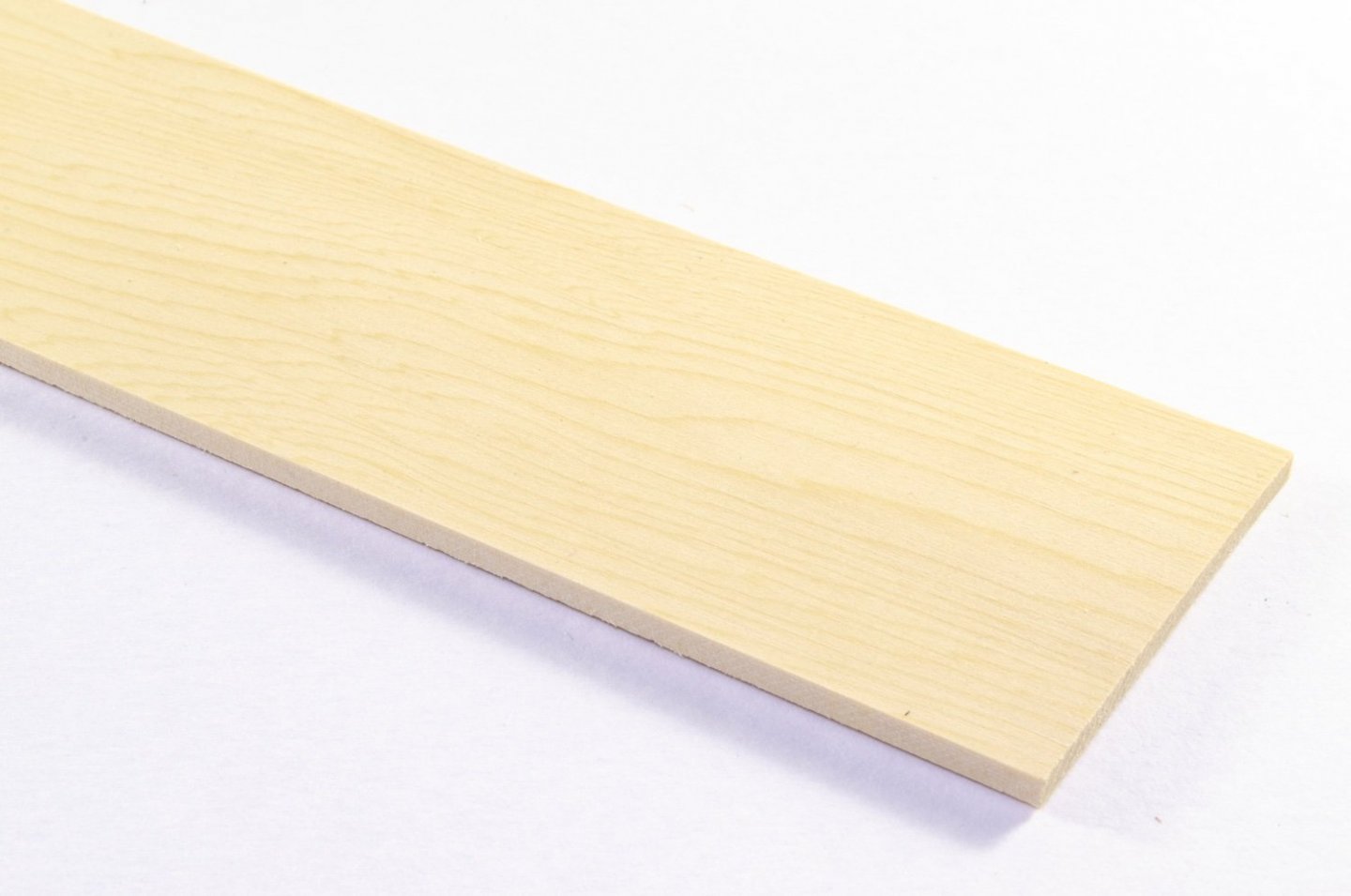

- White Hornbeam - 4mm sheet, 4mm x 2mm strip, 4mm x 1mm strip

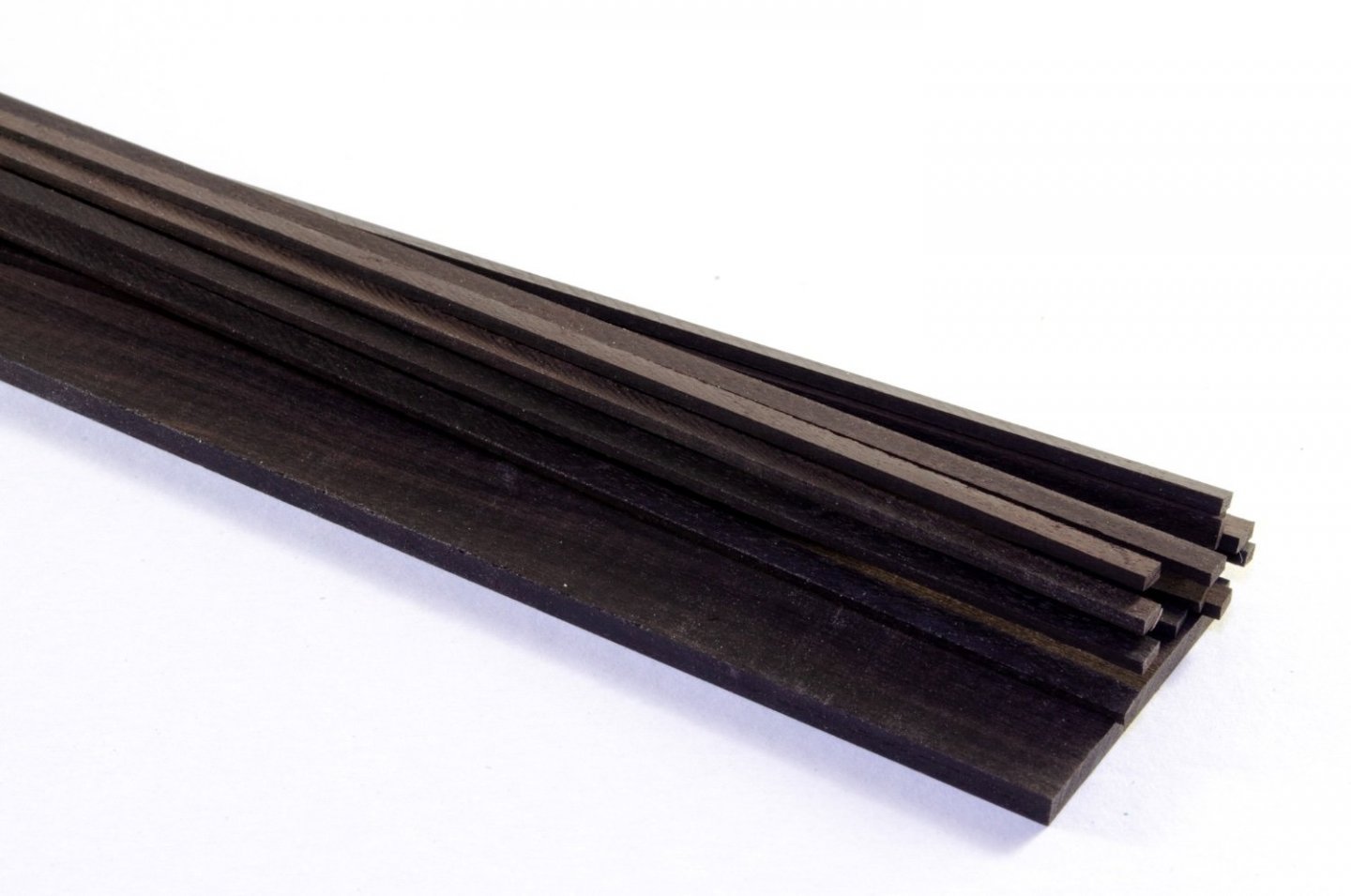

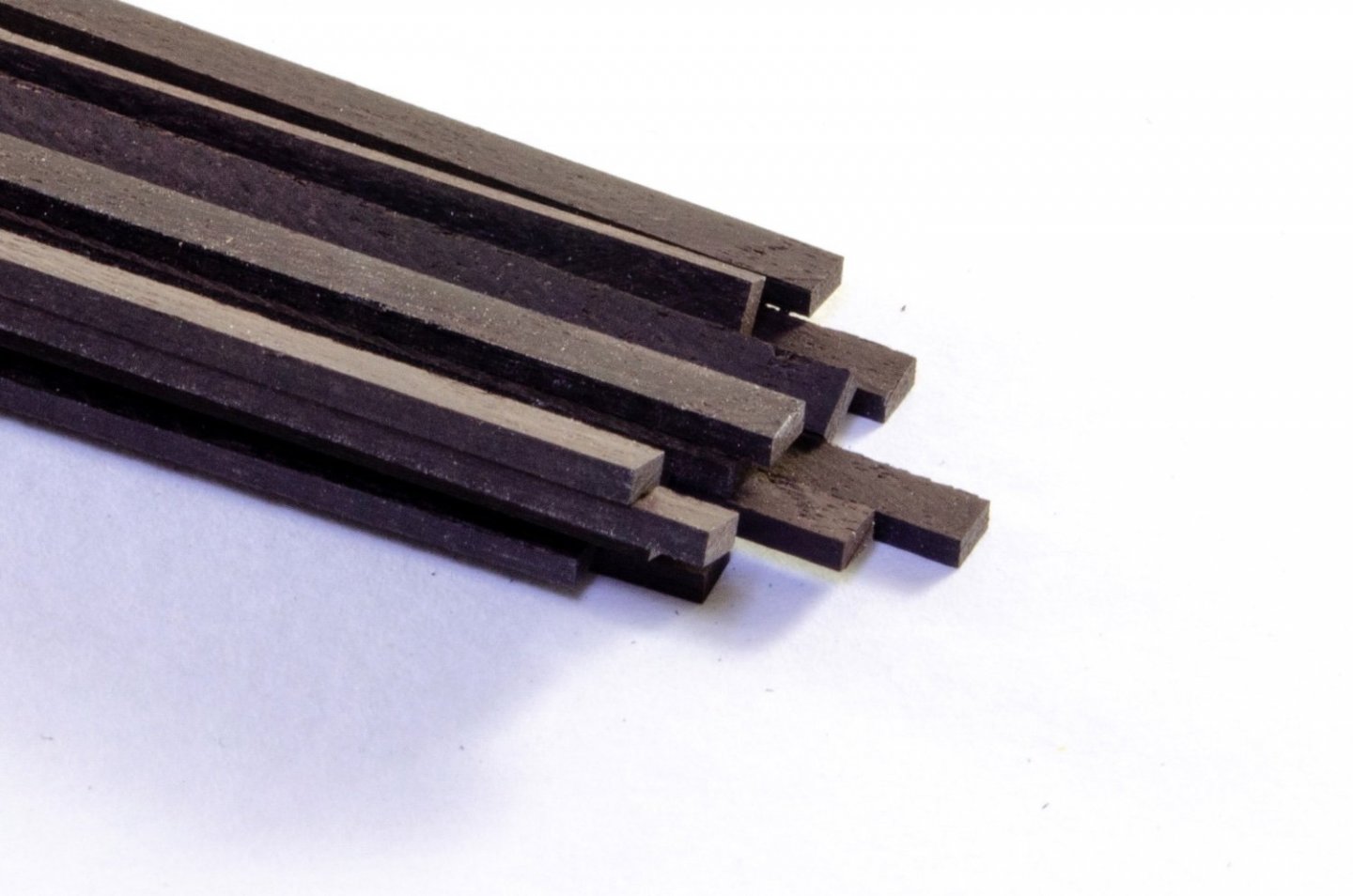

- Black Hornbeam - 3mm sheet, 3mm x 1.5mm strip

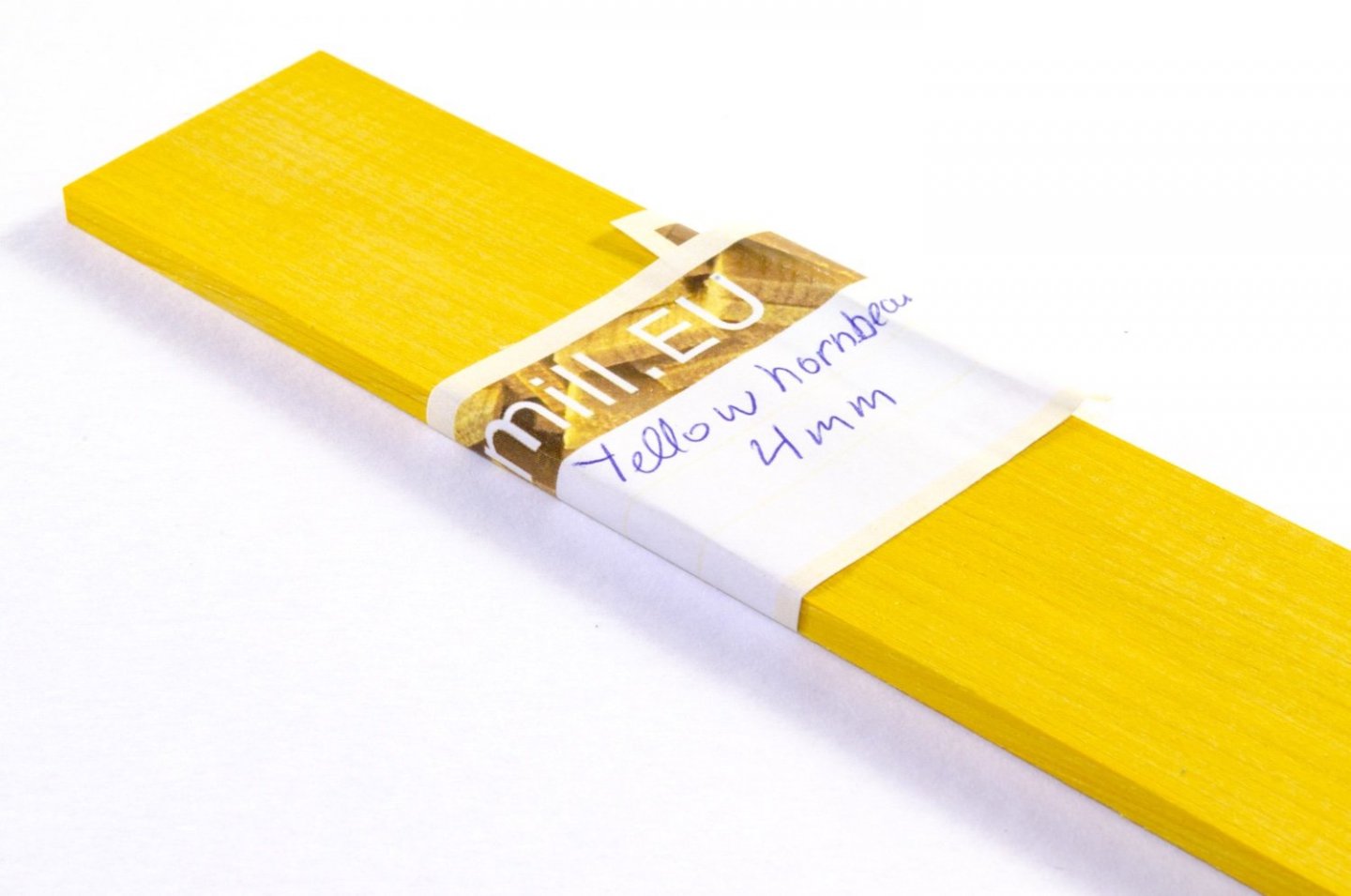

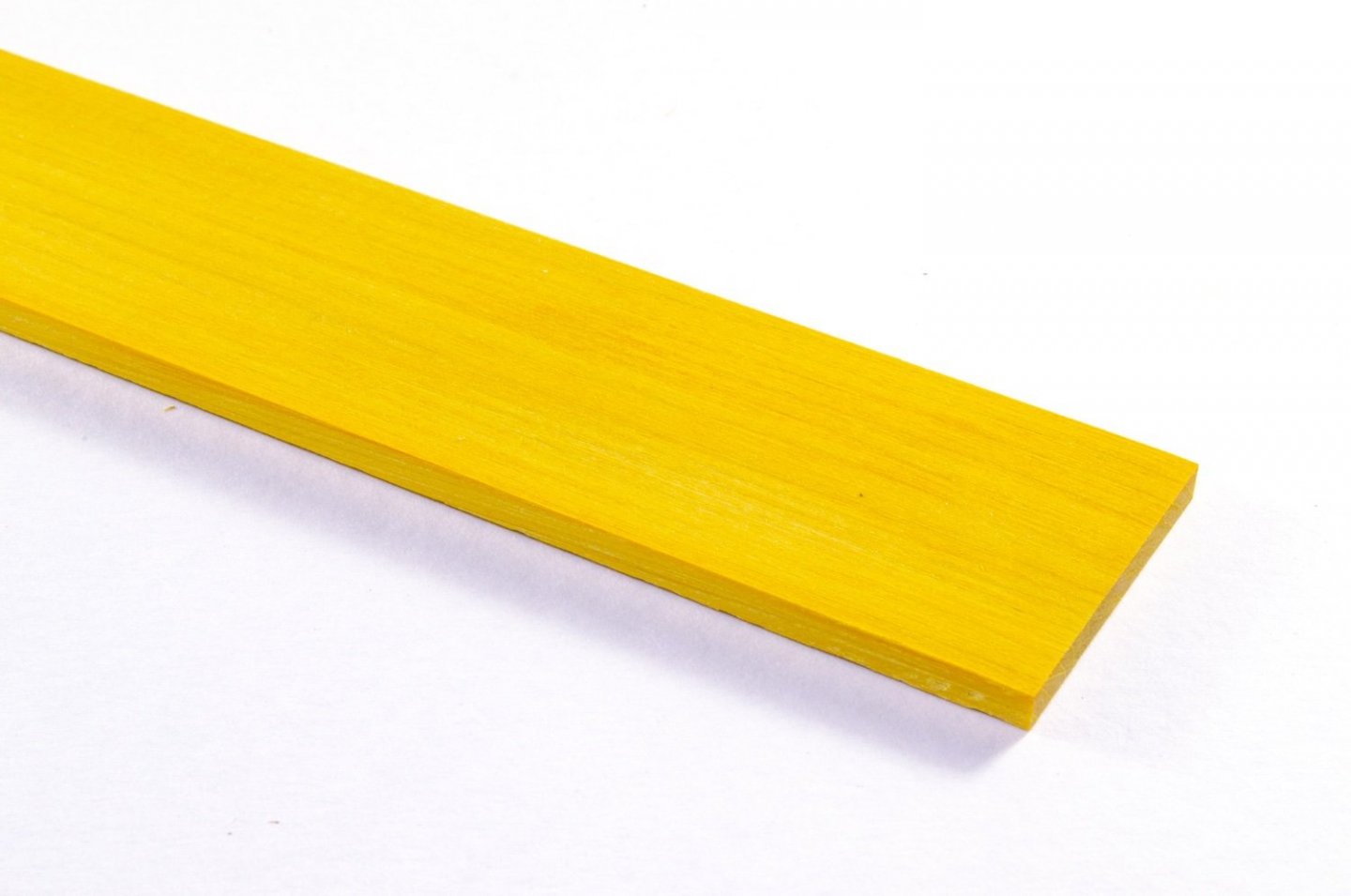

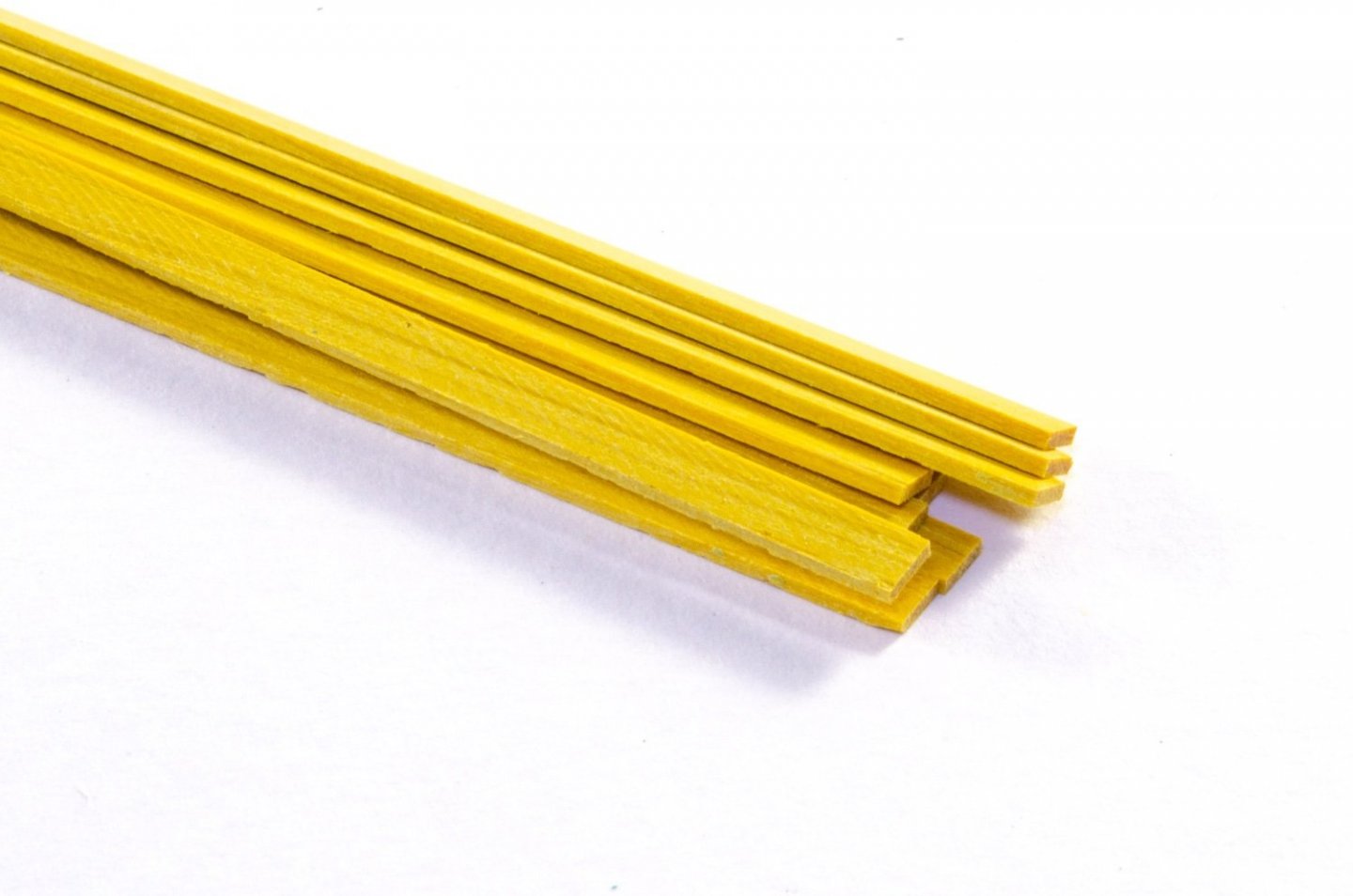

- Yellow Hornbeam - 4mm sheet, 4mm x 1mm strip

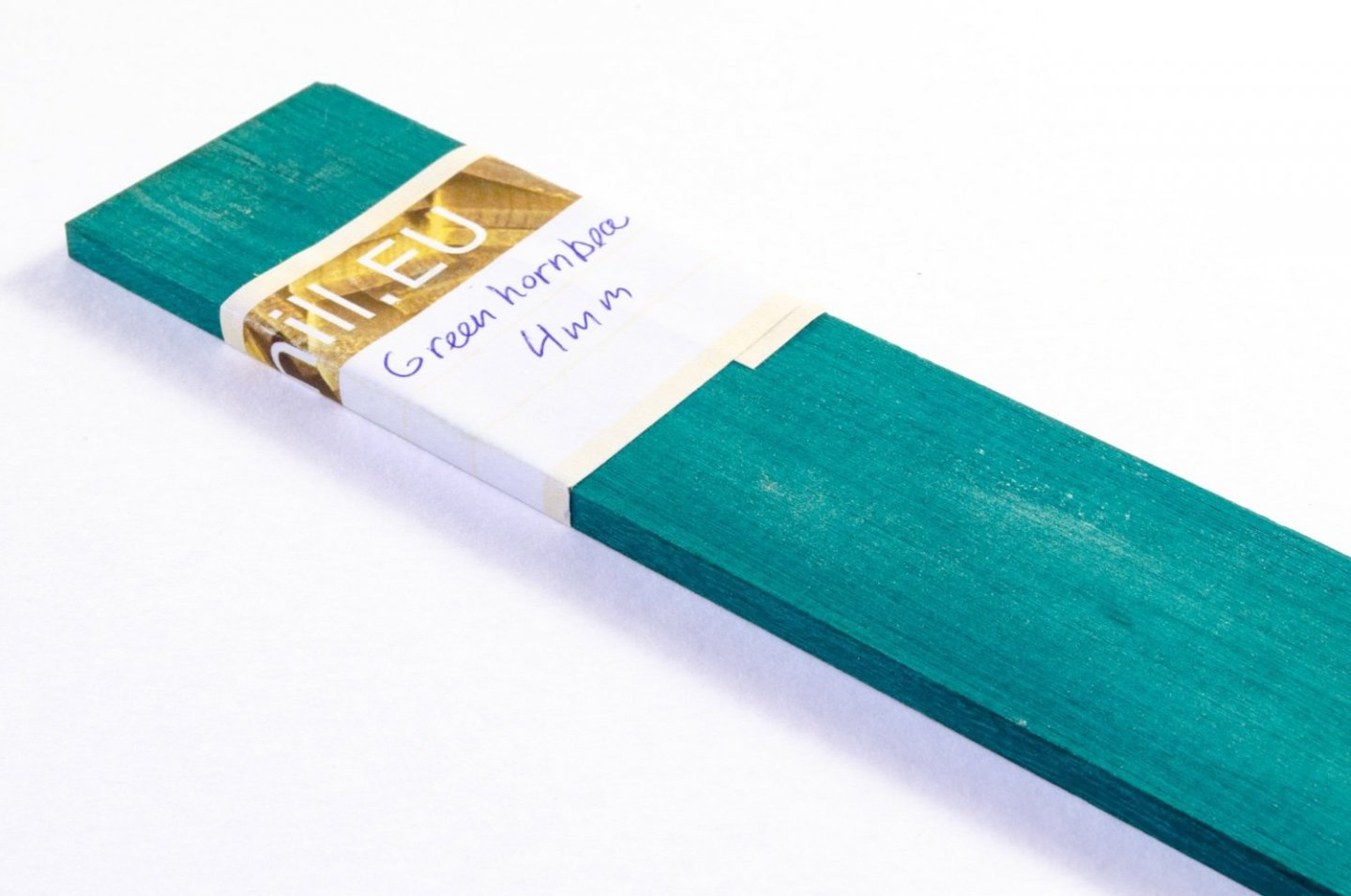

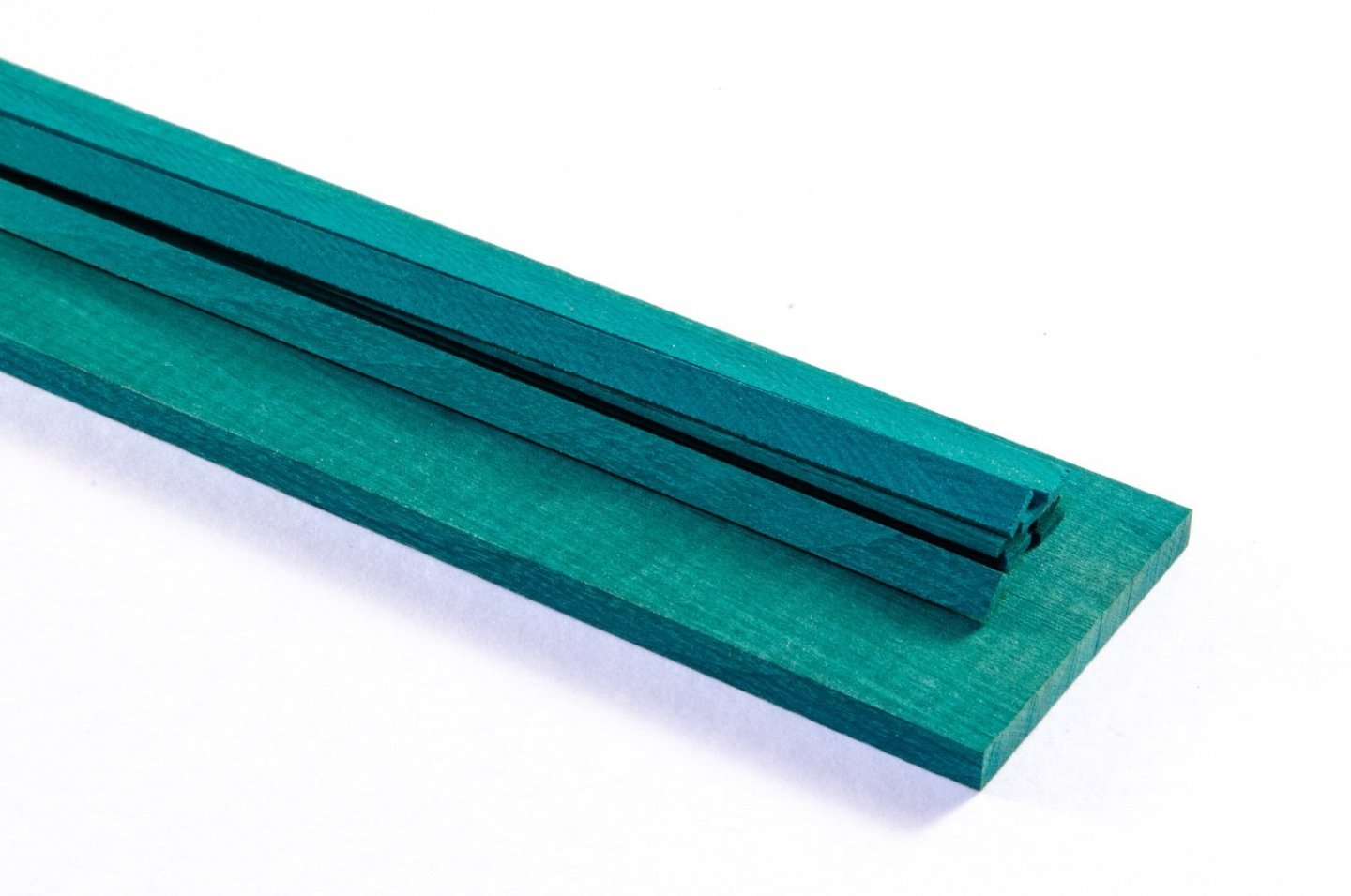

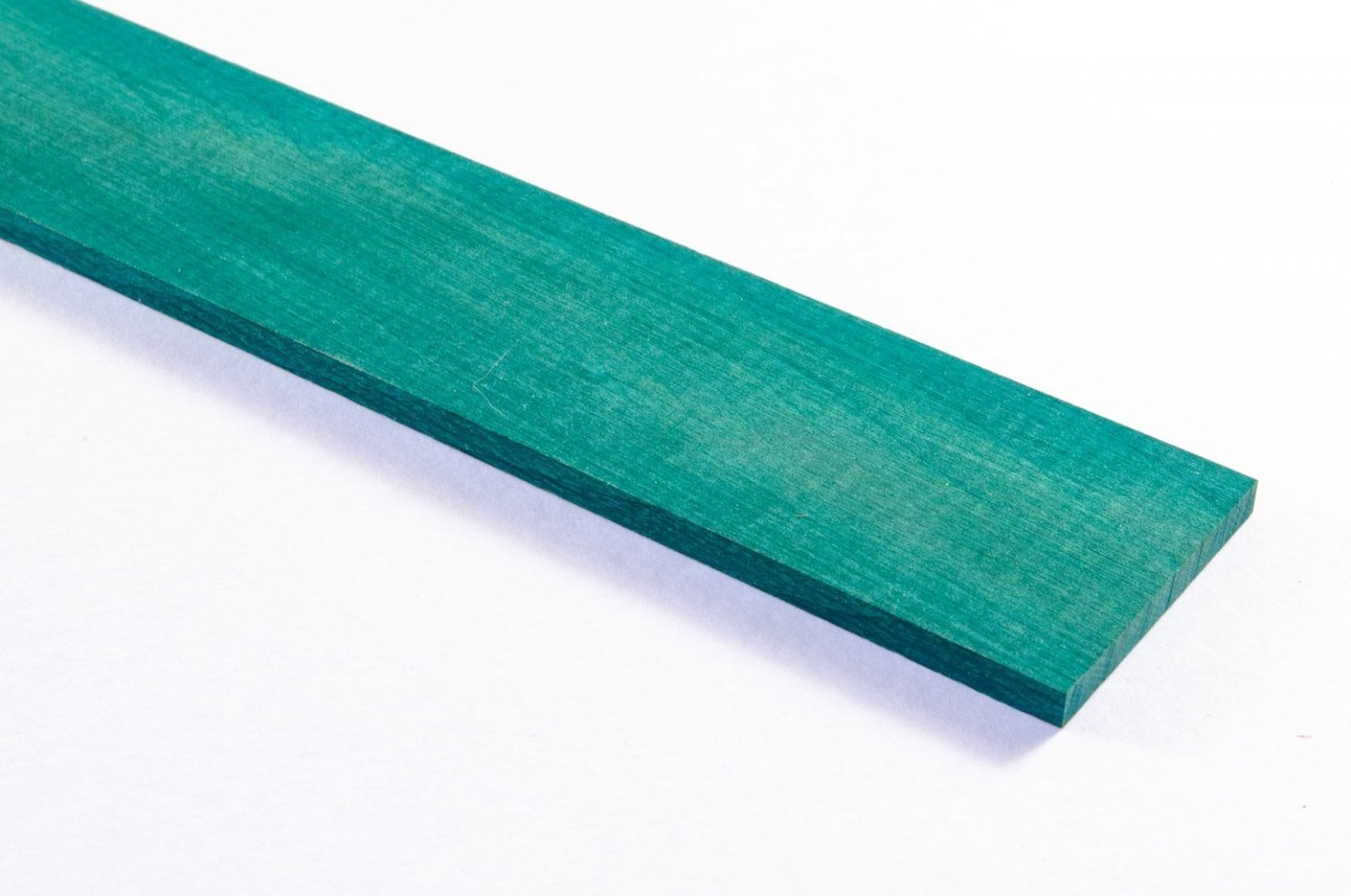

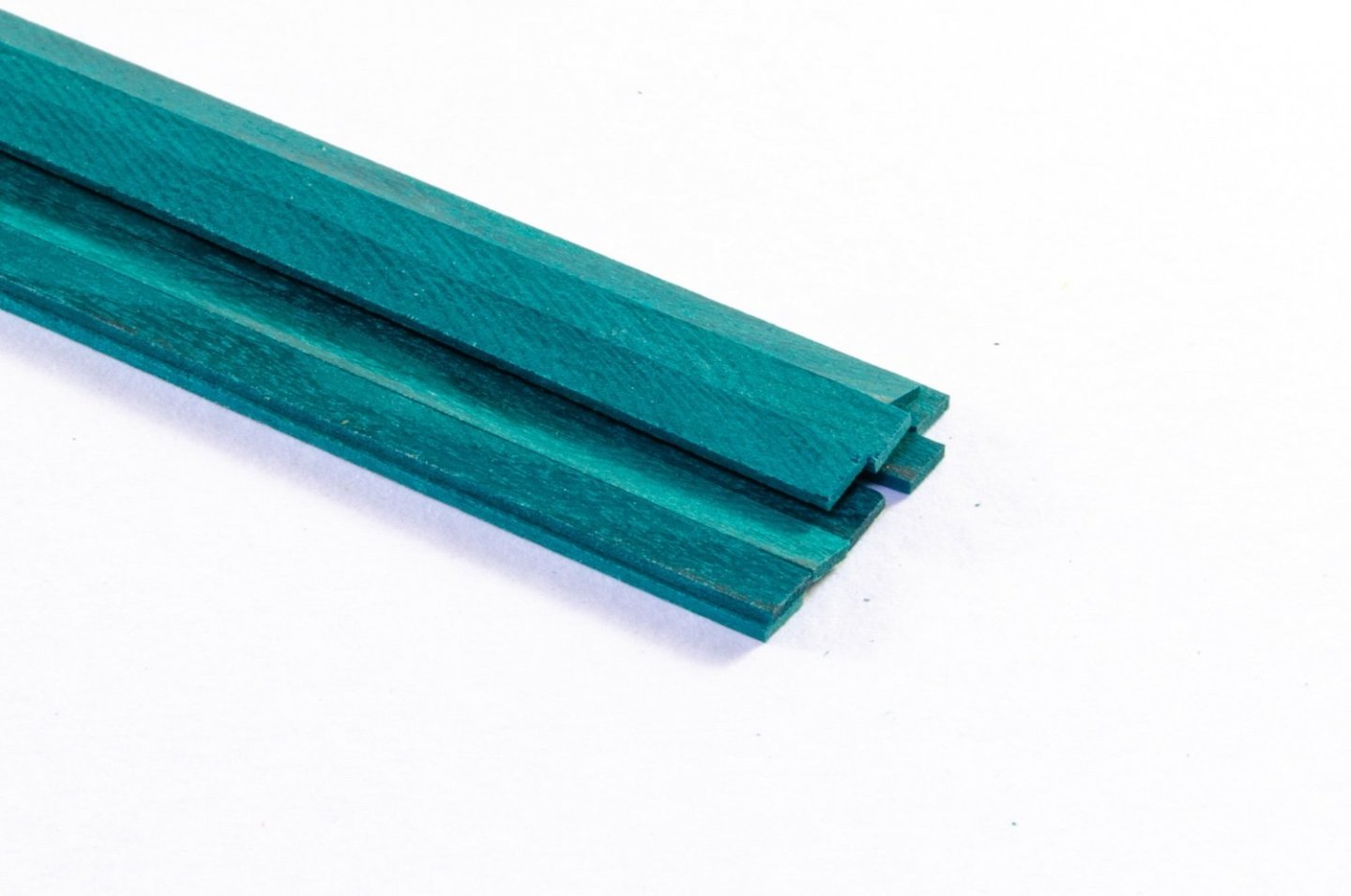

- Green Hornbeam - 4mm sheet, 4mm x 1mm strip

- Alaskan Yellow Cedar - 3mm sheet, 3mm x 2mm strip

- Castello Boxwood - 3mm sheet, 3mm x 1mm strip, 3mm x 2mm strip

- American Holly - 3mm sheet, 3mm x 2mm strip

- Swiss Pear (Light) - 4mm sheet, 4mm x 1mm strip, 2mm x 1mm strip

- Swiss Pear (Dark) - 3mm sheet, 3mm x 2mm strip, 3mm x 0.8mm strip

The wider sheets are 100mm wide x 500mm long, with the narrower ones being 50mm wide.

coloured hornbeam was added after this photo was takenThe package took around 8 days to arrive in the UK, from Estonia, via tracked mail. A rigid card box was used to pack the samples, and inside, the various sheets and strips were packed into sleeves and further protected by layers of bubblewrap film. Various strip packs were also bound with elastic too, and not so there was any deformation to the timber.

Pre-caulked planks?

HobbyMill also supply, to order, pre-caulked planks. You will need to enquire about those, but that would sure save some time when it comes to planking your deck!White Hornbeam

This really is very nice indeed, with a very fine grain. A very nice timber for deck planking. Nothing fibrous here as the nice, tight grain makes for clean cutting and a sharp edge. A very good timber for deck planking.American Holly

This is the palest of all the samples sent, and is very much creamy white in colour. The grain is almost invisible on first look too. Most definitely one of the nicest timbers I've seen.Castello Boxwood

This timber is a very nice light yellow-brown in colour, and also uniform in appearance. Also a nice alternative to European box. You'll notice the very fine grain in these photos.Alaskan Yellow Cedar

This is a very popular timber, and indeed, Chuck uses this on his HMS Winchelsea project. The colour of this timber is just gorgeous, imparting that very pale yellow look, and sporting a nice, tight grain. I can see why Syren favours this in their work.Yellow Hornbeam

I'm told that these timbers are favoured by Russian master model shipwrights and not so common outside of that region. It's certainly vibrant and yes, the colour remains when you cut it. I'm told this is due to the dye process presumably done in a vacuum so that the dye penetrates deeply. Hornbeam is finely grained, so of course you have that property transfer to a coloured timber.Green Hornbeam

Black Hornbeam

One thing I couldn't capture here is how nice this timber is. The grain looks more prominent on these photos, but it's actually not like this in reality. It's also darker than shown here and more even looking. Black hornbeam is a very good substitute for ebony. It's easier to cut, the dust won't be as nasty as ebony, it's easier to bend, and finally, it will be easier to glue.Swiss Pear (Light)

Pear can vary a little in shade, and HobbyMill provide this in both light and dark types. You can see the difference from my photos, from a pale pinkish timber to a darker and more slightly grey look. Perhaps grey isn't the colour I'm looking for, but my eye sees that very slight tint in an overall darker pink tone. All pear is very fine in grain with very little in the way of any flaw in the sheets.Swiss Pear (Dark)

Also available - Cutting discs for Byrnes saws

These aren't to be found on the HobbyMill.EU website, but if you enquire, you can order them for around €17 each. These are Czech made and definitely help those at this side of the pond where getting the original Byrnes blades can be a costly process due to import taxes etc. These are the same blades that are used to cut the timbers sold by HobbyMill.I have to say that it's been a pleasure dealing with HobbyMill.EU, and I'm sure @Wahka_est will be more than happy to answer any questions you have regarding his timbers and availability etc. Again, it's nice to deal with someone so passionate about their product. This really does seem to be a labour of love for him, and the product itself is definitely a testimony to his very exacting standards.

If you're in the need of something for a project, definitely consider this company. I don't think you'll be at all disappointed.

- Edwardkenway, tkay11, mtaylor and 10 others

-

13

13

-

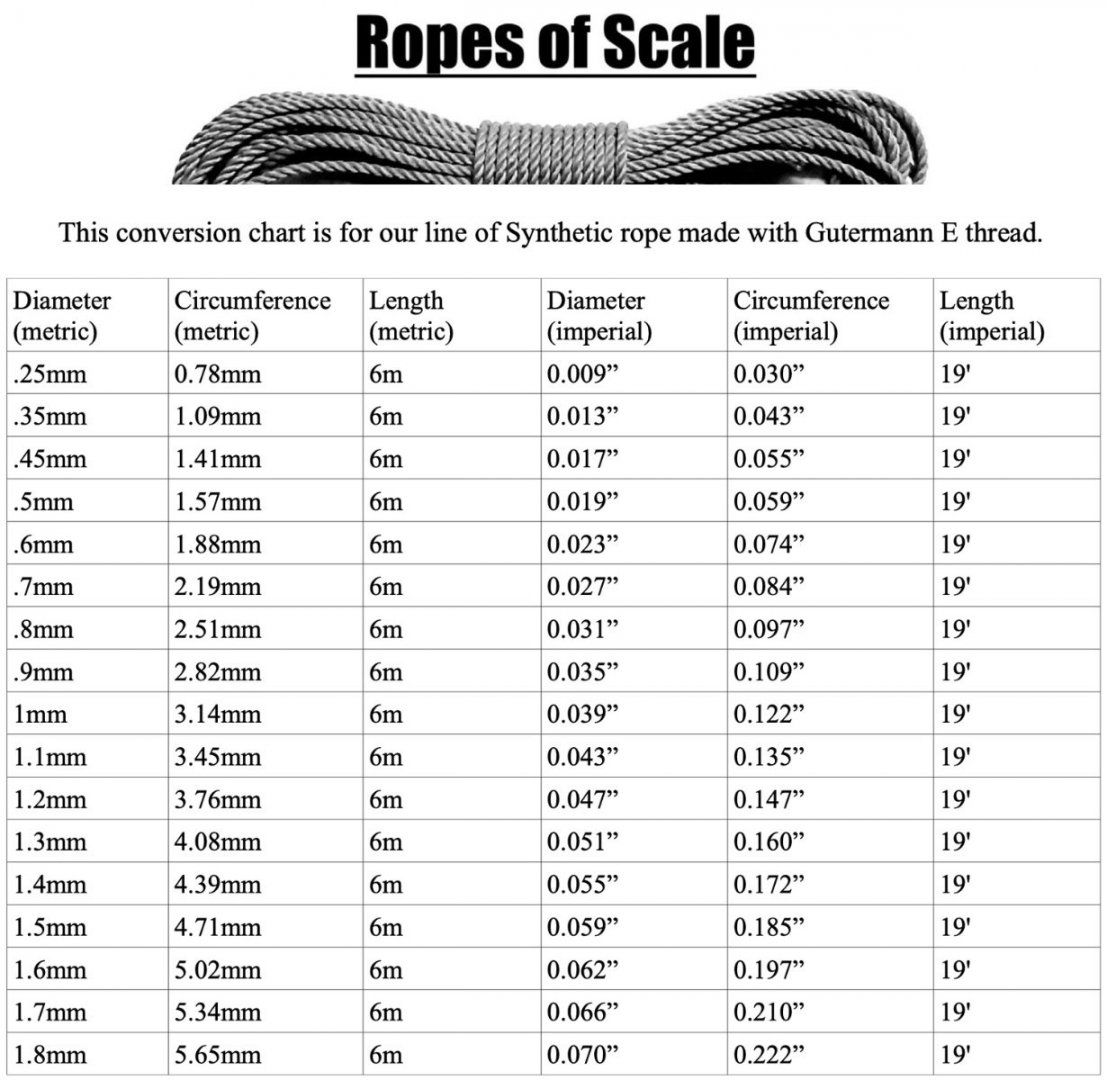

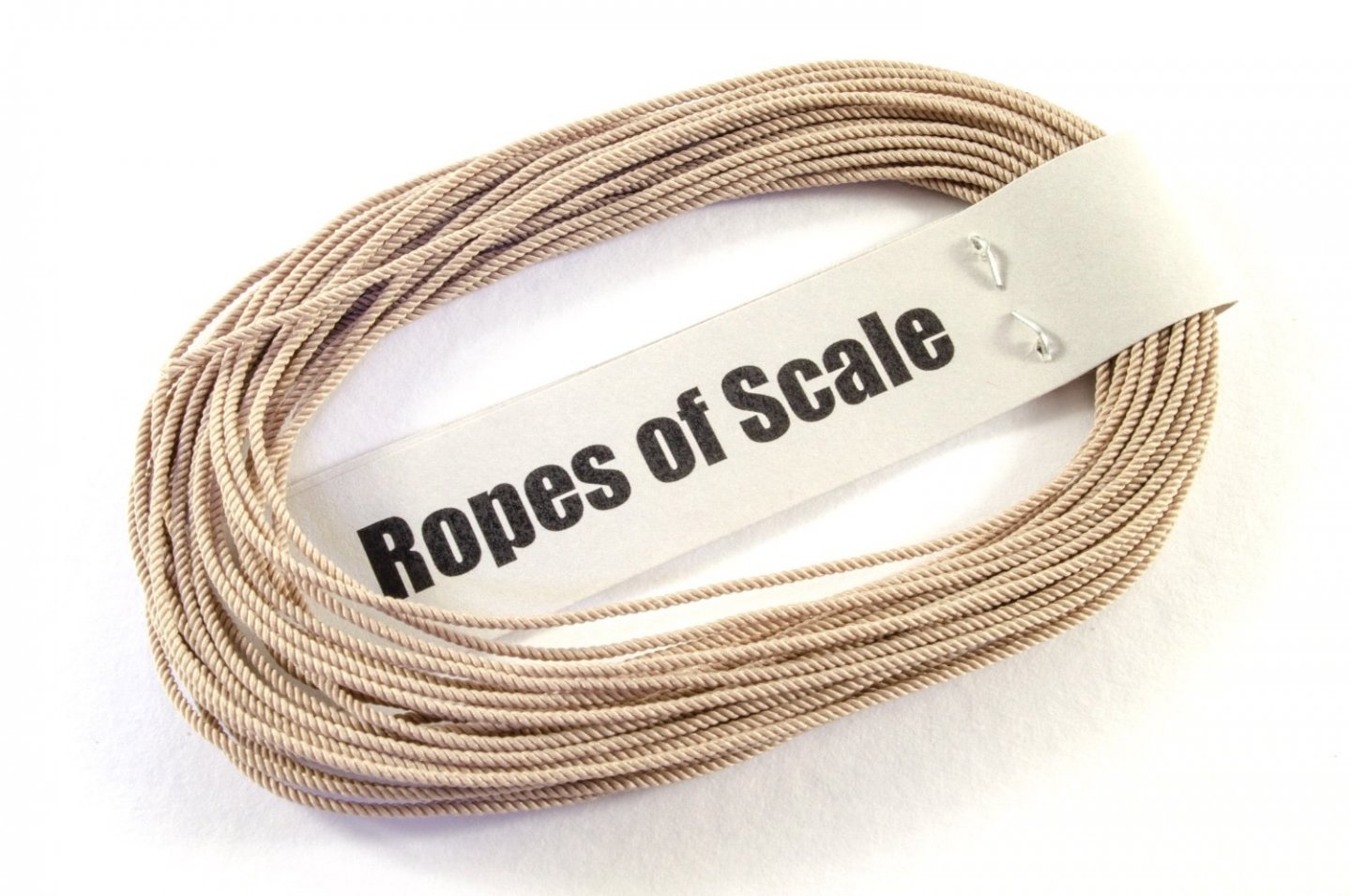

Rope and cable - various sizes

Ropes of Scale

Check website for specific price/sizeAfternoon all,

Ben from Ropes of Scale recently sent me a package of samples from his synthetic range of rope, and also a couple of of his rope-laid cables. Shipping from Canada took around 2 weeks, which I don't think is too bad in this current climate, and the pack came in a thick, protective Jiffy-bag, unmolested by the ravages of the various postal services involved!

Inside the pack were samples of rope in the following sizes:

- 0.25mm (0.009") x 6 metres

- 0.35mm (0.013") x 6 metres

- 0.45mm (0.017") x 6 metres

- 0.5mm (0.019") x 6 metres

- 0.6mm (0.023") x 6 metres

- 0.7mm (0.027") x 6 metres

- 0.8mm (0.031") x 6 metres

- 0.9mm (0.035") x 6 metres

- 1.0mm (0.039") x 6 metres

- 1.1mm (0.043") x 6 metres

- 1.2mm (0.047") x 6 metres

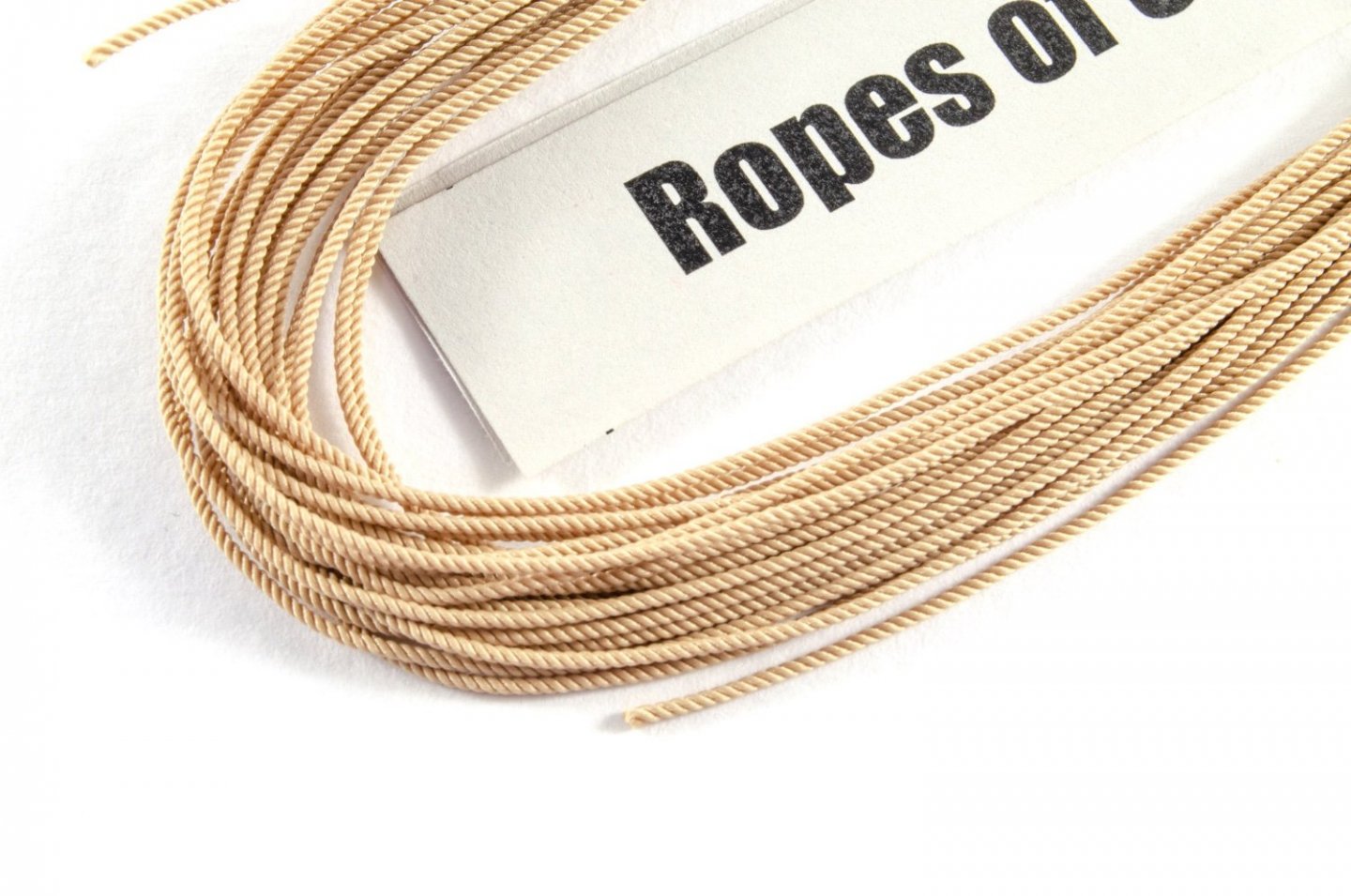

These sizes were all individually bagged into zip-lock wallets and supplied in nicely wrapped loops with a 'Ropes of Scale' label applied to stop the loops unravelling. All of the above sizes were supplied in Tan, Light Beige, Dark Brown, and Black. As well as the supplied sizes, Ropes of Scale also creates these in 1.3mm thru to 1.8mm, currently.

Also included in the pack were two samples of cable-laid rope. These are:

- 2.6mm (0.102") x 2 metres - Tan

- 1.7mm (0.066") x 2 metres - Black

All rope is right-hand laid (left-hand laid is denoted by an 'L' on the label), and very much covers the bases that a modeller would need for colour options. These cables are synthetic, although you can get them in cotton. For these synthetic ropes, Ropes of Scale use Gutermann E thread which is totally free from any of that annoying fuzz that sometimes accompanies the rigging process. According to their website, the ropes are also been heat treated to stop it unravelling when cut, although they do still note that a little CA on a rope end may be needed to thread them through your favourite rigging blocks.

Tan

The colours tend to cover all the required bases with two options for both running and standing rig. When it comes to standing rig, I would personally lean towards the dark brown as it perhaps more closely represents a tarred line than black, but many folk still prefer black, so that option is also there for you.

Light Beige

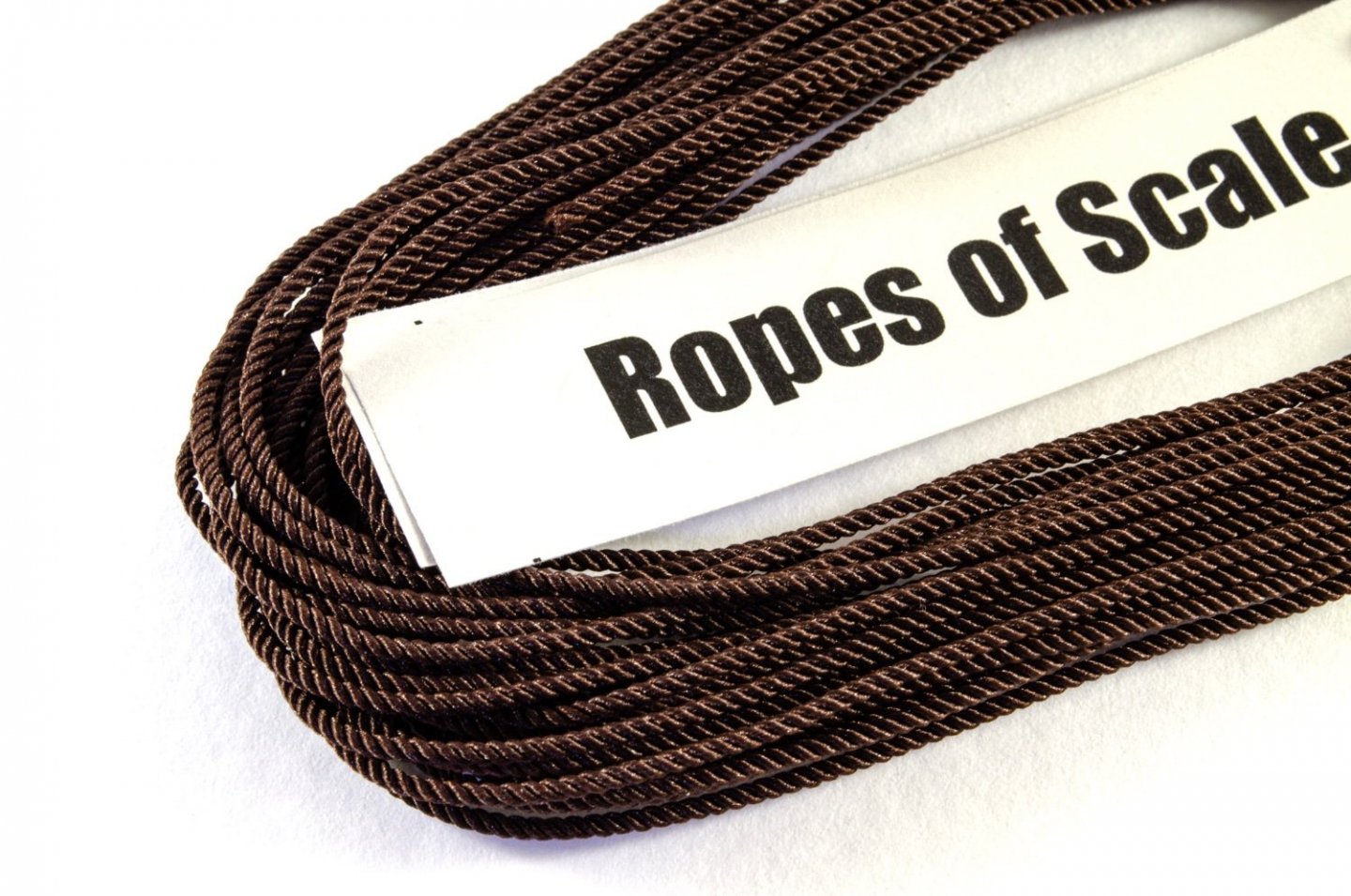

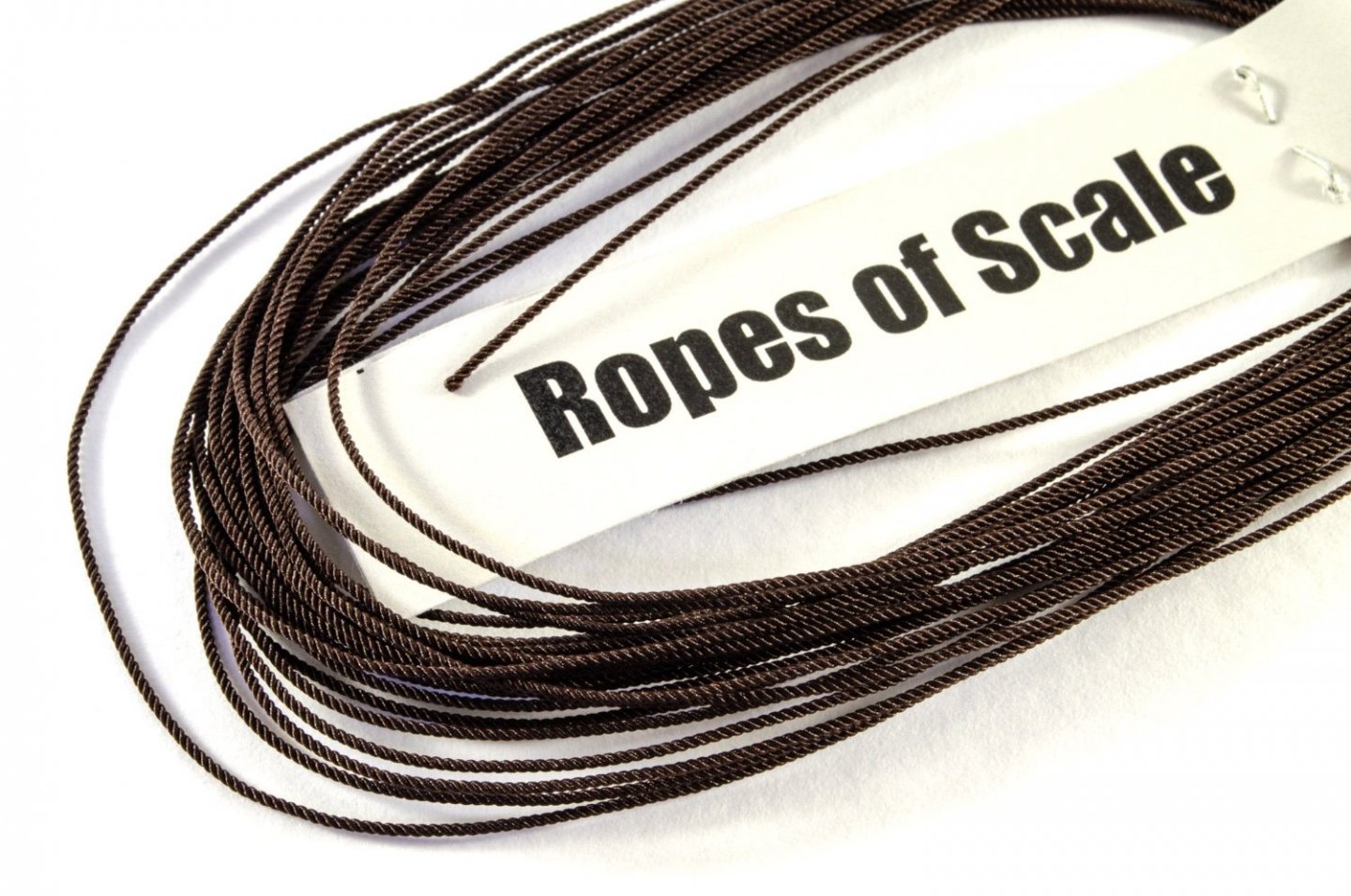

Dark Brown

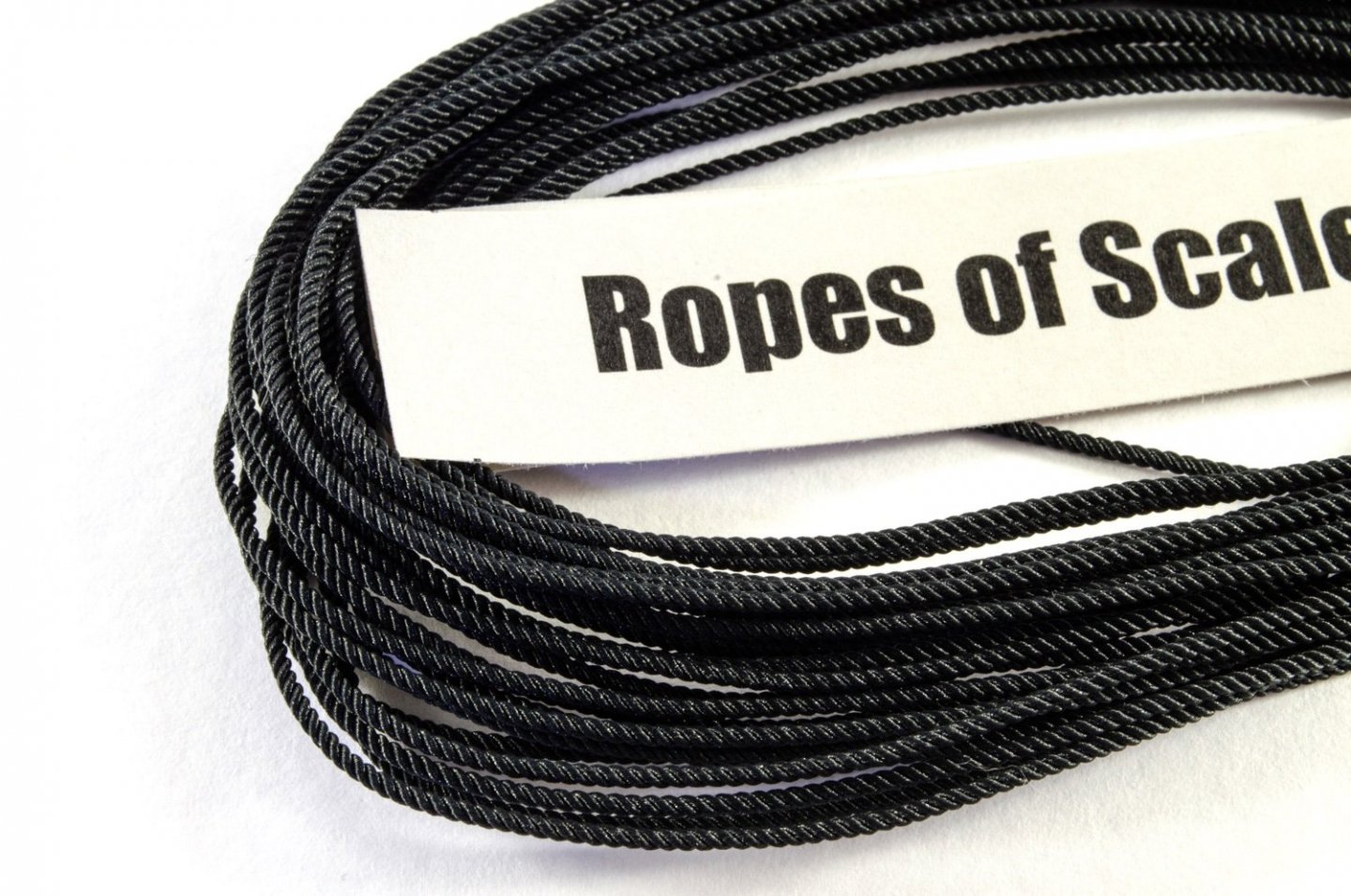

Perhaps the best solution for representing tarred standing rig.Black

Probably the favourite and most widely used colour for standing rig.Rope-laid Cable

These are supplied here in 2m lengths.I've been using some Gutermann rigging cord over the last year or so with my work on Vanguard Models' kits, and I have to say that I very much favour the brand as it's trouble-free when in use and doesn't have the common tendency to snag while working either, so these will be an absolute joy to work with. Manipulating the rope also doesn't result in the threads separating too. This is the first professional grade of rope that I've experienced in this format, and I have to say that I do like it very much indeed. I can also tell you that the forthcoming 1:64 HMS Indefatigable kit from Vanguard Models, will also feature hawse/cable and mast stays supplied by Ropes of Scale, so that is a very exciting development!

Ropes of Scale are a sponsor of Model Ship World. If you're in need of some amazing quality, fuzz-free rope that is going to have the exact scale fidelity you require for your build, you certainly won't go wrong with any of Ben's products. They are doubtless made with passion and dedication, and you can clearly see his attention to detail in every single packet.

- chris watton, Paul Le Wol, Archi and 15 others

-

16

16

-

2

2

-

The winch is now built. The drum part is 3D print and first primed then painted in Tamiya flat green. Just remember to put the engraved faces of the winch sides on the outside of the assembly. Some PE is used here for gearing etc.

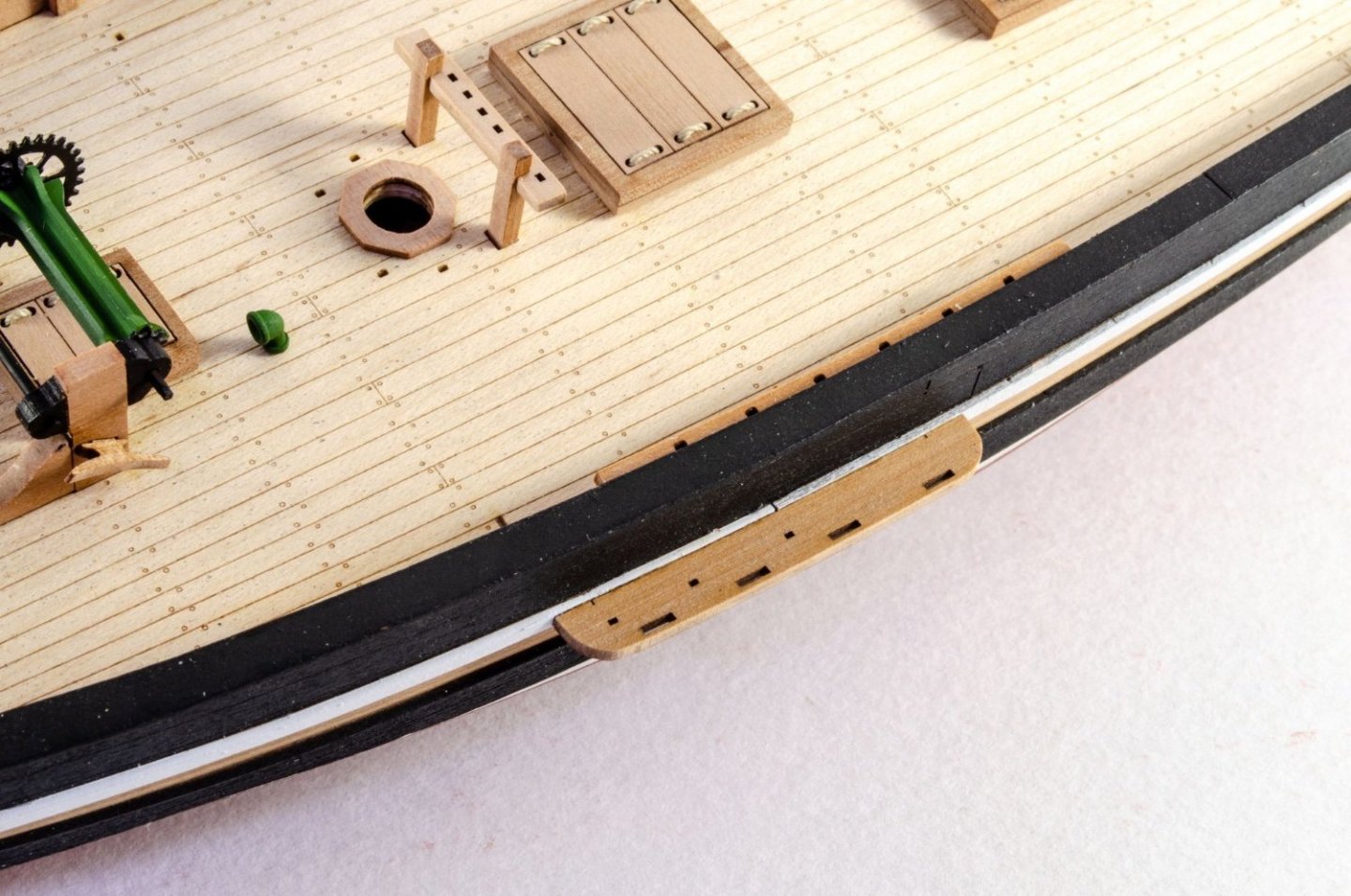

That nice little companionway is now fitted, as it the smoke stack. Provision is also made for pinning the channels. Those are now added too.

A smattering of PE is added, such as eyelets and belaying pins.

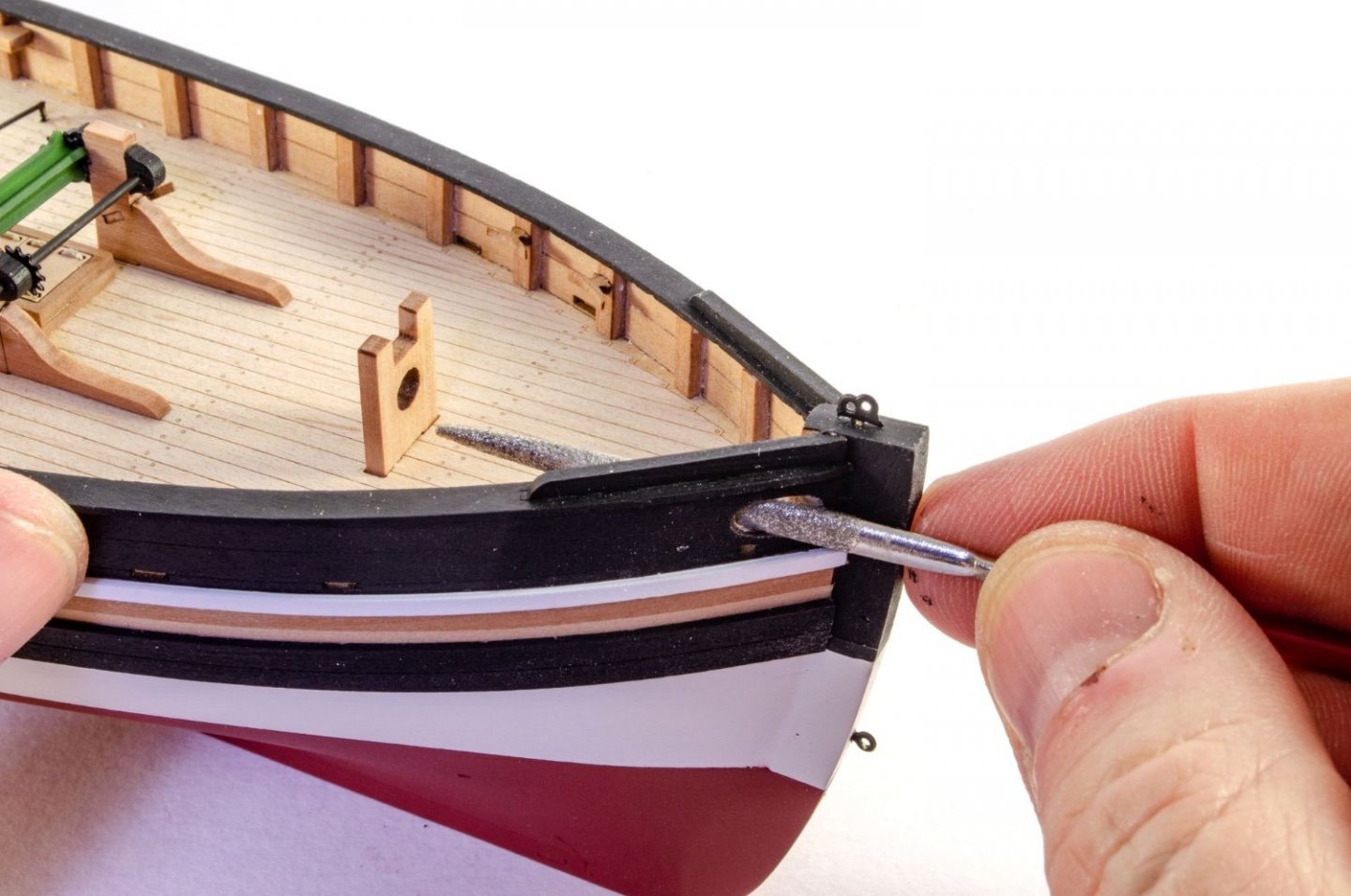

The bowsprit entry hole is filed to allow the down to pass through the bulwark and neatly into the bowsprit support.

Some decorative PE work is added. There is some stern work but I won't reveal that until the model is complete

A good friend painted this little cutter for me in oils. This will be included in the kit, so I thought I'd lash this down to the deck to complete the ensemble.

More next time...

-

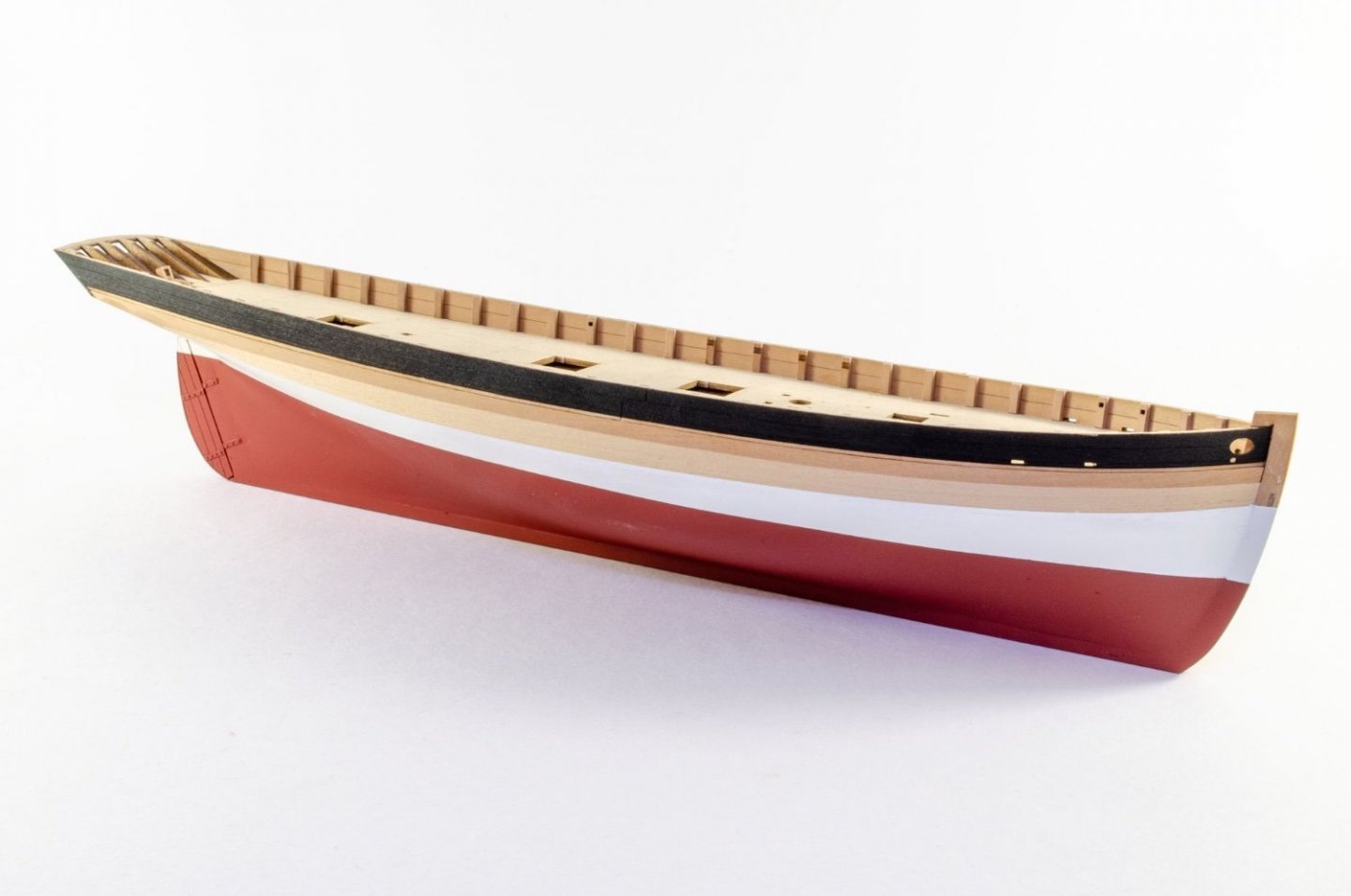

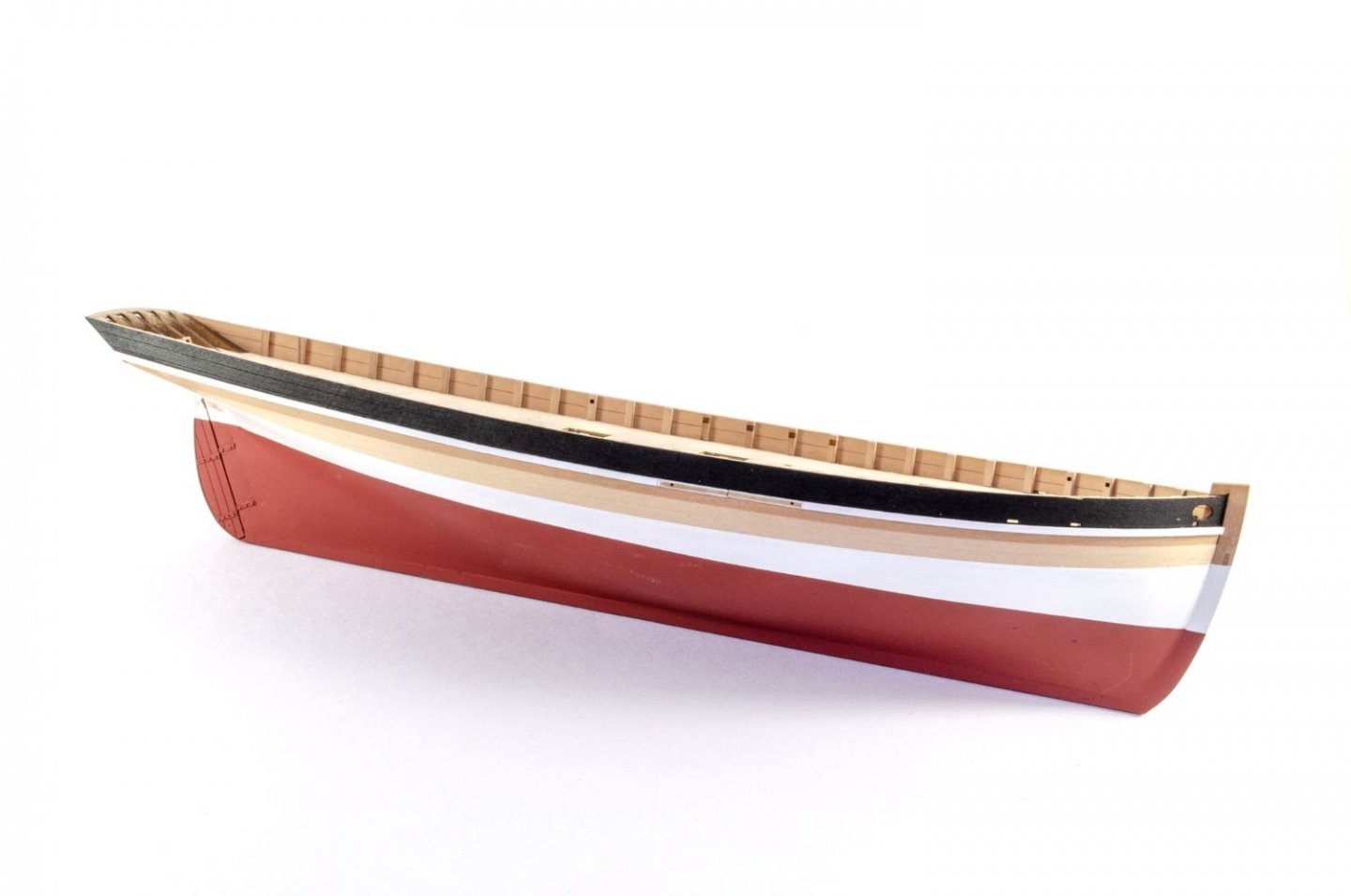

I like Plastikote red primer spray. It coats so very easy in a few passes. This is now added in a few thin coats, and when dry, the model is then unmasked.

The upper rails are added as halves, with the join line hidden under the channel position. I'm careful not to poly and paint that area so there's good adhesion when the channels are fitted. That rail is fitted up to the engraved line at the bottom of the bulwark. That also hides the joint between bulwark and planks.

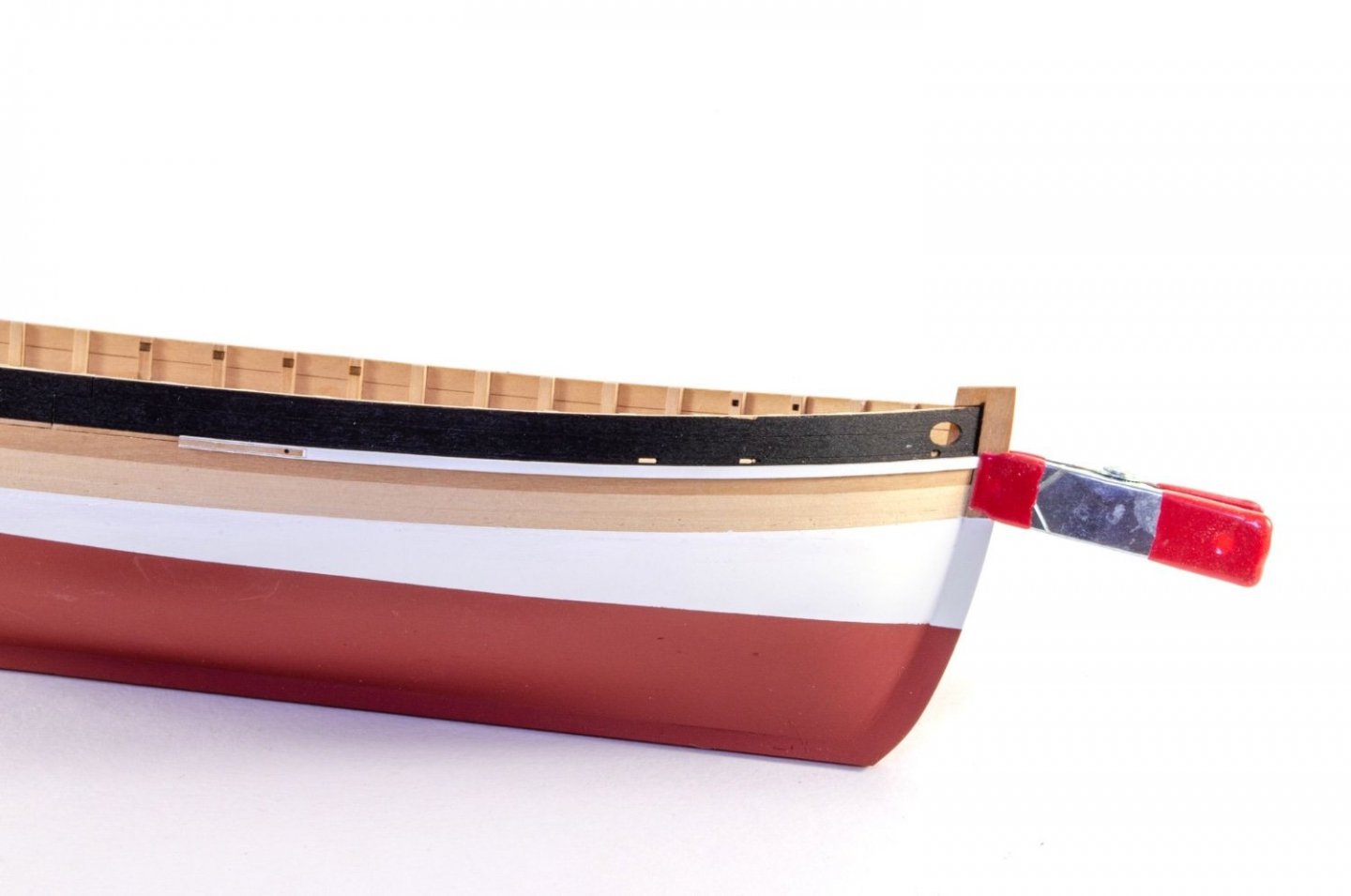

The single-piece wales are now glued into place with CA gel. The wales are placed 14.6 - 14.7mm down from the very top edge of bulwark. This means they'll be in the perfect position for the chainplates later.

The side gunwales are also two-part, and easily fitted. The stern section is separate too.

Time to fit out the decks. As I've had so much of this stuff ready since the beginning of the build, it's real nice to see it being used at last.

- AJohnson, Canute, GrandpaPhil and 6 others

-

9

9

-

The hull is now very much complete and the next stage is to building the mast etc. That's only a quick job so there'll be another post in the next week, but here's my 3-part update on model so far.

Once you have the deck down, the timberheads need to be added. These are so easy to do as each one is cut for you, labelled from A - Y, with four on each side being temporarily interconnected. Engraved letters in the hull explain position. No underside bevelling is needed either as the bulwarks are 90 degrees to the deck. Here you see the connected timberheads. These are done so the spacings are right for the belaying rack. Once installed, the tops of the bulwarks are sanded evenly.

All painted areas are first coated in many polyurethane varnish, The model is then masked off in readiness for the black upper bulwarks.

The bulwarks are then masked to protect the new paint, and the hull is filled and sanded.......repeatedly, until I am happy that it's as good as I can get it without checking under primer. There is no natural wood shown below the wales, so was happy to fill and sand this, masking to roughly where the bottom of the wale was to be later fitted.

PE is now fitted for the rudder hinges, and the rudder glued into position. The rudder itself is a 3-layer sandwich with engravings on the outer faces.

The hull is now masked again and white primer sprayed before small refills and sanding sessions. The final white coat is then applied. When dry, a waterline is added to demarcate the area under which will be red oxide.

- Canute, thibaultron, tkay11 and 4 others

-

7

7

-

On 4/23/2022 at 1:55 PM, bruce d said:

One thing that sometimes pops up in the UK is the 'invoice' from the carrier that demands about £40 for administrative fees incurred in getting the parcel through customs.

I refuse and so far have had no consequences despite a couple of sabre-rattles.

My reason is this: I ordered items from China and paid the quoted p&p, then paid the UK duties and charges. I have never engaged directly with the carrier (a big, well known company) and had no contract with them. If they are going to charge anyone for services, it can only be the person/company that engaged their services. In my case I checked with the vendor who was unaware of any further charges beyond those he had agreed and paid.

It is just something they do with commercial traffic and I believe no unsuspecting member of the public should be sucked in to the practice.

Grumble over.

I used to do the same with ParcelForce. A good way of dealing with it was asking for the charge to be separated from the duty, and then the duty paid. The parcel was then released and when they then invoiced you for there fees, they couldn't legally enforce it (because you had to contract with them) and the invoice was binned.

ParcelForce then stopped that happening. I have never since had success in getting a package released from any courier without the fees being paid prior. They hold your parcel and the 'third party' argument or the 'final mile' argument simply didn't work.

If you know how this is bypassed, and I've spent so long navigating this problem, PLEASE let me know what you say/send etc.

-

-

30 minutes ago, thibaultron said:

I've always thought it was 1600X1200. Has it changed recently?

No, there's been zero change in any of our requirements for almost 10yrs.

- Obormotov, thibaultron and mtaylor

-

3

3

HMS Indefatigable 1794 (prototype) by James H - Vanguard Models - 1:64 - FINISHED

in - Kit build logs for subjects built from 1751 - 1800

Posted

In all fairness, can that engraving be trusted as evidence? After all, it shows round gun ports on the quarter too. Also all main gun deck ports seems to be lidded on that illustration.