-

Posts

5,964 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by James H

-

-

40 minutes ago, BigDan said:

Sorry for the intrusion that got you so upset. It was my first time posting something on MSW and I hadn't figured out how it all worked. Again I apologize, I am slowly getting the hang of it. Thank you to the administrator for sorting it out by "splitting" away my post from PJG's.

No worries!

Your build deserves to have its own log so it can be referenced. If you've any more photos, please feel free to add to your log.

-

2 hours ago, PJG said:

You know you haven't been keeping up on your build when you return to find that someone else's model has taken over your log 😂😮!

Not that I don't think BigDan did a great job on his Fifie (I do), I'm just not sure the middle of my build log is the right place for it.

1 hour ago, Blue Ensign said:It certainly confuses the issue, I did a double take when I first saw the post I thought blimey he's moved quick, he's reinstalled the hull and finished off the model.😀

It is bad manners tho' to invade another modellers log, I see James has tried to give a large hint, to which Dan seemed oblivious.🙄

B.E.

Ok, I've split those photos into a separate build log.

-

Split from another build log to create one for @BigDan

-

Lady Nelson is a perfect model to build when starting out. Only one mast and limited ratlines to tie.

-

-

-

That looks so exacting. Loving the photos too. Very clear to follow.

- captain_hook and Canute

-

2

2

-

16 minutes ago, reklein said:

I'm currently building Trumpeters 1-350 Intrepid. The deck requires extensive decaling. I have applied the base coats and am now ready for decals. Is it recommended to clear gloss coat the whole deck before decaling and then flat coating after? I see a lot of plastic or any modelers doing that before decals.

Bill

You're always best glossing before decals, and if there's lots of moulded details on the deck, consider using a decal setting solution too. Once your decals are down, gloss over them before any weathering and a flat coat.

-

She is looking smart. You started painting the bulwarks yet?

-

6 minutes ago, FlyingFish said:

James, yes it was a great picture to take your date too - lots of opportunities for a reassuring arm on the shoulder!

Robert Shaw came from a town a couple miles from me too. (Westhoughton). There's a pub named after him. Quite ironic when you consider his predilection for booze!

-

That looks great! That pear came out real nice 😁

- FrankWouts and chris watton

-

2

2

-

-

She's looking real purdy 😍

There's not too much bare pear can be seen above the waterline, so it should be easy to sort a few of identical shade. I know my poly varnish did sort of level the colour across the ones I chose.

-

A good degreaser is acetone or nail varnish remover. There should be no need to wash afterwards, but you can just rinse them in water.

- Glenn-UK, Jim Rogers and Ryland Craze

-

2

2

-

1

1

-

-

I never tire of seeing this one come together. Looks like you've gripped this with both hands.

- Rustyj, FrankWouts and glbarlow

-

3

3

-

Following along 👍

-

That really looks like it's coming along very well, and your adjustments have nailed it with the bulwark to deck fit.

- chris watton, Glenn-UK and BobG

-

2

2

-

1

1

-

- JeffT, mtaylor, GrandpaPhil and 6 others

-

9

9

-

STAGE 69: ADDING A HEEL DETAIL AND ASSEMBLING FOOT PARTS

Every foot needs a heel, and this is now fitted, with a single screw locking things into position.

Now it's the turn of the toes. Some of these parts are angled, but if you follow the manual, you'll see the toe parts have an indent on one side with a part number on them. I used these ass reference to make sure I got the toes correctly positioned. The grub screw also has a little thread lock to stop it coming part later.

The toe tip and other toe part are fitted using a plastic bush insert and ridged pin to lock into position.

- GrandpaPhil, marktiedens, lmagna and 5 others

-

8

8

-

STAGE 68: FITTING THE ANKLE JOINT TO THE RIGHT LEG

All three pistons are removed from their sprue and the two shorter ones fitted with the rubber end caps with a black, flanged screw. The knuckle joint is also assembled and pushed into the lower leg.

I do have to say these pistons are way too sloppy. There's zero traction with the piston bodies and they wobble around like mad. I'll think of something to correct this...maybe a plasticard tube wrap for the shorter pistons. As the longer one has no rubber cap, that can't be changed, but it shouldn't matter with the other two being more sturdy

The foot is now pushed into position.

-

-

STAGE 66: ADDING ANOTHER PART TO THE LOWER RIGHT LEG

Onto another piston fits two end caps. These can only fit specifically to the correct ends, and they are simply a push fit.

Another screw and bush fitting are used to fit to the lower leg assembly.

Small details are fitted using a small drop or two of CA.

A single screw and spring washer is fitted, connecting the lower right leg to the T-800. This can be posed in any position, but I left it neutral. I don't know how easy it will be to loosen that screw when complete.

- mtaylor, GrandpaPhil, marktiedens and 5 others

-

8

8

-

STAGE 65: ADDING ANOTHER PART TO THE LOWER RIGHT LEG

Another piston is fitted in the same way as the previous.

The lower leg outer casing is now fitted. This also has a keyed system that stops it being incorrectly placed.

The shin is now fitted. A few spots of CA are needed at the top and bottom, and once in position, a screw fastens it to the stationary piston.

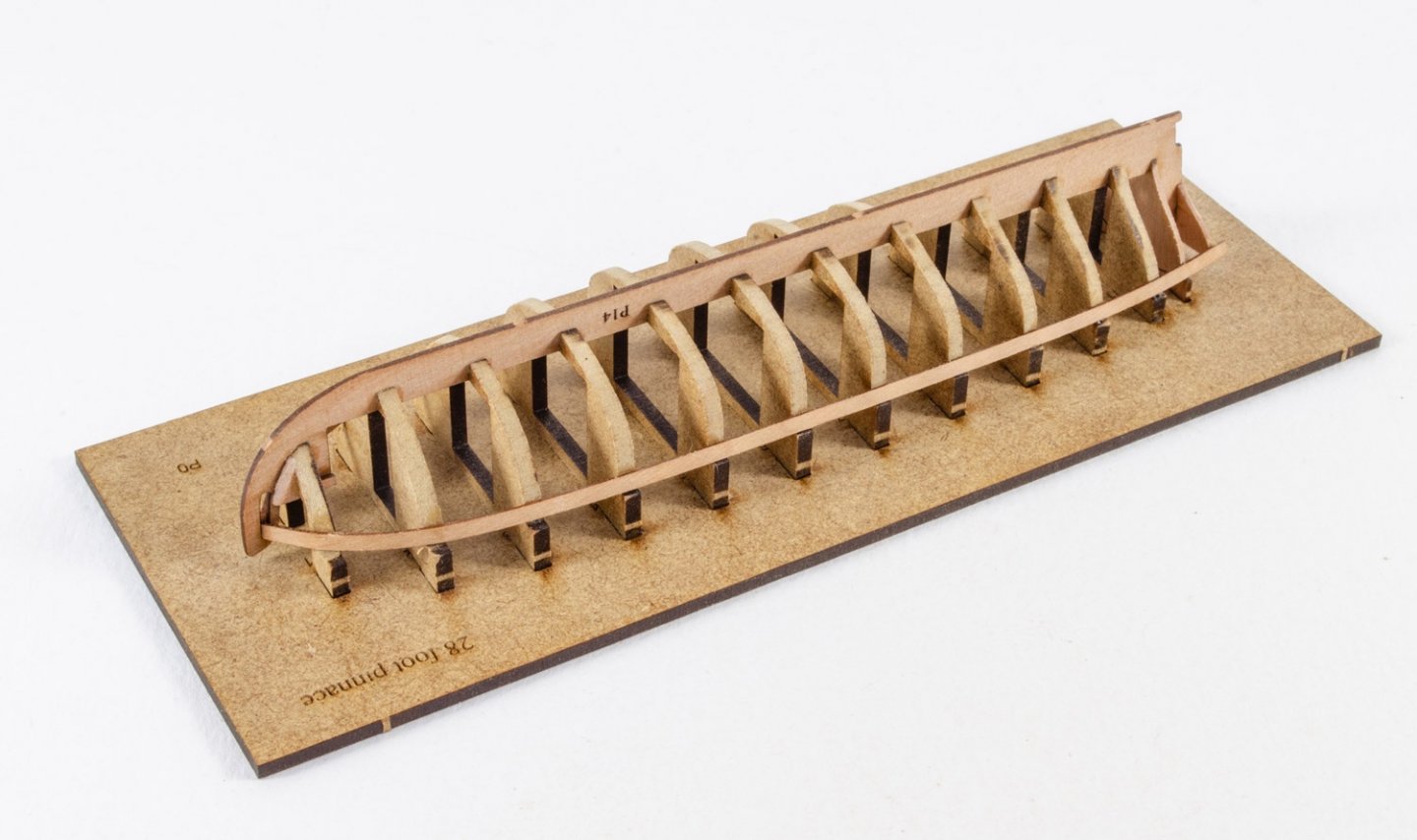

Granado by cafmodel - FINISHED - 1/48 - cross-section

in - Build logs for subjects built 1501 - 1750

Posted

That really does look very pretty. Looking forward to seeing the finished product.