-

Posts

2,237 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by WackoWolf

-

Excellent work, I enjoy you walk through as how you are going about these little upgrades. Keep the pictures coming.

-

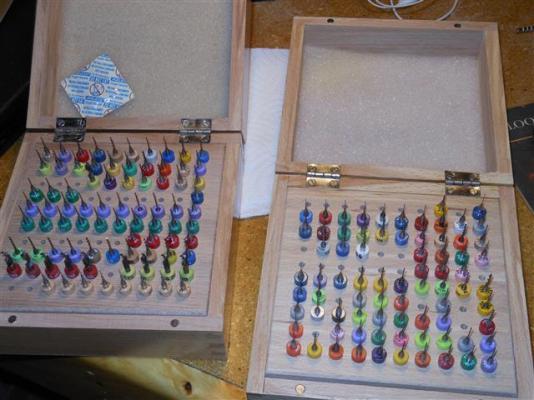

The picture's of the drills in the bottom box are numbers 31-80. Also as you can see the other two boxes are spares and odd one the I have gotten over the years beside the sets I have gotten for free with others. I also have the same set as Mark from Model Expo, beside what we all have in the metal boxes. I think I have all the drill bits I need. But you never know there is always that one odd size you don't have when you need it, but I do think I have that cover LOL.

-

This is how I store and keep my bits. I bought the box's from Model Expo when they had them on sale. I think I bought like five or six of them.

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

WackoWolf replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Doris, Thank you for the link to your log. I went through the whole log from page 1 to page 49, even though I do not know the language the pictures spoke for all that was there. I now understand what it takes to make a ship from card. Your work and detail is out of this world, there are no others words that can describe the talent that you have. You are the best in this hobby. Thank you for sharing all your fine work with all of us. Please never stop posting your builds. I wish you the best in the new year and all the years that follow. Than you.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Beautiful. Thank you for taking the time to let us know how you did the work. Keep the pictures and post coming, this is a Beautiful ship and the work you are doing is outstanding.

-

She came out Beautiful. You have done an excellent job. Thanks for sharing this with us.

- 58 replies

-

- model shipways

- 18th century longboat

-

(and 2 more)

Tagged with:

-

Starting Solidworks

WackoWolf replied to AntonyUK's topic in CAD and 3D Modelling/Drafting Plans with Software

Hmm, I talk this over with the person who is teaching me. First I am the wrong person to be teaching someone something that is being taught to me,so here goes. The pictures of all the boats in the water, the planking on them is clinker (not sure if you know this or not), also which is the Bow and which is the stern? Where is the rudder hook at and how, this is just some question that came up when looking at the picture. Also are you using plans to do this? Another thing because of it being a clinker planking, you have to start at the bottom and work up, putting one plank over the last. Another point in the picture of the boats, not sure which end is which but the way the planks end at each end is not going to be easy,take a look at the picture. Someone who knows these boats will be able to shed some light on how they were made. Don9of11. The way you are saying to do it can be done that way but if any of the frames have more points than the next when you loft you will not get a smooth loft. Try using the spline and then smooth the spline out. Like trace the frame if your working from a plan using the spline and don't stop until you have gone from A to B, then smooth the trace line using other features of the spline, do each frame like that and this way when you do loft it will be a heck of a lot smoother. I hope I shed some light on this. I am going to be gone in 13 days, but will be checking my email everyday while I am gone. I do hope I shed some light on this for you, sorry I couldn't be more help. -

Thank you very much for the information. I enjoy it very much. Thanks again.

-

If you are going to be using odd shape stock then the "independent" chuck is the way to go, thats why it is best if you can afford to get both, since you are not always going to have odd shape stock but when you do you have the right chuck to use. Just my option, and I am not an expert.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

WackoWolf replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Hmm. Now that is an idea, but will it look right is the question. Hmm- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Jerry, Beautiful work, I enjoy watching your build. Keep the pictures coming. And Happy New Years.

- 900 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

WackoWolf replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Looking at your pictures and your work I can understand why some people are jealous of what you do. But DAM you are the best. Keep the pictures. This is unreal.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

The planking is beautiful, your doing an excellent job on a ship that isn't easy. Love your work. Keep the pictures coming.

-

Nice work, your doing an excellent job. Keep the pictures coming.

- 43 replies

-

- santissima trinidad

- occre

-

(and 2 more)

Tagged with:

-

Ask all the questions you have, even though I haven't use the Lathe much I do have books and will try and help in anyway I can. I can always try what your asking about with my lathe and see how it turns out and then maybe be able to answer your question. The book is very very good, I seem to go back to it more and more for tips, I am sure you will like it. In fact I just order the 10,000 rpm pulley setup and some spare belts yesterday from Sherline.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Mark, Have you given any though about trying Indian Ink, I know some others have try it and have had good results with it. Just a though.

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

WackoWolf replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

I don't think that they is really any words that I can come up with to say how Beautiful and Excellent your work is. The only word that I can come up with, that I can say here is "WOW UNBELIEVABLE".- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.