-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

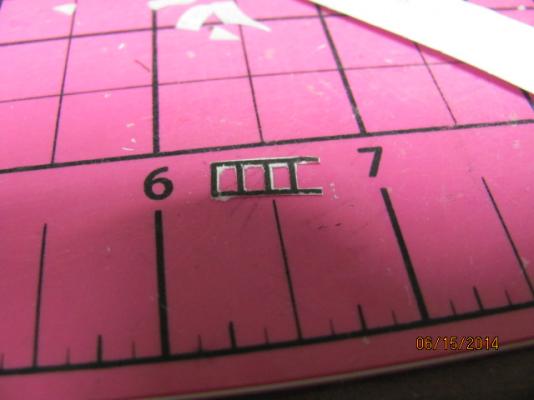

I finished off the pilot house with the guard around the periscope. When forming the part i used the shaft of a grinder that I had in my tool box. This made it easy to shape it without tearing. Once formed I gued it to the pilot house. When I get back to Raymond I think I wil order some scalpel blades. I am finding out the adage the sharper the better. I then touched everything up with a marker. David B

- 39 replies

-

- lehigh

- papercraft square

-

(and 3 more)

Tagged with:

-

Help with Mill handwheel and dial too tight

dgbot replied to rtropp's topic in Modeling tools and Workshop Equipment

I mess around with small bits all the time. When I bought my Foredom years ago I also invested in their drill fixture as we. Great investment, with the accuracy of a jewers drill and the foot speed control I rarey break a bit. As for Sherines sensidrill I know several modelers who love it for those small drills. David B -

Nice way to make use of different parts. Your planking and interior detail is nice. What kind of wood did you use? David B

-

If you had an x y table you could use that. What I have done is make a fixture to hold the part and marked out the holes with an awl or a pin. This made a spot that would hold the drill bit. Then I could drill out the part without the bit skipping. David B

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

You are doing a wonderful job. The nice thing about the Virginia is nice because you can do many things with it. David B

- 95 replies

-

- virginia

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks for the info. I will keep an eye open here. It would be perfect for my sisters place. David B

-

While in the hospital I used the table that they kept by the bed. What I found out was that the top could be extended to almost twice the depth. With the raised edges going around you would never have parts roll off. It is mobile and can be raised up so that it could fit over the bed or your lap if you are sitting in your lounge chair. If I knew where to get one at a good price that wood be nice for working in a small area for many of us. David B

-

If the plans show the dimensions and shape of the bulkheads I would always double check each one to make sure they were okay. Any that were not were marked and then repaired off or on the model as needed. However I do not remember if MS came with the bulkhead plans. Otherwise I would do like you and go by sight and a batten. Good work. David B

- 131 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Boxwood has always been a good choice. A couple of others are holly, apple, pear, and degame. These are used by modelers I know who build at 1/192 or smaller. They all have a very tight grain and have the strength. David B

-

Check out jewelry supply house. I use Sante Fe Jewelry Supply. There is also Connentti. David B

-

Nils, have you tried tweezers used by jewels for working with pearls? I know some modelers who have them and they are the cats meow for holding blocks securely. David B

-

Help with Mill handwheel and dial too tight

dgbot replied to rtropp's topic in Modeling tools and Workshop Equipment

Check the scale for a opening for an Allen wrench. That is what I did on my Sherline. David B -

You must be taking energy pills. Looking good. David B

- 83 replies

-

- sloop of war

- sloop

-

(and 1 more)

Tagged with:

-

Great metal work. You are doing a great job. I cannot wiat to see the finished model. David B

- 346 replies

-

- terror

- polar exploration

-

(and 2 more)

Tagged with:

-

Your coppering is coming along fine. David B

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

On your skylight try some acitate for the windows. It can be tinted or shaded as needed. David B

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

You are starting out well. Keep up the good work. David B

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

A unique model Bob. I found your build very interesting. Nice job. David B

- 196 replies

-

- higaki kaisen

- woody joe

-

(and 1 more)

Tagged with:

-

Harbor Freight Workbench

dgbot replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

Nice workshop. David B -

It seems to me that you are addicted to Her reshuffle David Bottob

- 142 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Harbor Freight Workbench

dgbot replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

There is a Harbor Freight in the Chicago area. I have gone on many times. Their prices are indeed good. But to me they are the Walmart of hardware. Great deals on many items. But on their tools both hand and power do not buy sight unseen. I got a good look at one of the bench drill presses because it was cheap. The item was made on the cheap. For extra $40 I could get a good one at Menards. David B

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.