-

Posts

4,280 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Baker

-

-

-

M29 Weasel family 1/72 (scratch) by Backer Finished

Baker replied to Baker's topic in Non-ship/categorised builds

I imagine I'm Henry Ford I invented a "assembly line" for plastic models. haha 😂 -

M29 Weasel family 1/72 (scratch) by Backer Finished

Baker replied to Baker's topic in Non-ship/categorised builds

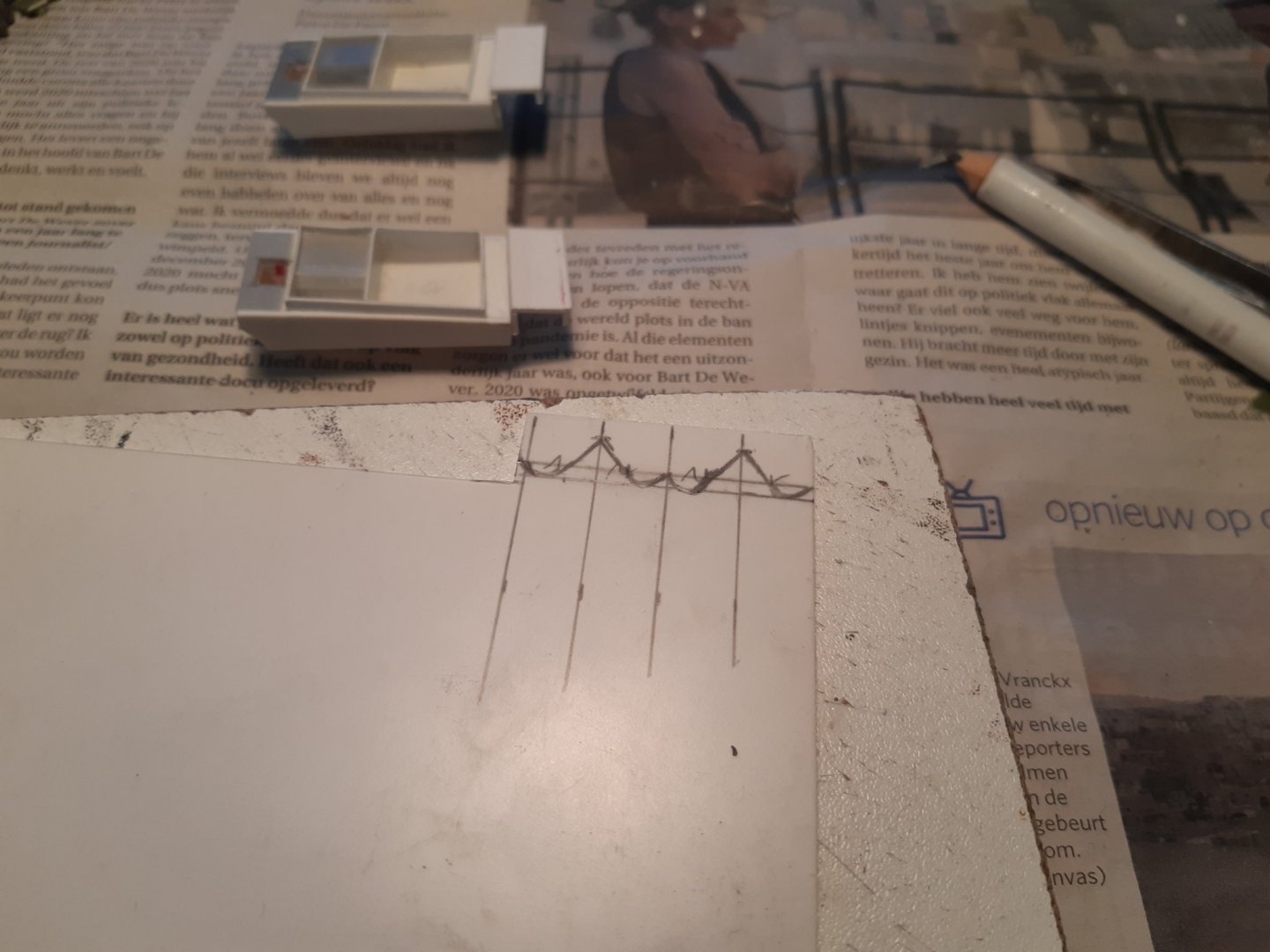

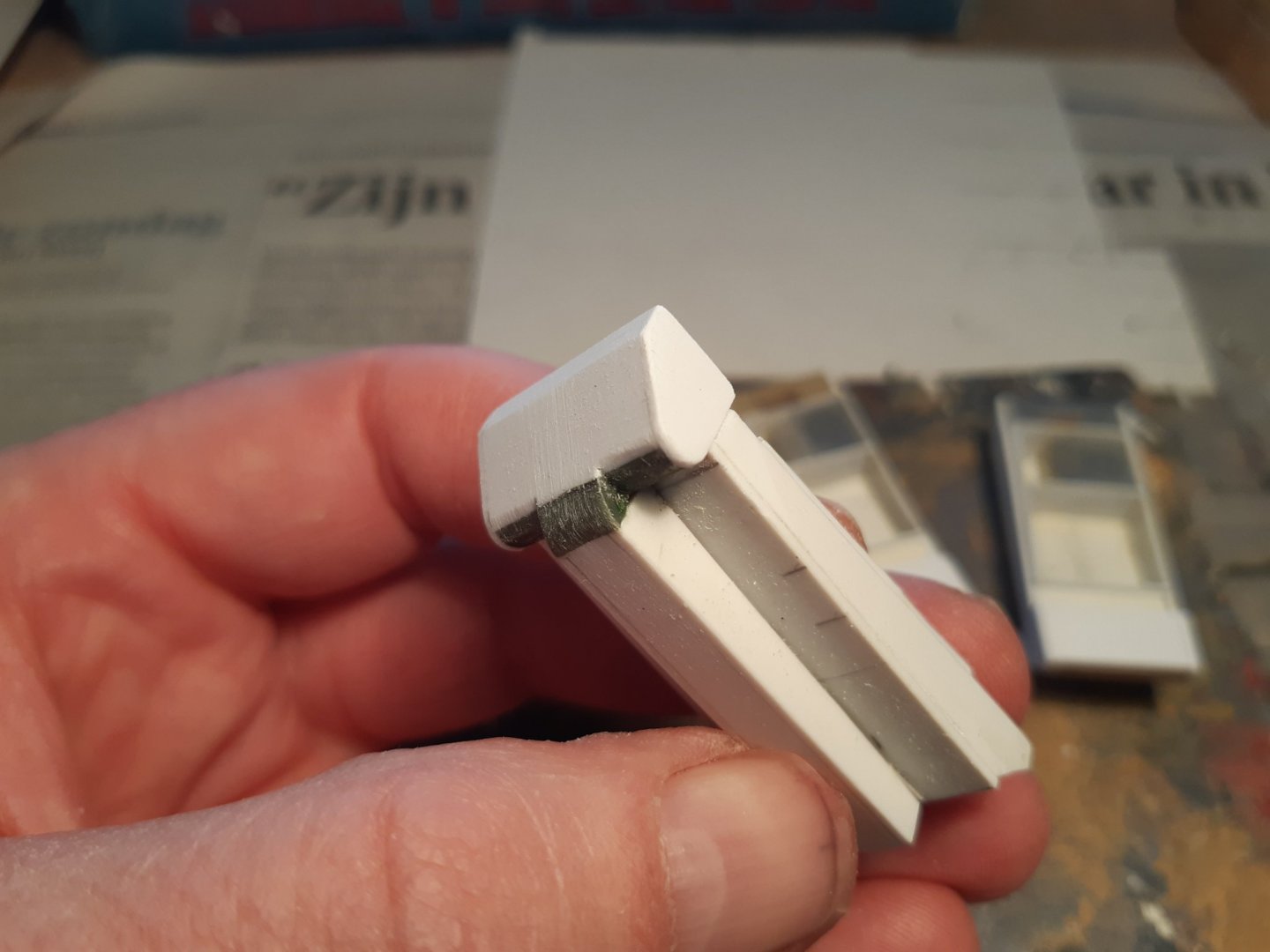

Building the rear "floating tank" This seemed to be the simplest of the 2 to build, so I started with this. Top sides "bottom" rear plate Ready for sanding an cutting rough shape ready Next to do, the front floating tank. Thanks for following -

M29 Weasel family 1/72 (scratch) by Backer Finished

Baker replied to Baker's topic in Non-ship/categorised builds

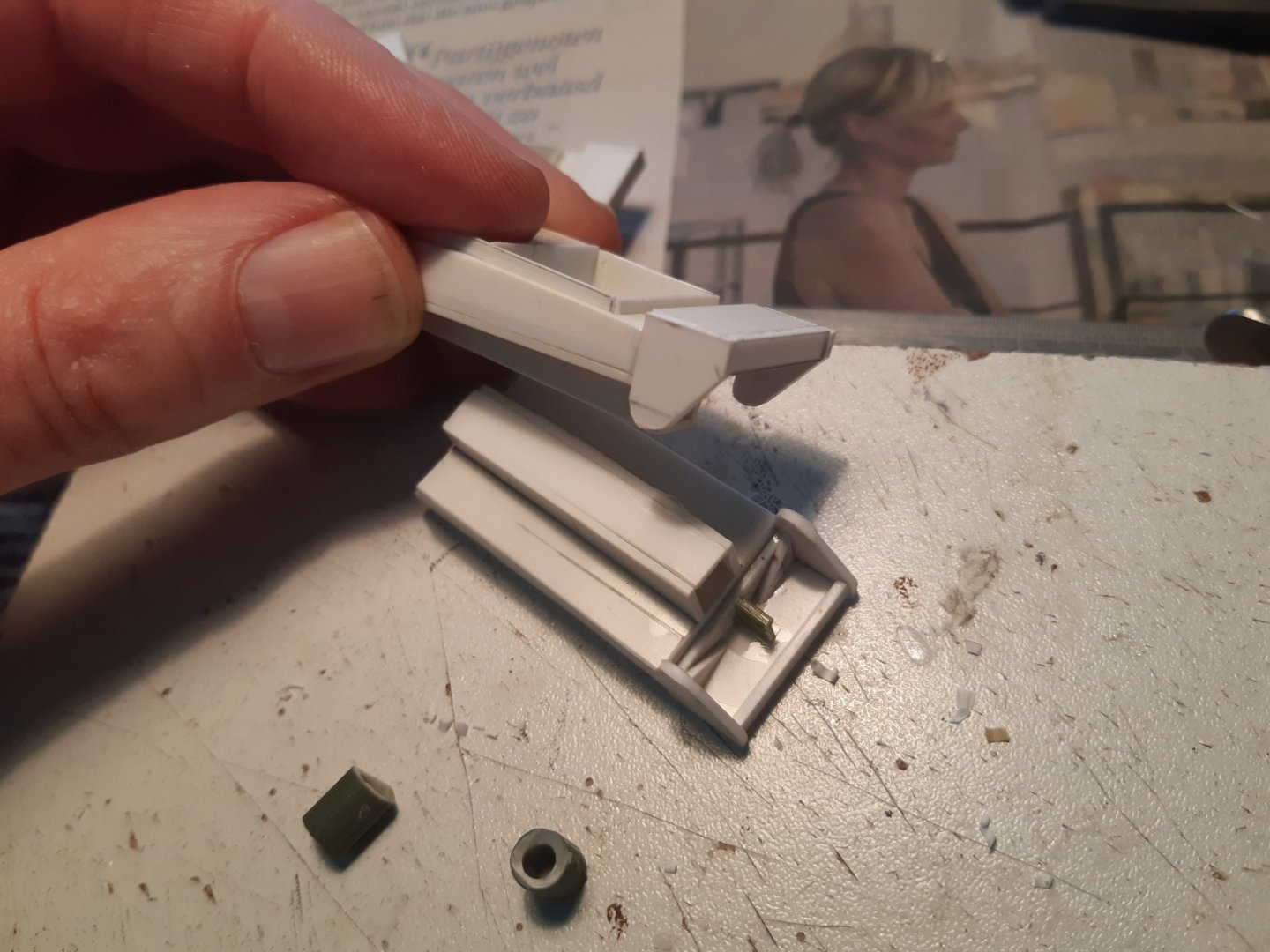

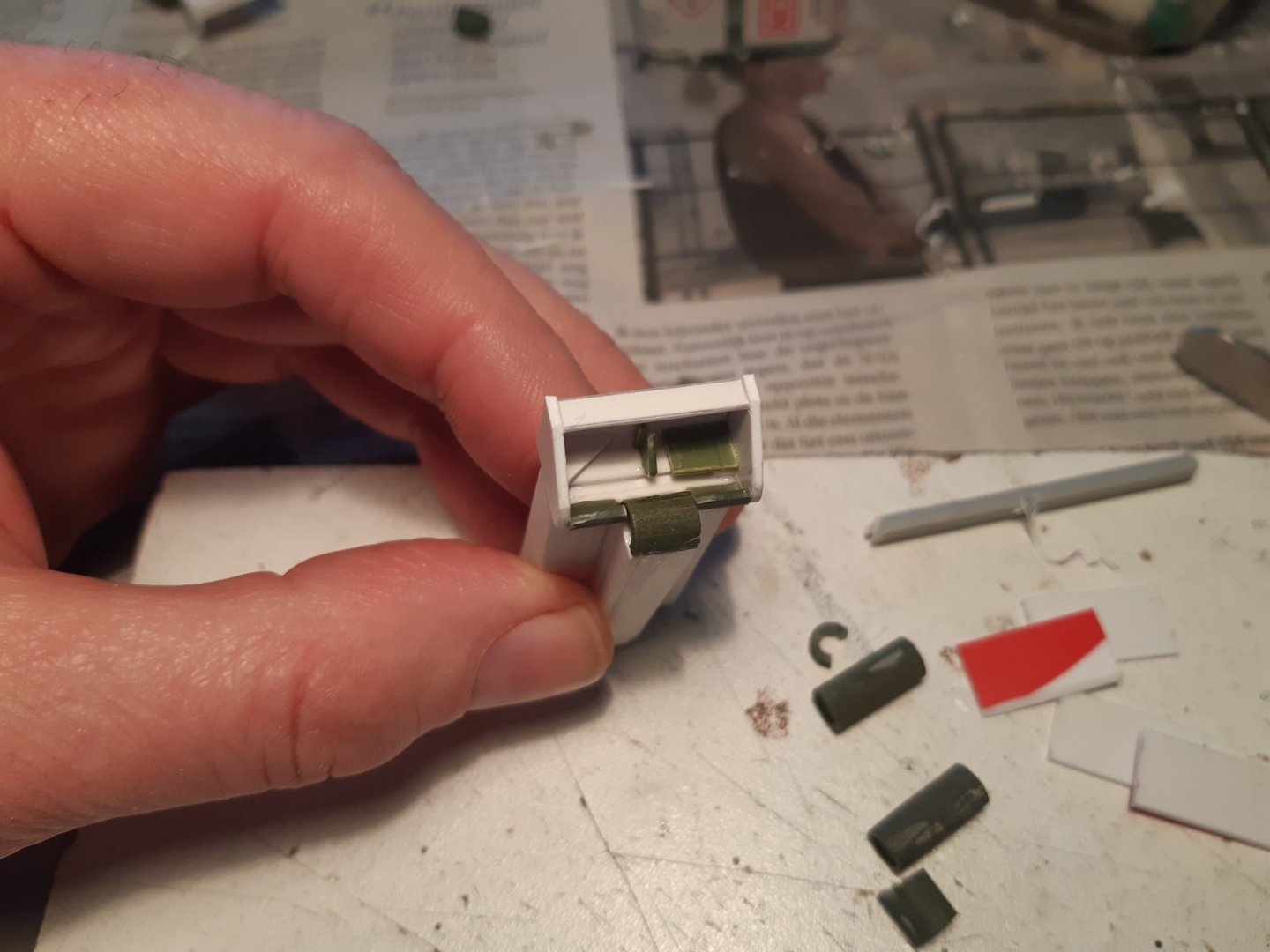

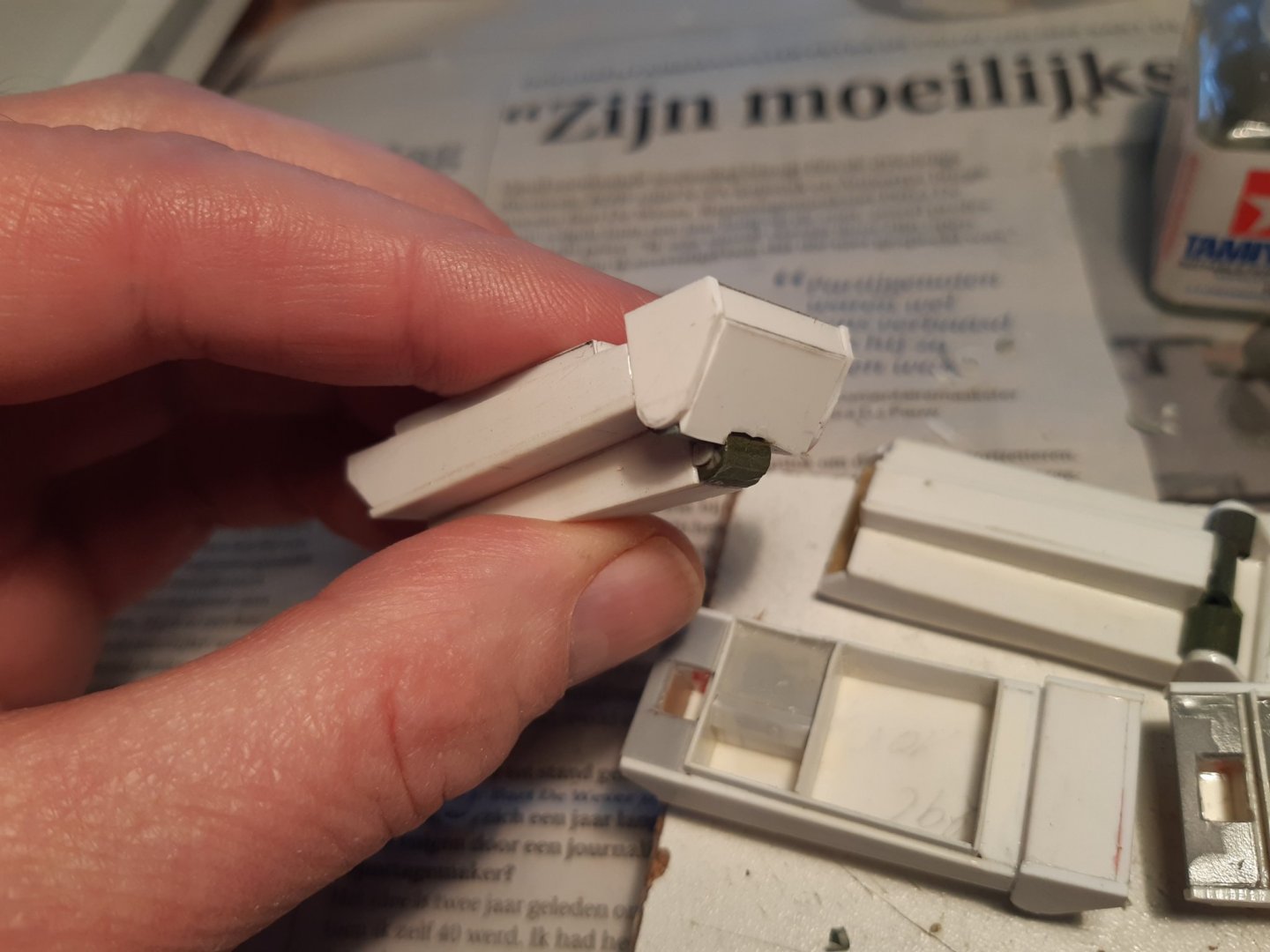

Update, Progress , with a Staghound Mk.2 under construction. The first step is backwards. Everything that was not good has been removed. Building the hole in front of the vehicle. The radiator of the engine will be placed in this later. These 4 will all become c models. A standard, a ambulance, a 75 mm recoiles and a Wasp flametrower. Thanks for following -

Die Kogge Von Bremen by kentyler

Baker replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Well Belgium is a difficult country politically. Believe it or not for the administration of 11 million residents we have 5 governments ... Explaining this whole political question is a very long story and a hopeless task. 😟 To make a long story short. Everyone wants to decide about everything, but no one wants to pay for it The cog Found in 2000 and disassembled. Then the question, what do we do with it, where do we place it, and especially who will pay for it Parts stored for 10 years in containers with water. In 2010 an investigation whether the parts were still suitable for restoration (luckily yes) Return to storage in containers with water. 2014 - 2017 money has finally been found to treat the parts. The planned reconstruction will start in 2023. However, a museum must first be built... I hope I live long enough to ever see this cog 😉 In Dutch http://schoolvoorscheepsmodelbouw.be/wp/specials/kogge-de-middeleeuwen-in-3d/ -

Die Kogge Von Bremen by kentyler

Baker replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Not far from where I live, a cog was once excavated during the expansion of the port of Antwerp. https://www.futurelearn.com/info/courses/shipwrecks/0/steps/7971 My hope is to one day make a model of this cog. So I follow with great interest. -

This is plastic modeling at the highest level

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Well done. Congratulations on your model

- 171 replies

-

- artesania latina

- bounty

-

(and 1 more)

Tagged with:

-

Nice model

-

Permission to come aboard . . . . again

Baker replied to Peanut6's topic in New member Introductions

Welcome back -

Nice model

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.