-

Posts

1,326 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigersteve

-

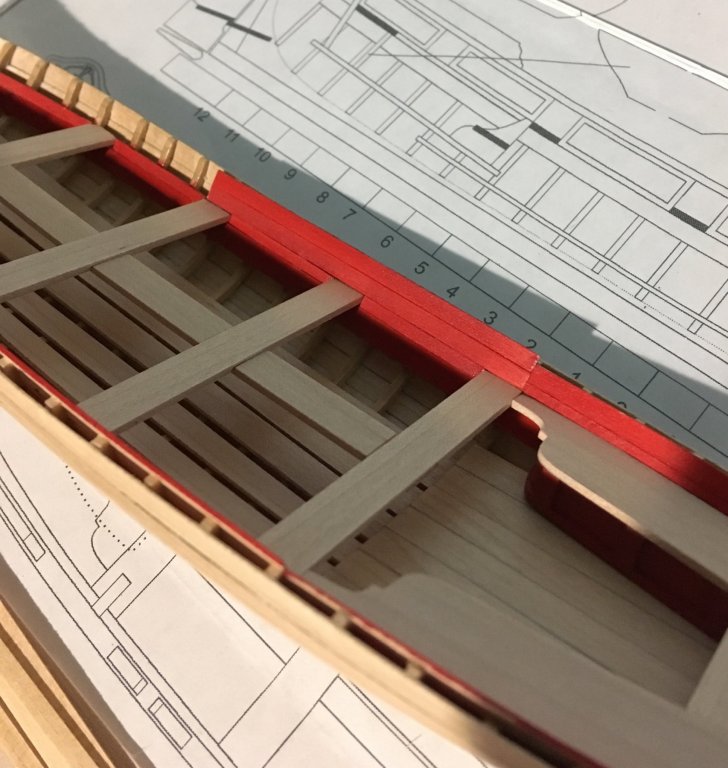

Another photo to illustrate the interior planking process. Midsection planks pre-painted and installed. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

I thought I had already followed this. Oh well- now I am. Steve

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

That is a good question. I thought that the basswood was much more flexible and easier to bend and it will be painted anyway. (I had forgotten just how much after working with the maple.) I will use mostly 1/8” x 1/32” for the remaining inboard planking. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

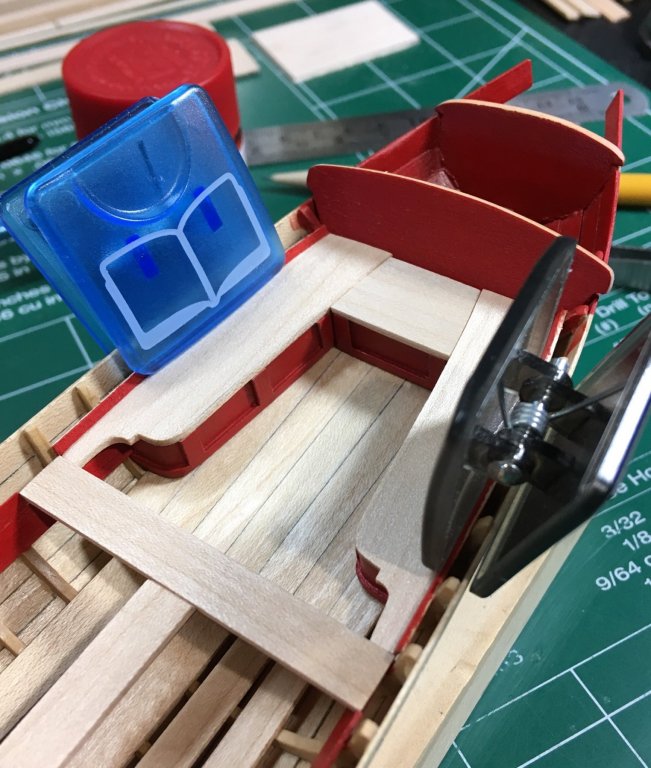

The inboard planking will be completed in sections due to the multiple curves required from bow to stern. I planked the cockpit section with pre-painted 1/16” and 1/8” strips. These will be filled and repainted when the rest of the planking is complete to hide any seams. I am using basswood for this part of the planking. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

A newbie...... And yet, not exactly a newbie

Tigersteve replied to Jake's topic in New member Introductions

@xken’s build log is a must see for your project. Best of luck. Steve -

Very well done. Can’t wait to see what’s next. Steve

- 82 replies

-

- naval smoothbore

- model shipways

-

(and 1 more)

Tagged with:

-

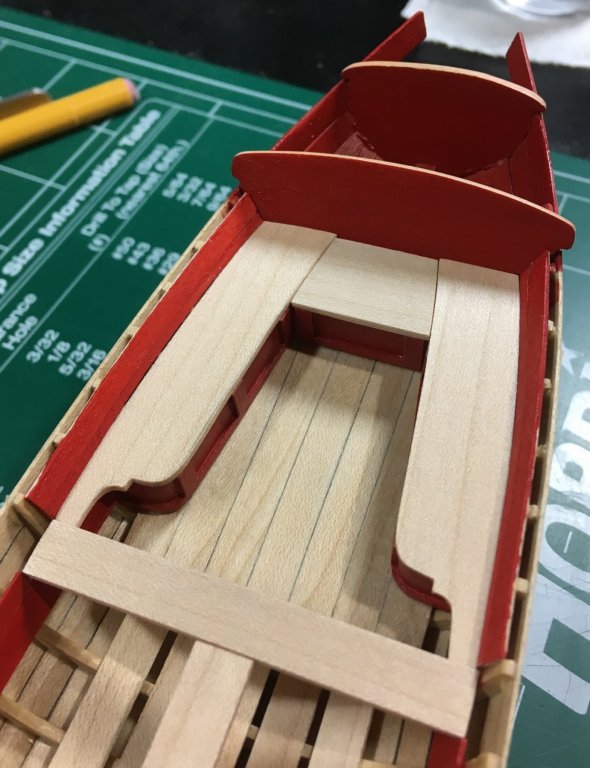

I decided to omit the cockpit trunk and installed seating as per the example I presented in an earlier post. I also completed the forward platform. Inboard planking is next. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks guys. Yes, but the time consuming part was marking the correct spots and dry-fitting. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

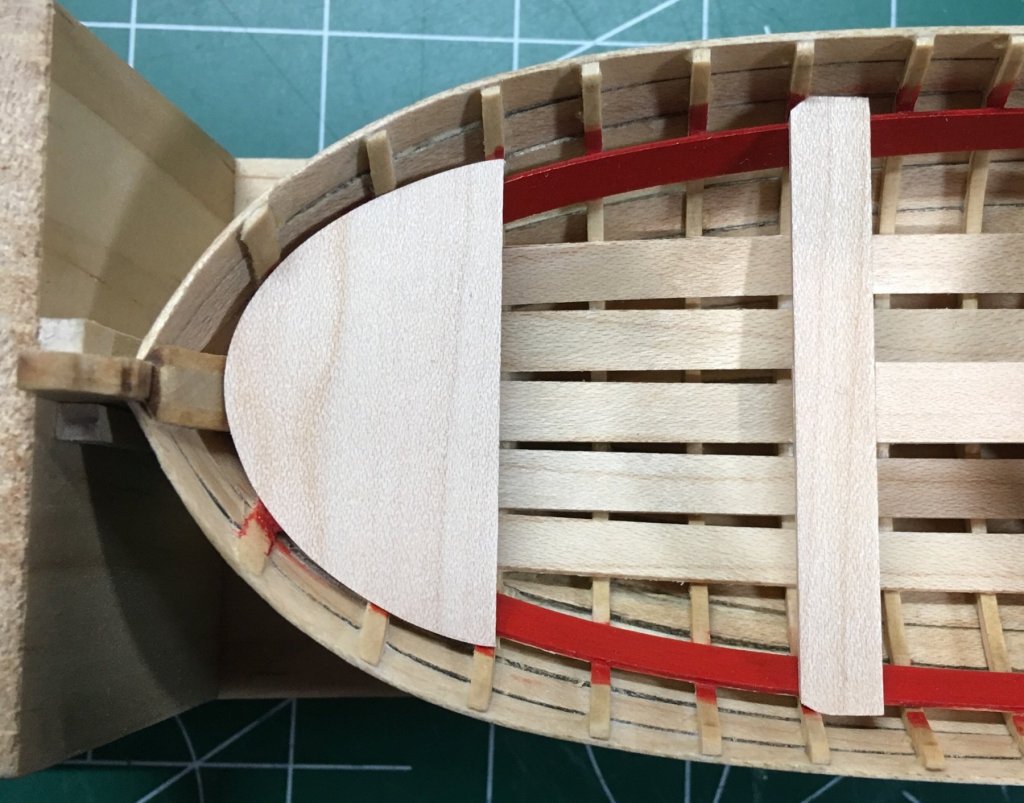

Instead of notching the thwarts to accept sections of the longboard, I decided to notch one long strip where the thwarts would be inserted. This resulted in a straight board. Something I was not able to achieve in earlier attempts. The board was clamped from underneath and marked before filing the notches. The thwarts were also notched to create a flush joining of the pieces. Lots of dry clamping before the final installation. I'm happy with the results and decided not to include the grooves for the sake of a crisp finish. I will have to remake the forward platform without the grooves. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Following along too. Steve

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Following along. Steve

- 74 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Oliver, I would seriously suggest ripping off those planks and doing some further reading on planking concepts. It looks like the step of "fairing" the hull has been skipped. You need to fair the hull so the planks lay against all bulkheads. I'm no expert by any means, but it's important to take your time and do some research before you get too far into the model. You will have a very difficult time otherwise. Here's one link from the forum: http://modelshipworldforum.com/resources/Framing_and_Planking/plankingprojectbeginners.pdf Steve

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.