-

Posts

1,323 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigersteve

-

How long is the bull at this point, Dave? Nice work throughout. Steve

- 742 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

A really superior Niagara model! I think I remember you using Syren rope, but did you also use Syren blocks or the kit blocks? Also- what type of wood did you use for your project? Sorry- I’m sure it’s mentioned in your log somewhere. Look forward to the boats you craft! Steve

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

It’s going to be a very popular project. Steve

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks, Mike! The maple is much harder than the basswood, but I didn’t invest much time into making a scraper so my attempts at this detail were short lived. I decided in the end to move forward. I think you were the only one to successfully reproduce Chuck’s results. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Generic Sharpie by DocBlake

Tigersteve replied to DocBlake's topic in - Build logs for subjects built 1851 - 1900

I’m in too. This looks like a nice project. Steve -

Coming along nicely. Is it rope from the kit? Steve

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

B.E.- Looks good. Nice call on the scale lengths. Kurt- Open a build log? Steve

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

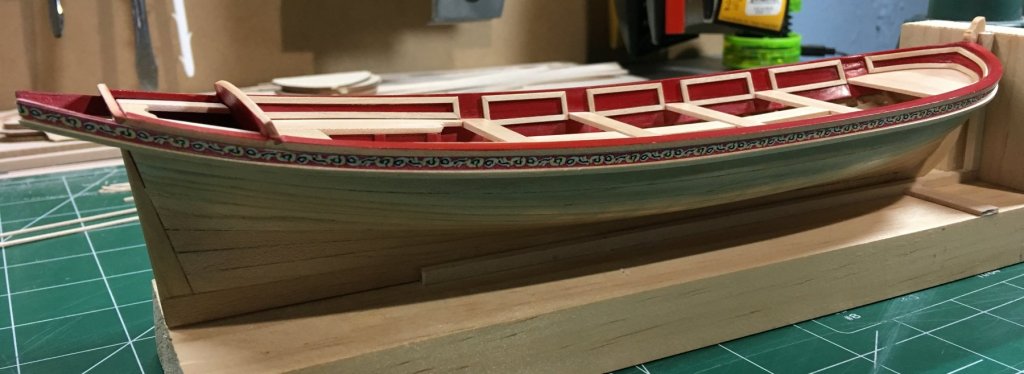

The friezes were treated with Minwax Polycrylic before using a glue stick to apply. The difficult part was cutting the friezes off the sheet. The mouldings were edge-bent with dry heat to conform to the shape of the hull. Gluing these was a challenge. After the glue dried, the mouldings and hull were sanded. Wipe-On-Poly was applied to the entire outer hull including the friezes. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you. I appreciate that guys! I installed the friezes last night. It really makes the boat “pop”. After I install the mouldings I will post photos. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks everyone for the positive feedback. The last and most difficult of the paneling is complete. Strips were edge-bent after soaking in hot water to create the curvature. One continuous panel was created to take the place of the knee at the bow. Not as crisp as the other panels, but this issue should fade as the knees are added. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Yes- it’s too bad he’s on a really long break! Steve

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

What was the experimental wood? Any clue why Wood Project Source’s store is “closed for maintenance”? Steve

- 130 replies

-

The rear panels were fitted and installed one piece at a time onboard. The bottom strip of each panel was slightly edge-bent to follow the curve above the cockpit seats. I skipped making the template and jumped right into this. I think the single panels change it up a bit. The panels really should be somewhere in between 1/16” and 1/32” wide in my opinion. Unfortunately, mine are not. ;-) Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

I’m sure there are many solutions to completing these tasks. Your metal work is mind-blowing though. An art in itself. Steve

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

The eight midship panels are completed. To accomplish this I created a template to capture the correctly sized rectangle. 1/16” wide maple strips were sanded and coated with Wipe-On-Poly prior to cutting the mitors. A jig was created to size, assemble, and glue the panels. After they were assembled, another sanding and coat of WOP was applied. The “fancy” profile was omitted. Many logs I viewed showed folks adding this detail, but at 1/32” thick almost none could produce a profile as clean as in Chuck’s prototype. Mike Y had the cleanest profile, btw. I created a scraper and tried it out, but even with hard maple it was difficult. I decided to save the hours on this detail and move forward. (It’s extremely tiny with the naked eye, but looks huge in photos.) Next task is to figure out the configuration of the rear panels. I will try a modification: one longer panel instead of two shorter panels. Another template will be made to see how it looks. Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Best of luck with this one. I’ll follow along. Steve

- 22 replies

-

- bluenose ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Echo the above comments. Insanely complex! Steve

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Thank you all for the positive comments and likes! I’ve certainly been taking my time with this project. I just realized I started this log in April! The panels should be fun. Who knows how long that will take... 😜 Steve

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.