-

Posts

1,298 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Papa

-

-

I am totally stuck. Did a lot of Googleing but can't find an image with enough resolution to see what this cabin is suppose to look like. No matter, the wife and I are going to be traveling to warmer weather until April so Helgoland and Granado are going into dry dock for the duration. i will have to focus on reading, drinking wine

, and perhaps making sketches of ships.

, and perhaps making sketches of ships.

-

On 1/3/2018 at 9:18 PM, Louie da fly said:

Two thoughts occur -

Both ships may have been staying well clear the coast until they reached the right latitude and then sailed east along the parallel until they reached the coast. Unless I was totally certain of the accuracy of my chronometer I'd be treating the longitudinal calculations not as totally reliable but "more of a set of goideloines". I wouldn't risk the safety of the ship on them unless I had to.

The other thing is the prevailing winds. If they are westerly, the coast becomes a lee shore - much to be avoided. Even if they only got occasional westerlies, I'd be staying well away from the coast if possible until it was time to go into port.

Steven

Those are good points. I am sure that the logs of all the California bound clippers would follow roughly the same route. The experienced captains knew where to find the winds.

Ron

-

Very nice work. i wish i could keep my work area so neat and well organized.

-

-

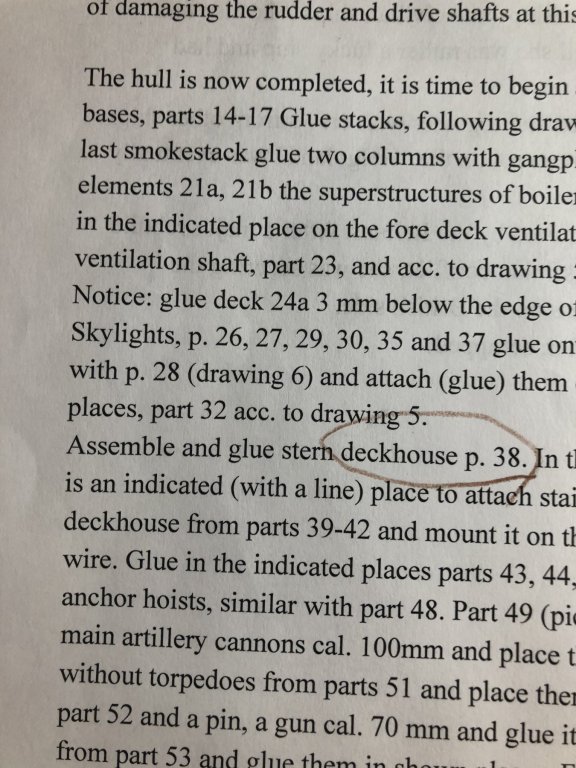

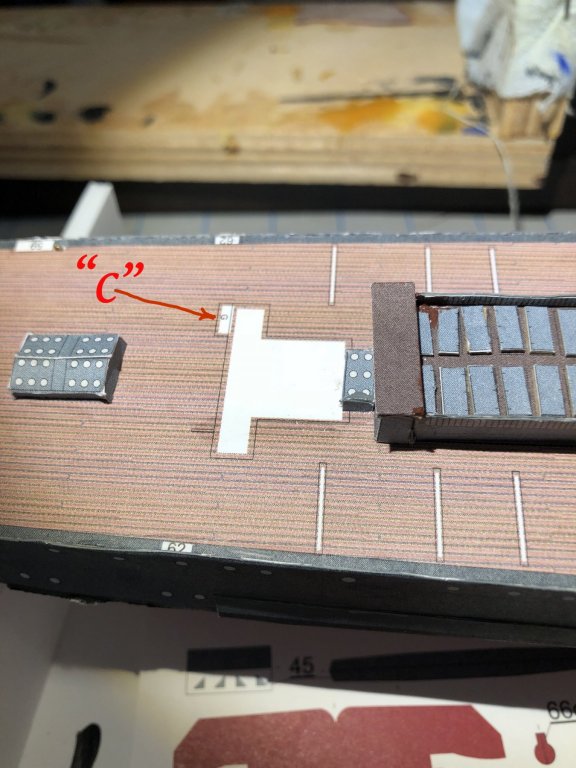

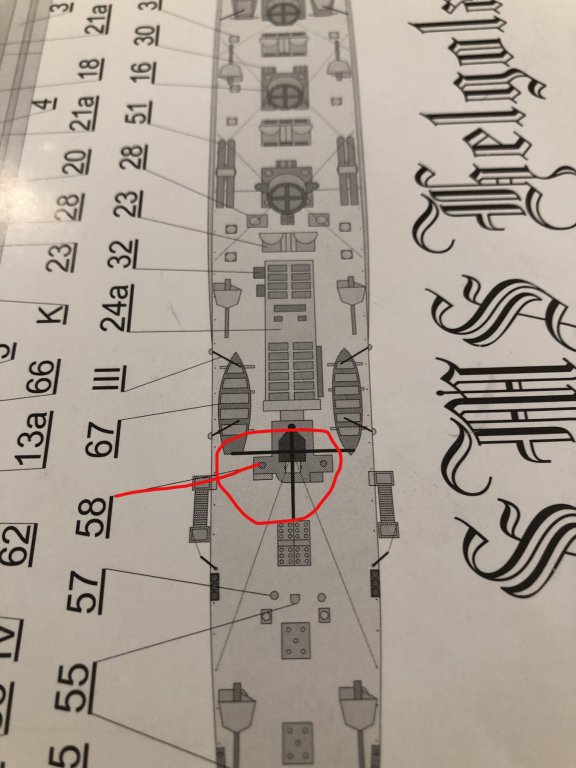

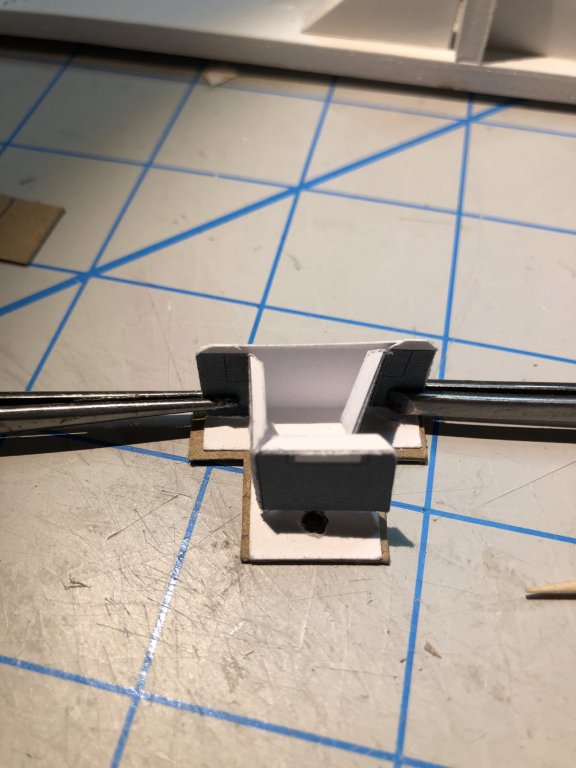

I need some help. I got to part 38, which per the instructions is the rear deckhouse. However there is no space on the deck labeled "38". I think it is the white area shown in the photo because the parts sheet has a 38c, and there is a block "c" next to the white space. Also there are 2 parts 58 that are identified by two small circles on 38a, see photo, and also on the deck plan and seems to be in the right general location. And, there is the mast hole in the right place. Now for the quandary. The deck house, part 38, has 6 sides. The white blank space has 8 sides, I've tried 2 different folds and neither makes much sense. There is also supposed to be a line to show where the stairs go, but I don't see it I am thinking that 2 sides were left out of the print. There is some extra grey on the parts sheet that i could cut sides from. Thoughts anyone?

- mtaylor, GrandpaPhil, Canute and 1 other

-

4

4

-

Here is a comparison of the Flying Cloud 90 day voyage in 1851 with the Andrew Jackson voyage of 89 days in 1859-1860.

Maximum distance in one day:

Flying Cloud 365 miles

Andrew Jackson 414 miles

Average Speed:

Flying Cloud 7.5 knots

Andrew Jackson 7.2 knots

Total Distance traveled:

Flying Cloud 16183 nm

Andrew Jackson 15399 nm

I think the key to Andrew Jackson's better time is that her course was nearly 800 nm shorter.

I am suspect of the funny jog down near Chile. I think the log entry might be in error. I found one clear error near San Francisco (the position was way too far west relative to the previous longitude) that I corrected with interpolation. Also on Dec 26, 28 and 31 Mr Williams, master, did not log any longitude. I estimated the longitudes by interpolating.

- mtaylor and Mirabell61

-

2

2

-

-

On 12/18/2017 at 7:19 PM, Roger Pellett said:

Very interesting, but it is probable that you used the wrong pronoun! Recent scholarship indicates that the vessel was actually navigated by Cressy's wife who was in turn influenced by the hydrographic work of Matthew Fontaine Maury.

Roger

Thanks for reminding me. When I was reviewing the log, I thought I remembered that his wife captained the Cloud but I didn't follow up on that thought.

I am in the process of inputting all the data in Appendix IV "California Voyages" to do some statistical analysis of the voyages. Watch this space.

-

-

If you are still interested, I have a Mamoli Victory kit from the 1980s that I have worked on and off for the past 5 years or so. Current state is picture in this forum toward the end of page 3 of the link. I am very unhappy with the materials and how it has been going together. I finally decided that life is too short to build a model I am not happy with. If you want it, hull as is, strip wood and fittings it is yours for the cost of shipping. Contact me though the message system.

-

-

Oh, and the total sailing distance was 16184.9 nautical miles

-

Cutler's "Greyhounds of the Sea", appendix V has the log of the Flying Cloud from New York to San Francisco under master Josiah P. Cressy in 1851. I transcribed all of the lat/long data into Wolfram's Mathematica and plotted the position of the Flying Cloud for each day of its journey. The route is very interesting. For example, he heads eastward until he can go straight south to clear Brazil and then clings to the South American Coast. Rounding the Horn he heads roughly NNW until he is about 950 nautical miles west of San Francisco and the shoots eastward to port. i am sure that the course is dictated by the prevailing winds. Some additional trivia:

Maximum distance in a single day: 364.9 nautical miles (about 15.2 knots)

Minimum distance in a single day: 13.8 nautical miles (about 0.6 knots)

Average distance in a single day: 179.8 nautical miles (about 7.5knots)

-

Beautiful model. Also a great example of why one can never have too many clamps!

- mtbediz and John Allen

-

2

2

-

-

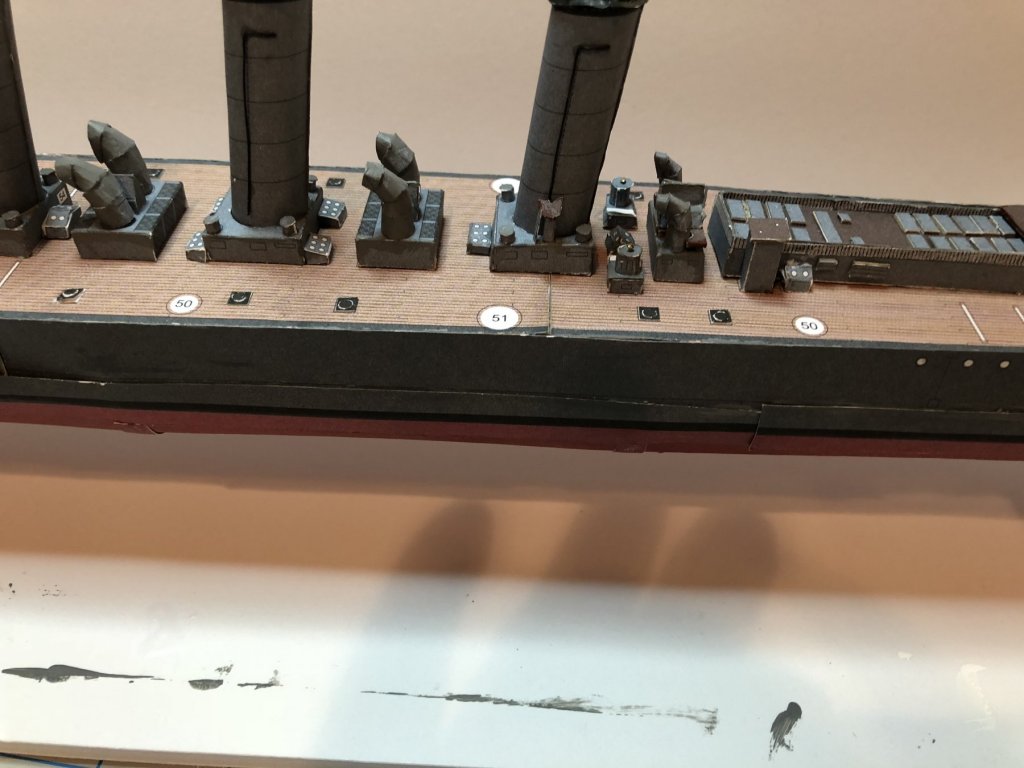

The detail is getting even more amazing!

- Canute, popeye the sailor and mtaylor

-

3

3

-

Reading the article "Making a Model of the USS Pennsylvania" in the latest NRG Journal I came across this: "The use of a marine walk to access the bowsprit ..."

Help me out here. What is a "marine walk." Google hasn't helped me out on this one.

Ron Gove

-

-

I love the detail on this model. Makes me want to try my hand at a plastic battleship!

- RGL, mtaylor, Old Collingwood and 1 other

-

4

4

-

-

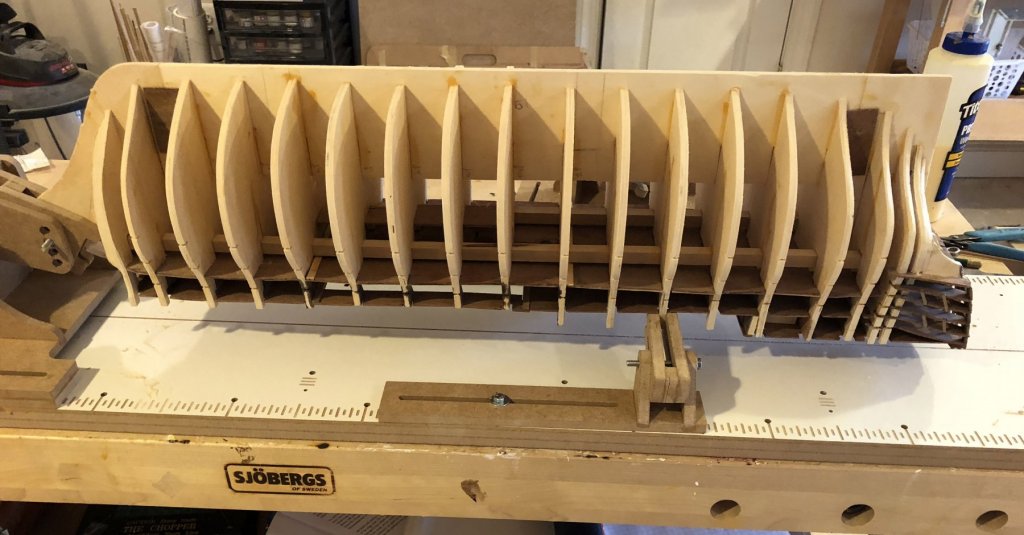

A bit of detective work on line and a visit to Lowes confirms that the bolts are metric M5-0.8. The "0.8" is "pitch" and it converts to a tad under 32 threads per inch (31.75 in fact ) That's why it looked like a #10 32. The M5 part i think refers to 5mm diameter..

The jig is turning out to be very handy. I am trying to shape the bulkheads for planking,

- Canute, Jack12477, Ryland Craze and 5 others

-

8

8

-

8 hours ago, semorebutts said:

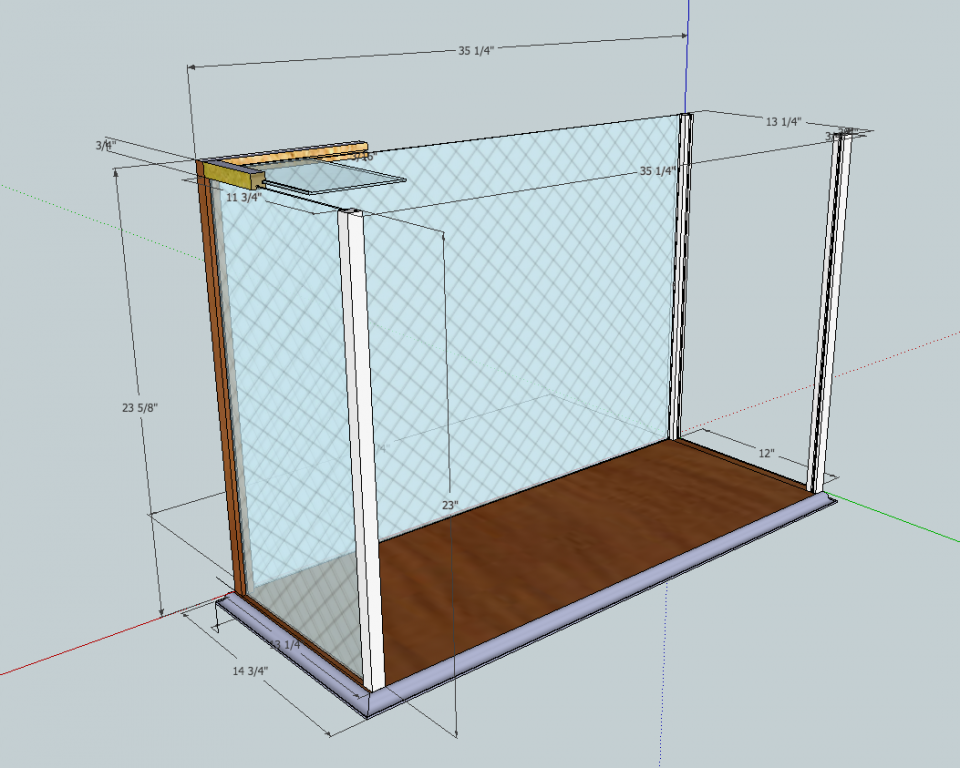

whoa thank you Ragove. yes i have a table saw. I think I am going to do it myself. There is a custom acrylic shop near me but it is expensive. I just dont know if I can get away with 1/8" acrylic over a 53" length or if I would have to use 1/4". If I use wooden framework 1/8" would be ok. also 1/4" slots would be to big. those plans are awesome thank you. It clears it up for me.

I ordered my acrylic on-line for a reasonable price. There are a number of vendors who will cut and ship custom sizes. I think i used 1/8th inch.

Ron

-

On 12/3/2017 at 4:54 PM, semorebutts said:

I have done two types of acrylic cases. One was all acrylic and I butt-joined the edges and used the recommended solvent cement. I was living in an apartment at the time and had minimal tools. It worked quite well but it was on the small side. For my Essex I built a wooden framework and used the acrylic as one would use glass--fitting onto slots. There is a photo of my case somewhere on this site. I think if you have a table saw and reasonable woodworking skills you should be able to make a case.

- harvey1847, Canute, cog and 4 others

-

7

7

-

Does anyone know the size of the nuts and bolts included with this jig? I wanted to substitute some thumb screws, wing nuts and some longer bolts. I thought they were #10-32 but that doesn't seem to work. I am guessing that they are metric.

Bismarck by Dan Vadas - FINISHED - GPM - 1:200 - CARD and PE

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Dan,

your work is simply amazing.