-

Posts

5,966 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

YOUNG AMERICA 1853 by Bitao - FINISHED - 1:72

BANYAN replied to Bitao's topic in - Build logs for subjects built 1851 - 1900

There's only one phrase to repeat, and repeat, for your work - stunning work! cheers Pat- 257 replies

-

- young america

- Finished

-

(and 1 more)

Tagged with:

-

74-Gun Ship Gun Deck by Jeronimo - FINISHED

BANYAN replied to Jeronimo's topic in - Build logs for subjects built 1801 - 1850

Lovely work as usual Karl; looks great. cheers Pat -

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

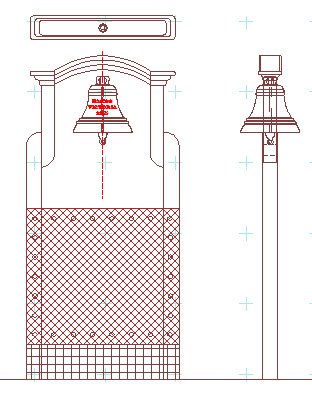

A little more progress folks; some dusting, removal of glue (when properly dry) etc still to do but here is the result for the Gallows and Belfry. In hindsight, I wish I had not secured the Elliott riding bitts in place as they need to be a little more forward, but in reality there is still room to work the cable around them if needed. I couldn't move the gallows further aft as I have to preserve room/space for the capstan bars when fitted. I still have to add the simulated bolt heads on the legs of the belfry. The bit of brass at the top is a breather pipe. The tank is 3D printed resin airbrushed with Mr. Metal 'iron'; although not clear, the bit bottom central is a cock for drawing fresh water which I think should no be at the back - too late now though. Sorry the challenge was not taken up re fitting a bell rope - the thing was just to small. I could not drill a small enough hole in the clapper's end without the drill bit wandering around (only 0.3mm end below the round part). I may end up just gluing a bit of twisted cotton (3 colours) on there. cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

A thing of beauty indeed, very clean work. cheers Pat

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Can only comment on the high quality of your build Mark as I am not familiar with the spars and rigging of these vessels. To eye, doesn't seem too thick. cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for all the likes, and the kind comments and suggestions Steven, Eberhard, Bruce, Chuck, Mark, Kevin, John and Ed. Chuck: The trick I have found (at this scale) is resistance soldering. I find it much easier to control the heat and using different heat activated solders can usually get the smaller details in place without disturbing the rest. Now, if I can get my woodwork up to the same standard as yours I would be real happy. Bruce and Ed, always appreciate you looking in and you much appreciated comments. Eberhard, Kevin, John: My intention is to try and add a bell rope BUT at this scale it would only be 0.2mm diameter so definitely no plaiting/weaving or fancy knot work. IF I can drill a small hole in the clapper, I will simply add a small length of very fine scale rope with a knot in the end. Thanks for setting the challenge (I think 🤯) cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

I know exactly where you are at Keith, I have the same issue with Victoria's rigging. I have bitten the bullet and gone back to first principles (so to speak). As you have found, there is no ready reference so I am trying to develop my rigging and belaying plan from several authors that cover the mid-nineteenth century. I am at least lucky to have found a copy of her Rigging Warrant so what I have done is use the listed rigging and associated items (blocks, hooks, thimbles etc) and see which author best describes the rigging set-up using that combination of rigging gear. I also allow for the fact that each Captain had their preferences and in this case, correspondence from the ship's build superintendent confirms that he allowed the Captain to rearrange some of the rigging to 'merchant' rather than naval practices, as he came from a merchant background. He apparently changed some of the rigging associated with the yards. Overall, I have found that the Rigging Warrant, supplemented with the imagery I have of the ship (quite accurate), suggests most of the rigging practices/set-up employed were in accordance with the descriptions given in 'Seamanship' by Lieutenant G.S. Nares, 1862; and for the more modern adaptions 'The Masting and Rigging of The Clipper Ship and Ocean Carrier' by Harold Underhill proves useful. However there are some departures / differences not covered by these authors so I have also used (consulted and verified with) Robert Kipping, John Fincham, Young, James Lees, D'Arcy Lever, John Harland, Marquardt and William L Crothers. I am now about 70% through having sorted the head sails, fore mast, and most of the mizen and auxiliary sails (stunsails, trysails etc). The main mast I hope is mostly a copy of the foremast (minus the head sails) with just the belaying and some of the leads to be adapted. Not sure how different yours would be as mine followed the British practices of the day for a steam-screw vessel - and as I have previously advised while conforming to a Barque rig in general principles, there were considerable differences to accommodate the additional fore-and-aft sails and modification required to work with steam (heat from the funnel especially). Give me a bell if you think there would be some similarities. cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks Keith. Now that the decision is made to go with a metal frame, I have made a start. The belfry is almost done, and a good start made on the gallows. There is still some metal polishing to be done to remove the final scratches (noting this is a super closeup shot). The frame is one piece brass bar 1.5 mm x 0.8 mm shaped to the profile. I drilled the sides after it was shaped to accept 0.5 mm brass rod on which the bell is free mounted (can swing. The bell is aftermarket. I then soldered the end caps on (small brass tube) and silver soldered the base plate. Have yet to decide whether to leave it like this or cut away the central bit. Leaving it intact will allow a better gluing surface and some additional strength. I am also still deciding whether to drill the 'clapper' and add a small rope. I have made the bitts, end boards and rails for the gallows; the side rails (to hold the FW tank) are in but need some final sanding. I have just painted the FW tank but no photo as it is still drying. I have painted the tank a metallic iron colour; I had considered white, but simply to allow the detail to show I have used the iron colour. cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Rob, your 'skeleton' is coming along well. With all the research going into this build, you should have a very well detailed and acceptably accurate hull. cheers Pat

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Hi all, there may be a subtle differentiation that needs some further discussion here? I approach this as an amateur researcher looking for info about mid-19th century equipment and maritime matters. I fully agree that any NEW Information/data developed by a company or individual can (should) attract a fee (nobody expects to work for nothing). However, I am now experiencing examples where some companies/individuals are trying to charge for information and imagery that they have not developed themselves, nor improved, and in many cases the source data/information is out of copyright and often freely available - if you are patient and prepared to dig further. One example is the imagery company 'Alamy' whom seem to try and grab whatever image they can and charge for it? This comment may be a little different from brunnellrussell's intention, and again I reiterate that any information/data resulting from a company/individual that is their work, by all means charge. If value adding to existing information has been done, then again, a fee is understandable (as long as it is reasonable) and the user will soon determine whether the company/individual is charging for good or poor quality information. What I do not agree with is for companies and individuals grabbing info that was/ and should be free, then charging for it having done NO work to improve it. My whinge over, I'll get off my soap box. cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Too true Mark cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks Tony and Mark, and for all the likes. I appreciate you all looking in. It's always a surprise to me that when researching, for days you just cannot find the info you really need, then all of a sudden .... cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

OK folks, a little more digging around has found something that may work and sort of conforms (roughly) with the lithograph detail. The NMM Collections holds a belfry and bell (items EQA0462_1 and EQA0462 respectively) that was fitted in the Yacht Fox (also built 1855) that is metal, and has projections - just a little different to the profiler in its upper parts. Close enough for it to work though I think? cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for looking in and the various great comments and suggestions, John, Eberhard and Steven - makes the decision even more perplexing though as each offers very convincing arguments for and against. I went back and edited the post t include a larger enhanced version of the small crop of the lithograph to see if that would help but --- Nope I think I will put this decision off for a little while longer as it can be added much later whether made from metal or timber as it fits to the top of the fore gallows crosspiece/end board and I will still have access to that area even if the standing rigging is in place. In the meantime though I might have a go at metal. Eberhard: I was thinking the same but all of the metal versions I have seen to date do not have those upper projections/stubs, but rather conform to the shape of the bell - which continues to make me shy away from a metal frame. I do agree though, the frame appears too lightweight to be timber - hence my quandary. This will give me time to get back into the Public Records Office Victoria (PROV) and see if there is anything in the remaining correspondence from the vessel's build Superintendent (Commander Lockyer RN). I had plans of doing that very soon but, as most will be aware Victoria has gone into yet another Covid Lockdown (so it will be a while yet). Hopefully Lockyer will have made a comment in one of his numerous reports that I have not yet seen/transcribed. Steven: Your proposed techniques are exactly what I had in mind, thanks for that. I have had a go with using the laminated technique but as you identify, the bends are just not achievable (at the projections). I went with 3 layers simply copying the traditional way (as you also correctly surmised). One technique I may yet fall back on is to 3D print the part - paint it either mahogany (as with the ship's wheel) or brass if metal. Cheating I know! but hey..... cheers, and thanks once again to all Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Oh great Just as I was resiled to the timber . Thanks for looking in and your suggestion Rob, much appreciated. cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks Mark, appreciate the suggestions. I may have been a little unclear above, but the iron water tank is framed/cradled by the gallows timbers and a couple of rails, and the belfry would sit centrally on the top of the fore crosspiece/end board. I am more inclined towards thinking it may be timber based on the non-conforming shape (to the bell) BUT, that said, if the majority feedback is more aligned with a metal frame I will certainly give that some serious consideration (and it would be easier to make ) cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Good find Keith - a perfect fit. If you wanted to, you could remove the front door and panels and replace with a larger single pane/door recycling the existing wood? It would look some of those older style display cases then. BUT, that is even more work for you cheers Pat

-

YOUNG AMERICA 1853 by Bitao - FINISHED - 1:72

BANYAN replied to Bitao's topic in - Build logs for subjects built 1851 - 1900

Ditto all the above - its a joy to see your build updates, tool manufacture and the quality of your work, even if it won't be seen later. cheers Pat- 257 replies

-

- young america

- Finished

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi Steven, remembering, like you (but not as small as yours) I am working at 1:72, so these will be quite small. The imagery I have of the belfry infers that it is a timber rather than a metal frame, however, a valid argument could be made for either. The belfry appears to be fitted on top of another structure otherwise it would not be visible above the roughtree rails. It is therefore possible that it forms part of the gallows structure (only place the gallows could be based on other equipment etc). HMCSS Victoria Lithograph (Crop) - original from State Library of Victoria (SLA) If the belfry was constructed with a metal frame, these were usually a single-arch (as shown below), and a relatively thin structure. However, the profile of the curves for such a frame conforms much tighter to the shape of the bell as depicted in the lithograph, and it is much thinner than what is shown by the artist. The version shown below sat on the riser timbers and would have been more conically depicted by the artisist if this type was used? Typical Metal Frame Belfry as fitted to MV Coho David Steel, ‘The Elements and Practice of Rigging and Seamanship’, Volume 1, 1794, - Folio XXXIV – for a wood structure, informs that for a Sloop of War, the belfry should stand 2’ 5” above the beams. This ties in well with the scaled version of the lithograph when underlain with the CAD plan and use the gallows end boards in lieu of the deck beams (i.e. 2' 5" above the top of the end boards). My interpretation so far is shown below which shows the 100 gallon freshwater tank which will be braced by the gallows end boards (and two rails - I have yet to completely draw/finish the gallows structure ) - the front timbers go down to/through the deck and will fasten to the deck beams in similar fashion to the bitts. I know the lithograph shows them more slanted, but the artist's perspective used had the ship on a slight bow on aspect, which may have influenced/skewed his depiction (well that is my current story ) cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks Keith and Jim, appreciate you looking in and for the kind comments. Yep, just a tad small for the scale to add the striker I will ensure it is included in the ship's bell up forward though. Speaking of which, i am having some difficulty coming up with an acceptable (doable) way of making the top of the belfry. I need to make this the usual centre curved (concave) with ears with minimal decoration. I am thinking three very thin layers of wood each slightly narrower in width to give appearance of staggered layers. Just not sure how I will go about forming the curve with horizontal projections yet. I have entertained the idea of milling a single piece with the steps and then trying to steam/water and heat bend over a former but first attempt deformed the steps. Trying this with laminated layers would separate them unfortunately All suggestions entertained. cheers Pat- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

If that is pedestrian then my current build will be relegated to prehistory before it is finished At least five years on this one and I am just starting the spars and rigging. cheers Pat

-

I admire the challenge you have set yourself Steven. What you have done already looks good. cheers Pat

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

If you find a source let me know - I could certainly make use of some better eyes and 'shake-free' hands cheers Pat

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.