-

Posts

343 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Pete Jaquith

-

-

-

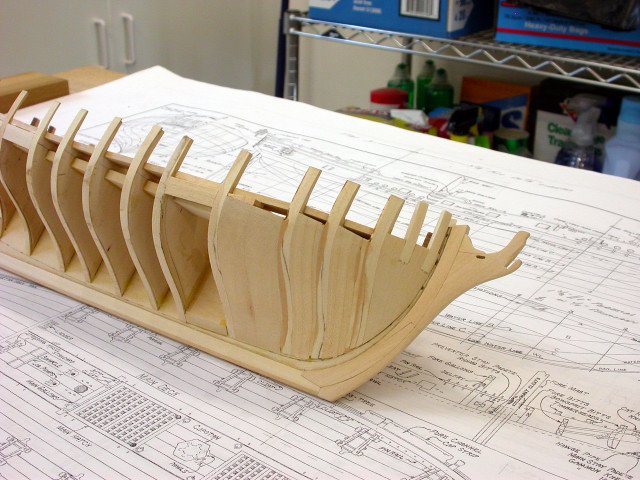

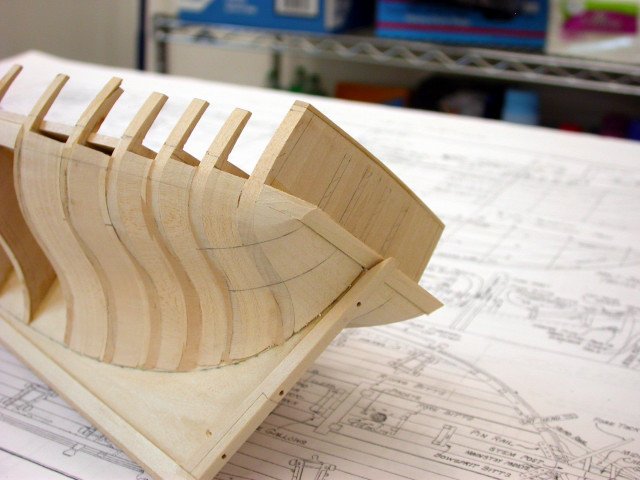

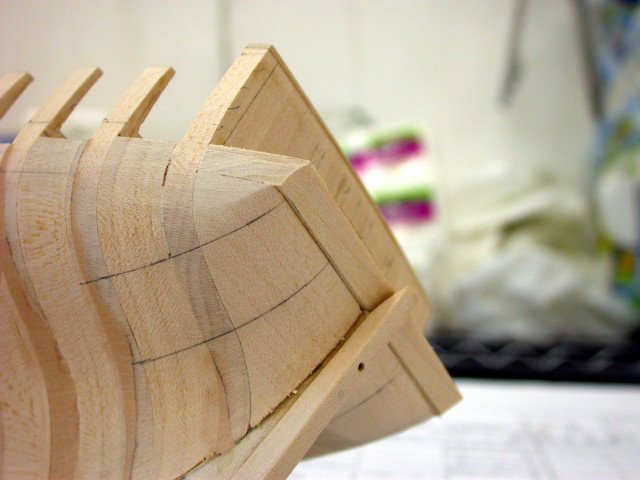

I used 1/8", 1/4" 1/2" and 3/4" basswood sheet laminated for the bulkhead spacing for filler blocks. If basswood is not available, I would use pine or popular. Shaping was done with #80 grit paper wrapped around 1" and 1.5" dowels. They turned out to be very effective fairing tools rapidly removing unneeded material. This was followed by #120 and #150 grit paper using the same large dowels.

After initial shaping with gouges and chisels, I use the same large dowels for fairing laminated solid hulls.

-

- Some Idea, dvm27, Landlubber Mike and 6 others

-

9

9

-

-

- uss frolick, CaptnBirdseye, mtaylor and 3 others

-

5

5

-

1

1

-

After graduating from Webb Institute of Naval Architecture and Marine Engineering, I joined Bath Iron Works in Bath, ME. My 1st year included an apprenticeship in the "full scale" and "1/10th scale" mold lofts. Very enjoyable time and I learned a lot re structural design, material routing, and design for production. Later in my career, I ran the mold loft at BIW and oversaw the transition to 3D CAD. Today, most of the traditional loft functions are preformed near automatically using artificial intelligence (AI) and the 3D CAD design product model. Recently I have assisted the US Navy and warship builders with recommendations re modern 3D CAD Product Model design systems.

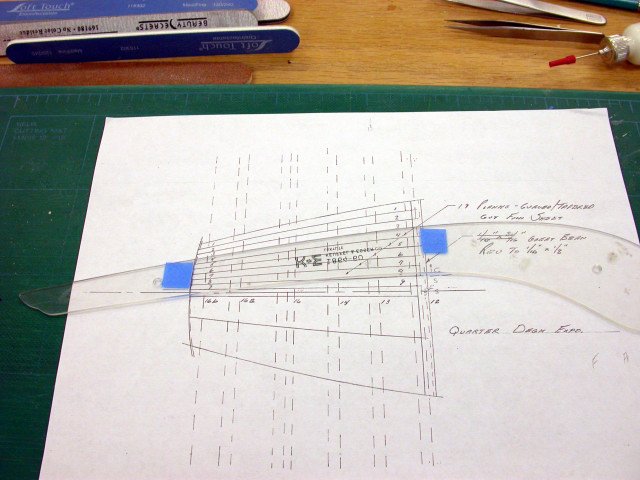

For model building, I prefer to draw my own lines using ship's curves, a tapered pine batten, and lead batten weights from my four years at Webb.

-

-

-

-

Shipbuilders,

My ship modeling has been limited in recent months due to:

- Preparation of a major Technical Paper on "Warship Design and Acquisition" to be published in the Naval Engineers Journal Sept. `21 issue, an American Society of Naval Engineers (ASNE) publication.

- Incredibly hot weather which prevents work in my garage shop.

With the paper complete and weather improving, I look forward to getting back to the shop.

Regards, Pete

- pjofc4, justsayrow, dvm27 and 3 others

-

6

6

-

Very interesting and informative build. We are all watching.

Pete

-

- GrandpaPhil, BobG, ccoyle and 2 others

-

5

5

-

-

-

With the Brig Fair American hull painting complete, construction continued with installation of hull outfit:

- Transom trim and carvings were highlighted/painted with Deco Color Prime-Premio gold metallic paint pens

- Transom windows were previously formed to follow the curve of the transom trim and planking

- Transom windows were painted, glazed, and installed (Micro Kristal Klear was used for window glazing)

- Ship’s name was installed (prepared and printed with MS Word)

- Rudder chains were blackened and installed

Next steps will continue with installation of the quarter deck rails.

Regards from the shipyard,

Pete Jaquith

- Duanelaker, GrandpaPhil, Rudolf and 11 others

-

14

14

-

An old article from the files using copper tape.

Regards from the shipyard,

Pete

- Devildog36, Jorge Diaz O and mtaylor

-

3

3

-

Shop conditions have improved allowing further progress. With the Brig Fair American hull painting complete, construction continued with installation of hull outfit:

- Chain plates were fabricated from 22 ga. silver soldered brass wire rings (1/2” and 7/16” dia. respectively), formed around the deadeyes, and closed with soft solder. A simple jig was used to check the forming of deadeyes.

- Deadeye/chain plate assemblies were painted/installed

- Channel caps were painted/installed

With the bow and P/S side zones complete, next steps will address completion of transom details.

Regards from the shipyard,

Pete Jaquith

- rafine, JpR62, Ryland Craze and 7 others

-

10

10

-

Shop conditions have improved significantly. Now working to relearn past skills (i.e. silver brazing, window glazing, etc.); however, overhanging potential of a large full scale shipbuilding project. I will have to work to balance priorities. Pictures will follow completion of chain plates, lower deadeyes, channel caps, etc.

Regards from the shipyard

Pete

- BETAQDAVE, Duanelaker, BobG and 4 others

-

7

7

-

With the Brig Fair American hull painting complete, construction continued with installation of exterior hull outfit:

- Gangway steps were painted/installed

- Gun port hinges were fabricated, painted, and installed based on a mini-kit from Syren Ship Models

- Quarter badges were painted, glazed, and installed (Micro Kristal Klear was used for window glazing)

Next steps will continue with installation of chain plates, lower deadeyes, and channel caps and then it’s on to complete the transom outfit.

Regards from the shipyard,

Pete Jaquith

- Rudolf, marktiedens, BobG and 5 others

-

8

8

-

Bob, Tim,

A little cooler/less humid this morning. Looking forward to some progress in the coming days.

Regards from the shipyard,

Pete

- Ryland Craze and BobG

-

2

2

-

Limited progress due to CA heat wave (~116 outside and high 80's in my shop). Working P/S exterior hull outfit:

- Gangway steps - complete

- Aft gunport hinges - in process

- Quarter badges - in process

- Chain plates, lower deadeyes, and channel caps - next up

Pictures will follow completion.

Regards from the shipyard,

Pete

- Ryland Craze and BobG

-

2

2

-

-

Working exterior hull outfit. Progress put on temporary hold due to CA heat wave and resulting high temperatures/humidity in my garage work shop.

Regards from the shipyard,

Pete

- Ronald-V, BobG, Ryland Craze and 1 other

-

4

4

-

With the Brig Fair American hull painting complete, construction continued with installation of the head rails and bow fittings:

- Head rails were previously fabricated/dry fitted from 3/32” laminated stock (3 layers of 1/32” sheet stock with opposing grain)

- Middle rails were previously fabricated/dry fitted from 1/16” sheet stock

- Cheek knees were previously fabricated/installed from 1/16” sheet stock

- Boomkins were previously fabricated/dry fitted from 1/8” sheet stock

- Catheads were previously fabricated/dry fitted from 3/16” sheet stock

- Head and middle rails were pre-painted and installed

- After checking the head rails from all angles; they were primed and finished painted. Gold trim was applied with Deco Color Prime-Premio gold metallic paint pens

- After completion of the head rails, catheads were painted/installed

- Figurehead was painted/installed

- Boomkins were painted/dry fitted

To avoid potential damage, the boomkins will be left loose for later installation during the rigging phase. To allow construction access, the bowsprit, bowsprit bitts, and fore bitts will be left loose until completion of bulwark interior fittings and cannon installation.

With completion of the head structure and gold trim she is starting to look like a fine little armed brig from the 1780’s. Next steps will continue with installation of exterior hull outfit.

Regards from the shipyard,

Pete Jaquith

Lucia A Simpson 1875 by cdrusn89 - FINISHED - AJ Fisher - 1/64

in - Kit build logs for subjects built from 1851 - 1900

Posted

Gary,

The scale is 3/16" to the foot (1/64). The hatch coamings are 3/16" above the deck planking. Timberheads are 3/32" sq., bulwark planking is 1/32" and upper hull planking above the copper sheathing is 3/64". The attached picture shows the ledge in hull planking at the top of the covering board.