-

Posts

338 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Pete Jaquith

-

-

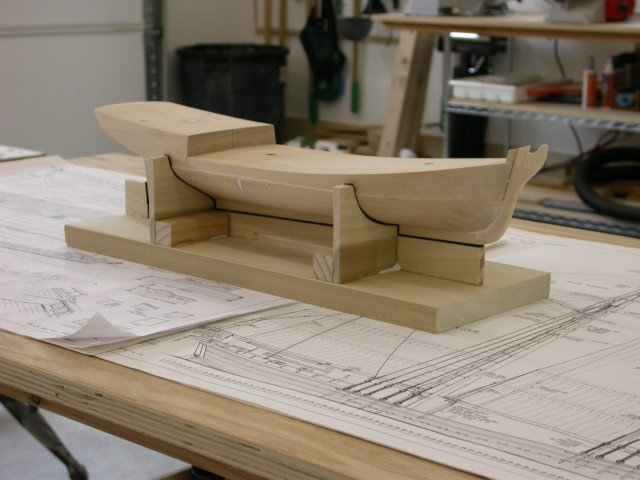

With the Brig Fair American hull planking complete, the next step was building a construction cradle. The cradle was designed to hold the hull upright with the waterline parallel to baseline. The construction cradle was lined with peel-and-stick felt tape.

With hull planking complete, construction will now focus on external hull outfit. The hull outfit sequence has been designed to facilitate painting and minimize potential handling damage. Hull outfit prior to paint includes channels and gangway steps; dry fitting the quarter badges; chess trees, fairlead and hawse holes; catheads, knightheads, and timberheads; cheek knees, bleak head, and transom trim; and cutting the bowsprit notch.

At the same time, I also plan to fabricate and dry fit the bowsprit and start fabrication of deck furniture. These assemblies will be held off for painting with their installation sequenced to ensure good access for cannon rigging.

Regards from the shipyard,

Pete Jaquith

- Stuntflyer, marktiedens, jwvolz and 8 others

-

11

11

-

- CiscoH, GrandpaPhil, BETAQDAVE and 4 others

-

7

7

-

With the Brig Fair American hull planking complete, the next step is confirming the pedestal fit. The pedestals had been initially fitted to the keel subassembly. At this point, they required minor adjustment to suit the hull planking. This task was accomplished at this point to avoid the need for adjustment at completion.

Next steps include: (a) building a construction cradle.

Regards from the shipyard,

Pete Jaquith

- Sea Hoss, Stuntflyer, John Cheevers and 4 others

-

7

7

-

With the Brig Fair American garboard and broad strakes, and lower “A”, “B”, and “D” Belt planking complete; a major construction milestone was completed:

- “C” Belt Strakes #9-12 – The third four strakes below wales (#9-12) were the last strakes installed. Note that lower “C” Belt strake #12 was the closing strake. These planks were ~9” wide amidships tapering to ~6” wide at the stem and 13-15” wide at the stern post.

- Fair Planking – After completion of planking (a major milestone), limited wood filler was used to fill a few open seams and the hull was lightly sanded using fine sanding sticks.

Lessons learned from hull planking include:

- Layout of planking belts and strakes is key

- Proportional dividers are great for dividing up planking belts

- Shaped planks were cut from sheet stock using ships curves (I may try Chuck’s heat bending technique on my next project)

- Fine sanding sticks from the beauty supply shop are great for fine tuning planks

- Filling the forward/after hull bays with basswood blocks provided need planking support

- Planks were edge glued with white glue – to date despite 7 years of storage and significant temperature and humidity swings from southern NH to the CA desert (60-100 degrees F and 15-90% humidity) I have not had any cracking or open seams.

Next steps include: (a) confirming pedestal fit.

Regards from the shipyard,

Pete Jaquith

- John Cheevers, Rudolf, abelson and 7 others

-

10

10

-

Greg,

Plan sections, elevations, and details appear to be slightly different scales. Also, bulkheads were poorly cut and were often different P/S. This requires great care be could be a frustration to new modelers. This is part of the reason I added bass wood fillers between the FWD/AFT bulkheads.

Regards,

Pete

-

Thanks for your interest and likes. After 7 years away I am now starting to get back into ship modeling. Still have to sort of the rest of my tools and supplies but I am getting there.

The Brig Fair American is a good looking model, but the kit has problems (bulkheads don't fair, bulwark height, etc.). I would not recommend it as a first build.

Regards,

Pete

- Stuntflyer and justsayrow

-

2

2

-

With the Brig Fair American lower hull planking belts "A" and "B" Port, and "D" Port/Stbd. complete, work continued on lower hull planking:

- "A" and “B” Belt Strakes #1-8 Stbd. – Completed the first eight strakes below wales (#1-8). These planks were ~9” wide amidships tapering to ~4.5” at the stem and ~7.5” wide at the counter. Due to their shape, the fwd/aft planks were fabricated from sheet stock.

Due to high temperatures in the shop (garage) during the afternoon and evening, I am currently only completing 1-2 plank strakes per day, however the end is in sight.

Next steps include: (a) install “C” Belt P/S, the middle four strakes. Note that lower “C” Belt strake (#12) will be the closing strake.

Regards from the shipyard,

Pete Jaquith

-

Continuing with Fair American lower hull planking. D Belt P/S, A Belt P/S, and B Belt P are complete. With B Belt S working, I will post pictures at completion of B Belt.

Regards,

Pete

-

- catopower, mtaylor, Ryland Craze and 1 other

-

4

4

-

-

Work continues on lower hull planking. With the Brig Fair American garboard and broad strakes and lower “D” Belt complete; work proceeded on “A” and “B” strakes:

-

Completed "A" and "B" Belts Port - Completed the 1st eight strakes below the wales port. These planks are ~9" wide amidships tapering to ~4.5" wide at the stem and ~7.5" wide at the counter. Due to their shape, the fwd/aft planks were fabricated from sheet stock.

My planking techniques included the following:

- Four planking belts were laid out and faired considering the maximum plank

- Shaped fwd/aft planks were cut from sheet stock using paper templates

- Plank width was determined/confirmed using proportional dividers

- Planks were cut using a single edged razor blade and ship’s curves

- Final sanding will follow completion of lower hull planking

Next steps include: (a) Install “A” and “B” Belts Stbd., (b) install “C” Belt, the middle four strakes. It is planned that lower “C” Belt strake (#12) will be the closing strake.

Regards from the shipyard,

Pete Jaquith

- Dwight, BETAQDAVE, Ryland Craze and 6 others

-

9

9

-

-

Working along on the Brig Fair American lower hull planking. A" Belt Port, strakes #1-4 below the wales, is nearing completion. Bow and stern planks are splined and cut from sheet stock. I will post pictures at significant milestones.

Regards from the shipyard,

Pete

- Tom E and GrandpaPhil

-

2

2

-

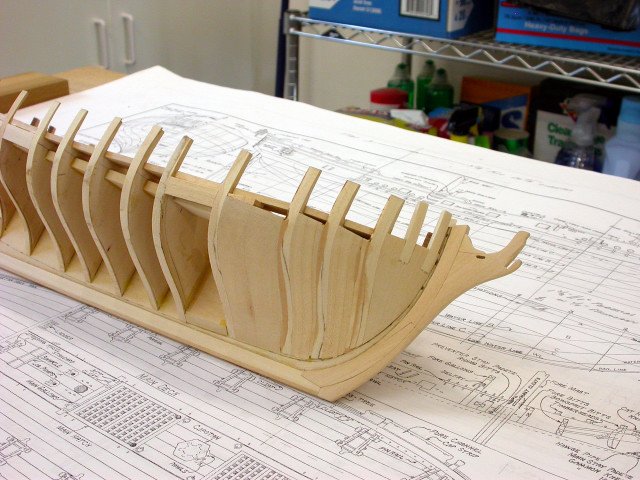

With planning for the Brig Fair American lower hull planking complete and some initial planking started; the following points describe the planking sequence:

a. Garboard and Broad Strakes – The garboard and 1st broad strakes were the first planks installed. Due to their shape, they were fabricated from sheet stock. These strakes were wider than the normal amidships plank width, being 12” and 10.5” wide respectively.

b. “D” Belt Strakes #13-16 – The first four strakes above the broad strake (#13-16) were the next strakes installed. Due to their shape, the fwd/aft planks were fabricated from sheet stock. These planks are ~9” wide amidships tapering to ~6” wide at the stem and growing to ~15” wide at the stern post.

Next steps include: (a) complete installation of “A” Belt, the 1st four strakes below wales (#1-4); (b) install “B” Belt, the 2nd four strakes below wales (#5-8); and, (c) install “C” Belt, the middle four strakes (#9-12). Note that lower “C” Belt strake (#12) will be the closing strake.

Regards from the shipyard,

Pete Jaquith

- Kenneth Powell, Gregory, tkay11 and 12 others

-

15

15

-

After surveying my 14 Gun Brig Fair American of 1868 build (in storage since 2011); I was pleased to find it survived with a minimum damage. As a result, I will restart the build log with planning and installation of lower hull planking (Note that I will repeat a few earlier posts in-order-to provide continuity). Planning and for lower hull planking included the following:

a. Layout Planking Belts – The lower hull will be single planked with 1/16” basswood. After examining the hull girths at alternate bulkheads, the stem, lower counter, and stern post; an amidships plank width of 3/16” or 9” was selected. After laying out the garboard and 1st broad strakes, the remaining hull surface was divided into four planking belts.b. “A” & “B” Belts – “A” and “B” Belts, the 1st thru 8th strakes below the wales, will be ~9” wide amidships tapering to ~4.5” wide at the stem and ~7.5” wide at the counter.

c. “C” & “D” Belts – “C” and “D” Belts, the 9th thru 16th strakes below the wales, will be ~9” wide amidships tapering to ~6” wide at the stem growing to 13-15” wide at the stern post.

d. Garboard & 1st Broad Strakes – The garboard and 1st broad strakes will be wider than the normal amidships plank width, being 12” and 10.5” wide amidships respectively.

e. Table of Hull Planking Butts – The Table of Hull Planking Butts was adjusted to reflect the addition of the above planking belts.

f. Planning for Hull Planking – The hull planking arrangement and planning were developed using the guidelines outlined in the book “Planking the Built-Up Ship Model” by Jim Roberts, available from Model Expo.

Regards from the shipyard,Pete Jaquith

-

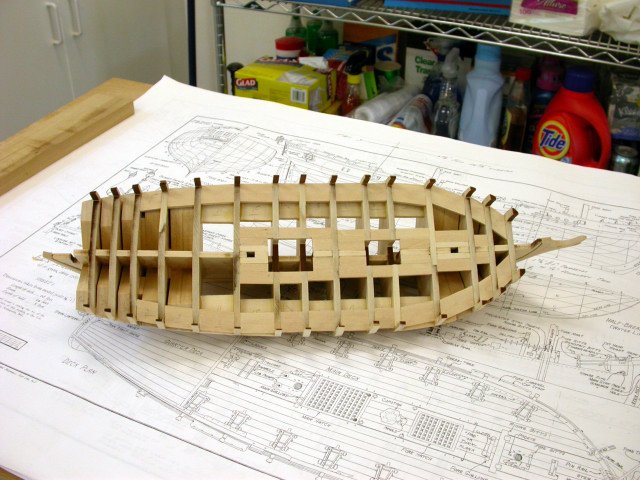

The 14 Gun Brig Fair American, circa 1780 is based on Model No. 60 of the Henry Huddleston Rodgers ship model collection at the U.S. Naval Academy Museum, Annapolis, Maryland. The model is representative of many of the small ships used as privateers during the American War of Independence. The brig Fair American had a length of 68’ 0”, beam of 24’ 0”, depth of 8’ 0”, and tonnage of 130 tons. The model is based on the Model Shipways Fair American kit developed by Erik A. Ronnberg, Jr. and updated by Ben Lankford. The model is plank on bulkhead construction at 1/4” to the foot scale (1:48) with single planking and scratch built details/fittings. I made a number of changes in both model design and construction sequence and these were discussed in my earlier posts.

My Fair American build has been in layup (storage) since 11/2011 due to conflicts with my consulting and full size shipbuilding projects. After working a number of full scale shipbuilding projects in the US and Canada and two home moves, I am now starting to resume my model shipbuilding. My shop/residence has moved from Hancock, NH to Indio, CA. My shop in Indio is located in my garage where summer temperatures limit construction to the morning hours. As I am still busy with several consulting projects, there may still be a need for short breaks in my construction activities.

Note: This is a restart of my earlier 14 Brig Fair American build log posted in 2014-2015. The actual construction work on this model was started in 2011.

Regards from the shipyard,

Pete Jaquith

- reklein, Dwight, justsayrow and 4 others

-

7

7

-

Bruce,

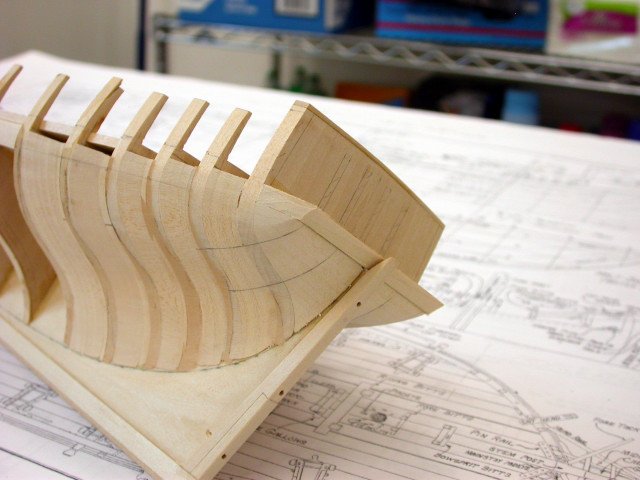

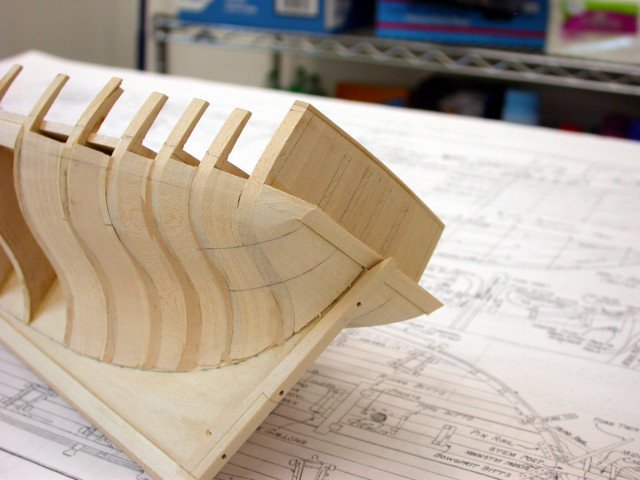

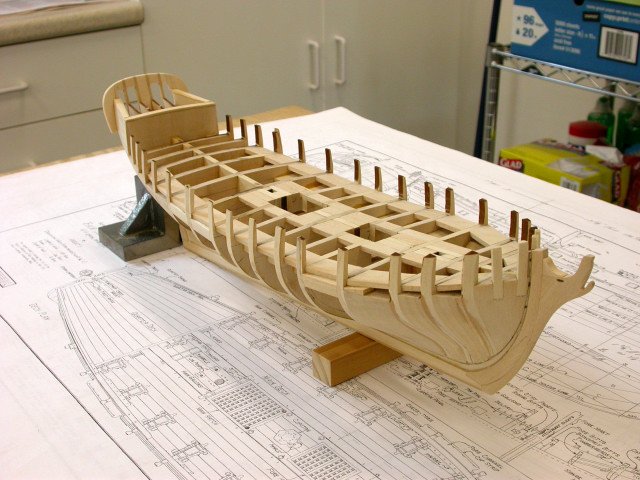

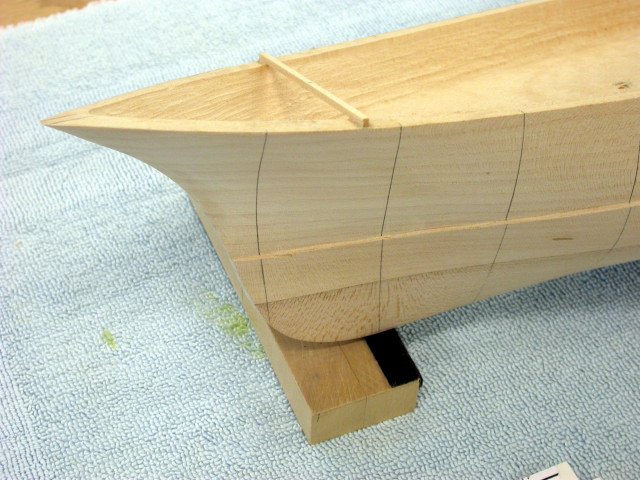

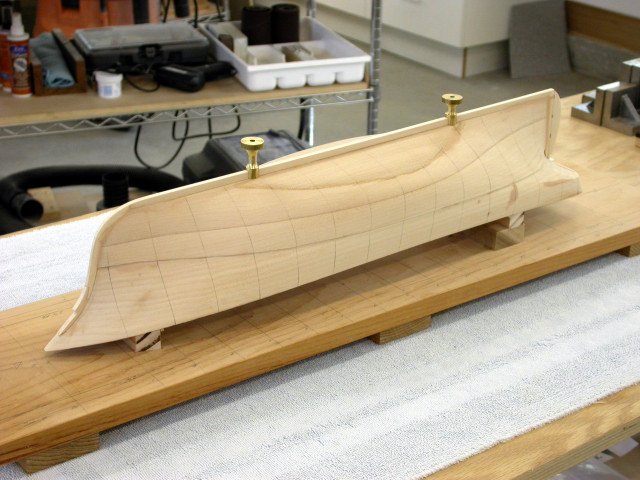

I prefer to single plank. That said, with single planking it is important to carefully fair the hull and ensure adequate support for planks in areas of significant curvature. As Kurt noted, the number of bulkheads is a key factor. The following pictures from my "Fair American" build show how I filled in between bow and stern bulkheads to help fair this hull and provide more planking support.

Pete

- Roger Pellett, kurtvd19, mtaylor and 2 others

-

5

5

-

- CaptainSteve, thibaultron, tkay11 and 1 other

-

4

4

-

-

-

Jay,

Roger makes an important point re datum lines. In my technique, I secure the hull in the inverted position to a reference board and all profile and station templates use the top surface of this reference board as a common baseline. This is shown in the above Eagle and Newsboy pictures.

- East Ender, thibaultron, mtaylor and 1 other

-

4

4

-

- Roger Pellett, thibaultron and mtaylor

-

3

3

-

Jay,

They should show up if you use the search function here on MSW.

- thibaultron and mtaylor

-

2

2

-

Jay,

Personally I prefer solid hulls. My build logs and instructions here on MSW document my practice for carving and then planking the topsides for solid hulls. You can check out the following:

- Plank on Solid ship Model Hulls

- Maine Topsail Schooner Eagle of 1847 build log

- Brigantine Newsboy of 1854 build log

- thibaultron, mtaylor and Roger Pellett

-

3

3

-

Personally, I prefer plank on solid (POS) to plank on frame (POF) construction. I have used both machine carved kit hulls and laminated scratch built hulls. The following notes apply:

Machine Carved Hulls

- Requires care in establishing reference lines

- May require hull, deck, and/or bulwark build up

- Hull carved inverted using reference board and templates

- Hull initially carved to outer plank lines

- Upper hull recessed for 3/64" planking, lower hull coppered

- Thinning carved bulwarks requires care, they may be replaced with built up bulwarks

- Reference my Brigantine Newsboy build log on MSW

Laminated Scratch Built Hulls

- Ease in establishing/maintaining reference lines

- Maintain rectangular configuration until completion of deck carving, deck layout, and drilling of mast holes

- Hull carved inverted using reference board and templates

- Hull initially carved to outer hull lines

- Upper hull recessed for 3/64" planking, lower hull coppered

- Requires built up bulwarks with timberheads slotted into hull block

- Reference my Topsail Schooner Eagle build log on MSW

I find both techniques work well and require ~ 60 hours for hull carving

Regards,

Pete

- Nirvana, BETAQDAVE, thibaultron and 4 others

-

7

7

Armed Virginia Sloop By captain_hook - FINISHED - Model Shipways - Scale 1:48

in - Kit build logs for subjects built from 1751 - 1800

Posted

Very nice build!

Pete